Super User

ANDRITZ to optimize fiberline at Stora Enso’s Enocell mill for more flexible and sustainable production

International technology group ANDRITZ has received an order from Stora Enso to optimize the fiberline at the Enocell pulp mill in Uimaharju, Finland.

This will help the customer meet the growing demand for non-bleached renewable packaging materials while at the same time reducing its ecological footprint.

ANDRITZ technologies will provide the customer with the required flexibility. In parallel, operational costs will be optimized through improved operational reliability and minimimized chemical, freshwater and energy consumption.

ANDRITZ technologies will provide the customer with the required flexibility. In parallel, operational costs will be optimized through improved operational reliability and minimimized chemical, freshwater and energy consumption.

This order shows the solid business relationship between ANDRITZ and Stora Enso and supports Stora Enso’s growth strategy in the sustainable packaging sector. The modernization will be carried out gradually with completion scheduled for the fourth quarter of 2024.

The Enocell pulp mill in eastern Finland is part of Stora Enso’s Biomaterials division. It produces softwood and hardwood pulp with an annual production capacity of 630,000 tonnes. The site was founded in 1967 and also includes a sawmill.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Toscotec starts up an AHEAD 2.2L tissue line at MEPCO

Juthor Paper Manufacturing, part of MEPCO Group, has started up a complete tissue line including an AHEAD 2.2L tissue machine and two OPTIMA slitter rewinders supplied by Toscotec on a turnkey basis at its new tissue mill in KAEC, Saudi Arabia. With this start-up, MEPCO, a leading containerboard manufacturer, effectively enters the tissue market.

The turnkey supply

The scope includes the entire tissue production line from cellulose bale handling to the wrapping and labelling of the finished wound jumbo rolls. The double-width AHEAD 2.2L line features a maximum design speed of 2,200 m/min and an annual production capacity of over 60,000 tons. It is equipped with a shoe press TT NextPress of upgraded design, a third-generation TT SYD Steel Yankee Dryer, and high efficiency TT Hood-Multigen with integrated cogeneration air system. The two OPTIMA 2600L slitter rewinders ensure the preservation of superior bulk and softness.

Efficient tissuemaking with a Combined Heat and Power production (CHP)

The AHEAD machine is perfectly integrated with the mill’s CHP system, in order to tap on its secondary heat production to meet the thermal energy needs of the tissue production line. The drying section of the machine uses the CHP-produced thermal energy to both generate steam to use in the Steel Yankee Dryer and to achieve the correct drying temperature of hot air circulating in the Yankee hoods air system. As a result, the tissue machine will rely entirely on the CHP system for paper drying and will not require any additional gas consumption and associated greenhouse gas emissions.

Adel Alfar, Operations Director at Juthor, says, “Our partnership with Toscotec has been marvellously successful. Even though we faced some challenges during the pandemic, we have successfully managed to deliver the test run and the commercial launch according to the scheduled timeline very smoothly and efficiently, producing premium quality tissue products.”

Stefano Raffaelli, Project Manager at Toscotec, says, “We are extremely happy of the positive outcome of this project. With a strong commitment to the project’s targets, we have overcome the global logistical challenges encountered during the pandemic and kept our focus on our shared goal of putting this state-of-the-art tissue line into operation. We are confident that the mill will benefit from its superior efficiency and paper quality right away.”

About MEPCO

MEPCO is the leading vertically integrated paper manufacturer in the Middle East, offering a diverse range of containerboard and specialty paper products serving the packaging, construction, furniture, and paper core industries around the world. MEPCO supplies its products to the local Saudi market, as well as the GCC, Middle East and Africa. The Company’s innovative approach to doing business enables it to deliver significant environmental and economic benefits to Saudi Arabia. MEPCO is listed on the Saudi Stock Exchange (Tadawul) under symbol ‘1202’.

Heinzel Group entrusts ANDRITZ with paper machine conversion for sustainable packaging paper production at Steyrermühl, Austria

International technology group ANDRITZ will convert the idled paper machine PM3 at Steyrermühl mill in Austria to produce kraft papers for sustainable flexible packaging. The machine previously produced graphic paper for UPM. The conversion project has been launched by the Heinzel Group, which will take over the Steyrermühl mill from UPM by January 1, 2024.

- Unique headbox and gapformer concept combined with shoe press achieves significant energy savings

- Softnip calender technology results in premium paper surface qualities

Once rebuilt by ANDRITZ, the paper machine (then PM6) will produce up to 150,000 tons of brown and white low-basis weight kraft paper per year to be sold under the Heinzel Group’s well-established StarKraft brand. The paper will be used for shopper bags, pouches, and other flexible packaging products.

Werner Hartmann, COO of Heinzel Pöls, says: “With this investment, StarKraft will become one of the world’s leading brands for bleached and unbleached kraft paper. ANDRITZ PrimeLine technology is already successfully operating at our Pöls and Laakirchen mills. The current rebuild by ANDRITZ will help us expand our product portfolio for sustainable packaging.”

PM6 at Steyrermühl will use an innovative ANDRITZ gap forming concept to produce bleached and unbleached calendered kraft paper grades. It is based on a unique headbox and shoe-blade gapformer combination. Together with an ANDRITZ PrimePress X shoe press and an upgrade of the existing steam and condensate system, it will achieve significant energy savings while producing high-quality end products.

ANDRITZ converts paper machine at Steyrermühl mill to produce kraft papers for sustainable flexible packaging © ANDRITZ

ANDRITZ converts paper machine at Steyrermühl mill to produce kraft papers for sustainable flexible packaging © ANDRITZ

The production of such kraft paper usually requires a Fourdrinier former. The PM6 gapformer rebuild will instead feature a new, unique concept that is based on the single-shoe setup of the PrimeForm TW: this fully adjustable shoe-blade gapformer (perfect for paper strength development and outstanding dewatering performance) enables crucial, grade-specific paper properties and will be combined with a PrimeFlow AT headbox with dilution control for excellent cross profiles. This concept was successfully proven in pilot trials during the sales phase.

A state-of-the-art PrimeCal Soft calender will replace an existing multinip calender to meet required optimum paper surface qualities in the future.

The PM6 will have a design speed of 1,500 m/min and a paper width at the reel of 6,300 mm. ANDRITZ’s scope of supply includes in addition upgrades of the stock preparation, approach flow, and broke handling systems as well as extensive upgrades of the automation systems (DCS, QCS, MMD), detail engineering packages, and mechanical erection. In addition, the existing steam and condensate system will be redesigned and upgraded, which will contribute to saving energy. Start-up of the rebuilt machine is scheduled for the beginning of 2024.

With its production companies Heinzel Pöls, Laakirchen Papier, Raubling Papier and Estonian Cell, the Austria-based Heinzel Group is one of the most important pulp and paper producers in Central and Eastern Europe. Heinzel and ANDRITZ look back on a long and successful business relationship. ANDRITZ converted the PM10 at Laakirchen and delivered Europe’s largest new MG paper machines (PM3 and PM2) to the Pöls mill.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Hinton Pulp mill acquisition supports growth in Mondi’s Americas paper bags business

Mondi plc (Mondi), a global leader in the production of sustainable packaging and paper, has agreed to acquire the 250,000 tonne per annum Hinton Pulp mill in Alberta, Canada, from West Fraser Timber Co. Ltd (West Fraser) for a total consideration of USD 5 million. As part of the transaction, Mondi will enter into a long-term partnership with West Fraser to access local, high-quality fibre from a well-established wood basket.

- Mondi has agreed to acquire Hinton Pulp mill in Alberta, Canada from West Fraser Timber Co. Ltd for USD 5 million.

- Intention to invest a further €400 million, primarily in a new 200,000 tonne per annum kraft paper machine at the mill.

- Customers will benefit from a fully integrated and much shorter supply chain, reducing the overall carbon footprint of Mondi’s packaging products in the region.

The intention, subject to pre-engineering and permitting, is to invest €400 million in the expansion of Hinton, primarily for a new 200,000 tonne per annum kraft paper machine, anticipated to be operational from the second half of 2027. The acquisition of the mill, and investment in the paper machine, will fully integrate operations in the Americas and enable Mondi to secure the long-term supply of high quality, cost competitive kraft paper into its network of 10 paper bags plants in the region, better positioning Mondi to support the growing market demand for industrial and mailer bags.

Customers will benefit from a fully integrated and much shorter supply chain reducing the carbon footprint of Mondi’s packaging products in the region. The kraft paper produced at Hinton will have the highest quality and strength parameters, which, in combination with Mondi’s expertise, will meet customer requirements for sustainable packaging solutions as paper is increasingly being used for packaging across the Americas.

Commenting on the acquisition, Andrew King, Mondi Group CEO, said: "Strategically, we are focused on investing to support the growing market demand for our sustainable packaging products, while delivering attractive mid-teen returns through cycle. The acquisition of Hinton is an excellent opportunity for us to secure locally produced kraft paper for our bags customers, helping to meet the current and anticipated future growth in demand for industrial and mailer bags in the Americas. This acquisition will also enable us to further strengthen our position as the global market leader in the production of kraft paper and paper bags.

"We are delighted to be making this investment in Canada and look forward to working with Hinton colleagues, West Fraser as a long-term partner, and other local stakeholders towards improving the mill’s environmental footprint and securing its sustainable future."

The acquisition is subject to customary regulatory clearance and is expected to close towards the end of 2023.

About Mondi

Mondi is a global leader in packaging and paper, contributing to a better world by making innovative solutions that are sustainable by design. Our business is integrated across the value chain – from managing forests and producing pulp, paper and films, to developing and manufacturing sustainable consumer and industrial packaging solutions using paper where possible, plastic when useful. Sustainability is at the centre of our strategy, with our ambitious commitments to 2030 focused on circular driven solutions, created by empowered people, taking action on climate. In 2022, Mondi had revenues of €8.9 billion and underlying EBITDA of €1.8 billion from continuing operations, and employed 22,000 people worldwide. Mondi has a premium listing on the London Stock Exchange (MNDI), where the Group is a FTSE100 constituent, and also has a secondary listing on the JSE Limited (MNP).

Toscotec launches Spare and Wear Parts in Voith Paper Webshop

Toscotec has successfully integrated its spare and wear parts portfolio into the Voith Paper Webshop. Customers can now order products quickly and easily around the clock using the latest functions. The Voith Paper Webshop has been operating for over six years and is constantly advancing to increase user-friendliness. Since June, Toscotec has onboarded more than 20 projects covering 3 multinational corporations.

The Webshop ensures easy consultation: users can access all the information they need on spare and wear parts in just a few clicks. It also allows for integration into the mill’s ERP (Enterprise Resource Planning) system so that customers can use their internal codes when planning for and purchasing spares.

Toscotec’s Webshop team (from left to right): Lorenzo Bonino, Spare Parts Technical Coordinator; Lorenzo Melani, Documentation Technical Coordinator.

Toscotec’s Webshop team (from left to right): Lorenzo Bonino, Spare Parts Technical Coordinator; Lorenzo Melani, Documentation Technical Coordinator.

Lorenzo Bonino, Spare Parts Technical Coordinator at Toscotec, says, “On one single platform, customers can both access their technical documentation and purchase spare parts. Information is made available for an entire paper mill, so that the staff of that production site can find everything in one place: topic-based and E-learning training, maintenance and operation manuals, as well as spare and wear parts for all their Toscotec equipment.”

Lorenzo Melani, Technical Coordinator of Toscotec Documentation Department, comments, “The Webshop saves time to the technical and administrative staff who search and purchase spares. They can access it from pc or tablet, and it allows for a much more quick, easy and efficient way to perform these tasks.”

Contact

Toscotec Spare Parts department

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Saica again relies on the leading digital solution OnEfficiency.Strength to save starch

Saica has selected the leading full-line supplier Voith to install the OnEfficiency.Strength digital solution. The innovative package for saving starch and consequently reduce CO2 emissions will be used at PM 10 at the El Burgo de Ebro site (Spain) as well as the PM 70 at Nogent-sur-Seine site (France). OnEfficiency.Strength is currently a unique solution on the market, developed specifically for paper production. The application is already successfully in operation worldwide. Especially after raw material costs have risen significantly, there is an increasing need for intelligent solutions that quickly reduce production costs.

Voith and Saica have already shared a very trusting and very good business relationship for a long time. The winning synergies combined with the technical know-how of Voith experts enable a best-in-class concept. Juan Luis Mendoza, Digital Officer at Saica, can also confirm this: "With Voith as one of our most important strategic partners, we are taking another step towards digitalization. The digital solution has already convinced us at other Saica sites. With the new installations in PM 10 and PM 70, we expect now to save significant amounts of starch at these plants and produce with less CO2 emissions. We look forward to improving Saica´s resource efficiency. We are sure it will quickly pay for itself."

Once installed at Saica, OnEfficiency.Strength will monitor key quality parameters and automatically adjusts starch application to the paper as well as other process and machine settings to customer requirements. Saica can thus save starch significantly. In addition, the solution increases the precision and reliability of the process, reduces manual handling and is easy to operate. Thanks to OnEfficiency.Strength, the current values for strength properties can be viewed in real time rather than only being available with manual sampling. In addition, the solution has the potential to reduce steam consumption and thus CO2 emissions as well as to ensure quality throughout the value chain.

"Voith's excellent reputation has been further reinforced with its strong focus on digitalization in the paper industry. I strongly believe that we offer by far the best added value to our partners, who are more than just customers," emphasizes Renan Fusco, Head of Digital Solutions Sales at Voith Paper. "By working with Saica, we are providing another important impulse for the paper industry in Europe."

More information on Voith's digitalization portfolio can be found here: https://voith.com/PaperIsOn.

About the Saica Group

The Saica Group is one of the leading companies in Europe in the manufacture of recycled paper for corrugated board, with a production capacity of 3.3 million tonnes. With over 10,000 employees and operations in Spain, France, Italy, Portugal, United Kingdom, Turkey, Luxembourg, Netherlands, Poland and United States, the Saica Group has four business lines: manufacture of recycled paper for corrugated card (Saica Paper), waste management and environmental services (Saica Natur), production of corrugated card for packaging (Saica Pack) and flexible packaging (Saica Flex). The Group’s turnover amounts to 4,394 million euros (consolidated turnover as of 31st December 2022). Saica.com

About Voith Paper

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

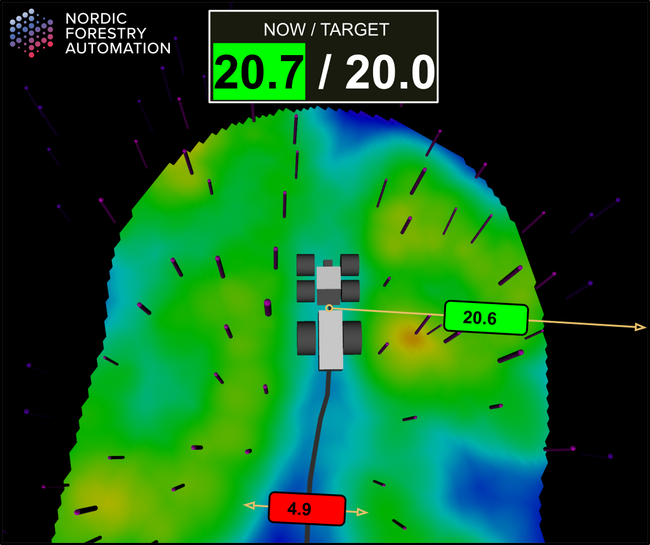

Södra invests in AI company and becomes a partner in Nordic Forestry Automation

Södra Ädla is a new partner of Nordic Forestry Automation (NFA). The company develops next-generation operator support systems for forest machines based on sensor technology from autonomous vehicles and AI algorithms. The investment is done together with Sveaskog and Almi Invest Syd and comprises a total of SEK 10 million.

Thinning a forest involves constant decision-making about which, and how many, trees to harvest in order to best promote the various values of the forest. How the thinning operation is carried out is important for the long-term development of the forest, but is usually done manually and based on the experience of each individual operator. To make the thinning task easier, Nordic Forestry Automation (NFA) has developed an AI-based system to continuously support the operator in forest management decisions.

The company started in 2021 based on the founders’ research work on self-driving vehicles and AI algorithms. The founders met during their PhD studies through the national Swedish research initiative Wallenberg AI, Autonomous Systems and Software Program (WASP). NFA recently received investment capital of SEK 10 million from Södra’s investment company Södra Ädla, Sveaskog and Almi Invest.

“Forest thinning is a craft that requires 100-percent focus and takes several years to master. The total cognitive load is comparable to that of a fighter pilot. Sensor-based operator support provides better conditions for operators and forest owners to promote forest values. We are grateful for the opportunity to continue developing this technology together with our new partners,” said Lars Svensson, CEO of NFA.

Investment to accelerate development

By supporting the operator, the NFA system makes harvesting more cost-efficient, which improves profitability for forest owners. In addition, the technology creates new opportunities for local forest adaptations, and enables systematic and cost-efficient execution of alternative forest management methods that promote biodiversity and carbon storage.

The new investment will enable NFA to further accelerate the pace of its development. In 2022 and 2023, the system was tested in pilot projects with SCA and Sveaskog and in the autumn of 2023, the company will start rolling out preseries products with Södra, Sveaskog and SCA.

“The investment and close collaboration with forest companies means that we can deploy the systems at an early stage and continue working closely with the operators. This is absolutely essential for building systems that can make a real difference out in the forest – for both operators and forest owners,” said Lars Svensson.

Better opportunities for forest owners

NFA’s operator support can be retrofitted to any type of forest harvester and supports operators in forest management decisions. The system measures, positions and classifies all trees around the machine automatically and in real time. It also gives the position of the machine and cutting head with centimetre accuracy. Data on each individual tree is continuously collected and delivered to the forest owner together with a report, enabling increased transparency, quality assurance of the harvesting and new opportunities for forest owners to apply alternative methods of management.

This factor and an improved work environment for machine operators are some of the reasons for Södra Ädla’s investment.

“We are delighted with our investment in NFA. The company’s AI-based operator support is a good example of the business models and technology that Södra Ädla wants, and intends, to invest in. The technology makes thinning easier and more precise, and enables a wider range of forestry measures. The technology also makes thinning easier for operators, which could eventually attract more contractors and forest machine operators to the industry. NFA’s technology generates direct value for forest estates and we are looking forward to contributing to the company’s development,” said Erik Bengtson, Investment Manager for Södra Ädla.

For contact or further information, please contact:

Lars Svensson, CEO, Nordic Forestry Automation

Tel: +46 (0)734-60 68 34

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Erik Bengtson, Investment Manager, Södra Ädla

Tel: +46 (0)340-63 34 32

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Södra was founded in 1938 on the idea that we are stronger together. We are now the largest forest-owner association in Sweden, with 52,000 family forest owners as members. Together, Södra’s members own a world-leading industry that processes forest raw material into renewable products such as pulp, timber, building systems, liquid bioproducts and energy. About 3,300 people are employed in our forest industry and in 2022, Södra generated sales of SEK 33 billion. Our products are exported all over the world and together, we are contributing to a more natural way of living. Rooted in the forest, we grow the future.

Toscotec launches E-Learning and Topic-based Training Center

Toscotec has successfully launched a new digital online Training Center, which offers in-depth and continuously updated technical information and user-friendly education tools. The onboarding of 10 tissue producers was completed in only three months.

Based on Voith’s web portal, the new Training Center has been fully developed and operationalized by Toscotec. The responsible team composed of Pietro Morrica (Training Technical Manager and Sales Support), Lorenzo Melani (Technical Coordinator), and Gabriele Belli (Technical Writer), answered a few questions to point out its key features.

What does the Training Center offer?

Pietro Morrica: First and foremost, it offers immediate access to a very comprehensive set of technical information anytime and on any device. It gives customers on-demand learning tools for their new technology so that they can promptly and independently learn about and resolve many problems that require expert knowledge to fix whenever they occur.

Toscotec’s Documentation team (from right to left): Pietro Morrica, Training Technical Manager and Sales Support; Lorenzo Melani, Technical Coordinator; Gabriele Belli, Technical Writer.

Toscotec’s Documentation team (from right to left): Pietro Morrica, Training Technical Manager and Sales Support; Lorenzo Melani, Technical Coordinator; Gabriele Belli, Technical Writer.

What kind of training can you find in the Training Center?

Pietro Morrica: Both topic-based Training Presentations and animated E-Learning Video Procedures for all tissue mill equipment from Stock Preparation, Main Machine, Support Sub Systems, all the way through Finished Roll Handling after Rewinders. The topic-based Training Presentations gives easy to understand explanations of the technical and functional concepts of Toscotec’s supplied equipment, how to set up the equipment properly, so those concepts work during operation, as well as in depth mechanical and electrical maintenance details of the various systems. Let’s take for instance the Shoe Press, a user will find all information relating to its mechanical structure and working theory, the hydraulic P&ID diagrams with explanations of the lubrication system components and function, its DCS operation (the tilt and all settings and adjustments), troubleshooting guides, and so on. In brief, all things Shoe Press from any point of view are included and easily accessible.

What about the E-learning part?

Lorenzo Melani: The E-Learning part is specifically designed for maintenance purposes, as it uses both animations and recorded video/pictures of actual equipment to clearly show each step of various maintenance procedures of the complex electro-mechanical automation systems. Firstly, being web-based, it can be accessed from any kind of device - pc, tablet, phone, or even augmented reality glasses/visor – on the mill floor while directly in front of the equipment. Secondly, operators can watch the video procedure they need to perform while doing it; they can simply play and pause the procedure as they go along. Finally, it is custom and all-inclusive, in the sense that Toscotec will work directly with a customer to develop whatever they will need and give suggestions according to our experience so all the information they need will be there. Before, maintenance operators worked with static mechanical assembly drawings, which required experience and advanced mechanical skills but don’t offer any electrical and automation detail. Or they had static procedures that gave limited sense of exactly which actions are needed. With Toscotec’s E-Learning, we go from that level of abstraction and compartmentalized information to the reality of on demand, in the field, motion demonstrated, access to any information (mechanical, electrical, and control-related) in an easy to follow and immediate manner.

What does continuous update mean and why does it matter?

Gabriele Belli: Toscotec custom develops the training using the project specific 3D drawings of its technology in order to guarantee that the information given matches the actual machine installed at the mill. For operators and maintenance personnel on site, it is vital that the user manual, the topic-based Training Presentations and E-Learning are spot on to what’s actually in front of them. We are in charge of continuous information updates in the Training Center, and it is a task we carry out daily. If there is an engineering change in the field, we can easily adjust the online material to match. So anytime someone goes online to view the information, the person is assured they are accessing the absolute latest and greatest design version.

Contact

Lorenzo Melani

Technical Coordinator, Documentation Department Toscotec

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet to supply a high-capacity winder to Gascogne Papier in France

Valmet will supply a new high-capacity winder to Gascogne Papier in France. The winder will be delivered for the paper machine PM 7 at their Mimizan site. The start-up of the machine is scheduled for 2025.

The order is included in Valmet's orders received of the second quarter 2023. The value of the order will not be disclosed.

“This winder will be a key contributor to the top-level quality of our future papers, which will reinforce the current positioning of Gascogne Papier as a world leading kraft paper producer,” says Régis Laffont, Industrial Director, Gascogne Papier.

“To meet their high capacity and quality targets, the customer was searching for a supplier capable of providing a high-quality winder. Our solution and expertise reassured them and confirmed that we are a frontrunner in the winding technology,” says Yannick Duperrier, Senior Mill Sales Manager, EMEA Area, Valmet.

Technical information about the delivery

Valmet's delivery will include a high-capacity OptiWin two-drum compact winder that has a wide production range with different widths and diameters of shipping rolls. As a key solution for high-quality multi-roll winding, the winder is equipped with pro-active dual spreading.

The winder is also equipped with an automated butt-joint splicing for achieving the customer’s high-capacity targets. In addition, the delivery will include a wide site service for easier project handling, maintenance master data, Slitter Management Program, a spare parts package, and Valmet Industrial Internet solutions, such as Valmet Winder Diagnostics.

PM 7 produces natural machine-glazed and sack kraft paper grades. The new winder will handle parent rolls with a width of 6,870 mm and a diameter of 3,200 mm. The paper machine’s design speed is 1,300 m/min and the daily design capacity is 450 tons.

About the customer

Gascogne Papier is one of Groupe Gascogne’s four businesses. Gascogne was founded in 1925 in the Landes area of southwestern France. Gascogne Papier offers a wide range of natural, technical, and innovative papers for packaging and industry. Gascogne Papier is a long-time leader in natural unbleached Kraft paper. Their integrated pulp and paper plant located in Mimizan, France produces 150,000 tons annually on four paper machines and one coating machine.

For further information, please contact:

Kari Räisänen, Vice President, Sales and Marketing, Board and Paper Mills, Paper business line, Valmet, tel. +358 40 518 0567

Esa Ananin, Product Sales Manager, Board and Paper Mills, Paper business line, Valmet, tel. +358 46 923 3643

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

ANDRITZ to supply complete MDF line to Roseburg Forest Products, USA

International technology group ANDRITZ has received an order from Roseburg Forest Products Co. to supply a complete fiber preparation line for medium density fiberboard (MDF) production to its new mill in Dillard, Oregon, USA. This investment is part of Roseburg’s major program to upgrade and expand its manufacturing operations. Start-up is planned for the third quarter of 2025.

Jim Salchenberg, Director of Engineering and Construction, Roseburg, says: “Superior fiber properties are crucial to manufacture technically advanced medium density fiberboard products. We are convinced that the well-proven refining technology from ANDRITZ will meet our expectations and look forward to a successful partnership.”

With a capacity of 40 bdmt/h, the new line will process timber from Roseburg’s own 243,000 hectares of timberlands. The state-of-the-art pressurized refining system featuring an S2064 M single-disc refiner and a 74” digester including C-feeder will be the centerpieces of the new fiber preparation line. An innovative 24” plug screw feeder will provide high dewatering efficiency ahead of the high-pressure zone to ensure low consumption of electrical and thermal energy – a major benefit of ANDRITZ pressurized refining systems.

From left to right: Christoph Leitner, Sales Manager, ANDRITZ; Jake Hyland, Director of Sales, ANDRITZ; Michael Rupp, Vice President Panelboard Systems, ANDRITZ; Jim Salchenberg, Director of Engineering, Construction, Automation & Robotics, Roseburg “Photo: ANDRITZ”.

From left to right: Christoph Leitner, Sales Manager, ANDRITZ; Jake Hyland, Director of Sales, ANDRITZ; Michael Rupp, Vice President Panelboard Systems, ANDRITZ; Jim Salchenberg, Director of Engineering, Construction, Automation & Robotics, Roseburg “Photo: ANDRITZ”.

Roseburg Forest Products Co., founded in 1936 in Roseburg, Oregon, is a family-owned company specialized in the manufacturing of high-quality, sustainably harvested wood-based products for the North American market.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.