Ianadmin

Fitnir analyzers to supply recovery and recausticizing systems to Södra Cell Mönsterås

FITNIR Analyzers has been awarded with a project to supply its state-of-the-art online analyzer system, for measuring green and white liquor properties, to Södra Cell Mönsterås.

“This is a very exciting time for FITNIR Analyzers, as we continue to expand our market penetration outside of North America,” stated Tom Sands, President of FITNIR Analyzers. “With our high uptime and measurement precision, the analyzer can provide a means for Södra to reduce liquor variability and increase production. We are optimistic that we will see more interest from other kraft pulp producers worldwide in the near future.”

One analyzer and two field sample stations will be installed at Södra Cell Mönsterås’s recovery and recaust areas. Replacing an outdated titration-based analyzer, FITNIR Online will monitor four streams (raw green liquor and weak wash) from two dissolving tanks, providing liquor compositions for TTA (total titratable alkali) control and RE (reduction efficiency) monitoring. In the recausticizing area, seven streams (clarified green liquor, slaker, four causticizers, and final white liquor) will be analyzed and used for TTA-trim control, slaker, and final CE (causticizing efficiency) control.

“We are looking forward to implementing FITNIR’s analyzers at SÖDRA Cell Mönsterås,” said Håkan Edvinsson, Project Manager at Södra Cell Mönsterås. “It is very important to our pulp mill to have this kind of analyzer for process control and we are satisfied with the high precision and availability FITNIR guarantees to deliver.”

Södra Cell Mönsterås’s system will be delivered in early February and start up is planned for April 2017.

About Södra

Södra’s pulp mills produce softwood pulp of spruce and pine, and hardwood pulp from birch. The pulp is mainly sold to European manufacturers of tissue, specialty paper, packaging and publishing papers. Södra’s largest pulp mill is Mönsterås. Operating since 1958, it has expanded over the years developing into one of the world's most modern plants. Here, 750,000 tonnes per year of pulp is produced. The mill's core business is pulp production. However, its capacity to serve as a source of electricity is becoming increasingly important. Mönsterås also produces district heating and transforms pine oil into biodiesel. www.sodra.com/en/pulp/production/monsteras/

About FITNIR Analyzers Inc.

FITNIR’s automated online and benchtop analyzers reliably measure complete pulp liquor compositions. Fast, frequent and accurate measurements drive control strategies that decrease process variability and environmental impact for improved efficiencies and profitability. Proven applications for the digester, recausticizer, recovery boiler, ClO2 generator, brownstock washer, and now kappa measurements for wet and dry pulp, FITNIR is the next generation of process analyzers. www.fitnir.com

A new Pöyry Point of View explores how e-commerce is creating unique opportunities for containerboard mills and converters.

The article, ‘The Delivery Economy: When boxes fly', outlines how the continual increase in delivery based, convenience shopping is making companies consider every ounce and pound of their packaging, as they seek to drive down shipping costs. Some well-known companies are taking this a step further; Amazon, Google and UPS are working on unmanned drone delivery systems where reduced size and weight of packaging will be even more vital. These developments are driving the emergence of lightweight containerboard in the delivery economy.

Soile Kilpi, Director at Pöyry Management Consulting North America states, "If you are a mill or a converter that provides the paper and board for packaging who is cutting precious ounces from the corrugated container, you could have a lot to gain from these new opportunities – however futuristic they may currently seem.”

Soile Kilpi, Director at Pöyry Management Consulting North America states, "If you are a mill or a converter that provides the paper and board for packaging who is cutting precious ounces from the corrugated container, you could have a lot to gain from these new opportunities – however futuristic they may currently seem.”

The article argues that the delivery economy provides multiple business development paths for a corrugated manufacturer in addition to drone delivery. The Point of View contains numerous best practice examples, highlighting real case studies to illustrate these points.

Kilpi continues, "Mega trends support the idea that the delivery economy is here to stay. The convenience of the delivery economy is supported by increasing urbanisation and household trends. Efforts for more sustainable solutions, whether done to reduce costs through lighter and less packaging or for environmental stewardship, are not going away.”

America’s population may be aging, but older generations are also getting tech savvy and embracing e-commerce. Millennials have practically lived their whole adult lives with e-commerce and have formed shopping habits around its existence. With this in mind, corrugated manufacturers must embrace all the new possibilities this presents.

Download the report

The Delivery Economy: When Boxes Fly Point of View report

About Pöyry

Pöyry is an international consulting and engineering company. We serve clients globally across the energy and industrial sectors and provide local services in our core markets. We deliver management consulting and engineering services, underpinned by strong project implementation capability and expertise. Our focus sectors are power generation, transmission & distribution, forest industry, chemicals & biorefining, mining & metals, transportation and water. Pöyry has an extensive local office network employing about 6,000 experts. Pöyry's net sales in 2015 were EUR 575 million and the company's shares are quoted on Nasdaq Helsinki (Pöyry PLC: POY1V).

The Lucart Group publishes The Sustainability Report 2015

A reduction of over 5,000 tons of CO2e into the atmosphere and the reduction of 9.1% in water consumption

The use of renewable energy and rail transport confirm the Group's commitment towards an eco-sustainable production

Over 5,000 tons of CO2e atmospheric reduction as well as the reduction of water consumption equal to 9.1% and raw materials made from 54% recycled paper.

These are the results of the sustainable production of The Lucart Group, published in the eleventh edition of the 2015 Sustainability Report that will be presented to the public during the Ecomondo fair in Rimini.

"In our Company “Lucart”, being sustainable means creating long lasting value not only for the Company and its Shareholders however also for our Employees and their families, for the Communities in which we operate and for our Partners, whether Suppliers or Clients. This has been made possible thanks to the transition from a linear economy to a circular economy, emphasizing the use of recovered fibers, with the capacity to protect the environment and safeguard the development of local communities, without foresaking the quality of our products" to quote Massimo Pasquini, the CEO of the Lucart Group.

Outlined as follows, is the performance of the Lucart Group, photographed by the Sustainability Report 2015, which can be viewed on our website www.lucartgroup.com:

- Recycled materials: in 2015 the pulp selected, whether from the industrial supply chains or from household collections, have reached 54% of total raw materials processed at our Lucart Group plants.

- Rail transport: from 2013 Lucart has doubled (from 572 to 1154) the number of carriages with a specific mobility program for both incoming and outgoing goods from the Diecimo plant (Lucca), with a significant reduction in traffic and typical pollutant emissions of road transport of 483 tCO2e less, released into the atmosphere.

-Reducing water consumption: thanks to the increase in the quantity of water recycled in the production process and the reduction of the requirements for the production process itself, in 2015 Lucart has reduced the consumption of water by 9.1% (vs. 2014) per tonne of paper produced, as well as the consumption of steam, another widely used resource for drying paper, which has been decreased compared to 2014.

- In 2015 the use of alternative renewable energy sources has prevented the emission of more than 1,500 tCO2e in total into the atmosphere. Specifically the two Photovolcaic plants installed: one in the Capannori area (2011) and the other in the Avigliano plant (active since 2013), have reduced emissions of 935 tCO2e.

Among the specific measures taken in 2015 in the Diecimo plant (Lucca), we would like to highlight that the installation of LED lamps and of an inverter of a pulper machine, has resulted in a reduction of carbon dioxide emissions by 98 tCO2e.

- The cogeneration plants fueled by methane gas in the Porcari and Castelnuovo in Garfagnana plants, which fully cover the energy needs and generate a surplus which is pumped into the network, together with other interventions for reducing the use of natural gas and steam, have reduced 3,600 tCO2e in the atmosphere, compared to 2014. This result was made possible thanks to the completion of the first Cogeneration plant with Integrated EcoRecupero. The fumes recovery project of the gas turbine for the direct drying of the paper in 2015, has enabled a reduction in the necessity of methane gas amounting to over 2 million m3.

All these measures, together with various other actions, have made it possible to reduce more than 5,000 tCO2e of emissions.

Almost 2 billion beverage cartons recovered and approx. 900,000 trees saved, are the calculations of what would have been necessary to produce the equivalent amount of virgin fiber paper, over 52,000 tons of CO2e prevented, thanks to the nonoccurance of landfill disposal of beverage cartons. These are the environmental benefits achieved in three years from 2013-2015 of the Fiberpack® project, the flagship of The Lucart Group, which testifies the total applicability of the principles of circular economy to the tissue sector.

Fiberpack®, the innovative treatment process, developed in 2011 by the Lucart Group, thanks to the collaboration with Tetra Pak®, which separates the cellulose fibers from the rest of the materials with precision, using clean technology and zero waste, enables the recovery of 100% of the components of beverage cartons.

Lucart Group

Lucart Group, a multinational Italian industrial group founded in the province of Lucca in 1953, is one of the main producers in Europe of mono-glazed paper and tissue products (paper articles intended for daily consumption, such as toilet paper, kitchen paper, napkins, tablecloths, handkerchiefs, etc.). The company's over 60 years of activity have allowed it to develop great know-how, experience and the technology needed to make top-quality products capable of meeting the customer's needs in the best way possible. The production systems installed at the Group's various plants make it possible to manufacture a wide range of products with complete control over every phase of the production process, from the choice of raw materials to the definition of the characteristics of the finished product. Lucart Group's production capacity is equal to 310,000 tons of paper/year, split over 10 continuous machines (one of which for air-laid paper) and 55 converting lines. The company's production activities are distributed over 3 Business Units (Business to Business, Professional and Consumer) operating in the development and sales of various products with distinctive brands such as Tenderly, Tutto, Grazie Natural and Smile (Consumer area), Lucart Professional, Tenderly Professional, Fato and Velo (Professional area). The ranges include products created to satisfy the needs of different types of users, from large companies to end consumers. The consolidated turnover is equal to about € 415 million, with a total workforce of 1,300 employees, 7 production plants (5 in Italy,1 in France and 1 in Hungary), covering a total surface area of 750,000 m2. The Diecimo (LU) plant is one of the largest facilities in Europe dedicated to the production and conversion of tissue paper. Lucart has always represented a company with a strong aptitude for innovation. For example, it was the first Italian company to develop the pulp de-inking technique for the production of tissue paper and of thin mono-glazed paper for flexible packaging. Lucart also developed the first system in Italy capable of recovering the cellulose fibres contained in Tetra Pak® containers, an eco-revolutionary project that has allowed us to obtain top-quality paper in full respect of the environment. The quality of the products and the respect for the environment are always the basis of the Group's strategic choices, proven by the various certifications it has obtained, such as Ecolabel (the first Italian company to be certified), PEFCTM, FSC®, UNI EN ISO 9001 and 14001 etc. The facility in Diecimo is one of the first integrated industrial facilities, paper mill and converting on the same site, in Europe for the production of tissue paper and to have obtained EMAS environmental registration.

Valmet to supply a headbox upgrade for Green Forest (QingXin) Paper Industrial Limited

Valmet will supply a headbox upgrade and two headbox recondition service packages to Green Forest (QingXin) Paper Industrial Limited paper mill in Qingxin County, Qingyuan, China. The delivery is scheduled to take place in September 2017, and the start-up to be in October and November 2017.

The order was included in Valmet's third quarter 2016 orders received. The value of an upgrade of this scope is usually valued around EUR 1 million.

"Valmet has proven technology, products and services bringing us reliability and performance. This upgrade turns our slice controlled headbox into a dilution-controlled headbox and we expect this to improve our board quality," says Mr. Wu Guixing, Production Director, Green Forest paper mill

"This RetroDilution headbox upgrade will bring better controllability of the headbox and improved end product quality with improved basis weight profile and fiber orientation to the customer. We are happy to bring this new technology to China and thank Green Forest for the excellent cooperation and mutual trust," says Kevin Jiang, Director, South Sales, China.

Board machine at the Green Forest (QingXin) Paper Industrial Limited paper mill in Qingxin County, Qingyuan, China

Technical information of the delivery

Valmet's delivery includes RetroDilution headbox upgrade to Green Forest (QingXin) Paper Industrial Limited's board machine 2 and headbox recondition service packages to paper machine 1 and board machine 2. This RetroDilution headbox upgrade delivery is first of its kind in mainland China.

The RetroDilution for headbox is a dilution control retrofit that provides a cost-effective way of modernizing an existing slice lip controlled headbox into a dilution controlled one.

About the customer Green Forest Paper Industrial Limited

Green Forest Paper Industrial Limited is part of Hop Fung Group Holdings Limited. Hop Fung Group is principally engaged in the manufacture and sale of quality corrugated paper ware products to its over 550 customers in the manufacturing sectors in Hong Kong and the Pearl River Delta area. The Group is listed on the Main Board of The Stock Exchange of Hong Kong.

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Verso Announces Plans to Temporarily Idle 200,000 Tons of Annual Production Capacity at its Androscoggin Mill in Maine

Verso Corporation (NYSE: VRS) has just announced plans to temporarily idle the No. 3 paper machine at its Androscoggin Mill in Jay, Maine, reducing annual coated paper production capacity by approximately 200,000 tons. Verso intends to implement this capacity reduction beginning in the first quarter of 2017. The mill also will idle a digester and recovery boiler that support the No. 3 paper machine. Most products currently produced on the No. 3 paper machine will be transitioned to other machines in Verso's highly flexible manufacturing system with no expected disruption to customer orders.

"It's critical to Verso's long-term success that we balance the supply of our products with our customers' demand for them, and we currently have more coated paper capacity in our mill system than we can fill," said Michael A. Weinhold, Verso Senior Vice President for Sales, Marketing and Product Development. "Verso made the decision to temporarily idle the No. 3 paper machine and transition the machine's production to lower-cost machines in our manufacturing system to help us stay ahead of the curve and move the entire company toward sustained profitability. At the same time, we are positioning the mill for future success by optimizing equipment, enhancing process efficiency and expanding production for the growing specialty papers market."

"It's critical to Verso's long-term success that we balance the supply of our products with our customers' demand for them, and we currently have more coated paper capacity in our mill system than we can fill," said Michael A. Weinhold, Verso Senior Vice President for Sales, Marketing and Product Development. "Verso made the decision to temporarily idle the No. 3 paper machine and transition the machine's production to lower-cost machines in our manufacturing system to help us stay ahead of the curve and move the entire company toward sustained profitability. At the same time, we are positioning the mill for future success by optimizing equipment, enhancing process efficiency and expanding production for the growing specialty papers market."

The idling of the No. 3 paper machine will result in the layoff of about 190 employees at the Androscoggin Mill. Verso anticipates that if the machine is not restarted, the capacity reduction will result in the elimination of those jobs.

"Challenging market conditions have made these types of actions far too frequent in recent years, and they are never easy," Weinhold said. "They are especially difficult for the employees and their families who are directly affected. Verso is committed to treating all of our impacted employees with fairness, dignity and respect and to communicating openly and honestly with each individual about how this decision will affect him or her. Our Human Resources team will begin meeting with our affected employees immediately.

"We're in business to help make our customers successful, and Verso remains steadfastly committed to those who currently purchase coated paper products made on the No. 3 paper machine at the Androscoggin Mill," Weinhold said. "Our sales team will begin contacting customers immediately to determine how to make this transition as seamless as possible."

Verso will continue to evaluate market conditions to determine if and when the No. 3 paper machine at the Androscoggin Mill will be restarted.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.

Verso Offers Microwave Popcorn Bag Producers an Attractive New Option with GlazeArmor™ Micro Papers

Verso Corporation (NYSE: VRS), a leading producer of flexible packaging, technical, and label and converting papers, has just introduced GlazeArmor™ Micro, a bleached, uncoated machine-glazed paper with oil and grease resistance (OGR) that is specifically designed for microwave popcorn bag applications.

The latest addition to Verso's GlazeArmor™ family of lightweight uncoated machine-glazed OGR papers, GlazeArmor™ Micro provides aggressive grease holdout for both inner and outer ply layers of microwave popcorn bags, offering kit grease resistance levels ranging from Kit 6 to 12 and excellent runnability and performance for high-speed bag converting and popcorn packing and filling operations.

The latest addition to Verso's GlazeArmor™ family of lightweight uncoated machine-glazed OGR papers, GlazeArmor™ Micro provides aggressive grease holdout for both inner and outer ply layers of microwave popcorn bags, offering kit grease resistance levels ranging from Kit 6 to 12 and excellent runnability and performance for high-speed bag converting and popcorn packing and filling operations.

"Our GlazeArmor™ Micro papers excel in the critical areas that matter most to microwave popcorn brands seeking high performance OGR paper options – quality, performance and run-to-run consistency," said Mike Weinhold, Verso Senior Vice President of Sales, Marketing and Product Development. "We deliver these American-made papers with the same level of highly personalized customer service, experienced technical resources and overall attention to detail that customers have come to expect from Verso."

The GlazeArmor™ product family is an integral part of Verso's broader portfolio of machine-glazed laminating and converting papers designed for flexible packaging applications. Featuring OGR levels ranging from Kit 5 to Kit 12, the GlazeArmor™ line offers excellent runnability, converting performance and multiple perfluorooctanoic acid (PFOA)-free chemistries, all key performance requirements for end-use applications such as sandwich and deli wraps, foodservice liners, microwave popcorn bags and laminated food pouches.

The GlazeArmor™ product line, including GlazeArmor™ Micro, is produced on paper machine No. 5 at Verso's Androscoggin Mill in Jay, Maine, and offers several basis weights, ranging from 15.5 lb. to 33 lb. (3000 sq. ft.), each optimized for specific end uses. According to Jason Handel, Verso Group Vice President of Product Development and Technical Sales, "The No. 5 paper machine has a long-standing reputation for producing OGR papers with outstanding quality and consistent performance. The GlazeArmor™ product line is no exception."

For more information on GlazeArmor™ or other products in Verso's broad specialty papers offering, email This email address is being protected from spambots. You need JavaScript enabled to view it. or visit versoco.com/specialtypapers.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.

BW Papersystems launches its new Hawk folio sheeter

Ideal for folding carton plants, small printers, paper merchants and converters

BW Papersystems and its brand MarquipWardUnited recently launched the newest addition to the broad range of sheeters available from BW Papersystems: the Hawk sheeter.

The Hawk, the bigger brother of the successfully exhibited eCon sheeter, (recently at drupa 2016) is a standardized dual rotary sheeter at a fixed working width of 1,650 mm (65 inches). This medium range sheeter is designed to meet the needs of folding carton plants, small printers, paper merchants and paper and board converters as well as small and regional paper and board mills.

Available in two or four web configuration, with different manual and auto splicing unwind solutions and a single cut reject system, the Hawk allows for efficient in-house sheeting of both paper and board grades.

“In-house sheeting with the Hawk sheeter, instead of buying stacks of sheets, allows our customers to reduce inventory, eliminate pile turning, lower material cost and increase press performance,” says Patrick Walczak, VP Global Sales White Paper. “Plus, it increases size flexibility, as customers can cut different sizes on the Hawk sheeter, and finally allows for smaller order sizes which clearly is a huge advantage towards their customers.”

Not to forget the cut quality and accuracy: with its high-quality twin synchronous knife, an advanced speed curve and an air assisted heavy duty stacker, the stacks that leave the Hawk are press ready and of superior quality. With its early track record of two machines already installed, a third about to ship and a couple more still to be built, the Hawk definitely follows the footsteps of its successful little brother eCon.

With selected options, like automatic tension control, automatic high-speed splicing or digital slitter settings, this sheeter can be configured for different requirements. And although offering an attractive price level for a quick ROI, the Hawk makes no compromise on reliability and diagnostics – knowing that the breakdown of a sheeter can quickly shut down production at printing and folding carton plants. Like all new machines from BW Papersystems, also this sheeter has the backing of the global BW Papersystems spares and service network.

ABOUT BW PAPERSYSTEMS

BW Papersystems incorporates nine of the strongest brands in the industry: BW Bielomatik, Curioni, JAG SYNCHRO, Kugler-Womako, MarquipWardUnited, SHM, VortX, WillPemcoBielomatik and Wrapmatic. Market leading technology is available for folio-size, cut-size and digital-size sheeting and packaging of paper, board and other materials, plus stationery, passport production, RFID processing, Book-on-Demand finishing and specialized paper converting applications. For the corrugating industry, we offer full corrugators, rotary die cutters, flexo folder gluers and starch mixing systems. bwpapersystems.com

ABOUT BARRY-WEHMILLER

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $2.4 billion organization with 11,000 team members united by a common belief: to use the power of business to build a better world. To see how, go to barry-wehmiller.com.

Metso's upgraded PlantTriage software simplifies real-time performance management and strengthens cybersecurity

Metso Expertune PlantTriage(TM), a control loop monitoring system, oversees process control loops night and day, diagnoses and prioritizes opportunities for improvements, and pinpoints major economic paybacks.

As a tool of the digital world, PlantTriage leverages Metso's decades of expertise in automation and control valves. It gathers process data from many different control systems, and monitors of thousands of control loops.

Metso's profound understanding of smart positioners and valve position feedback systems has been incorporated into PlantTriage to meet customers' needs for improved reliability. PlantTriage has also been tested intensively in different demanding industries, including refining, chemicals, and pulp and paper.

"PlantTriage delivers value to our customers by identifying and getting to the root causes of control system performance issues. We have started to see that valve position feedback information is becoming more available in control systems that can communicate with smart field devices. This data permits more accurate diagnostics of valve performance issues. We have introduced several new assessments and a problem solver report related to valve positioner performance," explains Steve Obermann, Senior Product Manager, Metso.

For increased security, PlantTriage Version 13 contains several cybersecurity enhancements. JAVA-related vulnerabilities have been eliminated. Integration with Microsoft Windows Authentication allows administrators to manage network security seamlessly, according to the customer's in-house IT policies.

In addition, PlantTriage Enterprise Systems have been upgraded. An Enterprise System provides a single view of the corporation; combining KPIs and results from individual plant sites to a central portal. In Version 13, PlantTriage Enterprise Systems provide alerts for conditions on loops and units in remote PlantTriage systems.

Metso is a world leading industrial company serving the mining, aggregates, recycling, oil, gas, pulp, paper and process industries. We help our customers improve their operational efficiency, reduce risks and increase profitability by using our unique knowledge, experienced people and innovative solutions to build new, sustainable ways of growing together.

Our products range from mining and aggregates processing equipment and systems to industrial valves and controls. Our customers are supported by a broad scope of services and a global network of over 80 service centers and about 6,400 services professionals. Metso has an uncompromising attitude towards safety.

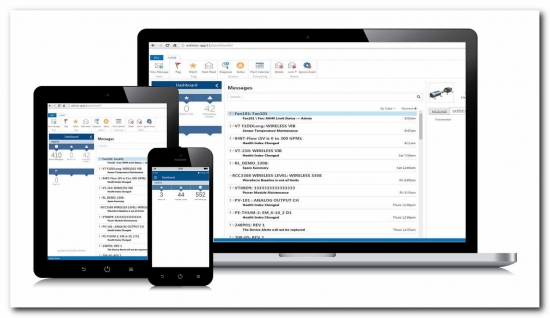

Emerson launches holistic asset monitoring platform to improve reliability and plant availability

New platform allows users to easily monitor asset health from inside or outside the plant

Emerson introduces the AMS ARES™ Platform, designed to prioritise and deliver asset and device health data, enabling maintenance decisions that increase operational and asset availability. Anywhere and anytime, users can securely access and share key data, with asset health summaries available on traditional desktop PCs, laptops, smartphones, and tablets−inside or outside the plant.

The introduction of the AMS ARES Platform represents an evolution toward a new, modern portfolio of AMS technologies and services, focused on providing digital intelligence and tools to help customers operate their plants and assets more effectively. Part of Emerson’s Plantweb™ digital ecosystem, the AMS ARES Platform gathers data from multiple sensing technologies, and provides a holistic view of the current health status of plant assets.

Persona-based access to information ensures the right personnel have instant access to clear health overviews of assets that are relevant to their plant responsibility. A streamlined dashboard and embedded tools for assigning prioritisation based on criticality allow users to determine quickly the urgency of an issue, facilitating faster workflows to increase plant performance.

“Plant personnel need to know the health of their assets in relevant time to when they need it,” said Duncan Schleiss, vice president of business development, Emerson Automation Solutions. “Emerson is committed to delivering solutions that provide information to those that can fix problems before they become production issues. By providing a secure, flexible and easy to deploy platform that communicates with many types of assets, asset health is published and available to all with minimal effort and in relevant time.”

The AMS ARES Platform marks a measurable shift away from managing data and toward delivering actionable insight. More asset visibility doesn’t have to mean slogging through more data. The AMS ARES Platform delivers information based on responsibility so that each person sees only pertinent data.

Designed as a platform to evolve with process industry evolutions, the AMS ARES Platform takes advantage of the OPC UA open architecture. Giving users the potential for HMI and historian connectivity and access to business intelligence and reporting tools, the AMS ARES Platform can make asset health truly part of the business dashboard.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Emerson Automation Solutions business helps process, hybrid, and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Emerson Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit Emerson.com.

Contact information

This email address is being protected from spambots. You need JavaScript enabled to view it.

Catalyst Paper Announces Principal Securityholder Support for Recapitalization

Catalyst Paper Corporation have just announced that it has received an alternative recapitalization proposal to be implemented if the previously announced acquisition proposal by Kejriwal Group International ("KGI") is not completed. The Board of Directors believes that the availability of such an alternative is in the interest of the Company and all of its stakeholders, and had requested that holders representing about 79% of the Company's outstanding common shares and 87% of its 11% PIK Toggle Senior Secured Notes (the "Principal Securityholders") consider making or supporting an alternative proposal.

As a result of the Board of Director's request, each individual Principal Securityholder has separately, following its own independent evaluation, indicated that it would support an alternative recapitalization plan, the terms of which have been communicated to the Company. These terms include converting the US$260 million 11.00% PIK Toggle Senior Secured Notes due October 2017 into (i) a new term loan in the principal amount of US$135 million with a maturity 5 years from the issuance date, and 12% interest to be paid-in-kind during year one, with the possibility thereafter of partial payment-in-kind at the Company's option, and (ii) common shares of the Company representing 95% of the outstanding number thereof after giving effect to such conversion.

The implementation of the alternative recapitalization plan would not affect any of Catalyst's contractual relationships with its trade vendors or any amounts owing to them.

The implementation of the alternative recapitalization plan would not affect any of Catalyst's contractual relationships with its trade vendors or any amounts owing to them.

In addition, the Principal Securityholders have each agreed to defer the interest that is scheduled to be paid to them on November 1, 2016 in respect of the Company's PIK Toggle Notes. The alternative recapitalization plan also contemplates the conversion of the amount of such deferred interest into equity. Together with the significant debt reduction and the terms of the new term loan described above, this deferral and conversion would provide the Company with enhanced liquidity.

"We are pleased that each of our Principal Securityholders is willing to support an alternative recapitalization plan which would significantly reduce debt and provide enhanced liquidity without affecting trade vendors," said Joe Nemeth, President & Chief Executive Officer of Catalyst.

The alternative recapitalization plan also contemplates a transaction under which common shares not held by three of the Principal Securityholders would be exchanged for cash consideration, subject to certain conditions, including so as to permit the Company to cease to be a reporting issuer under applicable securities laws. The completion of any such transaction is not a condition to the implementation of the alternative recapitalization plan. There can be no assurance that such an exchange transaction will be proposed and if so at what price.

KGI Acquisition Proposal

The support agreement among KGI and each of the Principal Securityholders in respect of the KGI acquisition proposal contemplated that an arrangement agreement in connection thereof would be entered into by October 25, 2016. No such arrangement agreement has been entered into. As a result, the parties to the support agreement are permitted to terminate it, although they have not yet taken any such action. There can be no assurance that the support agreement will not be terminated and that the KGI transaction will be completed.

Information regarding process and conditions

Catalyst and its Board of Directors are reviewing and evaluating the alternative recapitalization plan with the assistance of legal and financial advisors and will be providing an update as to such review in due course. The alternative recapitalization plan would be proposed under the arrangement provisions of the Canada Business Corporations Act and submitted for court and securityholder approvals in order to be binding on all affected securityholders.

The alternative recapitalization plan contemplates certain conditions and other provisions including the maturity extension of the existing credit facilities of Catalyst, and securityholder, regulatory, stock exchange and court approvals. There can be no assurance that definitive agreements to implement the proposed alternative recapitalization will be entered into by Catalyst, that any of the conditions to the recapitalization will be satisfied, or that these or any other proposed transaction or plan will be approved or consummated, and if so on what additional or amended terms to those described herein.

The Company does not undertake any obligation to provide any updates with respect to the KGI acquisition or the alternative recapitalization plan or the processes relating thereto, except as required under applicable law. The Company notes that Schedule 13D filings are made from time to time by certain of its stockholders with the U.S. Securities and Exchange Commission and can be consulted by visiting EDGAR on the SEC website at www.sec.gov/edgar.shtml.

About Catalyst Paper

Catalyst Paper manufactures diverse papers such as coated freesheet, coated one side (C1S), flexible and industrial packaging, coated and uncoated groundwood, newsprint, directory, as well as market pulp. Customers include retailers, publishers, commercial printers, and converters of specialty applications in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada, and has been ranked by Corporate Knights magazine for the 10th consecutive year as one of the 50 Best Corporate Citizens in Canada.