Super User

Stora Enso’s remuneration policy ranked the best in Finland

Stora Enso’s remuneration policy, published in January 2020, has been ranked the best for Large Cap companies in Finland.

The members of the ranking committee include representatives from the pension insurance company Varma, the Directors’ Institute of Finland, and Nasdaq. The aim of the ranking is to promote good governance practices. Analysis of the remuneration policies for governance bodies was based on, for example, the content, relevance and readability of the text, and how easy it is to find the document.

The members of the ranking committee include representatives from the pension insurance company Varma, the Directors’ Institute of Finland, and Nasdaq. The aim of the ranking is to promote good governance practices. Analysis of the remuneration policies for governance bodies was based on, for example, the content, relevance and readability of the text, and how easy it is to find the document.

Stora Enso’s remuneration policy was particularly praised for its connection to the Group's strategy and sustainability work. The policy was also considered thorough and precise.

“This is a highly appreciated accolade for the work we have done in Stora Enso to prepare this policy. The remuneration elements must drive the company’s business strategy and its long-term financial interests. Stora Enso’s clear and transparent remuneration policy is formulated to achieve that goal,” says Jorma Eloranta, Chair of Stora Enso’s Board of Directors and its Remuneration Committee.

Valmet to supply Valmet IQ quality management system to PJSC Kyiv Cardboard and Paper Mill in Ukraine

Valmet will supply Valmet IQ quality management system to PJSC Kyiv Cardboard and Paper Mill in Kiev, Ukraine. The new system will be installed in the corrugated packaging plant of the mill which is undertaking modernization actions. The investment is targeted to improve the quality of the corrugated board, and to increase productivity and profitability in converting operations.

The order was included in Valmet's orders received of the second quarter 2020. The delivery is scheduled by the end of September 2020.

“We are happy that PJSC Kyiv Cardboard has chosen Valmet IQ to improve their corrugated board quality and plant productivity. Our experience and results from Valmet IQ’s previous installations for corrugator had a big role in this decision. It is great to see that we can help PJSC to move their performance forward with this moisture-based quality control system,” says Mikko Talonen, Business Manager, Automation, Valmet.

“We are happy that PJSC Kyiv Cardboard has chosen Valmet IQ to improve their corrugated board quality and plant productivity. Our experience and results from Valmet IQ’s previous installations for corrugator had a big role in this decision. It is great to see that we can help PJSC to move their performance forward with this moisture-based quality control system,” says Mikko Talonen, Business Manager, Automation, Valmet.

Technical details about the delivery

The Valmet IQ quality management system is specifically designed for Corrugator plants and combines precise online moisture, temperature and warp measurements with reliable closed-loop controls and moisturizers including reporting system. It comprises Valmet IQ Multipoint moisture measurement system with IQ Wet-End Control, Valmet IQ Moisturizer, Valmet IQ Converting Scanners and Valmet IQ Warp Measurement with IQ Dry-End Control.

Information about the customer PJSC Kyiv Cardboard and Paper Mill

Kyiv Cardboard and Paper Mill Private Joint-stock Company is part of the Austrian company Pulp Mill Holding and one of the largest European producers of paper-based products. In terms of total output, the facility produces 30% of all paper products in Ukraine. Recycled paper is the main raw material used in production, and more than 1,000 tons of recycled material is processed at the mill daily. The box and packing cardboard produced at the facility is utilized in the fabrication of packaging for various consumer products.

SCA intends to invest in pulp production and initiates consultations to discontinue publication paper

SCA intends to invest SEK 1,45bn in the production of chemically pre-treated thermo-mechanical pulp (CTMP) at the Ortviken paper mill in Sundsvall. In parallel, SCA is initiating consultations with trade unions and employee representatives to discontinue the production of publication paper at the mill.

SCA intends to invest to achieve an annual production volume of 300,000 tonnes of CTMP pulp at Ortviken, using the existing infrastructure. The investment is expected to give a positive EBITDA-effect of approximately SEK 0.3bn per annum. Expected start of production in the new mill is the beginning of 2023. SCA today has a production capacity of 100,000 tonnes of CTMP pulp at the Östrand pulp mill. This production will be phased out when the new line starts up, which will allow a future increase in the production of kraft pulp at Östrand Pulp mill.

“Our pulp customers want us to grow with them in product segments such as packaging board and hygiene products, segments with healthy growth,” says Ulf Larsson, SCA’s CEO. “In line with our strategy, we have gradually reduced our exposure to publication paper. We now initiate negotiations to leave this product segment completely.”

“Our pulp customers want us to grow with them in product segments such as packaging board and hygiene products, segments with healthy growth,” says Ulf Larsson, SCA’s CEO. “In line with our strategy, we have gradually reduced our exposure to publication paper. We now initiate negotiations to leave this product segment completely.”

Currently, SCA produces coated and uncoated publication paper on three paper machines at Ortviken paper mill with annual sales of approximately SEK 4bn. Demand for publication paper in Western Europe has declined by approximately 5% per year since 2008. During the coronavirus pandemic, demand for publication paper decreased by a further 30-40% and production at Ortviken paper mill has been adapted to the weak order level. This low demand, combined with a weak price development, results in a negative profitability for the operation.

The closure of publication paper manufacturing at Ortviken paper mill proposed by SCA will affect about 800 employees, primarily at Ortviken paper mill, but also in other parts of SCA’s operations. The closure would result in non-recurrent costs with cashflow effects which are estimated not to exceed SEK 0.9bn and an impairment of about SEK 1.1bn.

“Through today’s proposals, we intend to continue to develop a strong, sustainable and profitable industry based on our renewable forest raw materials”, says Ulf Larsson. “This will have a significant impact on many people and we will in a responsible way seek the best possible solutions for those affected.”

Negotiations under the Co-determination at Work Act (MBL) with trade unions will now begin regarding the plans to discontinue paper production at Ortviken paper mill, the investment in CTMP production at Ortviken and the impact on other SCA operations. In other jurisdictions affexcted employees and their representatives will be informed and consulted in line with the legal framework.

Domtar Completes Successful FSC® Certification of the Wabigoon Forest in Ontario, Canada

Domtar has successfully completed a surveillance audit on the Wabigoon Forest for the new Forest Stewardship Council (FSC®) National Standard for Canada. The audit took place the week of July 13th ending with the auditor’s recommendation for certification to be maintained under the new Canadian standard. This new standard replaced the previous FSC® Boreal standard and has set the bar high for demonstrating sustainable forest management. The Wabigoon Forest was first certified to the FSC® standard in 2008.

“Our on-the-ground management practices, coupled with a rigorous provincially mandated forest management planning process, helps to hit the mark with FSC®,” said Marie Cyr, general manager of the Dryden pulp mill. “We are proud of our record of sustainable forest management. The fact that the Dryden mill has been operating in this forest area for over 100 years demonstrates that we are managing our forests sustainably.”

“Our on-the-ground management practices, coupled with a rigorous provincially mandated forest management planning process, helps to hit the mark with FSC®,” said Marie Cyr, general manager of the Dryden pulp mill. “We are proud of our record of sustainable forest management. The fact that the Dryden mill has been operating in this forest area for over 100 years demonstrates that we are managing our forests sustainably.”

The new FSC® National Standard for Canada requires a comprehensive audit of legal compliance, protection of high conservation values, environmental impacts, management planning and community relations including free prior and informed consent. The audit process, which is designed to identify opportunities for improvement, found 4 minor non-conformance issues, all of which have been addressed with action plans and approved by the auditing body.

“The success of this audit demonstrates progress towards our sustainability goals,” said Paige Goff, vice president of sustainability. “Independent third party forest certification like FSC® is important to our customers and reflects our commitment to sustainability.”

Domtar is also licensed to manage the Trout Lake forest in Ontario which is on target to undergo an FSC® pre-assessment audit later this year.

Pro Carton reveals new Carton Campaigners video for Earth Overshoot Day

Ahead of Earth Overshoot Day (August 22), Pro Carton, the European Association of Carton and Cartonboard manufacturers, is revealing the latest episode in the Carton Campaigners animation series.

With over one million online views of the Carton Campaigners’ videos this year, Pro Carton is launching the next in the series to educate young and old about their personal responsibilities when it comes to protecting the planet and its vital resources.

Anthropomorphic graphics bring the message of Earth Overshoot Day to life for younger generations

Anthropomorphic graphics bring the message of Earth Overshoot Day to life for younger generations

While the COVID-19 pandemic has caused this year’s expected overshoot date to be extended to the latest it has been since 2005, humanity's demand on natural resources continues to exceed what Earth's ecosystems can regenerate in a year.

In the new video, cartoon characters Ricki Recycle, Renée Renew, Ryan Reuse, Rhianna Reduce and Ronnie Replace will show how each of the actions they represent – the 5Rs of Responsibility – should be a priority for every individual. Pro Carton also hopes that spreading this message to younger generations will help to push Earth Overshoot Day later in the future.

The Carton Campaigners illustrate the 5Rs of Responsibility

The Carton Campaigners illustrate the 5Rs of Responsibility

Tony Hitchin, General Manager of Pro Carton, said: “We’ve had some wonderfully positive responses to the Carton Campaigners, so it seemed only right to use them to shine a light on Earth Overshoot Day and explain how our actions impact the planet.”

“Even though the date lands three weeks later than last year, this is predominantly due to COVID-19 lockdowns and reduction in travel. We want to make sure this trend carries on into the future through environmentally-friendly choices, such as opting for renewable, recyclable and biodegradable packaging materials like cartonboard.”

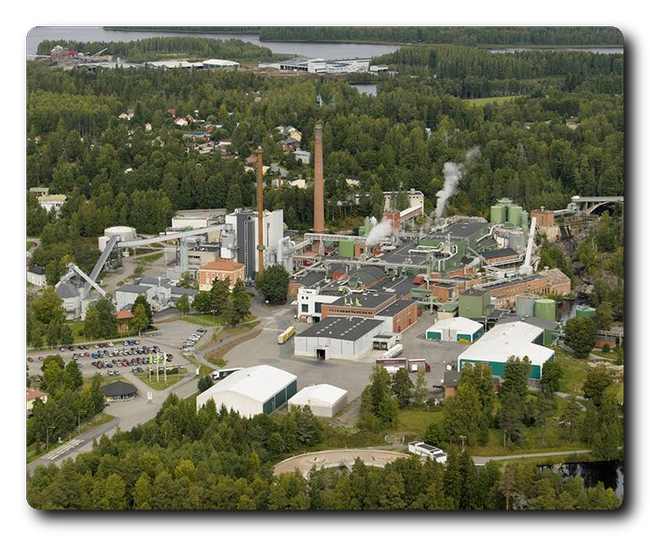

The modern board mill Metsä Board Kyro is celebrating its 150th anniversary

Metsä Board's Kyro mill will be 150 years old this year, 2020. The wood grinding plant along the Kyröskoski rapids was started up in 1870. Since then, the Kyro mill has manufactured market wood pulp, groundwood, sawn timber, various papers and paperboard for international markets. Today, it is a modern and efficient mill that produces high-quality folding boxboard for Metsä Board, part of Metsä Group.

“Kyro people are proud of their mill. Our staff have always lived with changes and challenging times have been overcome by working together. People commit themselves to the mill for a long time, with families often having several generations involved. This has positively influenced the kind of mill Kyro is today,” says Petri Huiko, VP and mill manager of Metsä Board Kyro.

“Continued development is key to the success, efficiency and production quality of our paperboards and we are proud to continue to develop Kyro as generations before us have done,” added Petri.

Last year, Metsä Board Kyro began manufacturing a new plastic free eco-barrier board for food and food service packaging and introduced artificial intelligence (AI) to its quality control. In addition, the mill’s board machine finishing area is presently being modernised. The rebuild includes a new reeler, a winder and the renewal of the reel broke handling system. The investment value is EUR 20 million and the new machinery is scheduled to start during the autumn of 2021.

Keeping customers working safely with advanced technical support from Ametek surface vision

AMETEK Surface Vision, a world leader in automated online surface inspection solutions, has extended its global service and technical support for industrial customers to ensure operations continue safely and effectively.

The pandemic has seen an increased demand in critical industries such as nonwovens, paper, and food packaging. AMETEK Surface Vision has fast-tracked its enhanced plans for remote support to ensure maximum productivity and efficiency in these areas.

Surface Vision’s two surface inspection and monitoring product lines, the SmartView® and SmartAdvisor® systems, are in use by customers around the world, requiring continual support in a range of industries including metal, paper, plastics, and non-wovens.

Surface Vision’s two surface inspection and monitoring product lines, the SmartView® and SmartAdvisor® systems, are in use by customers around the world, requiring continual support in a range of industries including metal, paper, plastics, and non-wovens.

In particular, the company has seen an increase in requests to optimize systems detection and classification as industrial mills have changed their product mixes in response to the pandemic. Surface Vision provides a full-featured remote support platform to facilitate these requests, allowing mills to adapt to changing priorities.

With travel restrictions in place due to the COVID-19 pandemic, Surface Vision customer support engineers are working more remotely, which has allowed the team to be more responsive as they are available online for longer.

Technical services have been extended with a new Preventive Maintenance Remote Check-up Service. This service will ensure that the equipment is proactively reviewed on a regular basis, uncovering potential issues before they become a costly problem.

Yamina Lansari, Global Manager of Technical Services at AMETEK Surface Vision, comments, “The pandemic has prompted us to evaluate how effectively we deliver services to our customers.

Our support service is built as a partnership with our customers, who often have mission-critical systems that need our help. Our service engineers are well versed in, and available for, remote service delivery. On-site service is also available to supplement and augment our remote offerings where it is business-critical and where regulations allow.”

Additional extended services include a secure remote portal where Surface Vision can quickly and safely restore service to critical surface inspection and monitoring equipment. The company will also provide customers access to internal expertise and a large product knowledge database.

AMETEK Surface Vision has a broad product range optimized for the monitoring and inspection of webs and surfaces, as well as process surveillance applications. For more information, visit www.ameteksurfacevision.com.

About AMETEK Surface Vision

AMETEK Surface Vision is a world leader in automated online surface inspection solutions with a broad product portfolio optimized for web and surface inspection as well as monitoring and process surveillance applications.

Its product portfolio includes two distinct product lines: SmartView® systems and SmartAdvisor® systems. Each product line uniquely enables customers to inspect the surfaces of materials processed in a continuous fashion across the metals, paper, plastics, nonwovens and glass industries. Learn more by visiting ameteksurfacevision.com.

AMETEK Surface Vision is a unit of AMETEK Process and Analytical Instruments, a division of AMETEK, Inc., a global manufacturer of electronic instruments and electromechanical devices with annual sales of approximately $5 billion.

Stora Enso appoints Annette Stube as Head of Sustainability

Stora Enso has appointed Annette Stube as EVP, Head of Sustainability and a member of the Group Leadership Team. She will start on 1 September 2020.

Annette Stube is a Danish citizen who joins from a position as Head of Sustainability in A.P. Moller–Maersk, an integrated transport and logistics company. Previously she has worked as Director of Sustainability programmes in the global healthcare company Novo Nordisk. She has a master’s degree in psychology and an Executive Board Education from Copenhagen Business School. She is also a member of the Board of Directors of the Finnish energy company Fortum.

Annette StubeAnnette Stube succeeds Stora Enso’s current Head of Sustainability Noel Morrin who retires in the end of year 2020. Noel Morrin joined Stora Enso in 2015.

Annette StubeAnnette Stube succeeds Stora Enso’s current Head of Sustainability Noel Morrin who retires in the end of year 2020. Noel Morrin joined Stora Enso in 2015.

“I would like to extend my warmest thanks to Noel for his valuable and committed work for Stora Enso. He has played an essential role in setting an ambitious sustainability agenda for Stora Enso and taking the Group’s sustainability reporting to a high level. We have set ambitious targets to reduce our greenhouse gas emissions and seen good progress in that during the past years,” says Stora Enso’s President and CEO Annica Bresky.

“I am happy to welcome Annette Stube to our leadership team. Her experience in pioneering and leading sustainability work in global organizations is very valuable and will support us in our continued transformation as “The renewable materials company”. Her background in developing sustainability-based business opportunities and innovations will also strengthen us,” Annica Bresky continues.

“I am happy to join Stora Enso, a true sustainability front-runner. Stora Enso is uniquely positioned as a solution provider in a low-carbon, circular bioeconomy with renewable raw materials, having sustainability at the core of its strategy. Standing on solid sustainability governance and high-quality reporting, Stora Enso is ready to take the next step,” Annette Stube says.

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 25 000 employees in over 30 countries. Our sales in 2019 were EUR 10.1 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com

Solenis Enables Tissue Maker to Achieve Unprecedented Autonomous Chemistry Control with Artificial Intelligence Platform

OPTIX™ Applied Intelligence platform identifies patterns in paper machine data, delivering digital process improvement recommendations for product quality purposes

Solenis, a leading global producer of specialty chemicals, is working with a North American tissue maker to deliver continuous process improvement with autonomous chemistry control through its secure OPTIX™ Applied Intelligence artificial intelligence (AI) platform.

Developed with ProcessMiner™, a leading AI platform, Solenis’ adaptive analytics system accurately learns complex variable relationships in pulp and paper manufacturing processes and yields a digital measure of product quality. Autonomous manufacturing using AI with machine learning allows for improved product quality, optimized use of raw materials and reduced water and energy consumption.

Deployed at St. Croix Tissue in Baileyville, Maine, OPTIX recently enabled the mill to accomplish something that was previously impossible. Using a closed-loop controller in conjunction with OPTIX quality parameter predictions, the mill was able to control its strength chemistry autonomously to ensure optimal chemical feed and adhere to target parameters.

Photo courtesy of St. Croix Tissue

Photo courtesy of St. Croix Tissue

“OPTIX has shown that it can reasonably predict different lab-tested parameters,” said Devin Rose, technical manager at St. Croix Tissue. “We’ve used this prediction in a closed-loop controller and successfully reduced variation in the final product. As a result, we’re excited about the value of this program.”

Launched by Solenis in early 2019, the novel OPTIX platform is operational in nine paper mills throughout North America and Europe, with additional deployments in progress. AI-powered predictive analytics of key quality parameters allows for on-the-fly process improvement, real-time process insights and continuous chemical control leading to improved target adherence, improved product quality and substantial cost savings.

COVID-19 is accelerating the need for autonomous manufacturing as operators seek to improve operational efficiency without making significant cap-ex investments and limiting human interaction. As a result, there has been mounting interest in the OPTIX platform, which enables the application of autonomous control to extend well beyond strength chemistry.

“Solenis continues to deliver innovative solutions that solve the complex problems that exist in the pulp and paper industry,” said Andreas Türk, president, Eurasia, Solenis. “Our partnership with ProcessMiner enables us to uniquely deliver the cutting-edge artificial intelligence and machine learning technology required for real-time, predictive analytics and autonomous manufacturing. Our latest OPTIX offering, autonomous chemistry optimization, is another example of Solenis delivering the value our customers need to stay competitive.”

“Solenis has been the ideal partner for driving autonomous manufacturing in the pulp and paper industry, leveraging the technology we’ve developed,” said Karim Pourak, cofounder and CEO, ProcessMiner. “The deep domain expertise the Solenis team brings, coupled with our industry-leading data science team, has been a winning combination. We expect rapid adoption and mill expansion of the OPTIX platform in this industry as a result of our recent autonomous control success at St. Croix Tissue. With a shrinking workforce in manufacturing, AI is an investment that manufacturers need to consider in keeping up with demand and product quality service levels.”

For more details on OPTIX Applied Intelligence, please visit solenis.com/OPTIX.

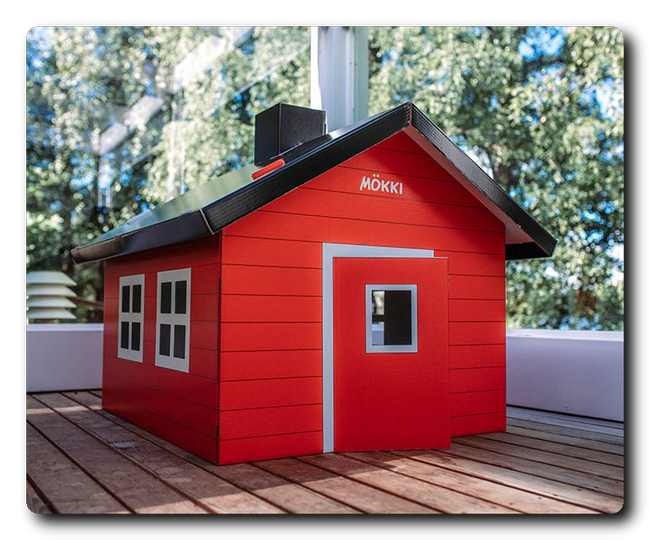

Eero Aarnio designs an eco-playhouse made with corrugated board

Eero Aarnio, an artist worldwide famous for furniture designs, such as the iconic Ball Chair, has designed an eco-playhouse made with corrugated board. Aarnio has always been interested in different materials and the opportunities they create. Corrugated board has a particular fascination for him due to its light weight and environmental credentials.

Thanks to its design and the lightweight board construction the playhouse can be conveniently moved from place to place. The playhouse can be set up indoors or outdoors, if the weather permits. It can also be folded up for easy storage. “During this exceptional period people have spent more time at home with their families. Assembling a playhouse is a nice thing to do together and gives enjoyment to the whole family,” commented Eero Aarnio. “In the past, my own children have built huts out of empty corrugated boxes,” Aarnio recalls.

The sustainable white kraftliner materials provided for the production of the playhouse are made by Metsä Board, part of Metsä Group. Metsä Board’s white kraftliners were used for the surfaces: MetsäBoard Pro WKL 160 g/m2 was chosen for the outside due to its smooth printing surface and MetsäBoard Natural WKL Bright 160 g/m2 for the inner surface. The used kraftliner type is B-flute.

“Screen printing technology gives the liner surface a uniform, beautiful colour tone. MetsäBoard Pro WKL provides fast drying of the printed ink. Thanks to its high printability and excellent production efficiency, it was an ideal material for this project,” comments Ilkka Harju, Packaging Services Director EMEA and APAC Metsä Board.

The playhouse has been produced by two Finnish company Futupack and Capertum.