Ian Melin-Jones

Accidental Deinking Trial: Liquid Toner Prints Cause Significant Damage in German Paper Mill

For the first time, a significant production loss could be traced back to a digital printing technology that is not compatible with the existing paper recycling system. For a long time it had been suspected that small flakes resulting from liquid toner films as used in HP Indigo's production printers are difficult to remove. INGEDE issued its first press release about these problems already in 2001. Still, trials in labs and pilot plants did not lead to enough evidence to ban liquid toner prints from the deinking* paper mills' list of raw materials. It had been assumed that sufficient dilution would allow the paper mills to cope with this new challenge.

For the first time, a significant production loss could be traced back to a digital printing technology that is not compatible with the existing paper recycling system. For a long time it had been suspected that small flakes resulting from liquid toner films as used in HP Indigo's production printers are difficult to remove. INGEDE issued its first press release about these problems already in 2001. Still, trials in labs and pilot plants did not lead to enough evidence to ban liquid toner prints from the deinking* paper mills' list of raw materials. It had been assumed that sufficient dilution would allow the paper mills to cope with this new challenge.

In late August, paper engineers at a German paper mill were alarmed by rapidly increasing dirt speck numbers in con-trol samples during the production of high quality graphic paper.  Though an intense search within the raw material used began immediately, seven reels with 20 tons of paper each had to be dumped until liquid toner prints coming from a photo book printer could be identified to be the source. This material had been bought together with other high quality recovered paper specified as grade “Multi Printing” (3.10).

Though an intense search within the raw material used began immediately, seven reels with 20 tons of paper each had to be dumped until liquid toner prints coming from a photo book printer could be identified to be the source. This material had been bought together with other high quality recovered paper specified as grade “Multi Printing” (3.10).

As the share of liquid toner prints had already been less than three percent, the remaining stock had to be diluted further and monitored carefully during the following weeks. The paper mill affected has the most sophisticated deinking plant in Europe, using a two-loop flotation system with two dis-persers that were operated at high energy input during the production. The estimated paper production loss sums up to about 140 tons of premium quality paper. The damage for the paper mill – only for the paper dumped, not including standstill or others – is more than 100,000 Euro.

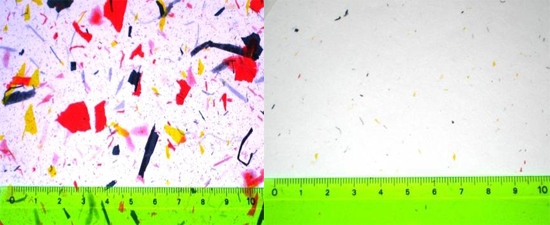

Indigo print samples from the original delivery, tested in the lab, after pulping (left) and after two flotations and one dispersing step (right).

Liquid Toner Prints to Be Avoided

As a consequence, liquid toner prints should be avoided in recovered paper for deinking and directed towards corrugated board production only. In other mills where less effort is used to produce e. g. newsprint, a comparable load of recovered paper could have lead to even more intense quality problems.

Dirt specks also have to be avoided in tissue mills. INGEDE and its members now advise recovered paper merchants, to collect liquid toner overprint separately from other graphic papers and direct it toward the production of corrugated board.

INGEDE is an association of leading European paper manu-facturers founded in 1989. INGEDE aims at promoting utili-sation of recovered graphic paper (newsprint, magazines and office paper) and improving the conditions for an ex-tended use of recovered paper for the production of graphic and hygiene papers.

* Deinking is the removal of printing ink from the recovered paper during the paper recycling process.

International Association of the Deinking Industry (INGEDE) Public Relations

Oetztaler St 5 B • 81373 München • Germany Tel. +49 (89) 769 2332 • E-Mail This email address is being protected from spambots. You need JavaScript enabled to view it.

European Paper Industry - the Bio-value Champion

Video presentation on the european paper industry the Bio-value Champion

New site agreement for Ludwigshafen site

BASF SE management and employee representatives today signed a new site agreement for the company’s Ludwigshafen site. The agreement, titled “Safeguarding the future through flexibility and operational partnership,” applies to the approximately 33,000 BASF SE employees at the site for the period from the beginning of 2011 to end of 2015. It replaces the site agreement from end of 2004 which expires at the end of this year.

A no-redundancy pledge is a key element of the agreement. Another is the company's promise to spend €9 to 10 billion on measures to safeguard the site’s future through to the end of 2015. Approximately two-thirds of the amount will be used on investment, modernization and maintenance to keep the Ludwigshafen site performing at its best in terms of technology and organization and thus strengthening core operations. The investment thus remains at the high level of the past years. Research and development expenditure will also be at the level of previous years and will account for more than one-third of the total amount. Ludwigshafen will remain the central platform for global research and development at BASF.

In a bid to meet the challenges posed by increasingly unpredictable fluctuations in market demand, management and employee representatives have agreed on a package of measures to enhance the flexibility of HR systems in the site agreement.

Close and trusting relationship in the economic crisis

“The recent economic crisis highlighted the importance of close and trusting cooperation between the works council and management, which enabled us to avoid short-time work at the Ludwigshafen site for a long time and minimize its impact at a later stage. This was possible because both sides were willing to show flexibility on human resources issues. The new site agreement captures this spirit and ensures that the site is equipped to weather future storms,” said Dr. Harald Schwager, Member of the Board of Executive Directors and Industrial Relations Director of BASF SE.

“We consciously invested a lot of time in these talks and engaged intensely with management in order to achieve workable models. The negotiations were very tough but the shared background of experience in coping with the crisis had a positive impact on the atmosphere of the negotiations. The new site agreement sends out important signals with regards to employment, while at the same time mapping out an effective plan to keep the Ludwigshafen site competitive on an international scale now and in the future,” said Robert Oswald, Chairman of the Works Council of BASF SE.

The Site Agreement highlights continuation of “flexible personnel deployment” as a key flexibilization element. During the economic crisis up to 600 employees from plants with low capacity utilization were deployed for a temporary period in other plants where there was more work to be done. Fluctuations in production capacity utilization could thus be better offset. Both sides have also agreed to a possible increase in the proportion of temporary staff to enhance flexibility even further.

Securing employment on a long-term basis

Another key element of the site agreement is a joint commitment toward safeguarding employment through training, personnel development and qualification, and the Generations@Work program to address demographic change. “ We wholeheartedly are committed to vocational training and intend to maintain the existing high level of vocational training at BASF SE and in the BASF Training Verbund with partner companies. Through this commitment we avoid any risk of a shortage of skilled labor and at the same time meet our responsibilities toward the young people in our region,” said Hans-Carsten Hansen, President Human Resources at BASF SE.

“Longer working lives are posing new challenges in terms of the working capacity of our employees. The agreed expansion of company health management will offer employees more opportunities to stay healthy and increase their fitness for work throughout the later stages of their working lives,” said Rainer Nachtrab, Chair of the Executive Representative Committee of BASF SE.

VAPA celebrates educational trophy

In the beginning of November the Dutch educational centre of the paper industry VAPA was invited present her recent project results during a big conference in Brussels celebrating the 15th anniversary of the life long learning program “Leonardo da Vinci ”.

During this conference VAPA presented the multi media educational program called FOCUS. This state of the art e-learning program provides training for machine operators and papermakers. The VAPA project was selected out of hundreds of projects that were realised in European during the past 15 years.

The educational FOCUS program is based on a blended learning system with the possibility for self-study using more than 3000 videoclips and animations. There are more than 40 modules developed in close cooperation with different experts in Europe. Not only from the Netherlands but also from Germany (Papiermacher Zentrum Gernsbach) and the Austrian education centre (PZ Steyrermühl).

“Seeing is believing”, says VAPA director Peter Lokhorst. “Everybody knows that reading information has less impact than if you see, hear and experience something. That’s why we choose for visualisation!” The whole program involves more than 100 hours of visualised information; video’s, animations, questions, simulations and selftests.

VAPA has developped the FOCUS modules for the Paper-, board- and corrugated board industry in 4 languages. At the moment VAPA is working on a Swedish translation together with Greenhouse from Karlstad Sweden. The modules are distributed world wide and at the moment there are 41 users in 11 different countries.

“With this FOCUS program the Paper industry is ahead of most other industries”, mister Lokhorst says. He was asked to present the FOCUS modules for the more than 300 participants of the Leonardo da Vinci conference in Brussels on the 9th of November, being one of the 5 selected projects that were judges as the best in 15 years educational innovation in Europe.

For the paper industry it will very easy in the future to educate their employees in a very flexible way with less traditional classroom training. The blended learning system is an optimal mix of in-mill group instructions, on the job training and self study.

For more information:

www.focustraining.eu

www.vapa.nl

P. Lokhorst

VAPA, Anklaarse weg 95 Apeldoorn The Netherlands

0031 55 578 69 60

UPM increases label paper capacity of Tervasaari Mill in Finland

UPM will respond to the growing demand for label papers by increasing the label paper production capacity at its Tervasaari mill in Valkeakoski, Finland. The rebuild of the Tervasaari paper machine 8 will increase the capacity by almost 30,000 tonnes annually.

The installation work will start in March 2011 and the main part of it will be done in early 2012. The whole new capacity will come on stream during the second quarter of 2012.

"With the rebuild of the Tervasaari PM 8 we want to ensure our market leader position in label papers and support our customers' growth," says General Manager Juha Kääriäinen of UPM Tervasaari.

UPM Tervasaari paper mill in Valkeakoski manufactures yearly some 360,000 tonnes of label, envelope and kraft papers. The mill employs about 400 people.

The PM 8 was built in 1996 and the machine produces label base papers. Its major rebuilt was in year 2006.

For more information, please contact:

Mr Juha Kääriäinen, General Manager, UPM, Tervasaari, tel. +358 204 162 300

Verso Launches Renewable Energy Project at Bucksport Mill

Verso Paper Corp. (NYSE: VRS) announced today the launch of a $40 million Renewable Energy Project at its Bucksport, Maine mill. This project will provide a 43% increase in thermal energy production from renewable biomass at the Bucksport Mill and will generate additional green power — equivalent to the amount needed to supply electricity to 30,000 Maine households.

"This project represents what Verso stands for when it comes to our position as a green energy company and as a leader in environmental stewardship. We will have the ability to generate more green energy from renewable biomass, which reduces our carbon footprint, all while increasing overall energy efficiency," says Verso President and Chief Executive Officer, Mike Jackson.

The Bucksport Mill will achieve these energy efficiency improvements by replacing coal with biomass in the #8 Boiler and installing a new 25-megawatt turbine generator.

Partnering with people and organizations at the local, federal and state levels is a key element in making this project a success.

"The forest products industry needs to change, and Verso is at the forefront of innovative practices such as improving energy efficiency by pursuing biofuel opportunities. Doing so also has the benefits of reducing greenhouse gas emissions and reducing overall energy consumption in Maine. We've been working aggressively to expand renewable power generation and have been recognized nationally for our efforts to promote energy efficiency. Partnering with private industry like Verso is essential for us to meet our goals," says Maine Governor John Baldacci.

Funding for the Bucksport Renewable Energy Project includes a grant from Efficiency Maine. Efficiency Maine is an independent trust that invests in cost-effective energy efficiency or alternative energy projects to reduce energy costs and improve Maine's business environment.

"This project illustrates Verso's commitment to Maine and its surrounding community. Such an investment shows the company's strong belief in this area, and also demonstrates its ability to adapt as a manufacturing business, thus keeping jobs at the mill. This project is another step in innovation that is helping to make Bucksport competitive in a tough global economy," says Bucksport Town Manager Roger Raymond.

Verso is committed to continuing energy-saving efforts in Maine and company-wide.

Bob Gemmer, Technology Manager with the Department of Energy Office of Industrial Technologies says, "Verso is a great example of our industry partnership, the Save Energy Now LEADER program. The company is fully committed to reducing energy intensity by 25% in ten years and producing green power in a sustainable way."

The Bucksport Renewable Energy Project is scheduled to begin construction before the end of the year.

About Verso

Based in Memphis, Tennessee, Verso Paper Corp. is a leading North American producer of coated papers, including coated groundwood and coated freesheet, and supercalendered and specialty products. Verso's paper products are used primarily in media and marketing applications, including magazines, catalogs and commercial printing applications such as high-end advertising brochures, annual reports and direct-mail advertising. Additional information about Verso is available on the company's website at www.versopaper.com. References to "Verso" or the "company" mean Verso Paper Corp. and its consolidated subsidiaries unless otherwise expressly noted.

Forward-Looking Statements

In this press release, all statements that are not purely historical facts are forward-looking statements within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934. Forward-looking statements may be identified by the words "believe," "expect," "anticipate," "project," "plan," "estimate," "intend" and similar expressions. Specifically, all statements herein relating to Verso's future compliance with the NYSE's continued listing standards, future operating and financial performance, and future share price and market capitalization are forward-looking statements. Forward-looking statements are based on currently available business, economic, financial and other information and reflect management's current beliefs, expectations and views with respect to future developments and their potential effects on Verso. Actual results could vary materially depending on risks and uncertainties that may affect Verso and its business. For a discussion of such risks and uncertainties, please refer to Verso's filings with the Securities and Exchange Commission. Verso assumes no obligation to update any forward-looking statement made in this press release to reflect subsequent events or circumstances or actual outcomes.

Verso Paper Corp.

Robert P. Mundy, 901-369-4128

Senior Vice President and

Chief Financial Officer

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.versopaper.com

Source: Verso Paper Corp.

Mondi wins three of the 2010 PPI Awards

Mondi wins at the 2010 PPI Awards gala on November 16, 2010 in Brussels, Belgium.

Mondi wins at the 2010 PPI Awards gala on November 16, 2010 in Brussels, Belgium.

Vienna, November 19, 2010– Mondi, the global paper and packaging company accepted 3 awards at the 2010 PPI awards in categories for company, mill, and individual achievements:

· The prize for the environmental strategy of the year in the company category for Mondi Group, Austria

· The prize for the environmental strategy of the year in the mill category for Mondi SCP in Ruzomberok, Slovakia

· The prize for the research achievement of the year for Andreas Kornherr from Mondi Uncoated Fine & Kraft Paper

Peter Oswald, CEO of Mondi Europe & International, says: “These awards mean a lot to Mondi. We have worked hard for this and it is gratifying to receive recognition for our efforts in so many areas.”

Environmental strategy of the year in the company category for Mondi

Mondi Group’s overall focus on sustainability is entrenched in the belief that industry should play an important role in the global efforts to reduce greenhouse gas emissions and protect the world’s ecosystems. To help meet these challenges, the Group concentrates on a series of environmental commitments regarding carbon-based energy consumption; water consumption; emissions to air and water; waste generation and disposal and recycling of paper and board materials. The award acknowledges the comprehensive environmental improvement programme that spans a 5-year period and is supported by a number of efficiency projects. “We are very grateful to receive such a prestigious award” says Christian Ramaseder, Group Environmental Manager. “It is a testimony to having taken the right actions for reducing our environmental footprint and therefore becoming more resource efficient.”

Environmental strategy of the year in the mill category for Mondi SCP

With the mill’s instrumental IMPULS project, Mondi SCP has implemented further environmental production processes to protect and maintain the ecosystem and beauty of the area. By implementing best available technologies (BAT), Mondi SCP decreased emissions to air by an average of 94% and water by 66%. Fresh water consumption decreased due to waste water reuse made possible by the mill’s biological waste water treatment plant. The mill also achieved reductions in energy consumption, relying primarily on green energy from biogenic sources for production. “We have undertaken significant measures to protect the surrounding environment at Mondi SCP and by doing so we also have a positive effect on the environment globally, “says Roman Senecky, Managing Director at Mondi SCP. “We are pleased to have this acknowledged by winning the award.”

Research achievement of the year in the category for individual achievements

The prize for the research achievement of the year went to Andreas Kornherr of Mondi Uncoated Fine and Kraft Paper. Together with team members Paul Achatz and Gerhard Drexler, and in close cooperation with Prof. Georg Reischl from the University of Vienna’s Physics department, Kornherr was nominated for his Acoustic Dust Tester (ADT), a patented new method, which uses acoustic waves to impose defined mechanical stress on paper sheets to measure nano- and micro particle emissions. Kornherr comments, “It is very fulfilling to be part of a project that has a direct impact on subsequent processes within the paper industry.”

The PPI Awards are organised by RISI, one of the leading information providers about the global forest products industry. The awards aim at honoring leadership, vision, innovation and strategic accomplishments within the pulp and paper industry.

Contact

Albert Klinkhammer, Marketing & Communication Director, Europe & International

Tel: +43 (0)1 79013 4056, e-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Marion Kaiser, Communications Specialist, Europe & International

Tel: +43 (0)1 79013 4059, e-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

European paper industry is at the core of green growth

The European pulp and paper industry today concluded its twelvth European Paper Week announcing that it is well prepared to play an important part in the upcoming bio-economy, which is one main political priority of the EU.

“We are at the core of green growth. The paper industry is perfectly built to support the new bio-economy through it’s knowledge of renewable raw materials, recycling , bio-energy and use of by-products. Paper is part of the solution and our discussions over the last three days have shown how we can support green growth.” said Teresa Presas, Managing Director of CEPI.”

The three-day event brought together over 330 people from the pulp and paper industry, related organisations as well as different institutions and provides a high-level platform for discussion.

At a moment when the European Commission is presenting its flagship initiatives to implement the EU2020 strategy for smart, sustainable and inclusive growth, the CEPI Annual Meeting provided the opportunity to address some policy views and industry initiatives that could contribute to making green growth a reality.

A panel involving industry representatives from Europe and Canada, as well as Tony Long head of WWF EU Policy Office, and Lars Kjellberg, a paper analyst from Credit Suisse, debated the transformation of the pulp and paper industry and its potential to innovate, from different stakeholder angles.

The key plenary event held during the European Paper Week, saw the contributions from European Parliamentarian Herbert Reul, as well as from Mattia Pellegrini, member of the Cabinet of European Commission Vice President Antonio Tajani, responsible for Industry and Entrepreneurship. They outlined the contents of the new industrial policy, the innovation union as well as the raw materials strategy. Berry Wiersum, Chairman of CEPI said,” we welcome the European Commission proposal for an integrated industrial policy that puts competitiveness at centre stage. We look forward to seeing it implemented in member states. Our sector is ready to deliver”.

The networking event of the year within the pulp and paper industry took place in Brussels at the Crowne Plaza – Le Palace Hotel in Brussels from 16-18 November. This year the event included four interactive seminars on a wide range of topics such as raw materials, climate policy, recycling and transport, which will help shape the work programme for CEPI over the coming year.

Metso to supply QCS replacement in UPM Kymmene - Papeteries de Docelles

Metso has signed an agreement with UPM Kymmene for the replacement of the ageing Quality Control System in Papeteries de Docelles (France). Start-up of the project is planned at the end of August 2011. The value of the replacement project will not be disclosed.

This replacement project concerns the PM1 in Docelles. The scope of supply will include two PaperIQ Select scanners. The first one will be installed at the reel and will be equipped with IQLaserCaliper sensor for the caliper measurement. The second scanner will be installed in size press.

With this new quality control system, Papeteries de Docelles will be able to make multivariable MD and CD controls together with color control. The system will also feature DNAhistorian and DNApaperMap applications for the history data and profiles storage.

Thanks to the accurate and stable measurements together with advanced controls featured by the PaperIQ Select quality control system, this investment will help UPM Kymmene – Papeteries de Docelles to improve performances of key indicators such as end-product quality. Furthermore, Papeteries de Docelles will benefit from local Metso’s expert service team to insure the continuous improvement of its production.

Papeteries de Docelles specializes in the production of printing and envelope papers and is situated in Docelles (Vosges, France) in the heart of Europe. Papeteries de Docelles is part of the UPM – Kymmene group, one of the world leaders of the forest industry with production units in 15 countries. In 2009, UPM's sales totalled € 7.7 billion. UPM has production plants in 15 countries and it employs approximately 23,000 people worldwide.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

For further information, please contact:

Patrick Rojo, Sales & Service Account Manager, Process Automation Systems, Automation business line, Metso, Tel. +33 557 92 10 40

Vacon signs supplier contract with KONE

The global AC drives manufacturer Vacon has signed a supplier contract with KONE Corporation. KONE is one of Vacon's global OEM customers. The value of the contract is estimated to be several million euros annually for the coming years.

The new supplier contract between Vacon and KONE covers new energy-efficient AC drives that have been designed in close cooperation. "This cooperation is a good example of Vacon's capability to develop new technology and products which are suited to the new market and customer needs. Vacon is able to create solutions that only a dedicated AC drives house can provide. We take pride in that KONE as a global elevator manufacturer chooses Vacon as its supplier. I think the quality, reliability, and innovative design of our products are the features our customers value most," says Heikki Hiltunen, Executive Vice President, Vacon Group.

The AC drives Vacon provides to KONE are built on Vacon's latest technology platform. The AC drives help the customer save a remarkable amount of energy due to the specific technological innovations that were incorporated into the products. The product deliveries will begin later this year, and their volume will increase during the years 2011-2012.

Vacon Group

Further information:

- Heikki Hiltunen, Executive Vice President, Products and Markets, Vacon Group, mobile +358 (0)40 8371 609, email This email address is being protected from spambots. You need JavaScript enabled to view it.

Press contact:

- Sebastian Linko, Director, Corporate Communications, Vacon Group, mobile +358 (0)40 8371 634, email This email address is being protected from spambots. You need JavaScript enabled to view it.

Vacon in brief

Vacon is driven by a passion to design, manufacture and sell only the best AC drives on the planet - and nothing else. AC drives can be used to control electric motors or to help generate power from renewable sources. Vacon has R&D and production units in Finland, the United States, China and Italy, and sales offices in 27 countries. In 2009, Vacon had revenues of EUR 272 million and globally employed 1,200 people. Vacon's shares (VAC1V) are listed and publicly traded on the Helsinki Stock Exchange.

Driven by Drives, www.vacon.com