Ianadmin

SCA participates in Volvo Ocean Race 2014-2015

About 80 percent of SCA’s consumers globally are women. This strong reason is behind SCA’s decision to sign an all-female crew for one of the sporting world’s most challenging events. SCA is participating with a boat in the next round of the world Volvo Ocean Race in 2014-2015.

“SCA’s participation in the Volvo Ocean Race is important in our continued journey of change. As a Group, SCA invests in global growth, particularly in the hygiene area. The Volvo Ocean Race will increase awareness of the SCA brand and create stronger links to product brands such as TENA, Tork, Lotus, Tempo, Saba and Libero. We also want to highlight how our products improve our consumers’ quality of life,” says Kersti Strandqvist, Senior Vice President, Corporate Communications at SCA.

SCA’s participation will be managed by a team headed by Richard Brisius, co-founder of Atlant Ocean Racing that has extensive experience of successful Volvo Ocean Race projects. Atlant has organised and managed five Volvo Ocean Race projects and won twice: in 1998 with EF Language and in 2009 with Ericsson Racing Team.

“SCA’s investment in an all-female crew is unique. Competing for nine months in the world’s toughest offshore sailing race is a challenge that deserves respect. The new boat design lends itself to an all-female crew, and our aim is to create a strong team that will have the best possible platform to undertake the challenge," says Richard Brisius, Atlant.

SCA is the world’s second-largest hygiene company and Europe’s largest private forest owner with sales in more than 100 countries.

PMT starts up a new secondary Headbox overseas

PMT has recently started up a new, approximately 6 m wide, secondary Headbox on a North American Linerboard machine, replacing an existing, older secondary Headbox. Identity and location of the Paper Mill are confidential and cannot be disclosed. The replacement of the old Headbox was quickly accomplished during a normal maintenance shutdown.

PMT has recently started up a new, approximately 6 m wide, secondary Headbox on a North American Linerboard machine, replacing an existing, older secondary Headbox. Identity and location of the Paper Mill are confidential and cannot be disclosed. The replacement of the old Headbox was quickly accomplished during a normal maintenance shutdown.Outotec's expert appointed professor in systems engineering of materials science at Aalto University

Outotec's expert in recycling and sustainable technologies, professor, Dr Markus Reuter has been appointed Adjunct Professor at Aalto University, School of Chemical Technology, Department of Materials Science and Engineering as of August 1, 2012. The professorship focuses on systems engineering with application to recycling, simulation and design for recycling and sustainability.

Besides his chair at Aalto University, Markus Reuter continues working for Outotec as Director - Technology Management responsible among other things for cooperation with universities and international stakeholder organizations. In addition, he is Professorial Fellow of Sustainable Technology at the University of Melbourne, Australia.

"This new professorship adds an important systems engineering viewpoint related to metals production and recycling to education and research in materials science," explains Dean Outi Krause from Aalto University, School of Chemical Technology and continues: "Recycling of for example electronics and critical materials makes the processing chain an ever more complex, multiphase system. Mastering that system requires a deep understanding of metallurgy and thermodynamics as well as knowledge of the entire life cycle of materials including their recycling. Metallurgical process solutions and technologies can be efficiently utilized in recycling. Systems engineering is an essential tool of sustainable metals production."

Aalto University's new professorship will increase material recycling knowledge globally and open new possibilities for technology development. Outotec as a leading developer and provider of metallurgical processes and technologies needs new experts in systems engineering. In addition, Outotec can participate in the related research programs.

"Through systems engineering we will be able to model and test processes and thus manage more complicated process combinations and develop process technologies for secondary raw materials inclusive of water. Furthermore, our customers will be able to recover a larger variety of metals and recycle rare minerals, which has not been possible before. New technological solutions enable reuse of materials, which saves non-renewable resources," says Outotec's CTO Kari Knuutila.

MarquipWardUnited’s Versatility Has Led to Milestone

MarquipWardUnited is celebrating the installation of its 300th dual rotary sheeter knife. In the 25 years that they have been manufacturing sheeters, MarquipWardUnited has installed dual rotary knives around the globe in paper mills, converters, folding carton plants and commercial printers.

MarquipWardUnited is celebrating the installation of its 300th dual rotary sheeter knife. In the 25 years that they have been manufacturing sheeters, MarquipWardUnited has installed dual rotary knives around the globe in paper mills, converters, folding carton plants and commercial printers.International Paper CEO to Speak at UBS Global Paper and Forest Products Conference

International Paper (NYSE: IP) Chairman and Chief Executive Officer John V. Faraci will speak at the UBS Global Paper and Forest Products Conference in New York City on September 13th. The presentation is scheduled to begin at 8:00 a.m. EDT and will be followed by a question and answer session.

All interested parties are invited to listen to the webcast live via International Paper's Internet site http://www.internationalpaper.com by clicking on the "Investors" tab and then clicking on the "Webcasts & Presentations" link. A replay of the webcast also will be available on the website beginning approximately three hours after the presentation.

SOURCE International Paper

BASF, Cargill and Novozymes target commercial bio-based acrylic acid process

Xerium Technologies announces the appointment of a new Chairman and a new CEO

Xerium Technologies, Inc, a leading global manufacturer of industrial textiles and roll covers used primarily in the paper production process, has announced the appointment of Mr. Harold C. Bevis, as the company’s new Chief Executive Officer, President and Director. Mr. Bevis has been CEO, President and Director of Pliant Corporation and Jordan Telecommunication Products, and has held executive positions with Emerson Electric and General Cable Corporation. He is a 1983 graduate of Iowa State University receiving an Industrial Engineering degree and earned his MBA from Columbia University in 1988.

Coincident with the appointment of Mr. Bevis, Mr. James F. Wilson, currently Xerium’s Lead Director, has been appointed the company’s Chairman of the Board. Mr. Wilson joined the Xerium Board of Directors in June 2010 and has served on the Compensation and Nominating committees since that time. Mr. Wilson is a principal at Carl Marks Management Company, LLC, an investment firm which is a significant shareholder of Xerium stock. As a consequence of the separation of the Chairman and CEO roles, the Board of Directors will no longer have a Lead Director.

As previously announced in December 2011, Stephen R. Light Xerium’s Chairman, Chief Executive Officer and President resigned from his executive and board positions coincident with the appointment of Mr. Bevis and Mr. Wilson. Mr. Light will remain a non-executive employee of the company to facilitate the executive transition until his retirement in February 2013. The company wishes to thank Mr. Light for his leadership and contributions during a time of significant change and progress for Xerium.

In connection with his appointment, Mr. Bevis was awarded 204,208 restricted stock units and options to purchase 781,701 shares of Xerium’s common stock. These awards were made in accordance with the employment inducement award exemption provided by Section 303A.08 of the New York Stock Exchange Listed Company Manual and were therefore not awarded under Xerium’s stockholder approved equity plan. The restricted stock units vest annually in one-third increments, beginning on the second anniversary of the August 15, 2012 grant date. Vested restricted stock units will result in the delivery to Mr. Bevis of one share of Xerium’s common stock per vested unit. The options will vest annually in one-third increments, beginning on the second anniversary of the August 15, 2012 grant date, have a 10-year term and an exercise price of $4.00 per share, the August 15, 2012 closing price of Xerium’s common stock on the New York Stock Exchange.

Source: Xerium Technologies, Inc.

Gardner Denver Announces European Restructuring Initiative

Gardner Denver has announced a restructuring initiative to optimize its global manufacturing footprint, reduce costs and expand margins. These initiatives, which focus primarily on its European Industrial Products Group, will consolidate manufacturing facilities and reduce associated staffing levels to increase operational efficiency and provide additional resources to invest in profitable growth. In connection with today's announcement, the Company also confirmed its prior earnings guidance for full-year 2012.

Gardner Denver expects to begin implementing its restructuring plan over the next several months and intends to conclude these initiatives by the end of 2015.

In total, these initiatives are expected to generate annualized, pre-tax cost savings of $35-$40 million by 2016, with $10-$15 million expected to be achieved in 2013.

"Gardner Denver has a solid track record of margin expansion and execution supported by the principles of the Gardner Denver Way," said Michael M. Larsen, Gardner Denver Interim Chief Executive Officer and Chief Financial Officer. "Today, we are announcing a series of strategic actions and plans designed to ensure that our company remains financially well-positioned and appropriately structured for profitable, long-term growth in our Industrial Products Group in Europe."

"After extensive analysis and consideration, we believe these restructuring initiatives will enhance the Company's prospects for growth and value creation, while ensuring that our businesses continue to meet and exceed the needs of customers every day. We further recognize that this will have a personal impact on people who have been dedicated to the mission of Gardner Denver. We recognize their contributions to the achievements of our business, and are committed to treating them fairly and with respect throughout this process," said Larsen.

The company noted that it expects to record cumulative, pre-tax restructuring charges related to the restructuring plan, consisting primarily of severance benefits and other integration costs, in the range of $85-$100 million which will be fully realized by 2015, with $35-$45 million expected to be incurred in 2013.

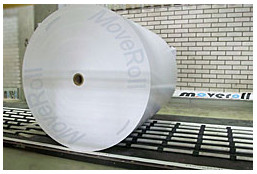

Finnish company MoveRoll launches Innovation Contest at China Paper 2012

On the first day of China Paper 2012 MoveRoll Oy will launch its innovation contest "Innovate China’s Paper Roll Handling!" For the first time ever, contest  participants can get a reward of up to 100 000 ¥ by finding new applications for MoveRoll.

participants can get a reward of up to 100 000 ¥ by finding new applications for MoveRoll.

During China Paper 2012 MoveRoll Oy shows an innovative new conveyor based on pressure elements without moving parts. The new roll handling technology reduces costs, doubles handling capacity, increases safety and diminishes material damages.

MoveRoll conveyors are already successful in Finland, Sweden, Brazil, Canada and USA. Now MoveRoll is ready to approach the Chinese market. At the occasion of China Paper 2012 MoveRoll Oy will also launch further innovative products for the roll handling industry. More information about the contest and the new products will be available at MoveRoll’s booth 1506. Please also take a look at www.moveroll.com

ANDRITZ to supply key components for testliner and corrugated medium machine

International technology Group ANDRITZ will deliver the paper machine approach, a save-all disc filter for fiber recovery, two PrimeFlow headboxes, and a PrimeDry  Hard 2 roll calender for the new testliner and corrugated medium machine at Sichuan F. Source Paper, China. Start-up is scheduled for September 2013.

Hard 2 roll calender for the new testliner and corrugated medium machine at Sichuan F. Source Paper, China. Start-up is scheduled for September 2013.

At a design speed of 650 m/min and a width of 4.9 m, the machine achieves an annual capacity of 150,000 t. The ANDRITZ headbox is of compact design and easy to install, which are decisive criteria especially for rebuilds. The PrimeCal Hard calender optimizes precalendering and final calendering of all paper and board grades.

With this order, the PULP & PAPER business area, which manufactures its paper machine components in Europe and China, is further strengthening its position as one of the leading suppliers of machines and local services in China.

International technology Group ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, solid-liquid separation in the municipal and industrial sectors, the steel industry, and the production of animal feed and biomass pellets.

In addition, ANDRITZ offers technologies for certain other sectors including automation, pumps, machinery for nonwovens and plastic films, steam boiler plants, biomass boilers and gasification plants for energy generation, flue gas cleaning plants, plants for the production of panelboards (MDF), thermal sludge utilization, and torrefaction plants.

The publicly listed company is headquartered in Graz, Austria, has a staff of more than 17,400 employees, and operates over 180 production sites as well as service and sales companies all around the world.