Ianadmin

Corporate Knights ranks UPM on the 25th place in the list of 100 most sustainable corporations in the world

UPM has been ranked on the 25th place in the list of 100 most sustainable corporations by Corporate Knights, the Canadian-based media and research company. UPM is the only company in the Paper and Forest Products category.

UPM has been ranked on the 25th place in the list of 100 most sustainable corporations by Corporate Knights, the Canadian-based media and research company. UPM is the only company in the Paper and Forest Products category.

The Global 100 Index is determined using 12quantitativesustainability indicators,includingtheamountofrevenue that companiesgenerateperunitofenergy consumed, theratioofCEOtoaverageworkerpayandpercentage of taxes paid. Companieswho maketheGlobal100 rankingarethetopoverall performers in terms of sustainabilityintheir respectiveindustrialsectors, selected from 4353 listed companies with a market capitalisation of over 2 billion USD on 1 October 2015.

"This is the first time that UPM has been ranked on this esteemed list, and we really appreciate reaching such a good position ," says Päivi Salpakivi-Salomaa, Vice President of Environment and Responsibility at UPM.

"For UPM, driving top performance is clearly linked to sustainability. Our vision is captured in one word Biofore. It means that UPM integrates the bio and forest industries and builds a new, sustainable and innovation-driven future. Versatile use of recyclable and renewable wood biomass, combined with innovation, efficiency and responsibility are at the core of UPM Biofore," Salpakivi-Salomaa continues.

"Global 100 companies demonstrate ambition and achievement on a broad spectrum of indicators.They are where people want to work, buy from and invest in over the long term," says TobyHeaps,CEOofCorporateKnights.

Forfullrankings, please visit: http://www.corporateknights.com/magazines/2016-global-100-issue/2016-global-100-results-14533333/

For further information please contact:

Päivi Salpakivi-Salomaa, Vice President, Environment and Responsibility, UPM, tel. +358 2041 50396

Toby Heaps, CEO, Corporate Knights, tel. +1416274 1432, This email address is being protected from spambots. You need JavaScript enabled to view it.

UPM

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 20,000 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM - The Biofore Company - www.upm.com

5 Interesting Facts about Thermal Paper Roll (Infographic)

Thermal printing is becoming highly popular among businesses these days, mostly due to its quality and reliability. More than any kind of printer that uses ink, a thermal printer generates long-lasting output minus the hefty price tag.

Thermal printing is becoming highly popular among businesses these days, mostly due to its quality and reliability. More than any kind of printer that uses ink, a thermal printer generates long-lasting output minus the hefty price tag.

The technology utilizes a kind of paper that doesn’t call for ink, so switching to thermal printing can help you earn significant savings in terms of money and time as you won’t ever need to buy ink or replace the printer’s ink cartridges. Thermal paper has a variety of applications in various settings, including restaurants, retails stores, ticketing agencies, lottery, banks, and healthcare.

You know that thermal papers are used as proofs of purchase, ATM receipts, and lottery tickets. But what else do you know about thermal paper rolls? Below, we give you five interesting tidbits you probably didn’t know about thermal paper.

Embedded from Pandapaperroll

Large hygiene markets and fast growing nonwovens drive global growth for fluff pulp, according to Smithers Pira

A new report from Smithers Pira, The Future of Fluff Pulp to 2020, provides a comprehensive outlook for the global fluff pulp market, with expert analysis of supply, demand and pricing forecasts to 2020.

Global demand for fluff pulp was 5.4 million air dried tonnes in 2015, up from 4.7 million air dried tonnes in 2010. Projected demand in 2020 is 6.5 million air dried tonnes for a projected annual growth of 3.6% by 2020.

Global demand for fluff pulp was 5.4 million air dried tonnes in 2015, up from 4.7 million air dried tonnes in 2010. Projected demand in 2020 is 6.5 million air dried tonnes for a projected annual growth of 3.6% by 2020.

Historically, fluff pulp has been a specialty pulp grade with higher prices and margins than the more common papermaking pulp grades. Accounting for about 10% of the total pulp market globally in 2015, fluff pulp has apparently ended decades of regular price fluctuation with only minor variations over the last five years.

“Fluff pulp is a very desirable pulp product, with production costs lower than for dissolving pulp, and prices higher than for papermaking grades,” said Phillip Mango, author of the report.

“The outlook for fluff pulp pricing is that it will not vary as much as it has in the past and list price will stay high while actual discounted prices slowly drop from 2015 through 2020. This will make fluff pulp even more attractive versus other fibres.”

Fluff pulp is one of the most sustainable raw materials on earth, based on tree species grown with no irrigation and few or no pesticides on land that has little value for food production. Despite continuing reduction in fluff pulp content in its major end uses, fluff pulp has proven amazingly resilient, gaining volume in adult incontinence and increasing baby diaper/nappy sales in emerging markets.

The large hygiene end-uses consume the majority of global fluff pulp and drive the growth of the fluff pulp market. The fastest growing major end-use for fluff pulp is nonwovens. These hygiene end-uses are projected to increase fluff consumption in air dried tonnes by 3.4% annually through 2020, while nonwovens are projected to increase their fluff pulp consumption by 5.4%.

The competitive landscape for fluff pulp is dominated by large pulp and paper companies located in North America, thanks to the optimal growing conditions in this region. The four largest fluff pulp producers are Georgia-Pacific, Weyerhaeuser, International Paper, and Domtar. These four account for about 80% of all fluff pulp production in 2015. The 10 largest producers account for about 99% of global fluff pulp production. Of the top 10 producers, six are in North America, one in South America and three in Western Europe.

The trend in fluff pulp production is expansion in South America and North America, while Europe has concentrated on modifying pure fluff producing mills to more sustainable, more profitable, biorefineries.

Geographically, consumption is driven by the large hygiene end-uses plus the growing nonwovens markets. Here, Asia is the market leader, with Western Europe and North America second and third respectively. The North American and Western European markets are relatively mature and as such have the lowest growth for fluff pulp, while Asia, South America and Eastern Europe all have higher growth rates.

With comprehensive market data and industry analysis based on new primary research, The Future of Fluff Pulp to 2020 examinesthe changing nature of the global fluff pulp market over the next five years.

Twin Rivers Paper Company Pledges $45,000 to Local Four Seasons Trail Association for Land Acquisition

Twin Rivers Paper Company shows its community support for the Four Seasons Trail Association (FSTA) by pledging up to $45,000 for land acquisition. The organization is looking to purchase the land on which their trails and lodge are located to make the multi-use trails permanent.

Twin Rivers Paper Company shows its community support for the Four Seasons Trail Association (FSTA) by pledging up to $45,000 for land acquisition. The organization is looking to purchase the land on which their trails and lodge are located to make the multi-use trails permanent.

“We are lucky to have a resource like FSTA that is committed to providing the recreational facilities that foster appreciation of the natural beauty in the St John Valley and encourage residents to be active. Supporting this organization and its world class trail system is a win, win for everyone”

“After seeing the work & dedication the volunteers put in to create the lodge in 2007, we knew that the trails, primarily on private land, had to become a permanent part of the facility. After the lodge was completed, the directors embarked on a multi-year initiative to ensure the trails would be permanently available for public use,” said John Ezzy, Executive Director of FSTA.

FTSA President Colin Jandreau added, “Ownership of the land gives us the opportunity to make much needed changes to the trail footprint, accommodating an even greater number of people from serious athletes in training, to recreational users looking to enjoy the outdoors and maintain their fitness.”

Over the past 8 years, the organization has been buying land from the owners, raising over $250,000 in local contributions and grant money to acquire more than 150 out of the approximately 240 acres of land.

Twin Rivers pledged to help with the final two parcels of land which total 90 acres through a program that matches funds raised by FSTA between 2015 and 2018. To date, FSTA has raised approximately $20,000.00 toward the goal.

“We are lucky to have a resource like FSTA that is committed to providing the recreational facilities that foster appreciation of the natural beauty in the St John Valley and encourage residents to be active. Supporting this organization and its world class trail system is a win, win for everyone,” commented Tim Lowe, CEO of Twin Rivers Paper Company.

To make a donation, visit www.fourseasonstrail.org. Donations of any amount are appreciated and will be used to purchase the final parcel of land.

Twin Rivers Paper Company is an integrated specialty paper company that manufactures packaging, label and publishing products for targeted markets and applications. The company has operations in Maine and New Brunswick. For more information, visit the website at twinriverspaper.com.

Four Seasons Trail Association (FSTA) is a non-profit, volunteer organization that fundraised, designed and built a world class Nordic ski, snowshoe, mountain bike and hiking facility that is accessible to the public. The lodge is surrounded by a network of trails historically privately owned but publicly accessible with landowner permission. The organization has been purchasing the trail land to continue creating a world-class outdoor recreation center accessible to the community. For more information, visit the website at fourseasonstrail.org.

SCA’s divestment of its business in South East Asia, Taiwan and South Korea for integration with Vinda approved

SCA’s divestment of its business in South East Asia, Taiwan and South Korea for integration with Vinda International Holdings Limited (“Vinda”) has been approved by the independent shareholders of Vinda. The transaction is expected to close on February 1, 2016. SCA is the majority shareholder in Vinda, one of China’s largest hygiene companies.

SCA’s divestment of its business in South East Asia, Taiwan and South Korea for integration with Vinda International Holdings Limited (“Vinda”) has been approved by the independent shareholders of Vinda. The transaction is expected to close on February 1, 2016. SCA is the majority shareholder in Vinda, one of China’s largest hygiene companies.

Vinda is listed on the Hong Kong Stock Exchange and the transaction was subject to approval by the independent shareholders of Vinda.

As part of the transaction, SCA and Vinda have signed an agreement regarding the exclusive license to market and sell the SCA brands; TENA (incontinence products), Tork (Away-from-Home tissue), Tempo (consumer tissue), Libero (baby diapers), and Libresse (feminine care) in South East Asia, Taiwan and South Korea. With this agreement, Vinda will hold the rights to these product brands in these Asian markets. Vinda will acquire the brands Drypers, Dr.P, Sealer, Prokids, EQ Dry and Control Plus in these markets. SCA will continue to provide innovation and technical support for the business.

“Asia is an important growth market for SCA with a large population and low penetration of hygiene products. The approved transaction strengthens the collaboration between SCA and Vinda and enables us to further leverage on our strengths to build a leading Asian hygiene business” says Magnus Groth, President and CEO of SCA.

SCA has been a shareholder in Vinda since 2007, became its majority shareholder in late 2013, and has consolidated Vinda financials since the first quarter of 2014. In 2014, SCA divested its hygiene business in China (Mainland China, Hong Kong and Macau) for integration with Vinda.

SCA’s hygiene business in South East Asia, Taiwan and South Korea had net sales of approximately SEK 2.2 billion in 2014. The business has approximately 1,600 employees and three personal care production sites in Malaysia and Taiwan. The purchase consideration amounts to HKD 2.8 billion (approx. SEK 3.1 billion) on a debt-free basis.

As a consequence of this transaction SCA’s Shanghai office will stop to have operations. This is expected to lead to approximately SEK 90m in restructuring costs that will be recognized as an item affecting comparability in the fourth quarter of 2015.

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Södra's sawmill at Värö is Sweden's largest

According to the aggregated results for 2015, Södra's sawmill at Värö is the largest in Sweden. In 2015, Värö produced a sawn volume of nearly 600,000 cubic metres.

Systematic work with planning, maintenance and efficiency improvements underlies the increase in production volumes. A third shift was also introduced in September 2015. The total raw material consumption is 1.2 million cubic metres.

"The type of construction timber produced at Värö is used for housing construction, for example, and is in high demand," says Anders Pålsson, Sawmill Manager.

Room for more

Production at the Värö sawmill comprises 80 percent spruce and 20 percent pine. While core markets are located in the UK and the US, the sawmill also supplies China, South Korea, Germany, the Netherlands, Belgium and Sweden. And full production capacity has not yet been reached:

"We have more capacity. Working in an industry with high demand, interested customers and strong regrowth of the raw material is positive," says Anders Pålsson. "Wood has many advantages. It absorbs CO2 throughout its entire lifetime, for example, which makes a positive contribution to the climate."

The sawmill and the pulp mill at Värö make up a combined plant, where both operations benefit from their proximity to each other. This includes environmental benefits, such as more efficient handling of bark, sawdust and chips which are converted to green energy and district heating. Both of the mill operations are electrically self-sufficient, and bark, for example, is sold for conversion to district heating.

Södra has been operating the sawmill at Värö since 1974, but the new facility was commissioned in 2011 and fully expanded in 2014. The facility has been adapted several times to increase production efficiency. And more adaptations are planned.

As production volumes increase, new opportunities and challenges are arising. And we are accustomed to taking advantage of such opportunities," says Anders Pålsson.

For comments:

Anders Pålsson, Sawmill Manager, Värö,

+46 (0)70 371 2086

Håkan Svensson, President of the Södra Wood business area,

+46 (0)457 316 00

WestRock Completes Acquisition of Cenveo Packaging

WestRock Company (NYSE:WRK) has just announced that it has completed the acquisition of Cenveo Packaging, a leading provider of value-add folded carton and litho-laminated display packaging solutions. Cenveo Packaging is a division of Cenveo, Inc. (NYSE:CVO).

WestRock Company (NYSE:WRK) has just announced that it has completed the acquisition of Cenveo Packaging, a leading provider of value-add folded carton and litho-laminated display packaging solutions. Cenveo Packaging is a division of Cenveo, Inc. (NYSE:CVO).

Through this transaction, WestRock has acquired seven facilities in North America with capabilities including MiraFoil ®, cold foil and low migration ink systems.

“Cenveo Packaging is an excellent addition to our folding carton and merchandising displays business,” said Craig Gunckel, executive vice president, Merchandising Displays and Folding Carton, Packaging Solutions, WestRock. “By combining WestRock paperboard with Cenveo’s packaging and printing capabilities, we expect to be able to further enhance the solutions that we are able to provide to our customers.”

The transaction is expected to generate significant synergies and be accretive to WestRock’s earnings immediately.

About WestRock

WestRock Company (NYSE:WRK) aspires to be the premier partner and unrivaled provider of paper and packaging solutions in consumer and corrugated markets. WestRock’s 41,000 team members support customers around the world from 268 operating and business locations spanning North America, South America, Europe and Asia. Learn more at www.westrock.com

“Yes, we plant”: Mondi plants trees with its new Green Range campaign

Every player in the Green Range online game also plants trees

Mondi launches a new campaign for its Green Range office paper under the motto “Yes, we plant!”. The campaign deals with the topics of sustainable forestry and responsible paper production, but maintains an easy-going attitude. The Green Range online game plays a central role, because it skilfully combines entertainment with information. Players can win attractive prizes each month, such as a “fair phone” or “paper trophy”. The “fair phone” uses conflict-free minerals, is produced under safe working conditions and workers are fairly paid. It also has a longer life-cycle than the normal telephone, thereby reducing waste. Participating is even worthwhile without prizes, as Mondi donates one euro for each registered user to NGO OroVerde, which makes concrete, sustainable contributions to the protection of rainforests and biodiversity every day. A tree is planted for each player in the online game – a concrete contribution that every individual can make. “We would like to invite all of our customers and consumers to plant, play and win in our new online game. Learning about sustainability has never been so entertaining”, encouraged Johannes Klumpp.

Mondi launches a new campaign for its Green Range office paper under the motto “Yes, we plant!”. The campaign deals with the topics of sustainable forestry and responsible paper production, but maintains an easy-going attitude. The Green Range online game plays a central role, because it skilfully combines entertainment with information. Players can win attractive prizes each month, such as a “fair phone” or “paper trophy”. The “fair phone” uses conflict-free minerals, is produced under safe working conditions and workers are fairly paid. It also has a longer life-cycle than the normal telephone, thereby reducing waste. Participating is even worthwhile without prizes, as Mondi donates one euro for each registered user to NGO OroVerde, which makes concrete, sustainable contributions to the protection of rainforests and biodiversity every day. A tree is planted for each player in the online game – a concrete contribution that every individual can make. “We would like to invite all of our customers and consumers to plant, play and win in our new online game. Learning about sustainability has never been so entertaining”, encouraged Johannes Klumpp.

What is Mondi Green Range?

Green Range is Mondi’s umbrella trademark for sustainable paper and packaging solutions. All Mondi uncoated fine papers belong to the Green Range. They are produced from FSC® or PEFC™ certified wood from sustainably managed forests or 100% recycled paper, or are produced totally chlorine free (TCF). This is how consumers can make a contribution – every day.

We are Mondi. IN TOUCH EVERY DAY.

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are in central Europe, Russia, North America and South Africa. We offer over 100 packaging and paper products, customised into more than 100,000 different solutions for customers and end consumers. In 2014 Mondi had revenues of €6.4 billion and a return on capital employed of 17.2%.

The Mondi Group is fully integrated across the packaging and paper value chain – from managing forests and producing pulp, paper and compound plastics to developing effective and innovative industrial and consumer packaging solutions. Our innovative technologies and products can be found in a variety of applications including hygiene components, stand-up pouches, super-strong cement bags, clever retail boxes and office paper. Our key customers are in industries such as automotive; building and construction; chemicals; food and beverage; home and personal care; medical and pharmaceutical; packaging and paper converting; pet care; and office and professional printing.

Mondi has a dual-listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc under the ticker code MNDI.

For us, sustainable development makes good business sense. We don’t just talk about sustainability; we make it part of the way we work every day. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is a business unit of Mondi’s Europe & International Division. In 4 paper mills in Austria, Slovakia, and Russia Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green

Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

ÅF modernises pulp mill in Sweden

ÅF has been contracted to modernise the control systems in linerboard manufacturer Metsä Board’s pulp mill in Husum, Sweden. The contract is for an end-to-end solution and covers conversion to new, modern Siemens control systems for the bleach, cooking and recycling plants.

ÅF is responsible for project management, hardware design, computer programming, construction management and commissioning, and the job is expected to continue throughout 2016, starting immediately.

“The challenge will be to minimise downtime and there is much to be done within a short period,” says Peter Bredal, project manager at ÅF. “Metsä Board will have a modern and future-proof plant after the conversion.”

The contract covers conversion of seven Siemens Teleperm M systems into Siemens PCS7 systems. ÅF has extensive experience with similar conversions, both in Sweden and internationally. They include a system conversion at the Spanolux MDF factory in Belgium.

For further information, contact Peter Bredal, project manager, ÅF, This email address is being protected from spambots. You need JavaScript enabled to view it., +46 10 505 24 71

ÅF is an engineering and consulting company for the energy, industrial and infrastructure markets, creating progress for our clients since 1895. By connecting technologies we provide profitable, innovative and sustainable solutions to shape the future and improve people's lives. Building on our strong base in Europe, our business and clients are found all over the world.

ÅF – Innovation by experience.

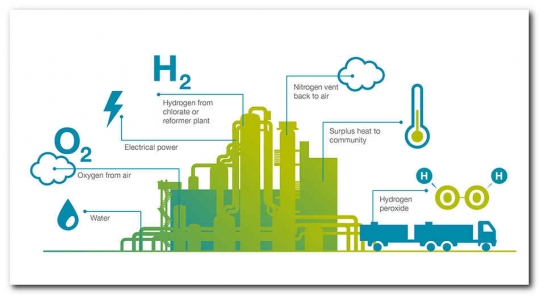

AkzoNobel acquires full control of hydrogen peroxide joint venture

AkzoNobel has strengthened its position in the North American hydrogen peroxide market after acquiring the outstanding shares in EkO Peroxide LLC from joint venture partner OCI Peroxygens LLC (a subsidiary of OCI Enterprises Inc.).

Established nine years ago and headquartered at AkzoNobel's site in Columbus, Mississippi, the joint venture owned and controlled the 70,000 short tons per annum (nameplate capacity) hydrogen peroxide manufacturing facility.

Hydrogen peroxide is a key component of AkzoNobel's bleaching chemicals product portfolio and is marketed by the company’s Pulp and Performance Chemicals business. It has essential applications in various markets, notably pulp bleaching, chemical processing and mining.

"This deal supports the strategic growth objectives for our bleaching chemicals activities. The hydrogen peroxide market in North America has improved significantly in recent years, with AkzoNobel well placed to grow the business," said Werner Fuhrmann, AkzoNobel's Executive Committee member responsible for Specialty Chemicals. "It will also enable us to strengthen our integrated platform for the production of hydrogen peroxide and sodium chlorate at the Columbus site."

Financial details of this transaction are not disclosed.