Ian Melin-Jones

Mondi launches DNS® high-speed inkjet to the professional digital printing market

DNS®high-speed inkjet was developed for the growing high-speed inkjet market. High-speed inkjet printing has emerged as a viable alternative to offset printing for transactional and transpromotional applications.

Professional print rooms continue to broaden their printing potential with state-of-the-art digital printing machines. In line with the latest technology to enter professional print rooms, Mondi has launched a new digital paper, DNS® high-speed inkjet. A part of the DNS® portfolio (short for Digital Needs Specialist), DNS® high-speed inkjet was developed in close cooperation with OEMs (original equipment manufacturers) with a specially optimised surface for the absorption of water-based dye or pigment inks at high printing speeds of 200 meters/minute and higher.

“The majority of the high-speed inkjet market still uses dye inks, although certain printing machines exclusively use pigment inks. DNS® high-speed inkjet is not limited for use on machines that use ‘either/or’; it has been optimised for both dye and pigment inks, which we believe is an important feature for printers and for future developments in ink technology,” explains Johannes Klumpp, Marketing and Sales Director for Mondi Uncoated Fine Paper.

High-speed inkjet machines offer the flexibility of digital printing — variable data and customer-focused personalised communication — and the cost effective, high volumes possible with offset printing. Reflecting these market trends, Mondi developed DNS® high-speed inkjet with transactional, transpromotional and direct mail applications in mind. The paper has a smooth surface and high whiteness level, which fosters sharp contrasts and even ink distribution.These surface characteristics and physical properties are also optimal for book-on-demand applications, where future growth for high-speed inkjet applications is expected.

Due to the special surface treatment of DNS® high-speed inkjet, pigment and dye ink absorption occurs without colour-bleed or dot gain, which is a necessity for accurate logo reproduction, barcode and text readability with transactional and transpromotional documents. In general, the colour uniformity achieved with DNS® high-speed inkjet ensures smooth colour transition for images and graphics. At the same time, impressive high colour density and excellent results are attainable at low ink levels, which support the economical consumption of ink.

“We are convinced of the benefits of high-speed inkjet technology and its growing position in the digital print market,“ says Mr. Lubomir Klinka , General Director of Cromwell Bratislava. Cromwell is one of the leading hybrid post operators, based in Bratislava, Slovakia, and a DNS® high-speed inkjet customer. “The print results achieved with DNS® high-speed inkjet are impressive and we are confident that it is one of the best papers for our Océ high-speed inkjet machine.”

DNS® high-speed inkjet is available in 80 and 90 gsm reels ranging in diameter from 700-1450 mm and offering reel widths from 21 cm and wider as well as vertical and horizontal reel orientations. A member of Mondi’s Green Range of eco-friendly papers, it is FSC® certified, CBS2 certified (clearing bank standard) in 90 gsm and offered with a CO2 neutral option.

BASF establishes partnership with MIT Center for Transportation & Logistics

BASF announced it is establishing a partnership with the Massachusetts Institute of Technology’s Center for Transportation Logistics (CTL). The company has become a Strategic Partner in the Center’s Supply Chain Exchange. The Supply Chain Exchange is an active community of companies that share a common goal to leverage cutting-edge research and knowledge to achieve supply chain-centric competitive advantages.

“The MIT Center for Transportation & Logistics is one of the foremost sources of supply chain innovation,” said Dr. Robert Blackburn, Senior Vice President Supply Chain & Process Innovation at BASF. “Joining the Supply Chain Exchange provides a great opportunity for BASF to continue our demonstrated track record of developing sustainable innovations throughout our supply chain as well as better aligning our global supply chain with our corporate business strategy to the benefit of all our stakeholders.”

“BASF with its innovative supply chain is paving the way for sustainable business practices,” said Prof. Yossi Sheffi, Director for the MIT Center for Transportation & Logistics. “We are confident our partnership with BASF will provide further insight into how they can continue to achieve profitable growth while considering the environmental impact. We are also convinced that this collaboration will provide value not only to MIT, but also to our other partners in the strategic partnerships program.”

The Supply Chain Exchange provides networking and educational opportunities within MIT and CTL’s corporate partner community, which includes representatives of some of the leading manufacturers, distributors, retailers, and transportation and logistics service providers. Additionally, BASF will directly benefit from interaction with MIT researchers on current industry issues and privileged access to CTL's symposia series, student recruiting and communications programs.

As part of the Engineering Systems Division at MIT, CTL is widely recognized as an international leader in the field of transportation and logistics. CTL coordinates extensive research on the understanding of transportation system planning, operations and management. The organization has made significant contributions to logistics modeling and supply chain management for shippers; to technology and policy analysis for government; and to management, planning and operations for motor, railroad, air and ocean carriers.

Walki Biomass Cover: Easy cover-up improves drying process and energy content of energy wood.

Logging residue is an inexpensive and easily accessible source of biofuel, but to improve the energy content it must first dry on the ground and after that it can be stored in piles for several months. To shelter the piles from moisture through rain, snow and ice, Walki has developed a paper-based, waterproof cover that can be chipped and burned together with the residue.

The importance of biofuels is increasing globally due to tightening emissions restrictions. Interest in wood-based biofuels has also increased because there are new combustion technologies available on the market that are suitable for solid biofuels.

The importance of biofuels is increasing globally due to tightening emissions restrictions. Interest in wood-based biofuels has also increased because there are new combustion technologies available on the market that are suitable for solid biofuels.

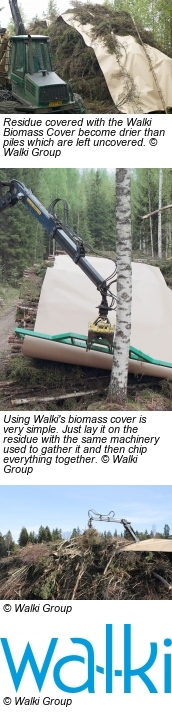

At first glance, Walki’s biomass cover doesn’t look very high-tech, but it’s an ingenious invention that very efficiently improves the energy content in logging residue. The cover itself is a four-meter wide laminate, mainly produced from renewable fibrous materials. It shelters the top of the pile but leaves the sides open, allowing moisture to evaporate.

A very thin plastic layer within the cover makes it both waterproof and very strong, but thanks to the characteristics of the plastic, the cover can be chipped along with the residue and used as fuel as well.

“The biomass cover is already the widest of its kind on the market and the production is constantly growing. Now we are also developing a six-meter wide version that can cover even bigger piles of logging residue and other wood-based biofuels,” says Hannu Nieminen, Product Line Manager at Walki.

In addition to shielding the residue from water and snow, the biomass cover also protects the residue from freezing, which can transform the pile into an icy heap that’s almost impossible to handle and has low energy content.

“The phenomenon is familiar to anyone who has piled chopped firewood outside and forgotten to cover it,” says Mr. Nieminen. “In the wintertime, the wood is icy and heavy and produces much less heat than dry firewood.”

In phase with the environment

Finland and Sweden are pioneers in harvesting energy wood, but because energy saving and biofuels are the latest buzz, interest in the technology is increasing in other parts of the world as well.

“Energy wood is, in many countries, an almost unused resource for producing energy in an environmentally sound way,” says Mr. Nieminen. “Our product maximizes the energy value of logging residue; measurements have shown that the solids content of wood can be raised by as much as 15% by using the cover.”

In Finland, the main reseller of Walki’s biomass cover is Uittokalusto Oy, a Finnish company owned by Grube KG Forstgerätestelle of Germany. The company has been selling the cover for about five years now and is very pleased with the feedback from customers. The main customers are big forest companies in Finland and their subcontractors.

“The cover is easy to spread with the same machinery that gathers the residue in the woods,” says Ilkka Leskinen, Sales Manager at Uittokalusto. “Our customers are satisfied with the benefits of the biomass cover and how easy it is to use the product.” /ins

BASF increases prices for polymer dispersions, powders, resins and additives

Effective April 15, 2011, or as contracts allow, BASF will increase prices in Europe, Africa and Western Asia for polymer dispersions as well as additives by 110 Euro per metric ton and acrylic resins and redispersible powders by 180 Euro per metric ton. The price adjustments are necessary due to significantly increased raw material costs.

The products affected by the price increase are used as polymers for adhesives, fiberbonding, architectural coatings and construction chemicals.

M-real plans to divest the Premium Paper business

M-real Corporation, part of Metsäliitto Group, has signed a Memorandum of Understanding (MoU) regarding a divestment of the Premium Paper business to a sister company of Papierwerke Lenk AG. The divestment would include the complete Premium Paper business and related assets as well as about 100 M-real’s employees.

Premium Paper products are used in high quality graphical end-uses, such as letterhead, brochures, books, calendars and envelopes. M-real will continue the carbonless business at the Reflex mill.

If the transaction is consummated as planned M-real books a negative EUR 12 million non-recurring item in Speciality Papers business area. Cash impact would be approximately EUR 1 million negative. The planned divestment does not have a material impact on M-real’s operating result. The transaction is expected to be closed during the 2Q 2011.

“The planned divestment of the Premium Papers is a natural step in M-real’s strategy and a proof of M-real’s capability to divest its non-core paper business consistently. We are satisfied with the good solution in which the Premium Paper business will be transferred to the new owner who can focus to develop this segment successfully in the future,” says Mikko Helander, CEO of M-real.

In October 2010, M-real sold the paper machine 5 and some related assets at the Reflex site to Metsä Tissue.

Papierwerke Lenk AG is a German Black Forest based paper producer with sales of approximately 35.000 tonnes of specialty papers (www.lenk.de).

APP starts up two ANDRITZ mechanical pulping lines in record time in China

Two P-RC APMP mechanical pulping lines delivered by ANDRITZ to APP’s mill in Jingui, Guangxi Province, China, have been started up in record time. The guaranteed production of 750 admt/d was achieved within only 2.5 months for Line #1 and 1.5 months for Line #2. This sets production records for single mechanical pulping lines in China. In addition, excellent pulp properties are being reported.

Focus on ‘green’ production

The lines at Jingui process eucalyptus fiber from plantations. A remarkable aspect is that the mechanical pulping lines operate totally free of silicates within the bleaching process. Effluents are recovered to reduce the environmental impact. White liquor is retrieved in the chemical recovery cycle and reused in the mechanical pulping process to a very large extent, resulting in a significant reduction in operating costs.

Collaboration on Deinkability of Inkjet Prints

On February 14, 2011, executives from the DPDA (Digital Print Deinking Alliance) and INGEDE (International Association of the Deinking Industry) together signed a Letter of Intent for collaboration to investigate the deinking of inkjet prints. The primary objective of this collaboration is to identify new solutions suitable for combined recovered paper streams with analogue and digital prints. The target is to enable inkjet manufacturers as well as deinking mills to better anticipate their commercial and environmental requirements as inkjet print volumes become more significant.

“Inkjet is likely to be a relevant process in digital production printing in the future,” said Ulrich Hoeke, INGEDE Board Chairman, “and it is essential to maintain recovered graphic paper as a raw material for recycled-content graphic papers by ensuring good deinkability of inkjet prints.”

This DPDA–INGEDE Letter of Intent for collaboration on inkjet deinkability provides a structure for regular, detailed exchange of relevant data, and jointly-sponsored research projects under the direction of a Technical Committee with representatives from both organizations. Both DPDA and INGEDE recognize that feasible solutions may involve optimization of ink, pre- and post-treatment, paper characteristics and the deinking process. This DPDA–INGEDE Technical Committee has already had its first meeting, and plans to conduct at least one jointly-managed research project this year.

The paper industry already experiences considerable problems in recycling prints with water-based flexo inks. In order to avoid similar problems with water-based inkjet inks, paper industry and printer manufacturers will intensify their cooperation. Speaking on behalf of the DPDA, Crit Driessen, Vice President Marketing and Strategy Production Printing, Océ Printing Systems GmbH, said that “the DPDA recognizes that although there have been no single inkjet deinking issues reported in recycling mills, lab-scale assessments show a range of deinkability performance, and therefore it is important to identify the attributes and thresholds for successful deinking so the overall solution can be optimized. This Letter of Intent for collaboration on inkjet print deinkability is an important step forward for the paper and printing industry to help ensure that the benefits of inkjet printing are realised by all participants in the value chain.”

Temple-Inland Announces Planned Retirement of Dennis Vesci

Temple-Inland Inc. has announced that Dennis J. Vesci (63) will retire as Group Vice President-Corrugated Packaging effective June 1, 2011. Commenting on the retirement, Doyle R. Simons, Chairman & CEO of Temple-Inland, said, "Dennis has provided 36 years of dedicated and superior service and has been a key contributor to Temple-Inland's success. We wish Dennis and his family the best in his well-earned retirement."

Larry C. Norton (52) has been named Group Vice President-Corrugated Packaging with responsibility for the Company's box plants and Company-wide supply chain management. Larry joined Temple-Inland in 2007 and has 26 years of industry experience.

George D. Obernesser (48) has been promoted to Group Vice President-Paperboard with responsibility for the Company's paper mill system. George joined Temple-Inland in 2005 and has 27 years of industry experience.

J. Patrick Maley III, President & Chief Operating Officer, said, "Larry has done an outstanding job in leading our mills and supply chain groups and George has done an outstanding job in a variety of assignments. I have the utmost confidence they will have the same success in their new roles."

Ashland Inc. Unveils Enriched, Intuitive Company Website

Ashland Inc. has announced the launch of a newly designed company website — www.ashland.com — with many significant enhancements to make it simpler and more useful for its customers, communities and investors. At its core, the new site features expanded product information with easy access to Ashland's broad portfolio of specialty chemical products.

It's not just about products, however. It's the people of Ashland, their talents and dedication that also come alive in video examples that show customers discussing the advantages of working with Ashland.

The new website makes it easy to conduct business with Ashland around the world. Expansive and readily available information for contacting sellers, customer service agents, chemists, applications specialists and other representatives in more than 100 countries is easily accessed, along with tools for posing questions.

From the home page visitors can find solutions by product name, market, application or product type; contact a representative; learn more about Ashland operations and history or inquire about career opportunities with the company. Ashland-featured news is also posted on the home page and RSS feeds are available so visitors can stay up-to-date on Ashland activities.

"We are extremely pleased to bring this new website online so that Ashland's many stakeholders can obtain the information or support they need," said Susan Esler, chief human resources and communications officer. "The website showcases Ashland's expertise in specialty chemicals and delivers on our company promise, 'With good chemistry great things happen.' We expect that visitors from the media, industry, financial arena, education or the general public will be surprised by discovering numerous intriguing examples of how Ashland's chemistry is solving problems, advancing various industries and improving our lives in so many ways."

Buckeye to Launch AIRspun(R) Flushable, a New Airlaid Nonwovens Wiping Substrate

Buckeye Technologies Inc. has announced that it is launching AIRspun(R) Flushable, a new airlaid nonwoven substrate for use in moist toilet tissue applications.

Chairman and Chief Executive Officer John B. Crowe said, "We are excited about the launch of AIRspun(R) Flushable as this adds a new dimension to our range of products for wiping applications and meets the needs of our customers who produce wipes for consumer markets."

Mr. Crowe went on to say, "AIRspun(R) Flushable was designed to meet the performance criteria of our customers including the flushability guidelines set forth by the nonwovens industries associations in North America and Europe. Additionally, the product is made predominantly with our own fluff pulp cellulose from renewable materials, so it fits well with our continued sustainability efforts."

Buckeye is showcasing AIRspun(R) Flushable and is representing all of its airlaid and fluff pulp products for the nonwovens industry at the Index11 Exhibition April 12-15 in Geneva, Switzerland - Booth 2619.

Buckeye, a leading manufacturer and marketer of specialty fibers and nonwoven materials, is headquartered in Memphis, Tennessee, USA. The Company currently operates facilities in the United States, Germany, Canada, and Brazil. Its products are sold worldwide to makers of consumer and industrial goods.