Ianadmin

Aditya Birla proposes to restart Terrace Bay by October for kraft pulp

ContiTech Sustainability Portal Augmented

Tembec to idle its high-yield pulp mill in Chetwynd, British Columbia in September

SCA’s Tork launches ergonomic packaging system in Europe

One millionth tonne of newsprint on Lynn PM7

On Friday 6th July, Palm Paper produced the one millionth tonne of newsprint on Lynn PM7. This is a remarkable achievement and a milestone that has been reached far earlier than was the expectation at the start-up of the machine on the 21st August 2009. To mark the occasion the rolls produced for pressrooms throughout the UK will be labelled with special gold one millionth tonne labels in recognition of this achievement.

Voith, the paper machine manufacturer of Lynn PM7, measures the respective learning curves of newsprint machines during the first two years of production and Lynn PM7 achieved the very best ever learning curve status in the world of newsprint.

Lynn PM7 has been running very stable at a constant speed of 1,875 metres per minute (equivalent to 75 mph) which is only 25 metres per minute behind the most efficient newsprint machine in the world!

In addition to the standard newsprint grades Palm Paper supplies to all national and most regional publishers, Palm Paper has been developing a new grade which is marketed under the trade name of Palm Top. The product is being supplied to the heatset and gravure printing sectors and is used for the printing of magazines and commercial fliers and brochures.

To accomplish the current level of performance Palm employs a production team that performs at the highest possible level due to the substantial commitment Palm makes in training all employees to be motivated and strive for excellence. Currently Palm has 21 full time or part time apprentices. They will be fully qualified and able to assume paper making roles within the mill by the time the two millionth tonne on Lynn PM7 finds it way to the winders.

Palm Paper is a division within the Papierfabrik Palm Group.

International Paper's Board of Directors Elects Christopher E. Kubasik to Its Board

International Paper Company has announced the election of Christopher E. Kubasik to its Board of Directors effective July 10, 2012.

Mr. Kubasik, age 51, is Vice Chairman, President and Chief Operating Officer of Lockheed Martin Corporation, a publicly traded global security and aerospace company. He will become Lockheed Martin's Chief Executive Officer on January 1, 2013. He previously served as Lockheed Martin's Executive Vice President – Electronic Systems from September 2007 to December 2009, and as Lockheed Martin's Executive Vice President and Chief Financial Officer from February 2001 to August 2007.

"Chris's deep experience as a global business leader and extensive interaction with corporate boards, paired with his experience in business outside North America, lends a valuable perspective to our Board of Directors. We are very pleased to have Chris join the Board of Directors of International Paper," said John Faraci, Chairman and CEO.

Mr. Kubasik received an executive engineering certificate from Carnegie Mellon University in 2008 and completed the Systems Acquisition Management Course for Flag Officers at the Defense Acquisition University in 2004. He holds a bachelor's degree in accounting from the University of Maryland.

With the election of Mr. Kubasik and the previously disclosed election of Ilene S. Gordon (effective October 1, 2012), the size of the Board has been increased to 11 members.

To learn more about other members of International Paper's Board of Directors, visit www.internationalpaper.com under the Company and Corporate Governance tab.

SOURCE International Paper

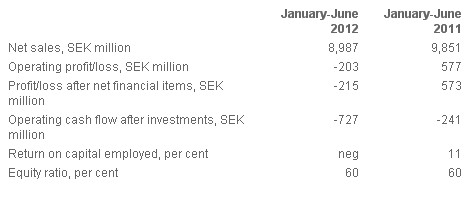

Negative result for Södra in the first half of the year

The first half of the year was characterised by weak economic development in the markets for Södra's products. Production in Södra's business sectors also declined as a result of the market stoppages that were implemented at the beginning of the year. The result was also impacted by one-off items.

The economic crisis in Europe is causing anxiety which is affecting all major markets for Södra's main products. The recession has had an adverse effect on European paper demand, in turn reducing demand for pulp. The consumption of wood products in Europe, meanwhile, has also remained at a very low level, while the interior products market, too, has been hit by the weak performance of the construction and the Swedish home renovation sectors.

"We expect to see our markets gradually growing stronger in the second half of the year. We have also implemented a series of measures to strengthen our earnings potential. As a result, we anticipate that the capacity utilisation at our pulp mills and sawmills will be normal. Despite this, the full-year financial result for 2012 is forecast to be significantly lower than in the last few years," said Saltin.

"Despite the negative result and global economic uncertainty, Södra is in a strong financial position. With an equity ratio of around 60 per cent, we are primed to handle longer and deeper crises than the one we are currently experiencing."

Pulp

The pulp market recovered slightly in the first half of 2012. The world market price of bleached softwood sulphate pulp rose in the first quarter before dipping again slightly. The strengthening of the Swedish krona against the US dollar weakened the pulp price in Swedish krona. World stocks of hardwood and softwood pulp have decreased.

Production at Södra's five pulp mills during the period was 856,000 tonnes compared with 1,001,000 tonnes in the same period the previous year. This reduction was due to the market stoppages that were implemented at Södra Cell Tofte and Södra Cell Folla at the beginning of the year.

"World stocks are at a good level and we expect to see the chemical pulp market gradually grow stronger in the autumn," said Saltin.

In May, Södra Cell's board of directors authorised two energy investments at Södra Cell Värö, including a new lime sludge reburning kiln and a new pelletizing plant. These profitable investments capitalise on the synergies that already exist between Södra Cell and Södra Timber in Värö.

"Through these investments, we can further enhance the efficiency of the Värö combine while at the same time creating a profitable processing operation for our members' wood raw materials," continued Saltin.

Wood products

The consumption of wood products in Europe remains at a low level and the market continued its weak performance during the spring. Production in the largest producing countries has been constrained, which means that stocks of wood products are under control. A weak market combined with high raw material costs are weighing down on the profitability of southern Sweden's sawmills.

Södra produced 720,000 cubic metres of sawn wood products during the period, compared with 767,000 cubic metres in the same period the previous year. Södra Timber's profitability was under great pressure in the early part of the year. Production at the new sawmill in Värö has not proceeded according to plan.

"We have reviewed and analysed the profitability of each sawmill and have introduced a series of measures to strengthen our earnings potential. Logistics is another key area and we decided to re-open the distribution centre in Kinda. We expect some of these measures to bear fruit in the autumn but it could take longer for the other changes to take effect," said Saltin.

"The decision to shut down production that was made ahead of the summer has been reversed. We expect capacity utilisation at our sawmills to be normal for the rest of the year," she says.

The process of starting up the new sawmill in Värö continues but is lagging behind schedule. Additional measures are needed, mainly in the refinement area, before production can reach the planned rate. Supplementary investments are being made to ensure the scheduled completion of the sawmill, which is expected to reach full production capacity - i.e. with the sawmill operating on a three-shift basis - in the second quarter of 2013.

"Work on the new sawmill has not been proceeding according to plan. But the work of getting the sawmill completed on schedule is going full steam ahead and it has naturally been given the highest priority."

Interior products

The economic recession is also affecting the interior products market, causing a decline in volumes and pushing down prices. And while Södra Interiör has defended its market share, the market has shrunk because of the prevailing uncertainties about the economy.

At the beginning of the year Södra Interiör acquired parquet flooring manufacturer Berg & Berg in Kallinge which has some 90 employees. The company produces more than 500,000 m2 of high-quality parquet flooring per year and has net sales of around SEK 130 million. This acquisition will further increase the range of products available to Södra Interiör's customers, while at the same time providing good opportunities for synergies between the companies in areas such as marketing, logistics and product development.

Forestry

Timber volumes handled by Södra Skog fell as a result of the market stoppages at sawmills and pulp mills at the beginning of the year. Volumes were down by around 10 per cent compared with the same period in 2011. To increase the contracting rate, a local market premium was introduced during the spring with good results. With the exception of certain hardwood varieties, the standing stock is at a good level ahead of the autumn.

During the spring, Södra Skog launched a hardwood initiative which embraces the whole chain from forest management training for forest owners to acquisitions of saw timber. Despite the growing volumes from members there is a slight shortage of sawable birch and birch pulpwood.

The spring's seedling sales were excellent. Södra Skog is continuing to invest in both its nurseries to increase seedling volumes to 45 million seedlings per year. A campaign of discounts was introduced in the autumn to stimulate increased autumn planting. Investments in seedling operations are planned this autumn to increase the volume of seedlings with mechanical forms of protection so that the use of chemicals can be phased out.

KapStone Paper and Packaging To Release Second Quarter Earnings On Wednesday, August 1, 2012

Wood fiber costs for the European pulp industry have fallen from the record highs of 2011.

Metso-supplied paper machine rebuild for SCA Graphic Laakirchen AG started up in Austria

The SCA Graphic Laakirchen AG PM 10 was successfully started up on January 23, 2012 after a Metso-supplied press section rebuild in Laakirchen, Austria. The main target of the modernization was to increase production and to decrease energy consumption.

“Our target was to increase sheet dryness after the 3rd press for increased speed. We also wanted to reduce the draw and specific energy consumption and at the same time maintain the high quality level as before the rebuild,” says Andreas Vogel, Production Manager of SCA Graphic Laakirchen PM 10.

“Our target was to increase sheet dryness after the 3rd press for increased speed. We also wanted to reduce the draw and specific energy consumption and at the same time maintain the high quality level as before the rebuild,” says Andreas Vogel, Production Manager of SCA Graphic Laakirchen PM 10.

Metso’s delivery comprised a rebuild of the press section with a new SymBelt shoe press. In addition, the delivery included mechanical drives for the whole press section and an automation system upgrade for the shoe press. The SymBelt shoe press significantly increases sheet dryness which in turn reduces steam consumption, improves machine runnability, helps reach higher speed and increases production.

The 7.3-m-wide PM 10 produces uncoated wood-containing paper (SC-A) within a basis weight range of 45-60 g/m2 at the design speed of 1,600 m/min. The production capacity of PM 10 is 260,000 tonnes annually.

SCA is a global hygiene and paper company that develops and produces personal care products, tissue, packaging solutions, publication papers and solid-wood products. The company’s sales in 2011 amounted to EUR 11.7 billion and it has approximately 44,000 employees.