Ianadmin

Endress+Hauser strengthens Supervisory Board

Endress+Hauser strengthens the Group’s Supervisory Board. The company’s long-serving CFO Fernando Fuenzalida (69) joins the body from 1 August 2012.

The Supervisory Board is expanding from six to seven members. This ensures that Mr Fuenzalida will continue to incorporate his knowledge and experience. The Supervisory Board advises and observes the Executive Board, the Group’s senior management body. Key decisions require the consent of the Supervisory Board.

Born in Chile in 1942, Fernando Fuenzalida completed a Master’s degree in industrial engineering at Columbia University in the City of New York. From 1968 he worked as a consultant and manager for various international companies until joining Endress+Hauser in 1998 as Chief Financial Officer. Since 2002 he has been a member of the newly formed Executive Board of the Group. Fernando Fuenzalida retired at end of 2011.

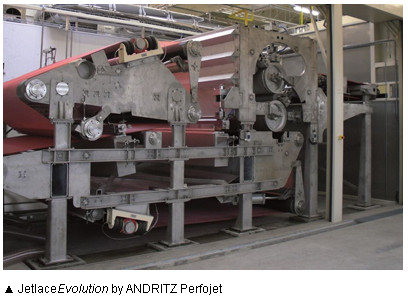

ANDRITZ presents its nonwovens solutions for the production of technical textiles

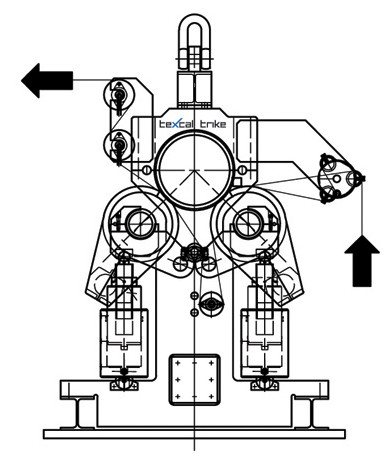

NipVision: A nip measurement system to make the invisible visible

- Real time system makes nip measurements possible while the paper machine is running

- Glass fiber embedded in the roll cover constantly transmits information from the nip

New Serla is here!

ANDRITZ to supply PrimeLineCOMPACT II tissue machine

The tissue machine has a design speed of 1,650 m/min and a width of 2.85 m. The steel yankee has a diameter of 3.65 m. The scope of supply also includes the complete stock preparation plant, automation, and drives.

The tissue machine has a design speed of 1,650 m/min and a width of 2.85 m. The steel yankee has a diameter of 3.65 m. The scope of supply also includes the complete stock preparation plant, automation, and drives.NewPage Files Joint Chapter 11 Plan

NewPage Corporation has announced that it has filed a Joint Chapter 11 Plan (the "Plan") with the United States Bankruptcy Court for the District of Delaware. The Company also requested an extension of time to file the disclosure statement related to the Plan.

"The filing of our plan of reorganization is an important and positive step forward to a successful completion of our financial reorganization," said George F. Martin, president and chief executive officer. "Discussions with and among our major creditor groups regarding the plan are ongoing. We are hopeful that these discussions will lead to broad support for our plan."

The Plan is available at http://www.newpagerestructuring.com/legal-filings/.

This release is not intended as a solicitation for a vote on the Plan.

New Ecolab Facility in Taicang, China to Help Enhance Chinese Food Safety and Public Health

Cascades Continues to Consolidate its Operations

Major Russian pulp & paper trade association back IPX Russia 2013

Metso to supply Automated Paper Lab to JK Paper Ltd. India

Lab, paper and board quality analyzer, for automatic testing of paper properties at its Rayagada paper mill. JK Paper Ltd. is also a leading player in packaging board and coated fine papers segments in India.

Lab, paper and board quality analyzer, for automatic testing of paper properties at its Rayagada paper mill. JK Paper Ltd. is also a leading player in packaging board and coated fine papers segments in India.