Ianadmin

Pöyry reduces operating profit estimate for 2012

Based on current information, the Pöyry Group's operating profit for 2012, excluding restructuring costs, is expected to remain stable compared with 2011. Previously the comparable group operating profit was expected to improve clearly from 2011. The outlook for Group's net sales for the full year 2012 remains unchanged, and is expected to remain stable.

The main reasons behind the reduced outlook are:

- Closure and divestments of low performing and non-core offices and business units

- Recognized one time project and credit losses in Urban business group projects mainly outside of our core markets

- Lower than anticipated activity levels in certain markets and especially in the Management Consulting business group

Pöyry continues the strategic review of its business portfolio, especially in the Urban business group. The previously announced operational excellence program aiming at improving the business units' performance will continue until end of 2012. The program also includes group-wide efficiency improvement measures, focusing on internal processes, support functions and associated costs that are expected to deliver significant annualized cost savings.

"The Company's financial performance has not been satisfactory, and we have taken necessary measures to adjust our costs to improve our efficiency and profitability. This work will continue through the targeted ongoing programs, aiming at reducing our cost base. We expect to gain significant improvements from these programs", says Henrik Ehrnrooth, President and CEO of Pöyry Group.

More details about the outlook will be issued in Pöyry's January-June interim report, which will be published on 27 July 2012.

Previous Group level outlook from Q1 interim report (25 April 2012):

Based on the current strong order stock and outlook for new orders, the Group's net sales in 2012 are expected to remain stable compared with 2011. The comparable operating profit for 2012 is expected to improve clearly from the operating profit, excluding restructuring costs, in 2011.

The outlook and comparison both refer to figures excluding restructuring costs.

Verso Paper Corp. Announces Grant Program to Increase Certified Forest Acreage near Its Paper Mills

Verso Paper Corp. has launched the Verso Forest Certification Grant Program, an initiative aimed at increasing certified fiber and certified acreage on lands near the company's four paper mills. The program will provide start-up funding to encourage and assist landowners, consulting foresters and other stakeholders in developing innovative new projects that will help expand and maintain certification in Verso's wood procurement zones.

"Verso's Forest Certification Grant Program helps us meet two important sustainability commitments," says Verso Senior Vice President for Manufacturing and Energy Lyle Fellows. "By encouraging expanded forest certification, we're advancing responsible management practices that keep U.S. forests vibrant and healthy. We're also helping to increase the available supply of certified fiber which, in turn, allows us to keep our pledge to provide paper products that help our customers meet their own sustainability objectives," he says.

"Verso already uses a high percentage of fiber that's certified to credible forest management certification standards — about 70 percent, but the availability of certified fiber in the United States remains limited with only about 28 percent of privately owned U.S. land certified," explains Verso Senior Vice President for Sales, Marketing and Product Development Mike Weinhold. "With customer demand for certified paper products increasing significantly, it's vital that we do all we can to make sure the supply of certified fiber keeps pace."

The Forest Certification Grant Program builds on Verso's track record of successful forest certification expansion initiatives. In 2011, the company completed a two-year group certification project in partnership with several of its customers and other stakeholders that resulted in an additional 1.4 million certified acres in Maine. In 2009 and 2010, a Verso grant to the Trust to Conserve Northeast Forestlands resulted in 160,000 additional certified acres across six Northeast states. Verso regularly encourages certification through collaboration with state forestry associations and certification organizations, and through its relationships with private landowners.

Source: Verso Paper Corp.

Walki announces appointment in Paper Packaging Business Area

Carlo van Houtum has been appointed Vice President, Sales and Marketing for the Paper Packaging Business Area and Business Line Reel Wrap as of June 11, 2012. Carlo has worked for several years in Sales and Marketing Management positions at Myllykoski Group, Sappi Group, and now joins us from delfortgroup in Tervakoski.

Carlo van Houtum has been appointed Vice President, Sales and Marketing for the Paper Packaging Business Area and Business Line Reel Wrap as of June 11, 2012. Carlo has worked for several years in Sales and Marketing Management positions at Myllykoski Group, Sappi Group, and now joins us from delfortgroup in Tervakoski.

The Walki Group is an international company, which produces wrappings for the paper and metal industries. We also have decades of experience manufacturing food and consumer packaging materials as well as decorative and functional laminates. In addition to this, we create specialist liners for solid and corrugated packaging, facings for the insulation and construction industries, and solutions for technical applications. To make working with Walki as easy as possible, our company structure is based on three business areas: Paper Packaging, Consumer Board and Technical Products. If you need help in any of these areas, you can rest assured that Walki has your business covered.

Walki has production facilities in Finland, Germany, the Netherlands, Poland, the UK and China. To best cater to our global customers, we aim to continue investing in state-of-the-art production facilities and promoting our tradition of innovation and exceptional service worldwide. The combined annual net sales of our factories exceed 320 million Euros.

Clearwater Paper Announces John D. Hertz as Chief Financial Officer

Clearwater Paper Corporation has announced the appointment of John D. Hertz as senior vice president, finance and chief financial officer. Hertz will assume the CFO responsibilities on August 6, 2012. He will replace Johnathan D. Hunterwho has been serving as interim CFO, and Mr. Hunter's role and title remains as vice president and controller.

Hertz, 45, will have responsibility for financial reporting and controls, investor relations, risk management, tax and treasury functions. He most recently served as vice president and chief financial officer for Novellus Systems, Inc. Novellus is a semiconductor manufacturing equipment supplier with annual sales of approximately $1.6 billion and a category leader. Prior to Novellus, he held senior positions at Intel Corporation including central finance controller of the digital enterprise group, finance controller of the enterprise platform services division and accounting policy controller. Prior to joining Intel, Mr. Hertz served as a senior manager with KPMG.

"John's 23-year track record as a successful senior leader in accounting, auditing and finance, combined with his strong investor relations management background, clearly make him a strong addition to our senior management team," said Gordon Jones, chairman and chief executive officer.

Hertz earned a Bachelor of Science in business with an accounting emphasis from Montana State University and was a practice fellow at the Financial Accounting Standards Board (FASB).

Source: Clearwater Paper Corporation

Save energy and improve total lifetime performance with nonwoven and hybrid TMO felts

Felts play a major role with regard to efficiency and cost savings. As the process is complex it is important to analyze the whole process, not only one part of it.

When purchasing a felt going for a cheaper option might, in the worst case, result in additional costs during the felt running time. It is better to analyze a felt’s real effect on machine efficiency by looking at the felt costs per produced paper tonnes and the savings (e.g. energy reduction and saved production time) that can be achieved with certain felts.

Energy savings through the right press felt choices

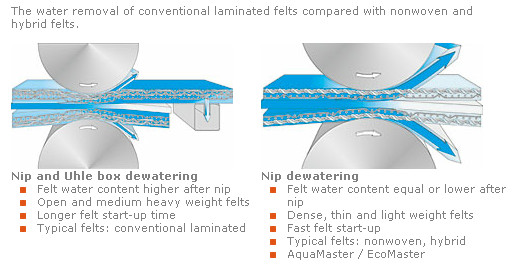

Big savings can be achieved by reducing energy costs in the paper machine. Electricity usage in the press section is huge and adds up to hundreds of thousands of euros every year. About 20-30% of electricity usage is related to Uhle boxes. Their friction increases the energy consumption of drives, and the Uhle box vacuum increases vacuum energy consumption.

Energy can be saved by using nonwoven and hybrid felts, which maximize nip dewatering meaning that minimized or no vacuums are required in the Uhle boxes.

Standard nonwoven and hybrid felts: AquaMaster and EcoMaster

AquaMaster’s immediately saturating structure allows a very fast start-up and maximal nip dewatering. As all the water is removed in the nip, Uhle boxes do not increase sheet dryness. Rewetting is minimized with a special layer.

EcoMaster is the combination of a woven and nonwoven structure. Its nip dewatering properties are excellent, but Uhle boxes can be used if necessary. Additional benefits compared with nonwoven felts include its smooth surface, insulation against marking, dimensional stability and less plugging.

Many machines already use AquaMaster and EcoMaster felts and run with maximized nip dewatering, which saves a lot of energy with closed vacuum pumps or blowers.

New: high-end TMO nonwoven and hybrid designs

Saving energy is not enough when the aim is to achieve efficient running. It is also important to improve runnability and total lifetime in other ways. In addition to good and even runnability, a minimal number of breaks, a high dry content and a maximal running speed are also important. A fast start-up and unchanged felt behavior are very important for the machine to run continuously at full speed. Minimal felt wear and a non-plugging structure ensure good life potential. A longer lifetime means fewer felt change shutdowns and savings in purchasing costs.

The sophisticated hybrid base TMO (TransMaster Open) felt has proven to be superior in this respect. It is a special felt for very demanding machines, such as highspeed printing paper machines.

Impregnated resin treatment ensures TMO’s even performance throughout its lifetime. This treatment makes the felt structure dense and non-compacting, and perfect for a fast start-up and immediate nip dewatering. The structure remains unchanged throughout the lifetime with no late life related problems such as edge flipping or plugging. Improved mechanical resistance gives the TMO felt long life potential and makes it durable, also under high nip pressures, even if the base fabric is nonwoven or hybrid.

The savings gained through making the right felt choices are significant. The picture on the next page shows an example of felt costs compared with savings achieved with the right felt choices.

The hybrid TMO felts are increasingly used in many of the world’s fastest newsprint and fine paper machines, especially in pick-up and 1st press positions, to ensure trouble-free running.

Hans-Joachim Müller to leave Clariant

Dr. Hans-Joachim Müller, member of the Executive Committee of Clariant, has decided to leave the company on June 30, 2012, for personal reasons. His current responsibilities will be transferred to the other members of the Executive Committee.

Hans-Joachim Müller was appointed member of the Executive Committee in July 2011. His responsibilities include Environment Safety & Health Affairs, Innovation Excellence, and the Business Units Catalysis & Energy, Emulsions, Detergents & Intermediates, and Oil & Mining Services. Until March 31, 2012, he was a member of the Managing Board of Süd-Chemie AG Munich, Germany. In this position, Hans-Joachim Müller was responsible for the entire Süd-Chemie operations since 2011. He initially joined the Managing Board of Süd-Chemie in 2007.

“I want to thank Hans Joachim Müller for his commitment and dedication during his time with our company, in particular for his contributions to the integration of Süd-Chemie during the recent 12 months,” said Hariolf Kottmann, CEO. “I wish him all the best and continued success in his future endeavors.”

Alfa Laval wins a SEK 60 million unique energy efficiency order from AkzoNobel

Alfa Laval – a world leader in heat transfer, centrifugal separation and fluid handling – has won an order to supply a unique evaporation system to an AkzoNobel chemical plant in Germany. The order is worth approximately SEK 60 million and delivery is scheduled for 2013.

The Alfa Laval evaporation system which will concentrate caustic soda based on evaporation and condensation heat exchangers, will be installed in a plant in Germany. By combining the advantages of different types of heat exchangers it is, for the first time, feasible to concentrate caustic soda in a 4-effect evaporation system. The unique Alfa Laval design will enable energy savings of 25 percent compared to the best traditional designs

“One of our strengths is our wide range of heat exchangers and application knowledge covering different needs from various industries”, says Lars Renström, President and CEO of the Alfa Laval Group. “This time we have used our expertise to create a unique system that enables large energy savings. This order is a good example of our ability to optimize our customers’ processes.”

Did you know that… caustic soda needs to be concentrated from 32 to 50 percent – and then it is used as a chemical base in the manufacture of pulp and paper, textiles, drinking water, soaps and detergents?

UPM named ‘Most Innovative Company’ at 2012 Ethical Corporation Awards

UPM has been awarded ‘Most Innovative Company’ at the 2012 Ethical Corporation Awards held in London. UPM was highlighted for its Eco Design approach and overall sustainable thinking. UPM’s innovative approach has seen new products created such as the world’s first biodiesel manufactured from wood raw material.

“Our focus on producing more with less is a clear example of UPM as a forest industry company is now creating tangible results with bio composites, bio fuels and the use of non-fossil fuel energy”, comments Hartmut Wurster, Executive Vice President Technology and responsible for new businesses and environmental issues. “The integration of the bio-based and forest industries has created the Biofore vision the foundation of our corporate responsibility.”

A spokesperson for Ethical Corporation commented: “The judges commended UPM for its commitment to creating innovative materials for increased recyclability and robustness. This is traditionally a very challenging category and the judges commended the effort of all entrants to demonstrate genuine innovation in their sustainability approach.”

UPM has brought to market several innovative products recently including UPM ForMi a composite material made from pulp fibres from sustainably managed forests and clean plastic polymers. It has also launched the fuel of the future, UPM BioVerno, the first wood-based biofuel. UPM aims to be a major player in the production of advanced transportation biofuels.

The Ethical Corporation Awards (http://events.ethicalcorp.com/awards/) recognises companies and individuals who have made significant advances in the field of corporate responsibility. Previous winners have included Unilever, L’Oreal and the Rainforest Alliance. UPM was shortlisted alongside Acelor Mittal, McDonalds Europe and CottonConnect.

Creditors approve Catalyst Paper restructuring plan

Catalyst Paper Corporation is pleased to announce that the company has received the necessary creditor approval for its second amended plan of arrangement under the Companies Creditors Arrangement Act in Canada. Approval of more than 99 per cent of secured and unsecured creditors was received in votes cast in person and by proxy at meetings held today in Richmond, BC.

The sanction hearing under the CCAA process is scheduled to occur on June 28, 2012 in the Supreme Court of British Columbia and pending the BC Court approval, the confirmation hearing under the Chapter 15 process of the US Court in Delaware is expected to take place in mid-July.

“We have received support from a majority of stakeholders since we began the reorganization process and today’s vote of support by creditors for the second amended plan of arrangement sets out a clear path forward,” said President and Chief Executive Officer Kevin J. Clarke. “With the cooperation of employees, vendors, customers, pensioners and investors, Catalyst has been able to make progress through a very complicated situation at an unprecedented swift pace.”

“The plan which received creditor approval today puts Catalyst on a stronger financial base to compete and adapt as the marketplace for our products continues to change,” Mr. Clarke said. “We’re now turning our attention to securing our exit financing and satisfying the remaining conditions of the plan with a target timeline to emerge from creditor protection in the near term.”

In a related proceeding, Catalyst received BC Court approval to extend the period of CCAA protection to September 30, 2012.

Catalyst also received confirmation of regulatory approval by provincial government Order in Council of its proposed modifications to its salaried pension plan to provide for a special portability election option and solvency funding relief. The amendments required provincial government approval. The company estimates that it will save some $7 million annually with implementation of these modifications following a successful plan of arrangement.

Further Information and Monitor Contact Information

Details of today’s voting results on a class-by-class basis will be available at www.catalystpaper.com/restructuring.

Additional information is contained on the Monitor’s website at http://www.pwc.com/car-catalystpaper and in Catalyst Paper’s information circular dated March 23, 2012 (the Circular) available on SEDAR (www.sedar.com), EDGAR (www.sec.gov) and Catalyst Paper’s web page (www.catalystpaper.com). Terms used in this news release that are defined in the Circular have corresponding meanings.

Creditors who have questions may contact the Monitor at PricewaterhouseCoopers Inc., 250 Howe Street, Suite 700, Vancouver, British Columbia, V6C 3S7 (Attention: Patricia Marshall), phone: 604-806-7070 or email: This email address is being protected from spambots. You need JavaScript enabled to view it..

Catalyst Paper manufactures diverse specialty mechanical printing papers, newsprint and pulp. Its customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With four mills, located in British Columbia and Arizona, Catalyst has a combined annual production capacity of 1.8 million tonnes. The company is headquartered in Richmond, British Columbia, Canada and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.

Buckman Wins Presidential Green Chemistry Challenge Award

Prestigious Award from the EPA is for Buckman’s Maximyze® Enzymes and Their Success in Energy Reduction and Decreasing the Amount of Wood Fiber Needed to Manufacture High-Quality Paper

At ceremonies in Washington D.C., Buckman was presented with the Presidential Green Chemistry Challenge Award from the EPA for its Maximyze® enzymes comprised of natural catalysts to reduce energy and decrease the amount of wood fiber needed to manufacture high quality paper and paperboard. The award, the second for Buckman, is in the Designing Greener Chemicals Award category. This is the 17th year of the EPA awards program that recognizes the design of safer and more sustainable chemicals, processes and products.

The award-winning Maximyze technology from Buckman consists of new enzymes and combinations of enzymes which allow for more sustainable production of paper and paperboard with improved strength and quality. These enzymes are derived from renewable resources and produced by fermentations, rather than typical chemical reaction methods. Maximyze enzymes provide a completely new way to increase paper strength. Previously, the papermaker was limited to the costly process of adding different pulps, increasing mechanical fiber treatment which requires significant energy expenditure, or using various chemical additives of which many are derived from non-renewable resources.

“We are proud to be recognized by the EPA for our work on Maximyze with this prestigious award,” said Buckman Chairman of the Board Kathy Buckman Gibson. “Buckman is dedicated to serving our customers by providing innovative product and process solutions, while at the same time maintaining a culture committed to a sustainable future. We strive to use our knowledge to help make the world a better place for all. This award is particularly rewarding to us because it reflects success in both sustainability practices and product innovation.”

The name Maximyze refers to a group of products developed and sold by Buckman that are comprised of carefully selected and designed enzymes, derived from natural sources, that modify cellulose fibers. This technology is now being applied successfully in many paper mills around the world.

The use of Maximyze provides a variety of potential productivity, quality and environmental benefits to Buckman customers in the manufacture of tissue, paper and paperboard materials. These include:

- Improved paper product strength, which enables a reduction in the amount of cellulose fiber required to attain the necessary product performance specifications. In one application, the basis weight of the paper product was reduced by three pounds per 1,000 square feet with no loss of quality, resulting in a one percent reduction in the amount of wood pulp required, and therefore fewer trees were needed to create the same product. This amounts to the reduction of wood needed to produce these products by thousands of tons annually.

- Lighter weight paper or board translates into reduced resources required for shipping.

- Improved strength of paper made from recycled fibers, allowing a papermaker to use more recovered paper.

- Significantly reduces energy requirements for refining, up to complete elimination. Refining is an energy-intensive process that collapses the fiber and modifies its surface to improve inter-fiber bonding.

- Improves water removal in the papermaking process so less steam is required to dry the paper on the paper machine. The combination of enzyme action and reduced refining results in fewer fiber fragments and fines.

- Increases fiber choice flexibility. For example, the paper maker may be able to increase the proportion of hardwood fiber or recycled fiber used. To the papermaker this reduces cost. In addition, Eucalyptus (hardwood) plantations supply cellulose fiber much more quickly, requiring less forest land compared to softwoods.

“Each of these benefits has a different level of importance to each of our customers, whether they are looking for opportunities to use more plantation and less forestation hardwoods, more strength with less fiber in their paper and tissue, less energy usage, or lighter end-products,” added Buckman Gibson. “From a global environmental perspective, the Maximyze product portfolio is an excellent example of a technology with meaningful impact as we look for ways to reduce the strain on natural resources in the production of such basics as toilet paper, office and printing papers, and packing materials for a growing world population.”

“We congratulate Buckman on receiving this prestigious and well-deserved award,” said Suhas Apte, Vice President, Global Sustainability for Kimberly-Clark. “As Kimberly-Clark continues to pursue innovation to help us deliver against our challenging sustainability goals, we are encouraged to see our valued supplier partner recognized for its development of Maximyze enzymes, which offer Kimberly-Clark the potential for fiber choice flexibility and reduced energy usage.”

Buckman is a major innovator and leader in the international paper industry, with a commitment to stewardship and sustainability that demands continuous improvement. This commitment means Buckman is focused at all levels on preserving our environment through more efficient use of resources like energy and raw materials, minimizing the use of non-renewable resources, and maximizing safety for everyone involved with our products and processes. The Maximyze technology delivers these benefits. One major advantage of paper is that its basic raw material (trees) is renewable; the paper industry has a strong commitment to sustainability in maintaining forest lands. Yet there is also a major commitment to recycling: 63.5 percent of paper consumed in the U.S. is recovered (2010 statistics) and recycled to be reused back in the manufacture of paper and paperboard.

The Presidential Green Chemistry Challenge Awards are bestowed in five categories: Academic, Small Business, Greener Synthetic Pathways, Greener Reaction Conditions, and Designing Greener Chemicals. The 2012 award is the second for Buckman. In 2004, its Optimyze® Enzyme Technology to Improve Paper Recycling won the EPA Presidential Green Chemistry Challenge Award in the Greener Reaction Conditions category. Since the program launch by the EPA, some 1,500 nominations have been considered and only 87 awards given.