Ian Melin-Jones

James Rubright of RockTenn wins Risi's 2011 North American CEO of the Year

RISI, the leading information provider for the global forest products industry, has named Mr. James Rubright, Chairman and CEO of RockTenn, as the 2011 North American Forest Products CEO of the Year. The award will be presented to Mr. Rubright at RISI's 26th North American Forest Products Conference in San Diego, CA on October 3-5, 2011.

Mr. Rubright was chosen as the RISI North American CEO of the Year by a group of investment analysts and portfolio managers covering the forest products industry. The analysts responded to a survey organized by RISI and the criteria for nomination included leadership, vision and strategic accomplishment. Mr. Rubright was selected as the winner due to his significant achievements and overall leadership of RockTenn. Specifically noted in his nomination was the recent acquisition of Smurfit-Stone by RockTenn. Both competitors and independent converters have responded positively to the recent acquisition which has brought RockTenn to a new level in the industry as one of the most respected and profitable integrated paperboard and packaging companies in North America. Responding to the announcement Mr. Rubright commented, “This award recognizes the success and global competitiveness RockTenn has accomplished through the hard work and innovative solutions of our 26,000 dedicated employees.”

Mr. Rubright is Chairman and Chief Executive Officer of RockTenn, one of North America's leading manufacturers of corrugated and consumer packaging and recycling solutions. Before joining RockTenn as CEO in 1999, he served as Executive Vice President of Sonat, Inc., a diversified energy company headquartered in Birmingham, Alabama. At Sonat, he was the head of Sonat's interstate natural gas pipeline and energy services businesses. Prior to 1994, he was a partner in the law firm of King & Spalding.

Mr. Rubright served in 2007 as Chairman of the board of the American Forest & Paper Association, the national trade association of the forest, pulp, paper, paperboard and wood products industry. He is a director of AGL Resources, Inc., an energy company, and Forestar Group, Inc., a real estate and natural resources company. He received a B.A. degree from Yale College and a J.D. degree from the University of Virginia Law School.

Mr. Rubright was also named RISI’s North American CEO of the Year in 2008 and he won the Global CEO of the Year Award at the PPI Awards in 2009.

In addition to collecting his award in at the RISI North American Conference, Mr. Rubright will join the CEO panel and present the keynote speech. Mr. Rubright will join a host of industry leading speakers at the event, including representatives from the AF&PA, Weyerhaeuser, Biomass Power Association, North American Wholesale Lumber Association, Deutsche Bank, JP Morgan, Bank of American/Merrill Lynch, CIBC, Boise,

Futuremark and Clearwater Paper. RISI’s economist and engineers will also give their two year outlooks for the North American and global forest products industry.

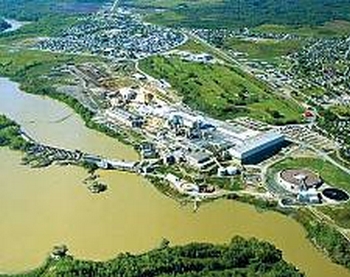

AbitibiBowater Announces Plan to Invest in its Iroquois Falls (Ontario) Paper Mill

AbitibiBowater Announces Plan to Invest in its Iroquois Falls (Ontario) Paper Mill, Improving its Competitive Position

AbitibiBowater has announced a reconfiguration and capital spending program for its paper mill located in Iroquois Falls, Ontario. The investments will improve overall product quality and the mill's competitive position.

The Company will be investing between C$12-$17 million in the thermo-mechanical pulp mill and on paper machine number 8, the larger of the mill's two machines. The pulp mill investment will result in improved pulp quality with the installation of additional pulp cleaning. Paper machine upgrades will result in improved wet-end formation and newsprint quality. As well, chip receiving and chip handling capabilities will be increased to allow the Iroquois Falls facility to operate on 100% externally supplied chips, with the mill's current woodyard and woodroom being phased out.

The Company will be investing between C$12-$17 million in the thermo-mechanical pulp mill and on paper machine number 8, the larger of the mill's two machines. The pulp mill investment will result in improved pulp quality with the installation of additional pulp cleaning. Paper machine upgrades will result in improved wet-end formation and newsprint quality. As well, chip receiving and chip handling capabilities will be increased to allow the Iroquois Falls facility to operate on 100% externally supplied chips, with the mill's current woodyard and woodroom being phased out.

"Today's announcement is a critical step in improving the competitive position of our Iroquois Falls operation for the foreseeable future," said Michel Maillé, Vice President, Pulp and Paper Operations. "While it has been a good site over the years, this investment is necessary to meet today's market and economic realities."

The reconfiguration follows consultation with both the Town of Iroquois Falls and the employees at the mill and their union representatives.

The increase in chip receiving and handling capability and the closure of the woodroom and wood yard will occur during the first half of 2012. The reconfiguration will result in a workforce reduction of approximately 60 positions, although the Company hopes the mill demographics will significantly reduce the number of employees who will be laid off given retirement eligibility over the next couple of years. The pulp mill and paper machine investments will be made over the next 12 to 18 months.

"In addition to improving mill economics, the conversion to 100% externally supplied chips will also provide an outlet for chip residuals from sawmills on the Highway 11 corridor. This will be particularly important as markets for Ontario lumber recover," added Maillé.

"The investments announced today are consistent with AbitibiBowater's overall strategy of achieving greater efficiency in its existing mills and building on proven competencies," stated Richard Garneau, President and Chief Executive Officer. "Newsprint remains an important component of our business. While market and economic conditions remain challenging, the Company will invest where there is a good resource base, a strong workforce and a receptive investment climate. The investments announced today reflect our view that the Iroquois Falls mill and its employees are worthy of our confidence and that Ontario is a good place to invest."

AbitibiBowater and other member companies of the Forest Products Association of Canada, as well as a number of environmental organizations, are partners in the Canadian Boreal Forest Agreement. The group works to identify solutions to conservation issues that meet the goal of balancing the three pillars of sustainability linked to human activities: economic, social and environmental.

ABB to supply automation and electrification for new bioboiler at Bomhus Energi in Gävle, Sweden

ABB’s automation and electrification systems help create an environmentally friendly, reliable and efficient operation

ABB, the leading power and automation group, has won an order for the electrification and automation system of a new bioboiler and turbine, including fuel management, from Bomhus Energi in Gävle, Sweden.

Bomhus Energi AB, a joint venture of Gävle Energi AB and Korsnäs AB, will supply steam and electricity to the Korsnäs plant in Gävle as well as district heating to the Gävle town district, with the new bioboiler. “The new boiler will replace an older boiler at Korsnäs, and will be both more environmentally friendly and more efficient,” says Mats Törnkvist, technical manager at Korsnäs and Bomhus Energi AB board member.

The ABB supply scope includes low-voltage switchgears for energy-efficient motor control and monitoring of more than 400 motors, 18 energy-efficient and environmentally friendly Resibloc transformers and shunt capacitors to improve power quality. Bomhus has also ordered an ABB Automation System 800xA for controlling and monitoring the boiler.

“The automation system will control and monitor a complex process with high safety requirements. The boiler, the fuel management, a new turbine and the integration of adjacent process sections must be monitored and 100% controlled, a function that now will be significantly simplified with the new automation system,” says Törnkvist.

In addition to advanced control and monitoring functions, the automation system includes new operator stations, integration of switchgear and motor operations and an environmental report system, as well as real-time monitoring of every instrument circuit. System 800xA will be based on virtual servers, saving space and considerably simplifying system testing and future upgrades.

To create a new joint operator environment, older operator stations will be replaced with new 800xA units for adjacent process sections. The project includes all system work, programming, test runs and commissioning.

The new boiler will be fully operational by fall 2012.

Management reshuffle at Södra

Urban Eriksson is to be the new CEO of Södra Interiör. He will be leaving his position as President of Södra Skog and Director of Forestry at Södra.

Urban Eriksson is to be the new CEO of Södra Interiör. He will be leaving his position as President of Södra Skog and Director of Forestry at Södra.

At the same time Håkan Svensson, current CEO of Södra Interiör, will be leaving his position and taking over as the new President of Södra Skog and Director of Forestry.

In other words, the two men will be swapping jobs with one another, remaining on the group executive team at Södra and reporting to Group President Leif Brodén.

"Fortunate circumstances mean that we are able to reposition ourselves with the best interests of everyone at heart. Both Urban and Håkan are men of outstanding calibre, and they have both expressed a great deal of interest in this reshuffle," says Leif Brodén.

Urban Eriksson has been Director of Forestry at Södra for four years. Prior to that, he was Vice President and Acting Group President at Sveaskog. Urban Eriksson is 52 years old and has a solid background in forestry. He is a certified forester and doctor of silviculture, and he also holds an MBA.

Urban was formerly Head of Research at Skogforsk, and he spent ten years in various positions at AssiDomän and, later, Sveaskog. Urban was also the CEO of Svenska Skogsplantor. He is married and has three children. Håkan Svensson, 46, has been the CEO of Södra Interiör, formerly Gapro, since 2005. Immediately prior to this, he was the CEO of Bengtssons Maskin in Stockholm, a company forming part of the listed technology trading group Indutrade.

Håkan Svensson, 46, has been the CEO of Södra Interiör, formerly Gapro, since 2005. Immediately prior to this, he was the CEO of Bengtssons Maskin in Stockholm, a company forming part of the listed technology trading group Indutrade.

Håkan Svensson studied to become a civil engineer in chemical engineering at Lund University and holds an MBA from the School of Business, Economics and Law. He was a member of the sales team and Head of Sales at chemicals group Dow Corning until 2000, when he began working for Bengtssons Maskin. He is married and has two children.

The switchover will take place on 1 September 2011.

ERPC launches “Assessment of Printed Product Recyclability” for adhesives

This ERPC (European Recovered Paper Council) document provides an assessment of the removability of adhesive applications of a printed paper product as one aspect of its recyclability. The assessment scheme deals with the fragmentation of adhesive applications and their removability through a laboratory screening process. It is applicable to all kinds of printed paper products containing any adhesive applications and serves as an evaluation for potential sticky problems at the paper machine and quality defects in the produced paper or board.

This ERPC (European Recovered Paper Council) document provides an assessment of the removability of adhesive applications of a printed paper product as one aspect of its recyclability. The assessment scheme deals with the fragmentation of adhesive applications and their removability through a laboratory screening process. It is applicable to all kinds of printed paper products containing any adhesive applications and serves as an evaluation for potential sticky problems at the paper machine and quality defects in the produced paper or board.

The sufficient removal of adhesive applications is one of the challenges for the paper manufacturers using recovered paper. In the recovered paper treatment process, adhesive applications disintegrate during pulping to “stickies”. Stickies is a broad term for all tacky components in recovered paper pulp.

Depending on their size and their behaviour they are called macrostickies, microstickies or potential secondary stickies. Mechanical screening with slotted screens is the most efficient tool for sticky removal. High removal efficiency can only be achieved if adhesive applications disintegrate into particles of large size. The smaller the particles are, the lower their removal efficiency is. In addition, they can re-agglomerate later in the papermaking process and thus form secondary stickies which lead to major problems in paper production and/or converting processes.

In this regard, the removability depends not only on the composition of the adhesive but also on the type of application, such as the shape of the application and the thickness of the layer. The larger and thicker the layer of a given adhesive, the less disintegration into small particles occurs.

All these characteristics have been taken into account in the resulting ‘Scorecard for the Removability of Adhesive Applications’ available on the ERPC website.

Marcus Bergström appointed CEO of Adforum

Mr Marcus Bergström, MSc (Econ.), has been appointed CEO of Adforum, the world’s leading organiser of pulp and paper events, as of September 1, 2011. Bergström has worked for Adforum as a Project Manager since 2007 and was appointed Vice President in January 2010.

- I’m delighted to assume this position and to continue developing Adforum’s international portfolio of events, says Bergström. It is a very exciting time for Adforum with two brand new pulp and paper events being organised in 2012.

Bergström succeeds Björn Delin, who has been the CEO of Adforum since 2009. Delin was amongst others responsible for the acquisition of the China Paper trade show in Beijing/Shanghai, and the launch of the new events Paptech and IPX India.

- Björn has made a very valuable contribution to Adforum over the past three years and I wish him all the best in his future ventures, says Patric Sjöberg, Chairman of Adforum and CEO of Stockholm International Fairs.

Marcus Bergström will remain Project Manager for the PulPaper, Paptech Finland and IPX India exhibitions until further notice.

For further information, please contact Mr Marcus Bergström on This email address is being protected from spambots. You need JavaScript enabled to view it. or telephone +358 44 56 24 524. Please also visit www.adforumworld.com

Ashland Inc. completes ISP acquisition

COVINGTON, Ky. - Ashland Inc. (NYSE: ASH), a global leader in specialty chemical solutions for consumer and industrial markets, today completed its acquisition of privately owned International Specialty Products Inc. (ISP), a global specialty chemical manufacturer of innovative functional ingredients and technologies. The purchase was an all-cash transaction for $3.2 billion, subject to post-closing adjustments for changes in net working capital and certain other items.

"This defining transaction is expected to be immediately accretive and will significantly expand our position in higher-margin, higher-growth end markets, including personal care, pharmaceutical, food and beverage and energy," said James J. O'Brien, Ashland chairman and chief executive officer. "We are excited about combining ISP's technologies and capabilities with our own. This acquisition enhances our ability to satisfy the increasing global demand for more technologically advanced consumer and industrial products, and to continue to generate industry-leading innovation and solutions for our customers."

Integration overview

ISP will be integrated into the Ashland Aqualon Functional Ingredients commercial unit, more than doubling the size of Ashland's highest-margin business. Effective immediately, the combined unit will be called Ashland Specialty Ingredients. Going forward, Ashland Specialty Ingredients is expected to contribute roughly half of Ashland's EBITDA. In addition, approximately half of Ashland's overall revenues will now be derived outside of North America.

An integration team with key representatives of both companies is being led by John Panichella, president of the new Ashland Specialty Ingredients business. Ashland anticipates approximately $50 million in annual run-rate savings by the end of the second year through eliminating redundancies and capturing operational efficiencies.

Added Panichella, "The addition of ISP greatly expands the breadth of our technology platforms and provides new resources and capabilities to better capitalize on market opportunities. In particular, we now can offer our customers one of the broadest, most functional portfolios of water-soluble polymers in the world."

Transaction Details

The transaction was funded through a combination of cash on hand and borrowed funds from Citigroup, The Bank of Nova Scotia, BofA Merrill Lynch and U.S. Bank National Association. BofA Merrill Lynch acted as financial advisor, and Cravath, Swaine & Moore LLP acted as legal counsel, to Ashland. Moelis & Company acted as financial advisor, and Sullivan & Cromwell LLP acted as legal counsel, to ISP.

To see a video of Ashland Chairman and CEO Jim O'Brien discussing the ISP acquisition, click here

Nalco Reports on Economic, Environmental and Social Sustainability Progress

Nalco, providing essential expertise for water, energy and air, has published its 2010 Sustainability Report which documents actions and progress toward Nalco's vision to earn customers for life and enhance the lives of employees while protecting the planet. "As one of the world's largest sustainability services companies we work daily to deliver water and energy savings and reduced emissions for our global customers and in our own operations," said Erik Fyrwald, Nalco Chairman and Chief Executive Officer. "This report highlights the many actions we have taken to deliver strong economic, environmental and social performance to our many stakeholders." The 32-page report includes a summary of expanded stakeholder dialogue efforts and examples of how Nalco programs help customers minimize their environmental footprint by improving the efficiency of their operations, saving water and energy while reducing emissions. It also details ongoing improvements and accomplishments in Nalco's own operations including: For the second consecutive year, the report is based on the Global Reporting Initiative framework, which is a standardized approach to reporting designed to stimulate demand for sustainability information. This report also serves as Nalco's annual Communication on Progress for the United Nations Global Compact and the CEO Water Mandate. The Global Compact is world's largest corporate citizenship and social responsibility organization committed to 10 principles covering human rights, labor, environment and anti-corruption. The CEO Water Mandate is a further commitment by companies to support and advance water sustainability solutions. You can view the 2010 Sustainability Report and the Detailed Appendix of the report at www.nalco.com/sustainability.

Mondi SCP’s PM18 beats own world record as fastest paper machine of its kind.

The world’s fastest running paper machine with a single shoe press, PM18, achieved a new speed record on August 9th 2011, producing 1620 metres of paper/minute.

Ružomberok, Slovakia, August 23rd 2011 – Since the start-up of PM18 eight years ago, the operations team at Mondi SCP in Ružomberok, Slovakia have reached two world records for speed. Mondi SCP set the first world record for PM18 in 2009 and surpassed it by 20 meters/minute on August 9th, 2011 with a new speed record of 1620m/min.

PM18 is the largest paper machine at Mondi SCP mill, producing over 10 million A4 sheets every hour. The mill’s managing director, Roman Senecky, commented on his team’s success and hard work stating, “Today’s record is tomorrow’s production target. Our team deserves a big thank you for their latest achievement. From wood processing to pulp production, cutting and proper logistics of the paper – the end success is being able to satisfy our customers.”

The mill’s smallest and oldest machine, PM16, has also maintained its top performing position as a Metso benchmark leader on lowest percentage in break time, shut-down time and broke among uncoated fine paper machines. PM16’s ranking in 2010 marks the paper machine’s fourth consecutive standing as Metso Benchmark top performer in these categories.

In response to the successes of PM 16, Mondi SCP paper division director Franz Aigner comments, “It is not all about technology. This is proven by the fact that same machines reach various outputs. What makes a major difference is having skilled people on board.”

ÅF wins consulting projects in Vietnam

ÅF has been awarded two contracts to serve as an advisor to the cities of Quy Nhon and Nha Trang in Vietnam. ÅF's task is to support the management of the cities' utilities in the fields of waste management and water treatment. The projects are funded by the World Bank.

In an additional consulting project, ÅF will serve as an advisor to Vietnam's Ministry of Finance. This assignment involves securing the environmental and social compatibility of local infrastructure projects, which will be financed by the Local Development Investment Fund of the World Bank.

The total value of these consulting services for ÅF is more than USD 2 million.

ÅF has an office in Hanoi and has been established in the Vietnamese market for over 15 years. ÅF has implemented over 30 major projects in Vietnam, ranging from large hydropower dams, pulp and paper mills, and coal and gas-fired power plants to urban development and environmental projects.