Ian Melin-Jones

Metso to help earthquake and tsunami victims in Japan

Metso is donating 20,000 euros to the Finnish Red Cross to help the victims of the earthquake and tsunami in Japan.

A strong earthquake occurred near the eastern coast of Japan on March 11, 2011. The earthquake and the ensuing tsunami caused widespread damage on the eastern part of Honshu Island. Thousands of people have been confirmed dead or are still missing. Additionally, the situation at the nuclear plants, damaged by the earthquake and tsunami, is still unstable.

Metso has a total of 116 employees working at five sites in Japan: Tokyo, Yokohama, Osaka, Okayama and Kitakami. Based on the information we have, no Metso employees were injured in the earthquake or tsunami, but some of the sites have suffered minor damage from the earthquake.

We encourage our employees to support the victims of the earthquake and tsunami in Japan through Red Cross and Red Crescent disaster relief funds. Additional information is available at http://www.ifrc.org/japan or at national web sites of Red Cross or Red Crescent.

New imaging technology increases the efficiency of flotation processes in concentration plants

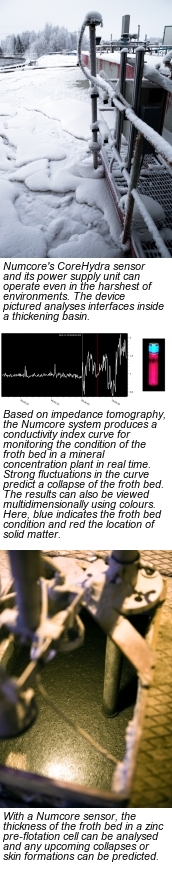

It is now possible to use measurement devices based on impedance tomography to create real-time 3D images from inside the pipelines and tanks used by the processing industries. One significant application for this technology, spearheaded by the Finnish company Numcore Oy, is concentration plants in the mining industry.

processing industries. One significant application for this technology, spearheaded by the Finnish company Numcore Oy, is concentration plants in the mining industry.

The technology opens up entirely new possibilities to control flotation processes, an important component in the concentration process of minerals. In simplified terms, the principle of flotation is to blow bubbles of air into a mixture of ore, water and chemicals, whereby the mineral particles cling onto the bubbles. Mineral-carrying froth is generated as the bubbles rise up to the surface and are collected from there.

“Problems emerge if the froth cannot carry the load of mineral particles or the process otherwise becomes disturbed. The froth bed then disappears, and restarting the process wastes valuable time,” says Jukka Hakola, Numcore’s Vice President of Sales and Marketing.

With Numcore measurement devices, the size and quantity of air bubbles and the solid matter content of the froth bed can be monitored by means of electric conductivity distribution.

“If the solid matter content and bubble size in the froth bed changes, and solid matter starts to gather under the froth, this can cause the froth to become rigid or to collapse. When this situation can be predicted, the problem can be solved by changing the operating parameters.

Real-time characteristics are a key functionality in this technology; in other words, the system continuously provides the operator with factual data on what is happening in the flotation cells, for example the location of minerals and the bottom surface of the froth bed.

“Because it has not been possible to look inside tanks, controlling a mineral concentration process has largely been based on experience-derived know-how. Now that operators can ‘look’ inside the process, it is possible for them to maintain an optimal mix all the time,” says Hakola.

In co-operation with the industry

According to Hakola, measuring as such does not create added value, rather the results should be used to control the operation. Therefore Numcore has, in close co-operation with a few key customers, developed measurement technology to better serve every-day work.

The company’s close partners include Outotec, a global supplier of mineral processing and metallurgical plants, and especially in the initial phase, the Geological Survey of Finland’s Outokumpu Mineral Processing Laboratory.

“At the moment, our sensors are in use at two concentration plants, where we have been able to see in practice which parameters need to be controlled and how we can really numerically prove the benefits that can be achieved for the customer. Our goal is to intervene in any upcoming problems at such an early stage that the process can go on without disturbances.

Numcore measurement technology is currently in test use at Inmet Pyhäsalmi Mine Oy’s copper and zinc mine at Pyhäsalmi, among others. According to Seppo Lähteenmäki, Processing Mill Manager, the system has provided accurate information on the condition of the froth bed, and the technology has functioned reliably.

“We have tested the device for a few months, and it has provided clear benefits for those operators who have received operator training for it and actively monitored the data provided by the system. The device appears to be so useful, in fact, that we are seriously considering buying it after the test period,” he says.

Help from mathematical modelling

Depending on the diameter of the pipeline or tank, Numcore measurement devices are realised either as a flow-through sensor or as a probe-type sensor for installation inside large pipelines or tanks.

By supplying a weak alternating current to the electrodes of the sensor, it is possible to measure conductivity differences between the phases, for example for liquids, inside pipelines and tanks, as different substances show different conductivity values. The actual image is created by means of inverse calculation, however, and this is where Numcore’s core know-how lies.

“Our CoreApus flow-through sensor lends itself for analysing material flows inside pipelines of less than one metre in diameter. Because processing tanks are generally larger than this, we have developed the probe-type CoreHydra sensor which can analyse a larger area of the tank. With several sensors, one can even analyse a large tank or cell,” says Hakola.

Both sensor types can accurately measure interfaces between liquids and solids, but CoreApus is also applicable for imaging rapidly flowing liquids for example in pulp and paper mills.

“The biggest difference compared to previous systems is that now you can analyse why and how something is happening in the process, and how you can prevent an event if necessary. We focused on making the system easy to use to enable real-time and on-site corrective measures rather than relying on, say, laboratory samples.”

SPCI 2011 – a forum for everyone in the pulp & paper industry

New at this year’s event is that some large companies that traditionally have been visitors to SPCI now participate as exhibitors. Södra Cell International, Holmen and SCA have previously visited the event as buyers. In 2011 they exhibit in large stands.

New at this year’s event is that some large companies that traditionally have been visitors to SPCI now participate as exhibitors. Södra Cell International, Holmen and SCA have previously visited the event as buyers. In 2011 they exhibit in large stands.

- Södra has chosen to exhibit to have the opportunity to meet several different target groups that we aim to have a good relation with at the same time, explains Therese Thelin, Marketing Communication Manager at Södra Cell. - Those targets groups are not only customers, but also suppliers and students. We would like our visitors to take part in discussions regarding paper products of the future.

Södra Cell International will present the “Södra Pulp Labs” and their thoughts on future pulp products. The children's chair Parupu, made of pulp, will also be on display. Both the chair and the stand of Södra Cell have been designed by the famous design trio Claesson Koivisto Rune.

Visit www.sodrapulplabs.com for further information.

Margareta Hed from the Corporate Communications Department of SCA says:

- SPCI is an important meeting place for our industry and a good opportunity to meet customers and potential customers. It is also rewarding to meet industry colleagues. We exhibit to highlight the width of what we do and visitors can meet representatives from all our business units in our stand.

Automated Tank Cleaning: Myth or Fact?

Learn How to Get Tanks Cleaner in Less Time and Lower Operating Costs

The benefits of automated tank cleaning are generally well understood -- reduced manual labor and more consistent cleaning; however, there are many aspects of automated tank cleaning that are widely misunderstood and prevent people from automating or achieving optimal results. This webinar will take a look at seven common myths about automated tank cleaning. You'll learn about why most of the perceived obstacles to automation aren't really obstacles at all and how to optimize cleaning efficiency while using less chemicals and water.

Myths addressed:

Automated cleaning isn't powerful enough to clean my tanks.

The payback on automating tank cleaning is too long.

I can't automate due to obstructions in my tank.

The residue in my tank is prone to sparking so automation is out of the question.

My tanks are too big/too small for an automated solution.

I won't be able to verify that my tanks are completely clean if I automate.

I'll still need hot water to remove residue even with an automated tank cleaner.

Register Now For This Live Webinar

Sonoco Releases 2010 Annual Report to Shareholders

Sonoco (NYSE: SON), one of the largest diversified global packaging companies, today announced that its 2010 Annual Report to Shareholders is now available on the Company's Web site at www.sonoco.com, in the "Investor Relations" section. The annual report entitled, "Ready to Grow," reviews Sonoco's financial performance in 2010 while highlighting how the Company made good on its commitment to grow and expand its business in the recovering economy.

"One year removed from the worst recession since the Great Depression, we turned in one of our strongest performances in Company history," Harris E. DeLoach, Jr., chairman and chief executive officer, wrote in his letter to shareholders in the 2010 Annual Report. "Sales reached a record, growing 15 percent, which was our highest growth rate in 15 years. Base earnings improved 33 percent and reached the second best performance in Company history. And, most importantly, our shareholders were rewarded with a 19.2 percent total return on their investment, including a 28th consecutive annual increase to cash dividends.

"Clearly, this performance says a lot about the strength of Sonoco's balanced portfolio of diversified global consumer and industrial packaging products and services. But more importantly, it says a lot about our people. I'm extremely proud of the way our employees responded going into, and especially coming out of, the recession. As we enter 2011, we are firmly back on track and more than ever we're 'Ready to Grow.'"

The 2010 Annual Report features Sonoco achievements in a two-page section called Sonoco Worldwide 2010. It includes a global map and highlights 21 projects or initiatives the Company completed during the year in different regions of the world. This section is followed by several articles that continue to highlight Company successes, including: Sonoco's growing presence in private label packaging; its new Sonoco Plastics brand; its acquisition of thermoforming packaging leader Associated Packaging Technologies (APT); growth of its Sonoco Recycling business; and the positive impact of green energy on its reels and spools business.

Sonoco has mailed the 2010 annual report and proxy statement to its shareholders in preparation for its annual meeting, which will be held on Wednesday, April 20, 2011, at the Center Theater, 212 North Fifth Street, Hartsville, beginning at 11 a.m. Eastern Time. For those unable to attend the meeting in person, a live webcast can be accessed via the Internet at www.sonoco.com, under the "Latest News" section. Those planning to participate should plan to connect to the live webcast at least 10 minutes prior to the start. The meeting webcast also will be archived on the "Investor Relations" section of Sonoco's Web site.

SOURCE: Sonoco

Buckman Features Range of Innovative Creping Products

Buckman, a global specialty chemical company with expertise in creping, is showcasing its portfolio of innovative tissue and toweling products at Tissue World in Nice, France, March 29-31.

Buckman offers tissue manufacturers worldwide an unmatched combination of new technology, application and technical expertise. Our experienced associates help you innovate, improve quality, and capitalize on new opportunities.

Exciting new technologies for 2011 include Buckman’s SELECTsm Yankee dryer adhesive system. This package provides coating optimization never before achievable with other Yankee dryer packages. SELECT uses a combination of a robust hybrid adhesive in combination with a soft rewettable coating to allow the tissue manufacturer to optimize pressure roll attachment and coating adhesion levels independently.

Buckman® 691 softening technology gives tissue manufacturers access to a lotion-like feel via a product that can be applied into the manufacturing wet end instead of converting.

Maximyze™ 2535 and 2523S are recently developed enzymatic products which were created specifically to condition virgin softwood and recycled fiber. This treatment can improve bonding strength, tensile, softness, and bulk as well as reduce energy usage.

Buckman’s innovative creping technology for TAD, ATMOS and other structured tissue technologies results in better quality and productivity for our customers.

Visit us at Stand D14 in the exhibition hall for more information on how these new products can help you improve your creping process.

For more information about Buckman products, please contact the company at This email address is being protected from spambots. You need JavaScript enabled to view it..

Pöyry awarded EPCM, Project Management and Owners' Engineering contracts for a new pulp mill project in Uruguay

Pöyry's Industry business group has been awarded services contracts by Montes del Plata for the integration of a greenfield pulp mill in Punta Pereira, Uruguay. Montes del Plata is an equal share joint venture company between Arauco and Stora Enso. The parties have agreed that the value of the assignment is not disclosed.

The capacity of the new state-of-the-art pulp mill is 1.3 million tonnes per annum and the start up of the mill is planned for the first half of 2013.

Pöyry has been chosen as the supplier of the overall project management, the Engineering, Procurement and Construction Management (EPCM) services for the Balance of Plant (BOP), and the Owners' Engineering services during the project implementation. The engineering and project management services will start immediately.

The contract further strengthens Pöyry's global leadership position in the pulp and paper sector for consulting engineering services.

AkzoNobel boosts growth momentum with China expansion

AkzoNobel is to invest more than €60 million in boosting production capacity for its Bermocoll cellulose derivatives (paint and building material thickeners), providing additional momentum for the company’s accelerated growth strategy which includes doubling revenue in China to $3 billion by 2015.

As well as constructing a new facility at its Ningbo multi-site in China, the company will also debottleneck the existing manufacturing site in Örnsköldsvik, Sweden. The two projects will increase capacity to close to 40,000 tons per annum and elevate AkzoNobel to a global leadership position.

“This investment is all about meeting rapidly increasing customer demand and seizing an ideal opportunity to become market leader by establishing production in Asia,” explained Rob Frohn, AkzoNobel’s Board member responsible for Specialty Chemicals. “High growth markets are central to our growth strategy and adding a second production unit for Bermocoll in Ningbo will add further impetus to our ambition to double revenue in China by 2015.”

The debottlenecking project in Sweden is due to be completed by the end of this year. The majority of the investment, however, has been earmarked for the new plant in Ningbo, where the company’s Functional Chemicals business already operates facilities for chelates, ethylene amines and ethylene oxide. An organic peroxides facility is also due to come on stream in 2011. The new Bermocoll unit should be on stream in early 2013 and the funding allocated for this facility will bring the total investment in Ningbo to more than €320 million.

“Ningbo is the ideal location for the new facility as the infrastructure is already in place and we have access to on-site production of ethylene oxide, as well as being close to other key suppliers,” added Managing Director of AkzoNobel Functional Chemicals, Jan Svärd. “The fact that Asia is the world’s fastest-growing market also means that building the plant in China makes perfect strategic sense.”

Based on a natural polymer, the company’s cellulose derivatives are sourced from wood pulp or cotton linters. The main application areas are water-based paints, building additives and pharma/healthcare.

AkzoNobel currently employs around 6,700 people in China, with revenue for 2010 totaling €1.3 billion. The majority of revenue is generated from local demand. The company now has 27 manufacturing locations in China.

Kemira at the Tissue World Nice 2011

Kemira will be exhibiting at this year’s Tissue World Conference in Nice, France, March 28 – 31, 2011, the leading fair for the international tissue industry. The main focus will be on Kemira’s complete process specific product line built on our expertise in water quality and quantity management (WQQM) and fiber chemistry. The solutions offered not only improve tissue quality attributes and process efficiency, but also help to make better use of scarce resources like water, energy and fibers.

Three technical papers will be presented during the conference including:

Dial-a-Coat™ Approach to Yankee Coating Optimization presented by Vladimir Grigoriev, Principal Scientis;

Bath Tissue Wet End Management, Clayton Campbell, Product Management;

Green Microbe Control on Tissue Machines, Jukka Savolainen, Senior Applications Specialist.

Kemira’s product, sales and applications specialists will be available at booth B115 to tell more about the offering.

Back to Nature: Mondi participates in World Forest Day and World Water Day, March 21 & 22, 2011

Mondi promotes the responsible management of forest and water resources, giving online participants a Color Copy branded water bottle and a chance to win a scooter.

To draw attention to water scarcity and the responsible management of the world’s natural resources, Mondi has launched an online site (www.mondigroup.com/waterday) to celebrate World Forest Day and World Water Day. The online contest runs until March 29, offering all participants a chance to learn more about Mondi’s initiatives to conserve forest and water resources. The first 100 participants will receive a re-usable Color Copy branded stainless steel water bottle and have a chance to win a scooter. World Water Day is an initiative that grew out of the 1992 United Nations Conference on Environment and Development (UNCED) in Rio de Janeiro. Similarly, World Forest Day is a day of observance to remind global citizens about the value of forests and the importance of exercising eco-conscious behaviour as individuals and as industry leaders.

As a global paper and packaging manufacturer, Mondi’s Green Range was first launched in 2006 within the business unit Uncoated Fine Paper to underline the areas where Mondi can make the biggest contributions to eco-friendly production. Forest + Water+ Air became the basis of the Mondi Green Range, which has now grown to include products from all business units and acts as a platform to deliver messages about new green initiatives and products developed by Mondi. Ultimately, the goal of the Green Range is to implement inherently sustainable practices.

As part of Mondi’s role in the responsible management of the world’s forests, water and air, among other activities Mondi plants 40 million trees each year to ensure sustained growth and works together with the WWF to support the rehabilitation of the wetlands in South Africa. Moreover, the CO2 emissions for each sheet of paper have been reduced by 15%. Mondi has been lauded by several organisations for its eco-conscious behaviours. In 2011, both Mondi Group and Mondi SCP mill in Ružomberok, Slovakia received PPI awards for Environmental Strategy of the Year. The same year, the WWF ranked Mondi No. 1 in the WWF’s Paper Company Environmental Index. For more information about Mondi’s green initiatives and products, please visit www.mondigroup.com/greenrange.