Ianadmin

James Cropper’s commitment to sustainability recognised with prestigious award

British master papermaker James Cropper has scooped this year’s Green Award at Luxe Pack Shanghai for its support of the Burneside Community Energy (BCE) project.

The project is a social initiative, which has seen the installation of a 250KW Solar PV Array on the roof of Cropper’s Burneside mill to generate clean, green electricity, and enables residents – many of whom are also employees – in the parish local to the business’ headquarters to benefit from investment in renewable energy.

The multi-award winning project, which launched in December 2015, has been praised as a sustainable eco-friendly solution, while James Cropper was commended for its commitment to green energy and the local community.

The installation generates 200,000 kWh of renewable electricity per annum – enough to offset the energy requirements of James Cropper’s specialist laminating and technical coating facility, or the equivalent of powering 50 UK homes.

Susan Wilson, group packaging director at James Cropper, presented the scheme to a panel of industry experts, including British sustainability advisor, Charlie Mathews and Damien Parenteau, vice president of purchasing and development from Chanel.

Susan said: “We’re thrilled that the Burneside Community Energy Scheme has been recognised by Luxe Pack. It’s just one of many green initiatives that we’re proud to be involved in. There is an enormous appetite for sustainability in the industry at the moment, from manufacturers like us to end clients and everyone in between. We’ve made a strong commitment to proactively innovate in this area, from ensuring our pulp supply is FSC® regulated to installing the a unique reclaimed fibre plant with the capability of recycling paper cups at our mill in 2013.”

As well as the positive impact on the environment, the scheme delivers a five per cent annual dividend to investors, and an additional £50,000 for a community fund to deliver projects of social and environmental benefit to Burneside over a 20-year period.

Julie Tomlinson, part of the James Cropper sustainability team, commented: “With BCE we set out to generate greener energy in a way that doesn’t compromise the special ecology or superb landscape of Burneside and Cumbria and the project also rewards the parish and its investors with ethical energy and financial benefits. It really is terrific to see that our efforts are paying off already. It’s estimated that the initiative will reduce our carbon dioxide emissions by 1.91 million kilograms over the next two decades.

“The scheme will create an invaluable amount of environmental and social benefit for the community, ranging from help and advice for those in fuel poverty and support for young people and the school, to provision of community services and conservation and wildlife enhancement. It’s helping to create a positive, sustainable legacy for future generations in Burneside, while reducing our dependency on fossil fuels.”

The scheme profits will be generated through the Government’s feed-in tariff and from the sale of electricity to James Cropper PLC, as part of the manufacturer’s long-term commitment to supporting the community of Burneside and reducing its carbon dioxide emissions.

Luxe Pack, which celebrated its 10-year anniversary this year, also acknowledged James Cropper as a loyal exhibitor since its inception at a special reception and award ceremony.

James Cropper has also recently been shortlisted for Insider Media’s Made in the Northwest Awards in its Green Manufacturer / Sustainable Manufacturer Award category.

For more information about James Cropper, visit www.jamescropper.com.

Pure Nature: Biochemicals of the Lenzing Group Given Official Biocertification

The U.S. Department of Agriculture grants its “biobased” certificate to the acetic acid, furfural and magnesium lignosulfonate produced by the Lenzing Group.

Lenzing – The biochemicals acetic acid, furfural and magnesium lignosulfonate manufactured in the biorefinery of the Lenzing Group were granted the Biobased Product Label by the U.S. Department of Agriculture (USDA). This prominent certification is further official proof that the above-mentioned products of the Lenzing Group are derived 100% from the natural and renewable raw material wood.

“Lenzing stands for a responsible approach to nature. For this reason, we use 100% of the natural resource wood, from the core to the bark – as pulp, bioenergy and biochemicals such as acetic acid”, explains Lenzing CEO Stefan Doboczky. “That is why we are very pleased that our pioneering role with respect to the issue of sustainability has gained worldwide recognition”, Mr. Doboczky adds.

“Lenzing stands for a responsible approach to nature. For this reason, we use 100% of the natural resource wood, from the core to the bark – as pulp, bioenergy and biochemicals such as acetic acid”, explains Lenzing CEO Stefan Doboczky. “That is why we are very pleased that our pioneering role with respect to the issue of sustainability has gained worldwide recognition”, Mr. Doboczky adds.

The Lenzing Group produces dissolving pulp at its sites in Lenzing, Austria and Paskov, Czech Republic. All the valuable raw materials are extracted from the wood within the framework of a cascading use. Acetic acid is derived from beech wood in the pulp production process, is recovered in several process steps and processed into high quality, food-grade acetic acid, for example for the food industry. Furfural is a product utilized as a solvent in the refining of lubrication oil, to name one example. Magnesium lignosulfonate is found in animal food or fertilizers.

On this basis of this award, Lenzing once again underlines its very high ecological standards. Just a few months ago, Lenzing Modal® fibers and Lenzing Viscose® fibers, including all product families, were also given the USDA Certified Biobased Product Label. The particularly environmentally compatible TENCEL® fibers have already been certified as biobased since the year 2011.

BioPreferred program

The certification of biobased products is part of the BioPreferred program implemented by the USDA. It is designed to motivate government institutions and companies to purchase biobased products or those which largely consist of biological materials.

The Lenzing Group

The Lenzing Group is a world market leader headquartered in Austria, which operates production sites in all major markets as well as a worldwide network of sales and marketing offices. Lenzing supplies the global textile and nonwovens industry with high-quality, botanic cellulose fibers. Its portfolio ranges from dissolving wood pulp to standard and specialty cellulose fibers.

Lenzing’s quality and innovative strength set global standards for cellulose fibers. With 79 years of experience in fiber production, the Lenzing Group is the only company in the world which is able to produce significant volumes of all three cellulose fiber generations – from the classic Lenzing Viscose® branded fibers to the Lenzing Modal® branded fibers and the TENCEL® lyocell fibers. In 2016 Lenzing introduced the RefibraTM branded recycling fiber, a product innovation based on recycled cotton scraps.

The Lenzing Group’s success is based on consistent customer orientation combined with innovation, technology and quality leadership. Lenzing is committed to the principles of sustainable management with very high environmental standards and can underscore this commitment with numerous international sustainability certifications for its business processes as the most sustainable company in the sector. In addition to fibers, which form the core business, the Lenzing Group is also active to a lesser extent in the field s of engineering and plant construction.

European paper industry lodges complaint against unfair Turkish import licensing on EU exports of office paper

CEPI (the Confederation of European Paper Industries) has presented a Trade Barrier Regulation (“TBR”) complaint to the European Commission against the unfair non-automatic import licensing system established by Turkey concerning, inter alia, EU exports of uncoated wood free (“UWF”) paper, which includes office paper, books, envelopes and paper used for direct mail marketing.

Following an inconclusive safeguard investigation on UCWF imports in 2014-2015, Turkey extended in 2016 an existing import licensing system which targeted €150 million of EU exports of UWF paper products.

Following an inconclusive safeguard investigation on UCWF imports in 2014-2015, Turkey extended in 2016 an existing import licensing system which targeted €150 million of EU exports of UWF paper products.

The Turkish non-automatic import licensing system with regard to UWF paper is based on an arbitrary price threshold and creates a significant and unfair obstacle to EU-Turkey trade. As such, the contested system poses a clear violation of WTO and EU-Turkey Customs Union Agreement which the Commission is currently seeking to strengthen.

“The European pulp and paper industry exports more than 20% of its production worldwide. It is essential that the EU ensures with all its trading partners the full respect of free trade and fair competition rules we have in bilateral agreements like with Turkey and at WTO level” say Sylvain Lhôte

For more information, please contact Bernard Lombard at This email address is being protected from spambots. You need JavaScript enabled to view it. or by phone at (+32) 2 627 49 22

A.Celli Slittomatic[TM] Upgrade: the ideal solution to every cutting demand!

Choose A.Celli for a guarantee of the best technology when it comes to longitudinal cutting, for an extremely high quality production.

Today more than ever, the concept of production flexibility in the nonwovens market is embodied in the ability to automatically manage a number of different cuts.

Changing recipes in record times; adapting to different production cycles; being able to count on an operational programming flexibility. These are the standards that every company must guarantee.

These features have given rise to A.Celli SlittomaticTM Upgrade: the evolution in the longitudinal cutting system.

In turning to A.Celli technology, you will be able to benefit from a dedicated development and quotation for the replacement of any cutting system (on A.Celli machines as well as on machinery built by other manufacturers) in favour of SlittomaticTM technology

Fully automatic, highly flexible and completely modular, A.Celli SlittomaticTM is a cutting management system that allows:

- Increasing productivity, making knife positioning and precision faster based on the recipe;

- Enhancing operator safety and eliminating the “human error” variable;

- Augmenting knife performance (electrostatic bar) + dust removal;

- Knife life management system;

- Reducing machine downtime thanks to intelligent maintenance monitoring.

The service offered includes:

- Engineering;

- Supervision for electrical and mechanical installation;

- Commissioning & start-up;

- Project Management;

- Training;

- Software modification and issuing of licenses and SW Keys;

- Updating of electrical and pneumatic diagrams;

- Review of manuals and layout;

- 24/7 Technical Support Hotline;

- 12-month guarantee from the date of completion of the modifications.

So what are you waiting for?

Contact This email address is being protected from spambots. You need JavaScript enabled to view it. for a quick consultancy or a dedicated study.

BillerudKorsnäs Growing again

CEO Per Lindberg comments on the development during Q1 2017:

“The first quarter of 2017 saw growth on the back of high demand in the markets across all business areas. Sales are showing better than expected growth, and our production is in fact at an all-time high for a single quarter. However, our operating profit during the quarter suffered from spillover effects from 2016, and we have as a consequence undertaken significant measures to address both our start-up performance as well as quality performance.

Two of the key elements in our growth strategy and production capacity are our major ongoing investments in Skärblacka and Gruvön. We are glad to see that the start-up of these projects has been successful and that they are well under way. Together with new solution sales initiatives we have laid a strong foundation for continued growth.”

Two of the key elements in our growth strategy and production capacity are our major ongoing investments in Skärblacka and Gruvön. We are glad to see that the start-up of these projects has been successful and that they are well under way. Together with new solution sales initiatives we have laid a strong foundation for continued growth.”

THE RESULT

Our operating profit SEK 550 million falls short of our expectations. This is due to the ramp up of Rockhammar after the rebuild in 2016 and quality costs emanating from production disturbances during the second half of 2016. Even if the situation has improved and stabilized in Rockhammar, we may experience some minor costs also in the upcoming quarter. However, looking at the current market, we see an overall positive development across the board and a solid performance in terms of sales growth, 5% during the first quarter compared to the same quarter last year. Within Consumer Board we even exceeded our expectations during the beginning of the year, driven by strong sales to all major liquid packaging board customers. During the quarter we were subject to an unexpected inspection under EU competition rules as part of a larger investigation of the market for bleached and unbleached kraft papers. We have no indications of the outcome from the inspection.

MARKET OUTLOOK

All of our business areas are currently showing a favourable development, partly due to underlying strong demand but also some seasonal improvement in Packaging Paper. We believe this will continue also in the second quarter and we now need to meet this strong demand with high production volume and quality.

The growing demand for sustainable packaging does not only drive demand for sustainable materials. We can also detect an increasing need for holistic packaging solutions throughout the whole value chain of the packaged product, especially in developing markets. Such solutions are necessary to enable a shift toward packaging that help create better packaging performance, especially in terms of sustainability. We are already in a position where we can offer such solutions – Managed Packaging within Corrugated Solutions, Sack Sales and system sales such as Axello Zap within Packaging Paper to name a few. Today these new solutions offerings still constitute a small part of our total business but they are growing more rapidly than material sales and we expect that development to continue and accelerate.

STRATEGY

Our target is to deliver profitable growth through offering both materials and solutions. Sustainability is becoming an increasingly integrated part of our core offer along with cost, protective and appearance performance criteria. It is often an entry ticket to new business and a result of our efforts to challenge customers to choose more sustainable alternatives, BillerudKorsnäs alternatives. One clear example of this is the launch in March of a Sack Sales partnership in Malaysia to serve the market throughout South East Asia. We can through delivering a complete packaging solution based on our material, but by sourcing the converting, provide the market with a product that replaces less sustainable solutions made of plastic. Our solution provides a better carbon footprint but also a much better working environment for the end user which for instance can be cement. Such examples of new sustainable solutions and business models in combination with the growth in production of sustainable materials generated by the large investments in our production structure show that we have the ability to deliver on our strategy for profitable growth.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4 300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Italian Cartiere Modesto Cardella enhances dryer section with repeated orders to Toscotec S.p.A.

In the last year, the partnership between the Italian machinery supplier and Cartiere Modesto Cardella, became closer with three important orders of advanced TT SteelDryers to rebuild the dryer sections of PM3 and PM4.

A first order of 8 TT SteelDryers and 4 TT Uni-Run Vac-Rolls were supplied and started up in 2014, a second order of 14 new TT SteelDryers in place of cast iron dryers were provided for PM3 in 2016 and already successfully started-up. A third order of 17 TT SDs has been repeated for the PM4.

A first order of 8 TT SteelDryers and 4 TT Uni-Run Vac-Rolls were supplied and started up in 2014, a second order of 14 new TT SteelDryers in place of cast iron dryers were provided for PM3 in 2016 and already successfully started-up. A third order of 17 TT SDs has been repeated for the PM4.

Toscotec Technical specialists will provide supervision, commissioning and start up assistance. The final start-up is scheduled for fall of this year, 2017.

Toscotec Steel Dryer is a well-known and a proven solution with over 1200 Dryers running worldwide, providing extremely high drying capacity.

The specific design of TT SteelDryer with flat heads welded to the shell allows to produce a wider and uniformed dried sheet. Toscotec was the first to introduce the revolutionary concept of Steel Dryers in the paper industry and it continues as the undisputed leadership worldwide.

About Cartiere Modesto Cardella.

The mill, whose location in San Pietro a Vico (Lucca) dates back to 1908, was taken over in 1946 by Cardella’s family. The company has invested progressively in rebuilding, technological upgrading and innovation, to achieve current levels of production for corrugated cardboard made from waste paper with a capacity of 200 thousand tonnes per year. Over the years new paper machines were continuously introduced, up to the current day capacity which sees the MC3 (size 250 cm) and the MC4 (width 280 cm) in production.

About Toscotec.

Since 1948, Toscotec offers complete production lines, plant retrofits, and individual machineries. Headquartered in Lucca, the nerve center of the Italian paper district, with offices in China and North America, the Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities.

Unplanned shutdown of the Vallvik Mill has a negative impact on production during the second quarter

Production in the Vallvik Mill has been affected by an unplanned shutdown due to leakage within the recovery boiler. The problem is now resolved and production is back to normal.

The shutdown represents an estimated production loss of about 4,500 tonnes in the second quarter, corresponding to approximately 7.5 percent of mill’s planned production for the quarter and about 4.5 percent of the Group's total planned production for the quarter.

The shutdown represents an estimated production loss of about 4,500 tonnes in the second quarter, corresponding to approximately 7.5 percent of mill’s planned production for the quarter and about 4.5 percent of the Group's total planned production for the quarter.

For further information, please contact:

Lennart Eberleh, President and CEO Rottneros AB, +46 270 622 65

Rottneros is an independent producer of market pulp. The Group comprises the parent company Rottneros AB, listed on NASDAQ Stockholm, and its subsidiaries Rottneros Bruk AB and Vallviks Bruk AB with operations involving the production and sale of market pulp. The Group also includes Rottneros Packaging AB, which manufactures fibre trays, and the wood procurement company Rottneros Baltic SIA in Latvia. The Group has just over 280 employees and had a turnover of approximately SEK 1.7 billion in the 2016 financial year.

Valmet introduces new and improved customer training offering - Valmet Learning Services

Valmet launches a renewed customer training offering for its customers - Valmet Learning Services - to help improve the reliability and performance of its customers' processes. The new offering is complementing the company's new services approach - Shared Journey Forward - introduced in 2016.

Valmet Learning Services offers organization-wide training solutions tailored to the customers' needs. The offering includes customized and standard courses, on-site, off-site, or via the Valmet Online Learning Portal. Furthermore, Valmet Training Simulators allow customers to safely practice hands-on procedures and scenarios to strengthen safe behavior and be prepared for troubleshooting and the handling of operational upsets.

"Today, the combined forces of globalization and digitalization are challenging companies to develop and continuously expand their expertise, and achieving business targets is not only about optimizing equipment and systems. We are launching Valmet Learning Services to better support our customers in training their employees so that they can stay competitive in today's challenging business environment. This is a concrete step toward our vision: to become the global champion in serving our customers," says Jukka Tiitinen, Business Line President, Services, Valmet.

Valmet Online Learning provides 24/7 access to courses and training resources from computers, tablets, or mobile phones

Valmet Online Learning provides 24/7 access to courses and training resources from computers, tablets, or mobile phones

Valmet Learning Services helps customers design their learning paths to progress in their chosen area of interest. Reaching a higher knowledge level not only represents an important achievement for the employees themselves, but can have an impact on KPIs like reliability, productivity, and product quality.

To make sure Valmet's customers get the most out of their training investment, Valmet Learning Services uses a four-step approach: identify individual skills gaps, design a program based on the customers' learning targets, deliver training using modern tools and methods, and secure the outcome through evaluation and assessment.

"We are committed to moving our customers' performance forward. Reducing risks, improving productivity, and increasing profitability all start with the employees. Confident and skilled personnel ensure safe, stable, and efficient start-ups and operations with minimized environmental risks. We help our customers maximize their potential by training their employees," says Emmeli Olén, Director, Valmet Learning Services.

Valmet is the leading global developer and supplier of process technologies, automation, and services for the pulp, paper, and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work closely with our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland, and its shares are listed on the NASDAQ Helsinki.

Valmet opened new regional office in Mexico City

Valmet has opened its new regional office in Mexico City to serve its customers. The opening ceremony of the office was held in February 2017. The inauguration event was held at the Residence of the Ambassador of Finland in Mexico

"Valmet has had business dealings with Mexico already for many years and this latest step is the proof of how interesting the Mexican market currently is", said the Finnish Ambassador Roy Eriksson in his speech.

Kari Lindberg, Jukka Tiitinen, José Rivera, Dave King and Charles Farmer cutting the ribbon at the new Valmet office

Kari Lindberg, Jukka Tiitinen, José Rivera, Dave King and Charles Farmer cutting the ribbon at the new Valmet office

Valmet is aiming to be close to its customers and growth markets, and opening an office in Mexico is a good example of getting closer to local customers. Last year Valmet opened new offices also in Chile and Vietnam. Besides this, Valmet will open a new services center in Indonesia this year. Valmet is aiming to provide significant customer benefits by utilizing our full offering of process technology, automation and services, and by continuously developing our local and remote services.

Valmet entered the Mexican market in 1954, when the first Valmet paper machine was commissioned. Today, substantial amount of all tissue and paper and packaging board in Mexico are produced by machines supplied by Valmet. Valmet's offering in Mexico also covers automation and services.

"We have worked diligently to earn the trust of our clients over these many years. What comes to the future of Valmet in Mexico, we feel there are many opportunities for us", stated Dave King, Area President, North America, Valmet.

Valmet currently has over 120 service centers, 88 sales offices, 34 production units and 16 R&D centers around the world. In addition, Valmet's experts are close to customers also with the help of Industrial Internet and remote connections.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

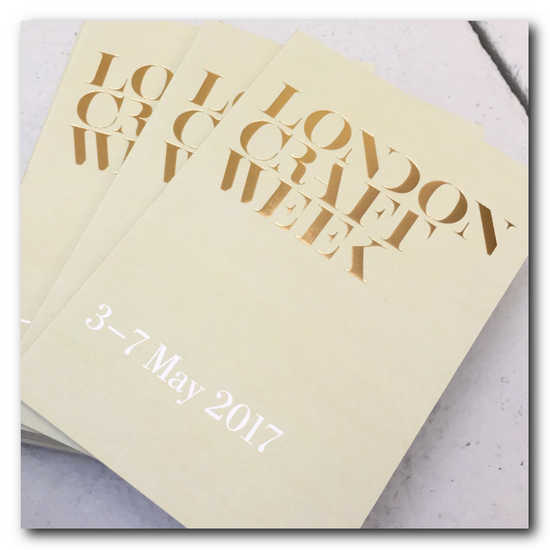

James Cropper sponsors London Craft Week

James Cropper is the official paper sponsor for London Craft Week 2017, an annual event that showcases the very best British and international creativity and craftsmanship.

The prestige paper innovator, based in the Lake District, has supplied London Craft Week with speciality paper made from coffee cup waste to create the London Craft Week guide. The up-cycled ‘Coffee’ papers, including Latte 350gsm in a textured Buckram finish and Latte 100gsm for the internal pages, are produced using fibre from the company’s unique coffee cup recycling facility.

The third edition of the event, running from 3 to 7 May, brings together a programme of more than 230 design, fashion, art, luxury, food and culture events taking place at venues including the V&A, The Shard, RADA and The House of Lords, as well as ‘off the beaten track’ settings, many of which are not normally open to the public.

Steve Adams, managing director of James Cropper, said: “We’re proud to be a partner sponsor of London Craft Week again this year. Our paper technologists and craftspeople have a 170-year heritage of creating beautiful, tactile papers for modern and traditional applications in bespoke colours, weights and finishes.

“Some of our papers can be seen in the creative innovation showcased at this event, which is a fantastic celebration of global creativity. Over the years we’ve worked closely with artists, designers, galleries and luxury brands and are committed to supporting the arts industry now and in the future.”

The business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

Guy Salter OBE MVO, chairman of London Craft Week, said: “James Cropper papers exude the superior craftsmanship that is synonymous with London Craft Week. The lovingly crafted papers and high-quality finishes demonstrate an exceptional attention to detail, which is the epitome of what the event is all about.”

For more information about James Cropper Paper, visit www.jamescropper.com

About James Cropper

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

About Technical Fibre Products (TFP)

As well as paper products, James Cropper plc also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

About James Cropper 3D Products

With James Cropper 3D Products, James Cropper plc has created the next generation of sustainable moulded paper packaging. Available in a wide variety of colours and with a naturally tactile finish, the product has a clear focus on quality and is design-engineered to suit all packaging needs. Features to improve product value and packaging integrity, such as personal embossing, natural hinges and cut-outs, enhance brand impact. All packaging products are recyclable and made from 100 per cent renewable natural fibres.

About London Craft Week

From 3 - 7 May 2017, the third edition of London Craft Week takes up residence in the capital. This annual event showcases the very best international and British creativity and craftsmanship through a ‘beyond luxury’ journey-of-discovery. The curated programme brings together over 230 events from all corners of the globe fusing making, design, fashion, art, luxury, food, culture and shopping. An accessible and immersive cultural experience, London Craft Week’s visitors can eat, drink and view performances, meet artists, designers, makers and engineers, get a glimpse behind-the-scenes of famous brands and landmark buildings, see familiar products deconstructed, learn how things are made and even have a go themselves.

London Craft Week, as a small private not-for-profit organisation, supported by our founding partner Vacheron Constantin and sponsors Grosvenor, Mulberry and St James's London.

For further information visit: www.jamescropper.com, www.jc3dp.com and www.tfpglobal.com.