Ianadmin

Outotec awarded Cristal Global's mega size ilmenite smelter project in the Kingdom of Saudi Arabia

Outotec has agreed with Cristal Global, the second largest titanium dioxide pigment producer in the world, on the design and delivery of technology and services for new ilmenite smelting facilities to be located in Jazan Economic City, Saudi Arabia, as well as installation and construction of the plant on a pure turnkey basis. The overall contract value exceeds EUR 350 million, which will be booked in Outotec's second quarter order intake with the revenues recognized gradually over three years. The order supports Outotec's long term growth and profitability targets and does not affect the company's financial guidance for 2012.

Ilmenite is an iron titanium oxide and the primary ore of titanium. It is also used in the manufacture of titanium dioxide, a bright white powder used as a base pigment in paint, paper and plastics. Cristal Global has ilmenite mines in Australia and pigment plants in the USA, Europe and Saudi Arabia. In this new mega size ilmenite smelter, Outotec's ferroalloy smelting technology is applied for processing the ilmenite to titanium dioxide slag. The plant's initial annual capacity will be 500,000 tonnes of titanium dioxide slag, and its design enables expansion to one million tonnes. In addition, the plant will produce 235,000 tonnes of high purity pig iron as valuable co-product.

Outotec's scope of delivery includes basic and detail engineering, process technology, supply of all equipment, site preparation and civil works, equipment installation, construction and commissioning of the ilmenite smelting plant on a pure turnkey basis. The new plant is scheduled to be operational in 2014, after which Outotec will provide operate and maintenance services for the first two years with an option to continue.

"The demand of titanium dioxide is growing rapidly in Asia along with the growing middle class. Outotec's ferroalloy smelting is the Best Available Technology, BAT as defined by European Union, and I am excited about the opportunities of this technology in sustainable pigment production. I am also very happy about the implementation concept of this large project. Our global resources will be used effectively for the customer: engineering and project management will be done in Finland, manufacturing globally and civil and construction in Saudi Arabia by Outotec's international site team", says Outotec CEO Pertti Korhonen.

ANDRITZ to supply paper machine to Zellstoff Pöls, Austria

International technology Group ANDRITZ has received an order from Zellstoff Pöls AG, Austria, for the supply of a PrimeLine plant for production of special paper. The new paper machine (width: 5.4 m; annual capacity: 80,000 t; design speed: up to 1,000 m/min) will produce very high-strength paper grades used primarily for shopping bags, high-grade medical packaging, and food packaging. Start-up is scheduled for the end of 2013.

The scope of supply comprises the stock preparation plant, an approach flow system, the complete PrimeLine fourdrinier paper machine, a high-precision steel yankee to increase drying rates (diameter: 6.5 m), a calender, and the automation systems.

With this investment, Zellstoff Pöls is extending its existing paper production capacities at the Pöls mill; the company is the largest manufacturer of high-quality, Elemental Chlorine-Free (ECF) sulfate pulp from bleached softwood in Central and Southeast Europe.

Metso introduces control valve innovations for improved safety and efficiency at ACHEMA 2012, in Germany

Metso's unique offering of products and solutions to improve safety and productivity in the oil & gas industry is now complemented with a range of control valve innovations which will be presented at Hall 9.0. Stand B21 at ACHEMA. There will be short info sessions daily on the stand in English and German. ACHEMA 2012 will be held 18-22 June in Frankfurt, Germany.

Improved version of famous Q-Trim

Noise and vibration generated by control valves constitute a typical environmental issue in process plants and their surroundings. Further improvements to Metso's famous Q-Trim™ noise reduction technology that will be on show at ACHEMA 2012 have resulted in advanced noise and vibration control in challenging applications. These solutions help process industry customers improve personnel and plant safety while simultaneously increasing efficiency and reliability.

Third generation valve diagnostics from Metso

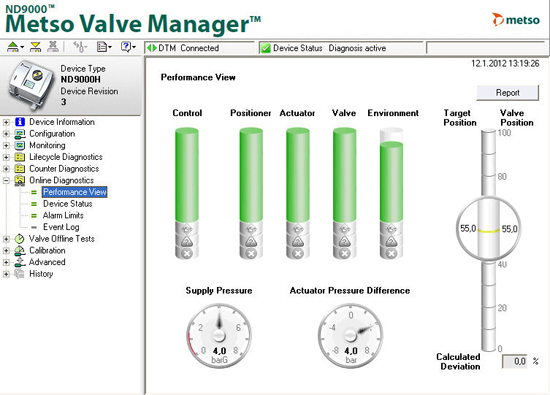

New Metso Valve Manager™ represents state-of-the art, 3rd generation valve diagnostics which is capable of processing the collected diagnostics information to visualize the condition of the valve in question with five different indices: Control performance, Valve condition, Actuator condition, Positioner condition and Environmental conditions.

With processed and visualized diagnostics information the maintenance managers and engineers and process operators are capable of making educated decisions concerning the control valve maintenance without deep valve know-how. Unexpected shutdowns can be avoided and the control valve performance can be maintained at optimum level by continuously monitoring the condition of the installed base at the plant or mill and by taking the necessary preventive actions based on the available diagnostics information. Also, with the help of the diagnostics, the available maintenance resources can be more efficiently allocated during shutdowns.

When so called preventive or schedule based maintenance strategy is followed, many valves are often needlessly maintained during shutdowns. By focusing the maintenance actions on the valves really needing maintenance, significant maintenance cost savings can be achieved through reduced spare part purchases and reduced need for maintenance resources.

Metso's new Valve Manager is available for the Neles ND9000 series intelligent valve controllers.

New features and services for intelligent emergency shutdown valves

New additions to Metso's market-leading intelligent emergency shutdown valves (iESDs) enhance the reliability and availability of emergency shutdown valves, and are designed to reduce plant safety costs efficiently and help customers maximize process plant uptime. Metso's valve sizing and selection software Nelprof® is the world's first valve selection software for safety valve optimization providing improved efficiency for safety valve selection process.

The Metso Valve HealthCare program supports the customer's preventive maintenance ensuring reliability of the critical emergency valves and helping to fulfill SIL requirements. Service is based on regular checking of valve conditions and analysing of diagnostics. The checking and reporting of recommended maintenance actions is done by Metso's certified service technicians.

The service reveals the condition of the critical valves and helps to avoid unexpected incidents affecting safety, environment or production. The service brings savings in maintenance costs by focusing on the valves needing attention or maintenance actions. Possible problems and degradation in performance are notified early to ensure time for maintenance planning.

On-going investments in global presence

Besides offering an extensive product offering, Metso is also investing in its global portfolio and presence to constantly improve services to customers in oil & gas and power. Just recently, Metso announced the acquisition of a globe valve technology and service company, Valstone Control Inc., in South Korea and established a new supply and service center in India. Currently, Metso is expanding its valve production premises in the US. Last year, Metso opened a new valve technology center in Finland, and another one in 2010 in Shanghai, China. In addition, Metso has high-class industrial valve facilities in Brazil and Germany.

Experienced in valves

Metso is the leading valve solutions and services provider. Metso's Flow Control solutions include control valves, automated on/off and emergency shut-down valves, as well as smart positioners and condition monitoring. Metso's world-leading brands include Neles, Jamesbury and Mapag.

Due to Metso's strong position in advanced valves technology, services are a major part of the offering. For example, customers like Petrobras and Arcelor Mittal have awarded Metso with large service contracts. For valve customers alone, Metso already has 32 service centers around the globe.

Walki gains stronger foothold in Russia

Walki Group, the leading producer of technical laminates and protective packaging material, has taken an important step in realizing its strategic growth plan for the emerging markets as the new plant in Svetogorsk in Russia celebrated its opening. The next step is already in the pipeline: establishing Walki’s own sales office in Moscow.

Walki Group, the leading producer of technical laminates and protective packaging material, has taken an important step in realizing its strategic growth plan for the emerging markets as the new plant in Svetogorsk in Russia celebrated its opening. The next step is already in the pipeline: establishing Walki’s own sales office in Moscow.

Establishing dedicated production facilities in Russia is a logical consequence of Walki’s close co-operation with many of its customers as well as a first step towards entering new business areas in the Russian market as a domestic supplier. The new Walki plant is located at the ZAO “International Paper” pulp and paper mill, cementing further our long-standing and successful partnership. For years Walki has been supplying ream wrapping for International Paper Russia’s well-known office paper brands Svetocopy and Ballet.

“We have plenty of experience in the Russian market when it comes to, for example, products for the paper industry, flexible laminates and packaging material for steel products. Our new establishment in Svetogorsk will enable us to provide faster and more flexible service to our existing customers,” says Timo Finnström, Vice President Paper Packaging and Sourcing, Walki.

Walki’s high quality products, solutions-focused attitude and service are the company’s competitive edge in the Russian market, and the local presence offers an excellent platform for entering the market with new products. In this, the Svetogorsk plant constitutes an important part of Walki’s long-term commitment in Russia.

“We have a range of products that in due time could be very interesting for the Russian market. A good example is flexible packaging applications and another is our range of high-class insulation facing materials and membranes,” Timo Finnström says.

Advantages of being local

In Svetogorsk Andrzej Kluczek, Managing Director, is happy to see the extrusion and printing capacity installed and running.

“Establishing a local base is a decisive step for us in building an even closer partnership with our key customers in the paper industry. An ability to act fast and with great flexibility is crucial in many cases. Ream wrappers are a good example of this; here designs are frequently switched and orders have to be met immediately,” Kluczek says.

The town of Svetogorsk is situated in western Russia, close to the Finnish border. Thanks to its location Walki Svetogorsk provides an excellent bridgehead into the huge Russian market; the nearby St Petersburg area has a population of 5 million.

Franz Marx, President of International Paper Russia, commented: «Our long-standing partnership with Walki has now reached a new level: this project of Walki packaging production plant at Svetogorsk site will advance International Paper's commitment to the operational excellence and therefore to our customers by improving the flexibility and security of supplies of our key product – multifunctional office papers. We also believe that this opening will have a positive impact for the region, creating new jobs, attracting investments and economic prosperity to the city of Svetogorsk”.

The next step for Walki will now be the opening of its own sales office in Moscow.

Two new Metso-supplied tissue machines started up at Shanghai Orient Champion Paper in China

On September 14, 2011, Shanghai Orient Champion Paper started up their new Metso-supplied tissue production line, TM 7, at their facility in Jinshan outside Shanghai, China. Now, less than eight months after the start-up of the first Advantage DCT machine, a second Advantage machine was even more successfully started up on April 26, 2012 at the same site. Due to the excellent cooperation between Shanghai Orient Champion Paper and Metso the TM 8 machine started up smoothly on schedule.

Metso’s scope of delivery included two complete tissue production lines, featuring one Advantage DCT 100+ and one Advantage DCT 135+ tissue machine. Each of the lines includes stock preparation systems, comprehensive Metso DNA automation systems and Metso IQ quality control systems with steam profiler and auxiliaries. Each of the machines is equipped with an OptiFlo headbox, a Metso Yankee cylinder, an Advantage AirCap hood, an Advantage WetDust dust management system for enhanced working environment and a ValReel reel.

The Advantage DCT tissue machine concept is developed for fast installation and start-up. These two installations were no exception. The TM 7 performance test was carried out two months after start-up. Within 10 days of the start-up the machine was up to guaranteed speed. The machine is designed for a production speed of 1,800 m/min. The start-up of TM 8 exceeded all expectations and the machine started up smoothly and timely. It is now operating with ease producing high-quality tissue paper.

“It has been a privilege for the Metso site crew to work together with the Shanghai Orient Champion Paper employees. The start-up crew led by Metso’s Niklas Ryman showed great professionalism when the “paper on” order was given. Without the skill and hard working attitude of the Shanghai Orient Champion Paper employees and the Metso crew the outcome would not have been this successful,” says Stefan Ziegel, Project Manager, Metso.

Just like for the start-up of TM 7, for the start-up of TM 8, too, a traditional inauguration ceremony was held to celebrate the new family member in Shanghai Orient Champion Paper’s machine park in Jinshan, Shanghai.

The rapidly growing Shanghai Orient Champion Paper currently operates six smaller tissue machines and converting lines at the Jinshan mill. The two new Metso machines add another 70,000 tonnes to the mill’s production capacity.

Shanghai Orient Champion Paper Co., Ltd. is part of the CIMIC Group which operates companies in various businesses. The CIMIC Group has operations in consumer goods, real estate, building materials, education, electronics and communications industries.

Magnus Hall New Chairman of the Board

Magnus Hall, President and CEO of Holmen, has been elected as successor to Mats Norlander, Stora Enso, in the position of Chairman of the Innventia Board of Directors. At the General Meeting of Shareholders, Mikael Hannus, Stora Enso, was also elected as new member of the Board, replacing Sven Wird, Holmen.

“We are very pleased to welcome Magnus Hall and Mikael Hannus and look forward to their support for our business,” says Birgitta Sundblad, President of Innventia.

“The forest industry is currently experiencing a period of structural change, in which research and development will play a more important role than ever before. It is now we need to identify the products of the future. Being part of this process as Chairman of the Board of Innventia is an incredibly exciting challenge,” says Magnus Hall.

Birch provides renewable plastic raw material

Green modification of the natural polymer xylan improves a number of material properties according to new licentiate thesis by Johanna Persson.

One of the biggest driving forces behind biorefining is replacing today’s fossil-based products with alternatives made from renewable resources. Wood raw materials are both renewable and plentiful, but the biggest gains are made if the residual products from the kraft pulp mill that leach out during cooking can be used. These residual products include lignin and hemicellulose. Innventia has carried out successful research and development into processes within the field of lignin with many potential products such as carbon fibre, activated carbon and dispersants. Now, hemicellulose is also being introduced.

A significant proportion of hardwood – up to 30 percent – consists of the hemicellulose xylan. Xylan is a natural polymer that is leached out from the fibres but not destroyed during kraft cooking. Xylan could therefore be used as a raw material for manufacturing barrier films for food packaging or other polymer materials. However, there are a number of difficulties when using xylan: it is water soluble, it is not thermally formable, and it is not easy to make films from. Johanna Persson has taken on these challenges in her studies.

“I took the fact that we can already produce xylan from black liquor as my starting point,” she explains. “Using chemical modification – an organic synthesis – I then tried to influence the hydrophilic, thermal and film-forming properties.”

The modification involves grafting lactide, which is produced in plants, onto xylan, thereby creating branches – or side chains – of polylactide. The length of these chains determines the properties of the material.

“The difficulty comes in controlling the length of these chains,” continues Johanna. “An article I read led me to discover a catalyst (triazabicyclodecene) that has proven to be highly effective. We can now produce lactide-grafted xylan with a specific branch length, giving us a broad spectrum of different materials that can be processed thermally and are not soluble in water. We can also produce strong self-supporting films with a tensile strength of up to 48 MPa.”

“Our use of ‘green modification’ may result in many new applications from renewable resources such as xylan,” adds Olof Dahlman, who was Johanna’s supervisor at Innventia.

ÅF wins SEK 600 million contract for new nuclear power plant in Brazil

On 12 January ÅF reported signing a contract worth approximately SEK 100 million for consulting services relating to the construction of a third reactor at the Álvaro Alberto Nuclear Power Station (CNAAA) in Angra dos Reis in the federal state of Rio de Janeiro, Brazil. This initial contract, which will be managed by ÅF Switzerland, related to services under the category of "Owner's Engineering Responsibilities".

Today ÅF can announce that a new contract, worth almost SEK 600 million, has been signed that includes the 3D Modelling of the piping, ventilation and electrical engineering design, technical support services and the as-built design for the Nuclear Island buildings of ANGRA 3 Nuclear Power Station. The project will be managed by resources from ÅF Finland and working with a significant number of local sub-contractors to ÅF.

As with the initial contract, the principal is once again Electrobrás Termonuclear S.A - Electronuclear (ETN). This company is a subsidiary of Electrobrás, a stock market listed company, which is majority owned by the Brazilian state.

ÅF's involvement in this new project is expected to begin in the third quarter of 2012 and is scheduled for completion during 2019.

ÅF won the tender primarily as a result of its high level of expertise and extensive reference portfolio from projects for the international nuclear power industry. ÅF is currently the world's sixth largest energy consulting company and one of the world's leading independent consultants in the field of nuclear power.

Metso reaches agreement concerning apparent patent infringement

Metso has reached an agreement with Airtherm Corporation, USA after an apparent patent infringement by Airtherm in a patent owned by Metso.

The Metso product protected by this patent is the so called Advantage WetDust system whereby the dust in a paper and tissue making line is entrained into a dust collector where water is injected directly inside the dust collector.

Airtherm have agreed to discontinue any further sales of the wet dust collection system protected by Metso’s patent. Airtherm Corporation have also agreed to pay for a onetime license for systems already sold.

The patent in question is the US Patent No. 6,176,898 issued in 2001 entitled “Method and System for Collecting and Handling Dust in a Paper Machine Environment”.

Pöyry awarded mill site engineering contract by UPM

Pöyry's Energy business group has been awarded an engineering contract by UPM for the Schongau mill site in Germany. The order has been booked in the first quarter order book and the parties have agreed not to disclose the value of the assignment.

The contract includes detail engineering for the Balance of Plant (BoP) and the overall plant integration of the main supply packages. The scope of work also comprises technical assistance to the UPM project team in purchasing the main machinery consisting of a gas turbine, heat recovery boiler and steam turbine.

The energy-efficient combined cycle power plant (CCPP) will replace the old plant facility which has operated more than 40 years. With this project UPM continues to invest in efficient energy generation to significantly reduce energy costs as well as to secure the energy supply. The total investment is about EUR 85 million.

Pöyry has extensive experience in building similar resource-efficient energy solutions. Pöyry's part of the project started in March 2012, and commissioning of the total plant is planned for the end of 2014.