Ianadmin

ContiTech Adds D-types to Air Actuator Product Range

D-type: The pneumatic air actuator can be disassembled into individual parts and replaced • Aluminum in the small sizes reduces weight • Replaces Dunlop “Springride”

ContiTech has added the D-type series to its air actuator product range. The unique thing about this series is that it is designed in such a way that every single component right up to the rubber bellows can be quickly and easily replaced. This simplifies the recycling process as rubber and metal parts can be separated more easily. In addition, ContiTech produces the connecting plates for the D-type series with diameters of up to 175 mm from aluminum. This is the standard material in many pneumatic products, and is now available in the ContiTech air actuators as well. “The products have been perfectly designed to meet market requirements,” says Dr. Olaf Kluth, head of the Industrial Applications segment at ContiTech Air Spring Systems. “The connecting parts have been designed in such a way that the air actuators can also be used as a replacement for bellows, as is already the case with the Dunlop ‘Springride’ in France, for example. Dunlop ‘Springride’ has now ceased production. One of the results of this is that demand for ContiTech has risen.”

Aluminum makes it more lightweight, flexible and easier to take apart and four fixing bolts ensure a firm hold: With the D-type series, ContiTech is presenting air actuators that are suitable for use in many sectors of industry.

Photo: ContiTech

The product range of the new D-types can be divided into eight different sizes, each of which is available as a one-, two- or three-convolution bellows and has dimensions of 80 mm/type 22 up to 435 mm/type 816. Without a piston rod, strokes of more than 400 mm are possible. The feasible lifting force range extends from 0.5 KN to 80 KN.

Based in Hanover, Germany, ContiTech produces its numerous air actuator designs using high-tech elastomer qualities. ContiTech air actuators are highly durable, have a long service life and are cost effective. The design of the dimensionally stable elements is comparable to that of a tire or air spring. They are used to produce extreme force in pneumatics where little space is available for installation and exceptionally harsh conditions are prevalent.

Very well-known applications of the D-types are power collectors in trains (pantographs) and paper machines. In addition, there are the comparable applications such as those with pneumatic cylinders based on a simple principle, e.g. in automation, glass, wood and agricultural engineering.

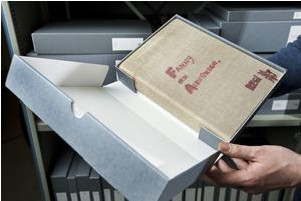

Billerud: Saving “Fanny and Alexander”

The handwritten screenplay for Fanny and Alexander, diary entries and letters are among Ingmar Bergman’s personal documents now being rescued for posterity thanks to Billerud. The secret? Smart packaging, of course!

In 2002 the Ingmar Bergman Foundation took over more than 40 packing boxes containing documents from the master director’s private archive on the island of Fårö. Most of the material was handwritten, which caused the foundation a lot of problems.

“The fact is that ordinary packing boxes literally suck the ink from documents stored in them. In short, Bergman’s notes ran the risk of disappearing into thin air thereby destroying a priceless cultural treasure,” says Jimmy Nyström, Business Development Director at Billerud.

The solution to the problem was Billerud Pure Archive, an acid free material of primary fibre, which is manufactured at Gruvön and protects paper documents from ageing.

“Billerud Pure Archive is a good example of our use of intelligent materials and smart packaging; it’s all about conserving, not storing. Many museums and institutions have digitised their archives but have not yet found a good solution for conserving the original documents. This means there’s a global market waiting to be developed and Billerud Pure Archive gives us a unique product to offer,” says Mikael Andersson, Sales and Marketing Director of Packaging Boards at Billerud.

Jan Holmberg, CEO of the Ingmar Bergman Foundation, is of course pleased that the old archive boxes are now being replaced by new boxes, with each box tailored to the measurements of the conserved documents. These include everything from customs documents for the export of yoghurt, to post from neighbours about snow clearing on Ymervägen outside Bergman’s former home in the Stockholm suburb of Djursholm, but above all, the notebooks that were the basis of Bergman’s theatre and film productions.

Jan Holmberg has two favourites:

“The screenplay for Love with no Lovers, which Bergman himself finally rejected and aptly wrote in an accompanying note that he ‘consigned the script to the archive department for unrealisable visions and dreams’. And the other is the stock of unused notebooks. It’s a titillating thought to reflect on what Bergman had planned to write in these books,” says Jan Holmberg.

The jewel in the foundation’s archive – listed at Unesco The Memory of the World Register – at the Film House in Stockholm is the workbook for the Oscar-winning film Fanny and Alexander, which Per Lindberg, CEO of Billerud, carefully leafs through when he visits the foundation.

“It’s a fantastic archive and of course a great honour for us to be involved in conserving this cultural treasure. Standing here with Bergman’s handwritten notes and knowing that they will now be conserved for many centuries thanks to a Billerud innovation is naturally very gratifying,” says Per Lindberg.

Link to filmclip about Billerud Pure Archive and the Ingmar Bergman Foundation

Sonoco CorrFlex's Rural Hall Plant Achieves 95 Percent Landfill Diversion

Sonoco Recycling, LLC, a unit of Sonoco and one of the largest packaging recyclers in North America, has announced that Sonoco CorrFlex's Rural Hall, N.C., facility has successfully diverted over 95 percent of its waste to landfill. The plant is the second CorrFlex facility to receive a silver-tier Star Award.

In September 2011, employees at Sonoco CorrFlex's Rural Hall, N.C., fulfillment facility formed Team Green, focused on achieving landfill-free status in two years. Since the plant is a fulfillment facility, its materials mix frequently changes based on the current customer and project. One of the major challenges for the team was staying on top of the flux of materials and determining the best outlet for each. To better understand their current program, the team began tracking landfill and recycling tonnage. Dumpster contents were monitored, assessing those areas that needed work to reduce the plant's landfill tonnage. Common recycling areas were set up in production and office areas, and employees were encouraged to bring in their recyclables from home.

The constant change within the temporary work force at Rural Hall posed another challenge for Team Green when implementing a shift in the plant's recycling culture, as the personnel within the work force changes daily and many are non-English speakers. By working closely with the plant's temporary staffing agency and using bilingual labeling, Team Green was able to overcome many recycling issues.

"In just eight months, Team Green was able to divert over 95 percent of Rural Hall's waste through a mix of recycling, reuse and waste-to-energy," said Harris DeLoach III, Sonoco Recycling representative for the Rural Hall facility.

A strong component of Rural Hall's recycling program is the initiative to reuse articles that aren't recyclable, or are difficult to recycle. Many old inventory items such as bags or boxes, previously slated as waste, are now distributed among employees. This initiative also includes items that can be reused by local non-profit organizations. Used work gloves, scrap bubble wrap and other items that were once thrown away now benefit non-profit educational programs within the community. Used computers, printers and other inventory items are donated to public schools in need of supplies for art or learning.

Additionally, management agreed to set up an Employee Recycling Account to collect funds from the new programs. The account is split at the end of the year among all permanent employees.

Created to recognize customer and Sonoco facilities for achieving significant milestones in landfill diversion and waste stream reduction, the Sonoco Sustainability Star Award program is composed of three tiers:

- Gold Star Awards, which recognize facilities that have achieved 99 percent landfill diversion;

- Silver Star Awards, which are given to facilities achieving 95 percent landfill diversion; and

- Bronze Awards, which recognize facilities that have made significant waste reduction achievements.

Learn more about our Sonoco Sustainability Star Award program at http://www.sonoco.com/productsservices/sonocorecycling/sustainabilitystarawards.aspx.

A recycling leader with 50 locations and expertise worldwide, Sonoco Recycling annually collects approximately 3 million tons of old corrugated containers, various grades of paper, metals and plastics. In addition, the Company has experts who provide secure, reliable and innovative recycling solutions to residential and commercial customers. Currently, Sonoco Recycling operates six material recovery facilities (MRFs) and serves nearly 150 communities in which curbside-collected residential and commercial materials are processed. The Company also provides recycling programs which identify waste reduction opportunities that reduce operating expenses for many of the largest consumer product companies in the U.S.

SOURCE Sonoco

Siemens - a reliable partner to the process industry for sustainable economic activity in dynamic times

At the Achema 2012 trade fair Siemens is focusing on the topic of lifecycle management. "We're demonstrating how the process industry can benefit from Siemens products, systems, solutions and services", said Axel Lorenz, Head of Process Automation for the Siemens Industry Automation Division, at a press conference in Karlsruhe, Germany. "Siemens is presenting itself to its process industry customers as a reliable partner for sustainable operations in dynamic times," according to Lorenz. The integrated portfolio of the company, he said, ensured high productivity, flexibility and efficiency throughout the entire plant and production life cycle. This could help to improve plant performance and energy efficiency and reduce the time to market. The Siemens approach to the integrated engineering of process and automation technology was groundbreaking and significantly reduced development and throughput times.

Cost pressure, global competition, a constantly and rapidly changing technological backdrop, as well as increasing environmental demands are the challenges facing companies in the process industry today. "Siemens has the right answers to these challenges. We work closely and reliably with the world's leading chemical and pharmaceutical companies, so that they can gain maximum performance from their plants", said Lorenz. This was also underlined by the motto used on this year's booth at Achema: "Guiding you through change – Your trusted partner for lifecycle innovation".

At the trade fair, Siemens is showcasing its extensive range of process instrumentation and analytical systems, drive technology, process control, manufacturing execution systems and plant engineering for the entire product and plant lifecycle – from research and development, through process analysis and design, plant engineering and production, to maintenance, optimization and modernization.

At the press conference, Hans-Georg Kumpfmüller, CEO of the Siemens Sensors and Communication Business Unit, stressed the considerable importance of reliable process instrumentation and analytics, as well as the growing requirements of users for suppliers who offer a complete product portfolio for all measurement variables: "Siemens is a complete systems supplier in the field of process instrumentation and analytics. Our portfolio covers all measurement variables such as pressure, level, temperature, positioning controllers, wireless solutions, weighing systems and flow measurement. We are a leading supplier in process analytics with our gas chromatographs and our gas analyzers". According to Kumpfmüller, there will be a series of important new products at Achema for the chemical and hygiene segment of the food and beverage industry and the pharmaceutical industry, as well as a wealth of additional applications. These ranged from groundbreaking innovations in level and flow measurement technology to new gas analyzers.

Andreas Geiss, Head of Comos Industry Solutions within the Siemens Industry Automation Division, underlined the growing influence of software on the various segments of the process industry: "Plant engineering is rapidly converging with significant gains in efficiency for the users." For plant management from plant engineering to production, Siemens is presenting Comos 10 at Achema – a new version of the software with a significantly extended scope of functions, enabling even the largest volumes of data to be managed. The integration of process engineering and automation has also been taken a stage further. A new interface ensures a consistent, bidirectional exchange of information between Comos and the Simatic PCS 7 process control system.

For research and development, Siemens is presenting a clean-room solution with access control, fire protection and evacuation, as well as special solutions for laboratories such as pure and ultrapure water and automation of typical laboratory applications.

In the area of process analysis and design Siemens is highlighting the potential of continuous production in the pharmaceutical industry. Companies can expect cost savings of up to twenty percent compared with batch production. There are innovations in the Sipat process analytical technology (PAT) software. These can easily be integrated into process control solutions by original equipment manufacturers (OEMs) in the new Version 4.

The main focus in production and maintenance is Version 8 of the Simatic PCS 7 process control system with a host of new functions. The new features range from improved data exchange and a simpler engineering workflow, more powerful communication, redundancy-related and high-availability functions, to new controllers and extended software tools.

The Siemens portfolio for the chemical industry is characterized by high-performance, plant availability and process reliability, exemplified by redundancy and failsafe fieldbus communication, as well as control and maintenance concepts. Furthermore, the company is presenting simple recipe sequence controllers with the Simatic PCS 7 APF (advanced process function) add-on for flexible hybrid processes.

In the pharmaceutical sector, Siemens is presenting a modular and flexible solution based on Simatic PCS 7 for fermenters according to the ISA-S88 standard. The TIA Portal engineering framework is used consistently in the manufacture of pharmaceuticals, from the definition and planning of recipes to the control of production and filling lines. The presentation for the pharmaceutical industry is supplemented by a serialization solution which enables companies in the industry to comply with future legislation and bring greater transparency to their supply chain.

Two topics determine drive technology: firstly, energy-efficient drive solutions for pumps, fans and compressors and, secondly, Loher motors and drives for hazardous areas and extreme ambient conditions. The Siemens portfolio in production and maintenance is completed by remote services, in which the company demonstrates the options and benefits of remote-controlled automation systems.

In optimization and modernization, Siemens is highlighting its engineering, consulting and service expertise and pointing out new ways to increase efficiency: for example, by optimizing resources, by simulation or modern plant control centers. Based on the main automation vendor (MAV) concepts, as well as the Simatic PCS 7 lifecycle service agreements, the company is presenting further solutions for increased plant availability, security of investment and lower total cost of ownership (TCO) throughout the entire lifecycle.

The Siemens booth at the Achema trade fair is rounded off by an extensive range of services for both the chemical and pharmaceutical industries. These extend from technical support, maintenance and lifecycle service agreements to professional consultation on industrial safety or energy management.

Nalco Constructing Dry Polymer Facility in Garyville, La.

Nalco, an Ecolab company, has announced construction of a dry polymer production facility at the company's complex in Garyville, La. The 300,000 square-foot facility will produce dry polymer products for use in removing contaminants from wastewater, increasing production efficiency in the paper industry and recovering minerals in the mining industry.

When completed late this year, the dry polymer plant will increase facility space at the Garyville complex to one million square feet and add 22 full-time positions to the company's current Garyville workforce of 235 employees.

"For more than 40 years, the Garyville community has had a significant role in the growth of Nalco, and we are extremely proud of the products and results our local employees have produced," said Jim Seifert, executive vice president, Ecolab. "The new dry polymer facility further strengthens our relationship with the community and the State of Louisiana, and we look forward to opening this facility and providing our customers with another innovative product solution."

Louisiana GovernorBobby Jindal andSt. John the Baptist Parish PresidentNatalie Robottom attended an event to announce the construction project.

"Ecolab decided to reinvest in Louisiana because of the track record of production success the company has had in St. John the Baptist Parish, and most importantly, because Louisiana has some of the best workers in the world," said Governor Jindal. "The company's expansion is a testament to Louisiana's strong business climate and the reliable and hardworking men and women of Louisiana."

Nalco first opened a production facility in Garyville in 1970. Today, the Garyville complex comprises more than 220-acres and produces industrial water treatment products, such as corrosion and scale inhibitors, used in boilers and cooling towers; wastewater treatment products; and process chemicals used in the papermaking, mining, petroleum, steel, power generation, food and beverage, metalworking and aluminum refining industries.

"Nalco has been a successful company and great community partner in St. John the Baptist Parish for many years," said Parish President Robottom. "The merger with Ecolab, another successful company, reassures their continued support for our community."

In addition to the 22 full-time positions necessary to operate the new dry polymer facility, it will take approximately 350,000 man-hours to complete the project, the equivalent of 167 full-time construction jobs. Construction of the facility is expected to be completed in December 2012.

Source: Ecolab

Domtar announces the acquisition of EAM Corporation

Domtar Corporation has announced that it has acquired EAM Corporation, a leading privately-held manufacturer of high quality absorbent composite solutions, from Kinderhook Industries, LLC for $61 million.

"The acquisition of EAM Corporation will give us long term research capabilities to further differentiate our full line of adult incontinence products while integrating the best available technology to grow our existing businesses," said John D. Williams, President and Chief Executive Officer. "EAM's patented airlaid manufacturing process provides the performance, quality, and cost competitiveness that we believe to be keys to success in the personal care market."

EAM Corporation produces airlaid and ultrathin laminated absorbent cores with brands such as NovaThin® and NovaZorb® used in feminine hygiene, adult incontinence, baby diapers and other medical, healthcare and performance packaging solutions. The company serves a diversified customer base and has long-standing relationships including well-known branded and private label consumer products manufacturers throughout North America and abroad.

The company operates a 71,000 square foot facility with state-of-the-art research campus and production lines in Jesup, Georgia. EAM Corporation has annual sales of approximately $45 million in more than 50 countries and a total of 53 employees.

Ahlstrom announces price increases for its Label and Processing papers worldwide

Ahlstrom, a global high performance materials company, announces price increases on its specialty paper materials produced by the Label and Processing business area, as a consequence of the recent rises in raw material and energy costs.

The price increase will affect all Label and Processing products worldwide and will be effective for all shipments made as of June 1, 2012. The increase range will vary depending on the products and markets. Specific details will be discussed with each customer individually.

Products manufactured by Ahlstrom's Label and Processing Business Area include graphic, packaging, processing, release and label papers. Their main end-use applications are release liners, self-adhesive labels, metalized wet glue labels, flexible packaging and repositionable notes. They are also used for the production of posters, abrasive materials and furniture foils. These specialty papers are manufactured in Brazil, France, Germany and Italy.

Södra's CEO to leave - President of Södra Cell Gunilla Saltin to take over temporarily

The Board of Directors at Södra has decided to start searching for a new CEO and Group President.

As the Board of Directors and CEO have differing views regarding the ongoing development of the company and what is required in the form of leadership and clarity, the Board has decided to terminate the employment of CEO Leif Brodén with immediate effect. At the same time, a decision has been made to extend temporarily the responsibilities of the President of Södra Cell Gunilla Saltin to also include the role of CEO for the entire Södra group. Recruitment of a new CEO will begin immediately. Until a new CEO is appointed, Board Chairman Christer Segerstéen will extend his involvement in the company and take over as Acting Chairman. In this role, he will mainly assist the Acting CEO with ownership and industry issues.

Leif Brodén has been employed by Södra since 1999, initially to head Södra Cell, Södra's biggest subsidiary, and then as CEO and Group President. Södra has developed very strongly during this time, to the benefit of its 51,000 members. Under sometimes very stressful conditions, such as when dealing with the consequences of the Gudrun storm, Leif Brodén has very professionally and successfully led and expanded Södra's industrial operations, forming a group which is financially very stable. Södra has a very strong foundation on which to stand, both financially and in terms of expertise, which will permit ongoing successful development and active participation in future structural changes. However, the Board has arrived at the conclusion that it is time for a new type of leadership, and for a new CEO to work together with the Board to produce and then implement the strategy to follow Södra's current long-term plan, which will remain in force until 2014.

Gunilla Saltin has been the President of Södra Cell, Södra's biggest business area, since 2008. She joined Södra in 2000, and she has previously held the position of Plant Manager at Södra Cell Värö.

"Business at Södra subsidiaries Södra Cell, Södra Timber, Södra Interiör and Södra Skog is successful in their respective areas. This guarantees that Södra will not suffer any adverse effects in the limited time it is estimated to take to find a new CEO," commented Christer Segerstéen, Chairman of Södra.

First Andritz Steel Yankee in Japan started up for Doh-Ei Paper

International technology Group ANDRITZ has successfully started up the PrimeDry Steel Yankee (diameter: 3.7 m; shell length: 4.3 m) supplied to Doh-Ei Paper, Japan. At its Hokkaido mill, Doh-Ei produces 4,500 t/a of facial tissue and 14,500 t/a of toilet tissue from 100% recycled paper.

International technology Group ANDRITZ has successfully started up the PrimeDry Steel Yankee (diameter: 3.7 m; shell length: 4.3 m) supplied to Doh-Ei Paper, Japan. At its Hokkaido mill, Doh-Ei produces 4,500 t/a of facial tissue and 14,500 t/a of toilet tissue from 100% recycled paper.

In June 2011, Doh-Ei commissioned ANDRITZ PULP & PAPER to upgrade its drying line. In addition to increasing production and improving the runnability of the tissue machine, this investment was also was made to reduce energy costs – a particularly important criterion due to the sharp rise in oil and gas prices. “Steel is a highly heat-conductive material. Following the installation of the ANDRITZ PrimeDry Steel Yankee, the energy efficiency and production output of our mill will be very high,” says Mr. Masashi Kobayashi, President of Doh-Ei.

With this successful start-up of Japan’s first Steel Yankee, ANDRITZ has confirmed its position as one of the leading global suppliers of such technology for the tissue, board, and paper industries.

BASF Venture Capital invests $5 million in China Environment Fund IV

BASF Venture Capital GmbH has participated with $5 million in the China Environment Fund (CEF) IV, L.P. Other investors include key development financial institutions, renowned family offices, strategic multinational corporations, and Fortune 500 companies. The China Environment Fund is a series of four funds and managed by Tsing Capital.

“China has a large number of highly innovative and sustainable technology companies of great strategic importance for BASF. Our participation in CEF IV enables us to set up joint activities with these companies in China. We also gain better access to technology areas of future potential and innovative chemical system solutions in the field of new materials,” said Johnnie Yuen, Regional Head at BASF Venture Capital in Asia Pacific. CEF has already demonstrated its performance track record in its three existing funds. “The performance to date and the outstanding fund management were further reasons for us to participate in CEF IV,” added Yuen.

Tsing Capital was established in 2001, and is the first fund manager investing in Chinese cleantech and environment related companies with an aggregate of assets under management over $600 million. China Environment Fund invests in portfolio companies across China in areas of renewable energy, energy efficiency, environmental protection, new materials, sustainable transportation, smart grids, sustainable agriculture and cleaner production. Further information can be found at www.tsingcapital.com.

About BASF Venture Capital

BASF Venture Capital GmbH was established in 2001 as a wholly owned subsidiary of BASF Future Business GmbH, Ludwigshafen, Germany, with the aim of exploring new growth potentials based on investment in startup companies