Ianadmin

Operating profit of SEK 334 million for the Södra Group

Södra’s operating profit for the first four months of the year totalled SEK 334 million (941). Sales amounted to SEK 6,239 million (6,243) and the operating margin was 5 percent (15).

“During the first four-month period, the forest economy was slightly weaker year-on-year, particularly in the sawn timber market. While sales and production volumes remained stable, exchange rates and price trends – which contributed to Södra’s historically high operating profit in 2015 – were less favourable. 2016 is a year of transition for Södra, since the effects of the investment programme at the Värö pulp mill will not be fully realised until 2017,” said Lars Idermark, President and CEO.

“During the first four-month period, the forest economy was slightly weaker year-on-year, particularly in the sawn timber market. While sales and production volumes remained stable, exchange rates and price trends – which contributed to Södra’s historically high operating profit in 2015 – were less favourable. 2016 is a year of transition for Södra, since the effects of the investment programme at the Värö pulp mill will not be fully realised until 2017,” said Lars Idermark, President and CEO.

The Group’s operating profit totalled SEK 334 million (941). The decline was mainly due to a weaker price and currency trend. The preceding year’s result included a nonrecurring item of SEK 133 million related to divestment of the shares in Södra Cell Tofte AS.

Operating profit for the Södra Skog business area totalled SEK 33 million (41). The lower result was mainly due to a lower rate of harvesting in Södra’s own forests, both in Sweden and the Baltic countries.

Operating loss for Södra Wood totalled SEK -107 million (profit: 22). The negative result was due to weaker prices for sawn timber and less favourable exchange rates. Steps are being taken to improve profitability.

Operating profit for Södra Cell totalled SEK 466 million (968). The lower result was mainly due to unfavourable price and currency trends.

| 2016 | 2015 | 2015 | |

| Jan-Apr | Jan-Apr | 1 Jan-31 Dec | |

| Net sales, SEK million | 6,239 | 6,243 | 18,267 |

| Operating profit/loss before depreciation, amortisation and impairment (EBITDA), SEK million | 649 | 1,262 | 3,146 |

| Operating profit/loss (EBIT), SEK million | 334 | 941 | 2,162 |

| Operating margin | 5 | 15 | 12 |

| Cash flow after investing activities, SEK million | -699 | 740 | 218 |

| Return on capital employed, % | 7 | 22 | 17 |

| Equity ratio, % | 58 | 62 | 62 |

For questions, please contact:

Annica Gerentz, Senior Vice President Corporate Communications

Tel: +46 (0)470-894 81

Valmet to supply a sulfuric acid plant to the Metsä Group bioproduct mill in Äänekoski, Finland

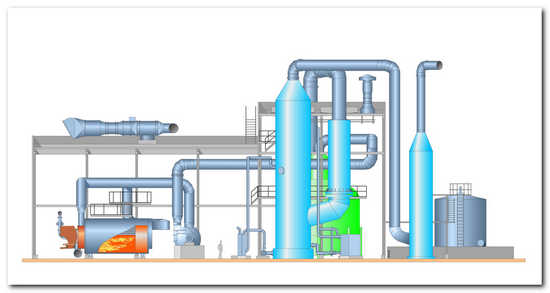

Valmet will supply a sulfuric acid plant to Metsä Group's bioproduct mill in Äänekoski for in-house sulfuric acid production. By means of the new sulfuric acid plant of its own the bioproduct mill can utilize the chemicals in the odorous gases of the pulp manufacturing process. This will help to reduce the wastewater load considerably. The start-up of the plant is scheduled for the third quarter of 2017.

Valmet's delivery is part of Metsä Group's sulfuric acid plant investment that is valued at roughly EUR 20 million. The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed.

"The sulfuric acid plant producing process chemicals from sulfur compounds from odorous gases is a remarkable step towards closed chemical circulation and further improves the environmental performance of the bioproduct mill," says Timo Merikallio, Project Director of bioproduct mill at Metsä Group.

"More efficient utilization of the raw materials and putting circular economy into practice within the industry increases the need for new innovations. The sulfuric acid plant technology that will be delivered to Äänekoski is developed by Valmet. We have developed also multiple new biotechnology processes for pulp and energy industries including lignin and bio-oil production," says Risto Hämäläinen, Director, Environmental Systems at Valmet.

Technical information about the delivery

The order includes a sulfuric acid plant developed by Valmet. The plant consists of a concentrated non-condensable gas (CNCG) incinerator and a sulfuric acid converting plant. The production capacity of the plant will be approximately 35 tons of sulfuric acid per day.This will be the world's first larger scale sulfuric acid plant that will be in operation at a pulp mill.

The new plant will enable the bioproduct mill to become nearly self-sufficient in sulfuric acid, as the odorous gases produced in the pulping process can be converted into sulfuric acid. This will bring significant environmental advantages. The amount of sulfate lead to the mill's effluent treatment plant will be reduced and the sulfate load in the nearby waterways will be smaller compared to the current mill in Äänekoski. The CNCG incineration plant can be used as a back-up boiler for producing process steam by incinerating CNCG, tall oil pitch or liquid methanol.

Information about the customer Metsä Group

Metsä Group is a responsible forest industry group whose products' main raw material is renewable wood from sustainably managed northern forests. The company focuses on tissue and cooking papers, fresh forest fibre paper-boards, pulp, wood products, and wood supply and forest services. Metsä Group's sales totalled EUR 5 billion in 2015, and the company employs approximately 9,600 people. The Group operates in some 30 countries. Metsäliitto Cooperative is the parent company of Metsä Group and is owned by approximately 116,000 Finnish forest owners.

For further information, please contact:

Risto Hämäläinen, Director, Environmental Systems, tel. +358 40 505 2001

Timo Merikallio, Project Director, Bioproduct mill, Metsä Group, tel. +358 50 598 9342

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Sonoco Recognizes Savannah Recycling Center for Sustainability Progress

Sonoco (NYSE:SON), one of the largest diversified packaging companies, has awarded a bronze-level Sonoco Sustainability Star Award to its Sonoco Recycling facility in Savannah, Ga., for successful and exemplary efforts to reduce its waste to landfill and implement sustainability-oriented processes.

Administered by Sonoco Recycling, the Sonoco Sustainability Star Awards program is comprised of three tiers. Gold awards recognize facilities that have achieved 99 percent landfill diversion; silver awards honor facilities achieving 95 percent landfill diversion; and bronze awards distinguish facilities that have made significant waste reduction achievements, such as drastically reducing their waste streams or implementing a new composting system.

Administered by Sonoco Recycling, the Sonoco Sustainability Star Awards program is comprised of three tiers. Gold awards recognize facilities that have achieved 99 percent landfill diversion; silver awards honor facilities achieving 95 percent landfill diversion; and bronze awards distinguish facilities that have made significant waste reduction achievements, such as drastically reducing their waste streams or implementing a new composting system.

Starting last summer, staff at the Sonoco Recycling facility in Savannah took a hard look at its business operations, in terms of both cost and sustainability. Working together, the team realized that by diverting dry waste material from their normal waste streams and taking it to a waste-to-energy service provider every month, they could save money and lessen their environmental impact. Now, only wet or bulky waste goes in the Dumpster, and all other waste is converted to energy via hauling trips that are often combined with normal hauling operations to optimize freight cost and lessen the facility’s carbon footprint.

“This process change is a first for a Sonoco Recycling location,” said Mike Pope, general manager and president, Sonoco Recycling. “The plant is doing a great job capturing a large amount of waste for recovery in waste-to-energy programming, and their improvements have positive implications for both sustainability and cost savings.”

A recycling leader with locations and expertise worldwide, Sonoco Recycling annually collects more than 3 million tons of old corrugated containers, various grades of paper, metals and plastics. In addition, the Company has experts who provide secure, reliable and innovative recycling solutions to residential and commercial customers. Currently, Sonoco Recycling operates four material recovery facilities (MRFs) serving more than 125 communities in which curbside-collected residential as well as commercial materials are processed. The Company also operates recycling programs, which identify waste reduction opportunities that reduce operating expenses for many of the largest consumer product companies in the United States.

About Sonoco:

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging, and displays and packaging supply chain services. With annualized net sales of approximately $5.0 billion, the Company has 20,800 employees working in more than 330 operations in 34 countries, serving some of the world’s best known brands in some 85 nations. Sonoco is a proud member of the 2015/2016 Dow Jones Sustainability World Index. For more information on the Company, visit our website at www.sonoco.com.

Ingevity Corporation Formed with Completion of Spinoff from WestRock Company

Ingevity Corporation (NYSE: NGVT) has just announced that it has begun operations as a standalone, publicly traded company, following a tax-free spinoff from WestRock Company (NYSE: WRK). Starting today, the “regular” trading of Ingevity common stock on the New York Stock Exchange (NYSE) commenced under the symbol “NGVT.”

Ingevity is the specialty chemicals division of WestRock, formerly MeadWestvaco, and is a leading global manufacturer of specialty chemicals and high-performance carbon materials headquartered in North Charleston, S.C. The company operates eight manufacturing facilities in the United States, Brazil and China, with a global network of technical centers, sales offices, warehouses and distribution facilities, and employs approximately 1,500 people. Revenues for the division were $968 million in 2015.

“We are excited about the opportunities that being a standalone company will provide us,” said Michael Wilson, president and CEO, Ingevity. “For the past 100 years, our business has been part of larger paper and packaging companies. Now, as an independent company, Ingevity will have the strategic flexibility and financial resources to pursue multiple avenues of growth. We are poised to build upon our legacy of innovation and success and look forward to driving profitable growth and creating value for our new shareholders.”

The separation occurred by means of a pro-rata distribution of all of the stock of Ingevity to WestRock stockholders. Under the terms of the separation, stockholders who held WestRock stock as of the close of business on May 4, 2016, the record date for the distribution, received one share of Ingevity common stock for every six common shares of WestRock. This distribution occurred on May 15, 2016. No fractional shares of Ingevity stock were issued.

Since May 2, 2016, Ingevity shares have traded on a “when-issued” basis on the New York Stock Exchange, under the symbol “NGVT.WI,” permitting investors to trade the right to receive Ingevity shares in the distribution. “When-issued” trading of common shares ended at the close of the market on May 13, 2016.

Ingevity: Purify, Protect and Enhance

Ingevity (NYSE: NGVT) provides specialty chemicals and high-performance carbon materials and technologies that help customers solve complex problems. These products are used in a variety of demanding applications, including asphalt paving, oil exploration and production, agrochemicals, adhesives, lubricants, printing inks and automotive components that reduce gasoline vapor emissions. Through a team of talented and experienced people, Ingevity develops, manufactures and brings to market products and processes that purify, protect and enhance the world around us. Headquartered in North Charleston, S.C., Ingevity operates from 25 locations around the world and employs approximately 1,500 people. For more information, visit www.ingevity.com.

How do we want to make the world more sustainable?

How do consumers want to get a more sustainable world? What sacrifices, measures and opportunities do we see, today and in the long term? How do we feel about a transformation in which raw materials from the forest are used to manufacture new products? A new report from Innventia investigates the actual conditions for a more circular and biobased society. 2,500 consumers from five countries have had their say on how we can best make the world more sustainable.

Innventia's latest report, Innventia Global Outlook: A Cellulose-Based Society, investigates the conditions for a transition to a circular and biobased society. What global changes, future opportunities and constraints do we have to deal with? How do the views of consumers differ in different parts of the world? How do we best accept responsibility for the development we see before us? This is Innventia's third report in a series of forward-looking reports that have gained a lot of international attention.

Innventia's latest report, Innventia Global Outlook: A Cellulose-Based Society, investigates the conditions for a transition to a circular and biobased society. What global changes, future opportunities and constraints do we have to deal with? How do the views of consumers differ in different parts of the world? How do we best accept responsibility for the development we see before us? This is Innventia's third report in a series of forward-looking reports that have gained a lot of international attention.

Together with Kairos Future, Innventia has completed a consumer study in Sweden, Germany, the United States, Brazil and China. 2,500 consumers were asked about sustainability, the environment, lifestyles and impact. The report reveals several surprising results regarding where consumers really are, in thought and deed, prior to a switch to a more circular and sustainable society.

The key insights from the report will be presented on 24 May, when representatives of Innventia and Kairos Future will be on hand.

Time: 16:30-18:00, 24 May 2016

Venue: International Wood Biorefining Week, Stockholmsmässan, Mässvägen 1, Älvsjö

To register and for more information, contact Marco Lucisano:

+46 (0)768-7 67 285, This email address is being protected from spambots. You need JavaScript enabled to view it..

ABOUT THE REPORT

The report, A Cellulose-Based Society, comprises an international survey, a global analysis and future scenarios. The survey was distributed digitally at the start of 2016 to 2,500 people between the ages of 16 and 88 in five countries (500 respondents per country in Sweden, Germany, the United States, Brazil and China).

ABOUT INNVENTIA

Innventia is a world-leading research institute that works with innovations based on forest raw materials. Our business concept is to generate and refine research findings and ideas based on forest raw materials for the benefit of customers throughout the value chain. We call this approach Boosting Business with Science. Read more about us at www.innventia.se

ABOUT KAIROS FUTURE

Kairos Future is an international consulting and research company that helps businesses and organisations to understand and shape their futures. We provide our customers with the big picture using trend and business intelligence analyses. The company was founded in 1993. It has its head office in Stockholm and has representatives and partners around the globe. Read more about us at www.kairosfuture.com

Verso's Futura® Digital Coated Papers Celebrate 20 Years of Top Digital Printing Performance

Verso's Futura® Digital Coated Papers Celebrate 20 Years of Top Digital Printing Performance with Push Performance to the Limit

New Promotion Highlights Futura® Line's Boundless Potential For High-end Digital Printing

Verso Corporation, a leading producer of digital coated papers, has just introduced Push Performance to the Limit, a new promotion for its Futura® digital coated paper line.

"The quality of digital printing has significantly improved since Futura® was first introduced 20 years ago," said Verso Senior Vice President of Sales, Marketing and Product Development Mike Weinhold. "Digital reproduction quality and innovative print techniques that were once seen only in high-end offset printing are pushing the limits to new heights. Anything that can be done in offset printing can now be done digitally, from the use of metallic inks or match colors to varnish-like coatings, and Push Performance to the Limit is proof that Futura® can handle it all."

"Futura® was first introduced in 1996 as a direct response to the first-ever color laser printer and has been delivering top performance ever since," said Verso Director for Digital Papers Dennis Essary. "Designed with a patented coated surface, Futura® offers users peace of mind with jam-free runnability and printability for unsurpassed productivity."

"Futura® was first introduced in 1996 as a direct response to the first-ever color laser printer and has been delivering top performance ever since," said Verso Director for Digital Papers Dennis Essary. "Designed with a patented coated surface, Futura® offers users peace of mind with jam-free runnability and printability for unsurpassed productivity."

Futura® is known for optimal performance on dry and liquid toner printers, color and black and white laser printers, and digital offset technologies. It is guaranteed for digital offset and production laser equipment; guaranteed for the Xerox iGen series, HP Indigo certified by Rochester Institute of Technology and Kodak NexPress qualified by the Rochester Institute of Technology.

"Push Performance to the Limit shows off the product's smooth 96 bright surface and demonstrates a variety of print techniques on Futura® gloss, dull and matte covers," said Essary. "Today's newest digital equipment can accommodate larger sheet sizes from 14.333"×26" to 14"×39" all the way up to a 20.75"×29.5" sheet, and Futura® can easily meet those growing needs."

Like all Verso digital papers, Futura® is precision cut to prevent paper edge bonding jams and duplex registration issues. Strict quality control yields ultra-clean paper, reducing paper dust contamination and increasing print productivity and equipment life. Verso digital papers are also vapor barrier wrapped to prevent moisture absorption that can lead to curling and jamming in digital equipment.

The Futura® product line is made in the USA and complies with Lacey Act requirements and also carries three chain-of-custody certifications: Forest Stewardship Council® (FSC®) (BV-COC-953662), Programme for the Endorsement of Forest Certification™ (PEFC™) (BVC-PERCCOC-US09000012) and Sustainable Forestry Initiative® (SFI®) (BV-SFICOC-US09000011).

Futura® is best suited for high-end marketing collateral, advertising, annual reports, photo books and brochures, and its 7 pt. and 9 pt. caliper covers meet United States Postal Service requirements for postcards and direct mail.

To learn more about Verso's Futura® product line visit versoco.com.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. The FSC® trademark license code for Verso Corporation is FSC® C014984. For more information, visit us online at versoco.com.

ÅF reduces sulphur emissions at Skutskär Mill in Sweden

ÅF has been commissioned by Stora Enso to build a new lean gas system at Skutskär Mill to reduce sulphur emissions and improve the smell in the surrounding area. The assignment is an end-to-end solution worth about SEK 10 million. The new system is expected to be operational in autumn 2017.

The assignment includes project management, process design, piping design, electricaland automation, construction and fire safety.

“A major technical challenge is finding an optimal process design that connects the dispersed odorous gases in the factory to a pipe system for combustion,” says Stefan Hännestrand, project manager at ÅF. “This project requires expertise and collaboration between disciplines.”

In addition to a new lean gas system, ÅF was entrusted to modernise the control systems on the roll cutters at Skutskär Mill, a project that has been ongoing since 2015.

ÅF was also recently commissioned by Stora Enso to plan a new chemical plant at Skoghall Mill.

For further Information:

Stefan Hännestrand, project manager, ÅF, +46 (0)10 505 86 88, This email address is being protected from spambots. You need JavaScript enabled to view it..

Lars Olsson, account manager, ÅF, +46 (0)10 505 87 12, This email address is being protected from spambots. You need JavaScript enabled to view it..

ÅF is an engineering and consulting company for the energy, industrial and infrastructure markets, creating progress for our clients since 1895. By connecting technologies we provide profitable, innovative and sustainable solutions to shape the future and improve people's lives. Building on our strong base in Europe, our business and clients are found all over the world.

ÅF – Innovation by experience.

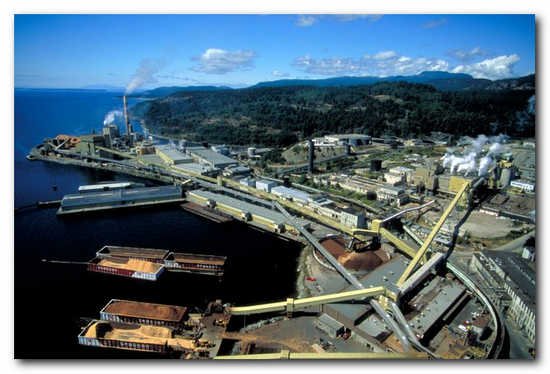

Powell River G13 Turbine Project Wins National Energy Conservation Leadership Award

Catalyst Paper have just announced that its Powell River mill has won the prestigious Canadian Industry Program for Energy Conservation (CIPEC) Leadership Award. Powell River was recognized in the category of Energy Performance Management in recognition of its successful installation of the G13 Turbine.

The G13 Turbine, which was installed in 2015, converts waste steam to electricity, increasing the mill's power output by 8 megawatts, enough to power almost 7,000 homes. The $24 million project was developed in partnership with BC Hydro and was completed in the fall of 2015.

The G13 Turbine, which was installed in 2015, converts waste steam to electricity, increasing the mill's power output by 8 megawatts, enough to power almost 7,000 homes. The $24 million project was developed in partnership with BC Hydro and was completed in the fall of 2015.

"This award recognizes the tremendous efforts of our team to reduce costs, create efficiency and support our commitment to environmental sustainability," said Fred Chinn, Vice President & General Manager, Powell River Mill. "It's a critical part of our effort to revitalize the mill for the future to ensure our long-term sustainability."

Award recipients were selected by the Industry Division of Natural Resources Canada's Office of Energy Efficiency. G13 was selected because it demonstrates achievements in energy efficiency and environmental stewardship, and is well aligned with the Government of Canada's commitment to advancing its clean growth agenda.

"I would like to commend Catalyst Paper on their CIPEC Leadership Award. Their innovative Powell River Mill project demonstrates how new technologies help reduce the environmental impacts of energy production and output," said Kim Rudd, Parliamentary Secretary to the Minister of Natural Resources. "Their commitment to improving environmental sustainability and energy efficiency is impressive and a great example to other manufacturers."

The award was presented on May 17 at an awards dinner in Niagara Falls, Ontario as part of the Energy Summit 2016 conference.

About Catalyst Paper

Catalyst Paper manufactures diverse printing papers such as coated freesheet, C1S, coated and uncoated groundwood, newsprint, directory, as well as market pulp. Customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada, and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.

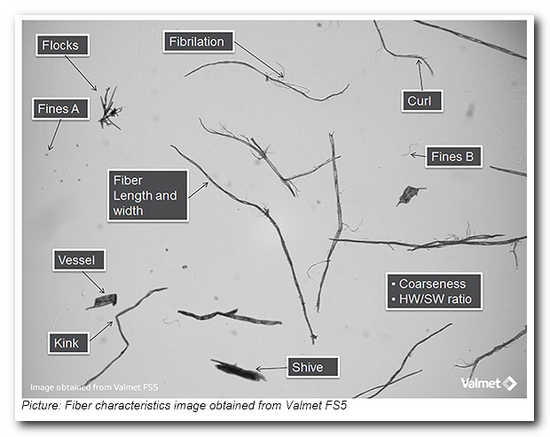

Valmet adds new capabilities to the fiber image analyzer

Valmet adds new measurement capabilities to Valmet Fiber Image Analyzer (Valmet FS5). These features take the laboratory testing of pulp and paper fiber samples to a new level.

Launched in 2013, more than sixty Valmet FS5 analyzers are now in use, continuing Valmet's 30 year fiber analytics history with more than 1000 fiber property measurements delivered. Fully meeting the ISO fiber length measurement standard requirements, the analyzer is simple to use with no lengthy training needed. Easily measuring the fiber properties of 100 samples in an eight hour shift, the automatic consistency adjustment eliminates operator error by allowing samples to be inserted without any special preparation.

Analyzers are individually customizable, equipped with only the required measurements and easily programmable for customized analysis and reporting. Maintenance requirements are minimal and no on-site calibration is required as each unit is calibrated with an accredited calibration tool at Valmet's production center in Kajaani, Finland.

New measurements predict end product quality better

The strength potential of the pulp can now be predicted easily from the process samples. Better understanding of the characteristics of the fibers helps papermakers to manage better the process and get targeted end product quality by optimizing the blend and using less energy, for example, in grinding.

"The new gravimetric coarseness feature in Valmet FS5 has been accepted very well by our customers. The true coarseness value is an important value which predicts the paper structure and now it is possible to get this result easier and faster than ever before without tedious and time consuming sample preparation. Our approach of combining both optical and gravimetric coarseness values is a result of out-of-box thinking by our R&D - helping our customers to save time and money," says Tuomo Kälkäjä, the product manager of Valmet FS5.

Cell wall thickness and cross sectional area, available in a previous generation of Valmet's analyzer, is also now derived by the Valmet FS5 which reports average values for the whole sample. Results provide a better understanding of the paper making potential of the pulp.

Improvements to the operator interface

Based on user feedback Valmet has implemented improvements to the operator interface, including customizable measurement templates and reports. Valmet FS5 is now easier than before to use in regular mill testing, and it also meets the requirements of research laboratory use. The increased capabilities offered by these new measurements and improved interface are also available as upgrades for existing users.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

FITNIR Secures Landmark Project with APP Mill

FITNIR ANALYZERS SECURES LANDMARK PROJECT WITH APP MILL IN SOUTHERN INDONESIA

FITNIR Analyzers Inc. is opening its doors to the Asian market with its largest single online FT-NIR analyzer implementation to date. This landmark project was secured with APP’s (Asia Pulp and Paper) newest mill site, PT OKI Pulp & Paper Mills, located in Southern Sumatra, Indonesia. “It’s exciting to be on the ground floor with this new mill,” said Tom Sands, President of FITNIR Analyzers, “Having our technology contribute to the efficiency and productivity of a leading-edge operation is a major win for us.”

FITNIR Online will measure key pulp liquor properties from the mill’s recaust and recovery streams. This data will feed into a supervisory control system for process optimization. Expected to be the world’s largest pulp mill once operational, a total of two analyzers and six field sample stations will be implemented to provide fundamental liquor properties at strategic process locations for optimal control.

FITNIR Online will measure key pulp liquor properties from the mill’s recaust and recovery streams. This data will feed into a supervisory control system for process optimization. Expected to be the world’s largest pulp mill once operational, a total of two analyzers and six field sample stations will be implemented to provide fundamental liquor properties at strategic process locations for optimal control.

“This is the first project for FITNIR in the Asian market and we believe a proven system of that magnitude will open doors for us throughout Asia,” stated Thanh Trung, FITNIR’s Vice President of Technology. FITNIR is working in coordination with Elof Hansson International of Sweden. Elof Hansson facilitated the project contract and will provide local support and implementation services. Analyzer implementation is expected to commence in the fall of 2016.

About PT OKI Pulp & Paper Mills

PT OKI Pulp and Paper Mills, Asia Pulp and Paper Group’s (APP) newest mill located in Southern Sumatra, Indonesia, is slated for a production of 8,000 air dry tonnes of pulp per day. APP, one of the world’s leading pulp and paper manufacturers, is responsible for delivering quality products to meet the growing global demand for tissue, packaging and paper. Founded in 1972, APP now runs operations across Indonesia and China with an annual combined pulp, paper, packing product and converting capacity of over 19 million tons per annum. Today, APP markets its products in more than 120 countries across six continents.

About FITNIR Analyzers Inc.

FITNIR’s automated online and benchtop analyzers reliably measure complete pulp liquor compositions. Fast, frequent and accurate measurements drive control strategies that decrease process variability and environmental impact for improved efficiencies and profitability. Proven applications for the digester, recausticizer, recovery boiler, ClO2 generator, brownstock washer, and now kappa measurements for wet and dry pulp, FITNIR is the next generation of process analyzers. Visit www.fitnir.com.

About Elof Hansson International

Elof Hansson International is an international Trading House and Service Provider focusing mainly on the Pulp & Paper Industry. With its sales and services offices in South America, Middle East and Asia, it connects suppliers and customers around the world. Elof Hansson represents suppliers in many segments, but focuses to a large extent on laboratory equipment as well as on-line/in-line analysis equipment and supervisory control programs.

For further information please contact:

FITNIR Analyzers Inc.

Thanh Trung, Vice-President of Technology

+1 (604) 221 2230

This email address is being protected from spambots. You need JavaScript enabled to view it.

Elof Hansson International.

Bjorn Olausson, President

+46 765 430791

This email address is being protected from spambots. You need JavaScript enabled to view it.

Anthony Shum, General Manager, Asia

+65 9009 0163

This email address is being protected from spambots. You need JavaScript enabled to view it.