Ianadmin

ANDRITZ successfully starts up the rebuilt board machine at Iggesund Paperboard mill, England

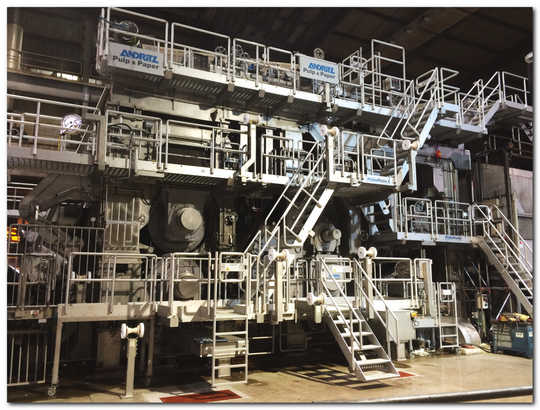

International technology Group ANDRITZ has successfully completed the board machine rebuilt at the Iggesund mill in Workington, England. The new, state-of-the-art press section delivered by ANDRITZ will increase the production capacity by 20,000 tons, reaching 220,000 tons per year, and will further enhance the product quality and runability of the board machine at the same time. Energy consumption has also been reduced by almost 10 percent.

ANDRITZ has successfully installed and started up the new press section at Iggesund Paperboardʼs Workington mill, England. “Photo: ANDRITZ”.

ANDRITZ has delivered a turnkey solution including basic and detailed engineering – a complete new press section with three presses: a jumbo press (LNP) with large-diameter rolls, a PrimePress X shoe press in the second nip, as well as a smoothing press. The new PrimeFeeder for ropeless tail threading from press section to dryer section is a state-of-the-art vacuum tail threading system that reduces the threading time and makes the threading process safer for the operators due to its remote control function.

The scope of supply also comprised a new FibreSolve FSU under-the-machine pulper, field instrumentation, PrimeControl machine control systems, multi-motor drive integration into the existing drive system for 13 motors, the motor control center (MCC), electrification, and new wire section drives and press section drives. Full erection services, including supervision, commissioning, start-up, and optimization after start-up, were also performed by ANDRITZ.

“Looking back, this was a super job by both our own staff and the contractors involved,” says Ulf Löfgren, Managing Director of the Workington mill. “They worked day and night to give us the best possible results.”

“We are very pleased that we have been able to complete this important project for Iggesund Paperboard to the full satisfaction of our customer. The very good cooperation between Iggesund and ANDRITZ made it a big success. We are very proud of this project,” says Roland Scheiflinger, Vice President Paper and Board at ANDRITZ.

Valmet to supply brown stock washing plant modernization to Södra Cell's Mörrum pulp mill in Sweden

Valmet will supply a modernization of the brown stock washing plant of the dissolving line to Södra Cell's Mörrum pulp mill in Sweden. The rebuild is part of the second stage of a long-term initiative at Södra Cell Mörrum mill.

The brown stock washing plant rebuild will increase the mill's pulp production capacity by 45,000 tons. The project will commence in spring 2016 and is scheduled for completion in the fourth quarter of 2017.

The order is included in Valmet's second quarter 2016 orders received. The value of the order will not be disclosed. A rebuild with this scope is usually valued below EUR 10 million.

"The successful cooperation with Valmet on the dissolving line that began in 2011 continues with the next step. The investment will enable increased production and increased opportunities to further enhance the production quality of our dissolving pulp," says Martin Säll, Engineer and Project Manager at Södra Cell Mörrum.

During the strategy period 2014-2020, Södra Cell Mörrum will gradually offer larger volumes and expand production capacity from 380 000 tons to 500 000 tons of which 200 000 tons will consist of high quality dissolving pulp.

Technical details about the delivery

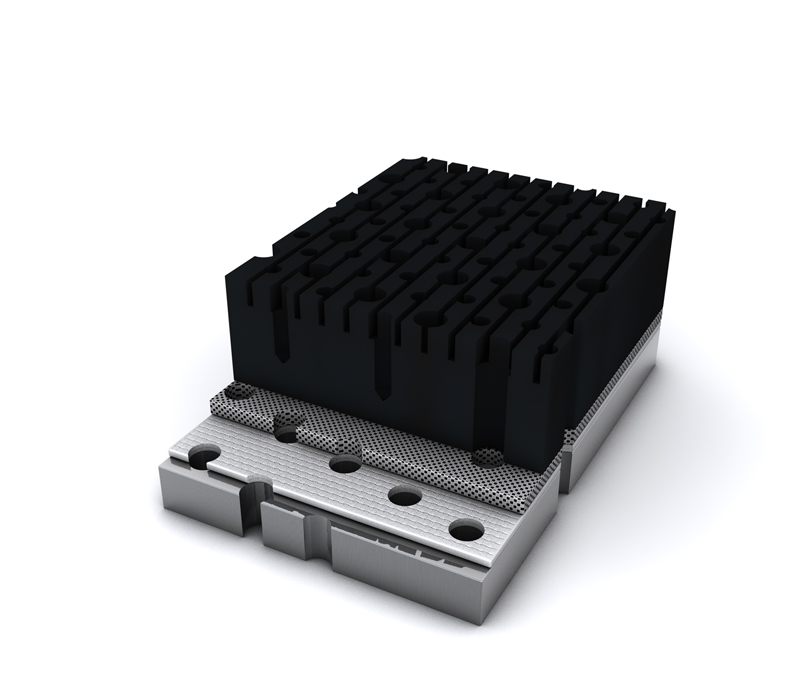

The modernization of the brown stock washing plant mainly contains the installation of three new Valmet TwinRoll presses, two before the oxygen stage and one before the bleach plant.

"The latest Valmet TwinRoll generation takes dewatering and washing to a new level by increasing capacity by up to 30 percent, improving consistency, and optimizing operation while minimizing operational and maintenance costs.Our TwinRoll presses have proven their functionality in several dissolving lines over the years. We are confident that this is a good solution for Mörrum mill and look forward to a great collaboration also in this project," says Mikael Gustafsson, Sales Manager at Valmet.

About the customer Södra Cell

Södra is an economic association with a membership base of 51,000 forest owners in southern Sweden. Södra has built up a considerable production of paper pulp, wood products and biofuels. Södra employs about 3,800 people and has four business areas Södra Skog, Södra Cell, Södra Timber and Södra Interiör.

Södra Cell is one of the largest players in the world in the area of softwood pulp and operates three pulp mills in Sweden: Mörrum, Mönsterås and Värö. Södra Cell Mörrum currently produces high-quality pulp and is the only Södra mill to produce textile pulp, for which demand is growing rapidly.

For further information, please contact:

Mikael Gustafsson, Sales Manager, Pulp & Energy Business Line, Valmet tel. +46 70 653 38 09

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

BW Papersystems at drupa 2016: impressive range of stationery converting solutions plus live demonstrations of folio sheeter and ream wrapper

At drupa 2016, visitors to BW Papersystems’s booth 10D20 will not only see live demonstrations of an eCon folio sheeter and a Wrapmatic GREC folio size ream wrapper, but also will be able to find out about the group’s extensive machinery range for stationery products like exercise books, note pads and spiral or wire bound products.

The greatly enhanced stationery product range of BW Papersystems, after the addition of the paper processing product division of Bielomatik, now includes three brands: BW Bielomatik, Kugler-Womako and WillPemcoBielomatik.

Dedicated kiosks on the booth of 458 sqm will inform about the variety of available solutions. Part of the portfolio, for example, are now high-productive, fully automatic exercise book machines for medium to high output of max. 36,000 exercise books/hour. The lines are Z-shaped for a compact layout that allows for easy access to deep pile and stitching unit and can be operated with 1 or two webs. Entry-level machines for small to medium output of max. 18,000 exercise books/hour complete the portfolio.

Semi and fully automatic machines for the production of steel and PVC spiral as well as double wire note pads offer extraordinary product quality, flexibility and additionally convince with high production output for medium and large runs. The modular concept and the economic design fulfills basically every production requirement. Stand-alone or inline double wire forming machines are available as well. A newly developed, double wire binding machine from the brand Kugler-Womako, the ProFlex, is ideal for cost-efficient, entry-level binding of notepads.

Another kiosk will be dedicated to digital print converting – including an innovative book converting method for digitally printed softcover books, flexible sheeters for digital paper sizes and book-on-demand binding solutions for hardcover books for small order volumes starting already from a single book.

Additionally, visitors can find information about RFID transponder laminating and finishing solutions, including reel-to-reel converting machines for dry and wet inlays and chip modules. A modular machine concept suits entry level to high end production needs.

There is a lot to discover at the booth of BW Papersystems! From May 31 to June 10, live machine demonstrations will take place every day, showing the cut quality and reliability of the eCon folio sheeter as well as the precise wrapping and flexibility of the GREC folio ream wrapper.

BW Papersystems, MarquipWardUnited, WillPemcoBielomatik, Kugler-Womako and BW Bielomatik look forward to welcoming you at drupa 2016 – see you in hall 10, booth D20. We are Paper Converting. We are BW Papersystems

Stora Enso evaluates expansion of Ostrołęka Mill production

Stora Enso has decided to commence a feasibility study with the aim of expanding containerboard production at Ostrołęka Mill in Poland by 500 000 tonnes annually. The findings of a recently completed pre-feasibility study supported continuation of the process. The feasibility study, which is expected to be completed by the end of 2016, will evaluate the profitability of the possible expansion. The studied investment will be cost competitive and it has synergies with the newest containerboard machine in Ostrołęka, which went into production in 2013.

Stora Enso has decided to commence a feasibility study with the aim of expanding containerboard production at Ostrołęka Mill in Poland by 500 000 tonnes annually. The findings of a recently completed pre-feasibility study supported continuation of the process. The feasibility study, which is expected to be completed by the end of 2016, will evaluate the profitability of the possible expansion. The studied investment will be cost competitive and it has synergies with the newest containerboard machine in Ostrołęka, which went into production in 2013.

If the investment is approved following the feasibility study, the capital expenditure for the expansion is estimated to be in the range of EUR 350-400 million over a couple of years.

Stora Enso’s long term investment criteria is to keep the capital expenditure into fixed assets approximately at the same level as depreciation. The planned investment at Ostrołęka Mill would fit this frame. In addition to fixed asset investments, Stora Enso invests approximately EUR 100 million annually in biological assets.

“Poland is a large and growing market where we have a strong presence and customer base. Stora Enso regularly conducts feasibility studies to explore potential expansion opportunities. The decision regarding a possible expansion at Ostrołęka Mill will be made once the assessment is completed,” says Gilles van Nieuwenhuyzen, EVP Division Packaging Solutions.

For further information, please contact:

Carl Norell, SVP Communications, Division Packaging Solutions, tel. +46 722 410 349

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Our aim is to replace fossil based materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 26 000 people in more than 35 countries, and our sales in 2015 were EUR 10.0 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market. storaenso.com

Metso continues to expand its strong local presence: New valve service center in Poland in operation

Metso has opened a new service center specialized in process valve and field equipment solutions in Poland. The center has a key role in supporting pulp and paper, refinery and petrochemical industry customers with daily services, shutdowns and long-term maintenance programs. This investment enables Metso to continue strengthening its unique flow control service model to support its customers' businesses.

Metso is responding to the growing demand for local valve expertise close to its customers by opening a service center in the city of Torun in northern Poland. Services are provided for Metso and third-party field devices, including valves, actuators and smart devices. In addition, the new center provides spare parts as well as a wide range of field support and diagnostic services.

Metso is responding to the growing demand for local valve expertise close to its customers by opening a service center in the city of Torun in northern Poland. Services are provided for Metso and third-party field devices, including valves, actuators and smart devices. In addition, the new center provides spare parts as well as a wide range of field support and diagnostic services.

"We continuously improve our service capability, knowledge and scope of offering to help our customers achieve outstanding long-term process performance with high reliability and safety. Our flow control service network is very unique and enables excellent service levels for our customers globally," says Timo Hänninen, Vice President, Services business line, Metso's Flow Control.

The center is ideally located close to pulp and paper, refinery and petrochemicals customers in the Central and Eastern European region. The facility houses a valve service center, office premises and warehouse to keep an inventory of the most commonly required valve package components needed for emergency and scheduled repair and maintenance services. The modern service center accommodates professional personnel who are factory certified to ensure the highest quality of work. This guarantees the capability to service a large number of valves that meet customers' high-volume, fast-turnaround repair and maintenance needs during scheduled plant shutdowns.

Metso is a trusted partner for Grupa Lotos

Metso has had a long-term customer relationship with Grupa Lotos, one of the largest oil refineries in Poland. The Grupa Lotos and Metso cooperation dates back to 1980 when the first valves were delivered to the site. Since then, maintenance and service cooperation has extended to cover intelligent maintenance, device management and inventory optimization. Metso has close to 1,000 on-off valves and control valves at the Lotos site in Gdansk.

Metso's service professionals will play a key role in supporting the turnaround activities at the refinery in Gdansk in 2017. With the help of Metso's intelligent shutdown solution, Grupa Lotos is improving plant reliability, availability and safety as well as optimizing maintenance costs. Metso's service experts can correctly select which equipment requires adjustment or repair thanks to the remote diagnostics enabled by Metso's intelligent controllers. Grupa Lotos has also entrusted its PSA unit valve maintenance to Metso.

Metso is expanding its network worldwide

"Our customers are looking for improved support from their suppliers. Life-cycle services are recognized as a major requirement and differentiation factor between different suppliers. Metso's answer to this requirement is to build a service network that provides professionals close to customers to support them in meeting their goals. Operational reliability, availability and safety are core KPIs for our customers. Metso wants to be its customers' preferred choice, helping meet their goals with optimized costs," states Piotr Kulisz, Country Manager in Poland.

Experienced in valves

Metso's extensive flow control services offering covers business solutions and services that optimize the use of equipment and total cost of ownership.

Metso manufactures all valves and spare parts according to international standards and quality systems. Original parts and Metso maintenance procedures guarantee the same quality and warranty that Metso offers for new products.

Metso's valve technology centers and valve production facilities are located in Finland, the United States, Germany, China, South Korea, India and Brazil. Metso's flow control services are available from more than 40 service centers worldwide.

Metso has solid experience in delivering engineered performance and reliability to oil and gas, pulp and paper, and power customers through its leading product brands - Neles® and Jamesbury® - and has delivered millions of control valves and on-off valves globally over the last 90 years. Metso's extensive Neles® control valve offering also includes standard and severe service globe valves, which offer reliability to most critical processes and operate at extreme pressures and temperatures. Additionally, Metso has become the leading supplier of intelligent valve controllers.

For further information, please contact:

Piotr Kulisz, Sales Manager, Metso, Poland, Tel. +48 22 381 72 42, Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

New MatchPress and MatchFlow Roll Covers from Voith

Two new roll covers, MatchPress for press rolls and MatchFlow for suction press rolls, are additions to Voith‘s product portfolio. MatchPress and MatchFlow are designed for graphic and packaging paper machines with a wire width of up to 6,000 mm and speeds up to 800 m/min. The new covers are specifically designed to meet the demands of these machines and enable the operator to lift production to a new level and thus gain a competitive advantage.

- Tailored to the requirements of small and medium-sized paper machines

- High dewatering performance through customized surface design

- Improved material characteristics for reduced wear

MatchPress and MatchFlow offer markedly improved material characteristics. These enable surface designs that increase dewatering capacity in the press section. Furthermore the material characteristics are key for the high wear resistance of the covers. Constant high grinding intervals can thus be achieved for the operator.

Unique groove dimensions and blind-drilled design in the covers guarantee high dewatering of the paper web. This effect is reinforced thanks to high open area of the new roll covers MatchPress and MatchFlow. This leads to higher production volumes or lower energy consumption. Initial runs in actual operating scenarios demonstrate these characteristics impressively: For example, a Voith customer was able to increase its annual production with MatchPress by 10,000 metric tons, or by nearly 4%.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

New biobased packaging, sustainable textiles and second generation biorefineries

Innventia is involved in three new European projects aiming for innovative solutions for a future bioeconomy. PULPACKTION will develop packaging solutions for specific food and electronic packaging applications. The objective for NeoCel is to processes enabling the sustainable production of textile fibres and the BIOSKOH project will showcase how a number of Innovation Stepping Stones can realise a breakthrough in techno-economic viability of lignocellulosic biorefineries. The three projects are all partially financed by BBI JU, a partnership between EU and the Bio-based Industries Consortium.

Today, products with medium and high barrier requirements such as specific food and electronic packaging applications are packed in polymer fossil based solutions. The new PULPACKTION project will develop 100% bio-based integral packaging solutions with similar properties to existing fossil-based solutions. This will be achieved by using wet-moulding production of wood pulp mixed with other bio-based compounds in order to tailor the properties of the final material. To fulfil the fully bio-based approach, new barriers of optimised biopolymers will be implemented onto the wet moulded substrate. PULPACKTION involves 13 partners and is coordinated by Rottneros Packaging. Innventia will be responsible for the activities regarding consumer insight and play an active role in the development, production and evaluation of new fibre formulations. Furthermore, Innventia will participate in investigating the performance of developed fibre formulations in pilot scale trials as well as sustainability evaluations of produced materials and concepts.

For information, contact This email address is being protected from spambots. You need JavaScript enabled to view it.

The driving force for the NeoCel project is the growing need for textiles produced from sustainable resources using environmentally friendly processes. The main objective is to develop innovative and techno-economically feasible alkaline processes which could be integrated with pulp mills. This will enable the sustainable production of higher quality eco-innovative textile fibres from reactive high-cellulose pulps. A consortium of 15 partners representing the whole chain from cellulose raw material to cellulose garments has been formed. Innventia with well renowned skills in pulping technology, chemical recovery/regeneration, advanced fibre characterisation and techno-economic evaluation plays an active part in most work packages. The consortium, coordinated by SP Technical Research Institute of Sweden, expects that a successful project will enable creation of 75,000 new jobs and a turn-over increase of Euro 9.5 billion for European forest products, textile and clothing industries within 15 years.

For information, contact This email address is being protected from spambots. You need JavaScript enabled to view it.

The BIOSKOH project will pave the way for a European bioeconomy by showcasing how a number of innovation stepping stones, such as yield, biomass cost, brownfield and industrial symbiosis, can realise a breakthrough in techno-economic viability of lignocellulosic biorefineries. The overall aim is to realise the largest second generation biorefinery in Europe and the first step is a flagship plant that will produce 55 kton of cellulosic ethanol per year for EU bio-fuel mandates. This will be built on a brownfield industrial site in the eastern part of the Slovak Republic. The BIOSKOH consortium is coordinated by Energochemica and involves 11 partners from 7 European countries. Partners include the full value chain starting from land owners and feedstock producers. Innventia is involved in lignin valorisation which is an important part in building the commercial concept.

For information, contact This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet AB delivers brown washing plant to Södra Cell Mörrum

In February 2016, Södra's Board of Directors decided to invest SEK 1 billion in a new evaporator and modernisation of the brown washing plant in the dissolving pulp line, where textile pulp is produced. Södra is now awarding Valmet AB the contract to supply the new brown washing plant.

Södra is growing together with its customers. During the 2014-2020 strategy period, Södra Cell Mörrum will gradually begin to offer larger volumes and increase production capacity from 380,000 tonnes to 500,000 tonnes, of which 200,000 tonnes will consist of high-quality dissolving pulp.

"The successful cooperation with Valmet AB in the dissolving pulp line that started in 2011 now continues with the next step. The investment will enable increased production and opportunities to further enhance the product quality of the dissolving pulp". Says Martin Säll, Project manager at Södra Cell Mörrum.

The start-up of the new upgraded pulp line is calculated to the fourth quarter 2017.

For further information, please contact:

Stefan Sandberg, mill manager Södra Cell Mörrum

+46(0)454-555 50

Navigating a Changing Specialty Papers Industry

Smithers Pira and TAPPI are excited to share an exclusive preview of the 2016 Specialty Papers US agenda. This year's agenda will focus on thriving and surviving in the changing specialty papers industry. It will provide you with the answers to the questions that are keeping you up at night.

Smithers Pira and TAPPI are excited to share an exclusive preview of the 2016 Specialty Papers US agenda. This year's agenda will focus on thriving and surviving in the changing specialty papers industry. It will provide you with the answers to the questions that are keeping you up at night.

Newly researched, with the assistance of our expert advisory board, the agenda will boast expert speakers from suppliers, mills and end-users. Many of your colleagues from around the industry have already made their plans to attend this year's conference and exhibition. We are anticipating our biggest conference to date!

What will you learn this September? Below is a snapshot of topics to be discussed by the most influential names in the industry:

- Thrive and Survive: a look at where the specialty papers trends are going

- Specialty Paper Packaging: packaging solutions from small sustainable packaging to larger luxury packaging

- Innovations with Specialty Papers

- Non-wood Pulps and Fibers

- And much more!

Valmet's Interim Review January 1 - March 31, 2016: Orders received, net sales and profitability increased

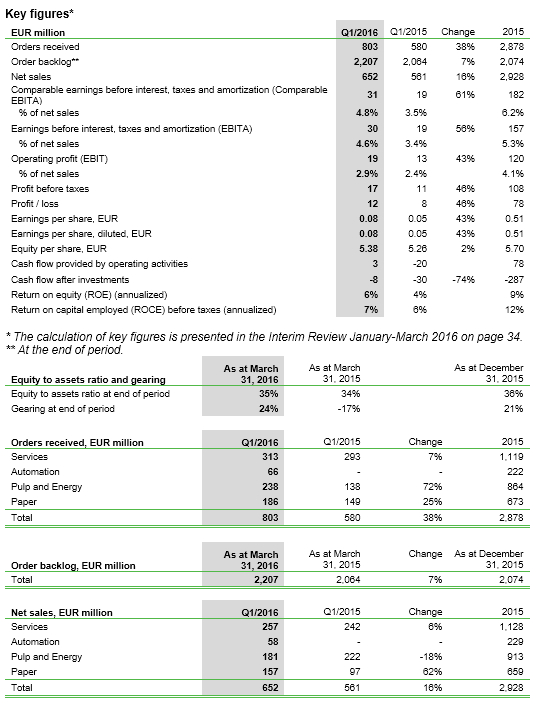

Figures in brackets, unless otherwise stated, refer to the comparison period, i.e. the same period of the previous year. Automation has been consolidated into Valmet's financials since April 1, 2015, when the acquisition of Automation was completed.

Due to new regulation by the European Securities and Market Authority concerning alternative performance measures, Valmet has decided to replace the performance measure 'EBITA before non-recurring items' with 'Comparable EBITA'. The content of items affecting comparability, i.e. items previously disclosed as non-recurring, remain unchanged and therefore 'Comparable EBITA' equals previously disclosed 'EBITA before non-recurring items'. Items affecting comparability consist of income and expenses arising from activities that amend the capacity of Valmet's operations or are incurred outside its normal course of business. Valmet discloses alternative performance measures to describe the underlying business performance and to improve comparability between reporting periods.

Due to new regulation by the European Securities and Market Authority concerning alternative performance measures, Valmet has decided to replace the performance measure 'EBITA before non-recurring items' with 'Comparable EBITA'. The content of items affecting comparability, i.e. items previously disclosed as non-recurring, remain unchanged and therefore 'Comparable EBITA' equals previously disclosed 'EBITA before non-recurring items'. Items affecting comparability consist of income and expenses arising from activities that amend the capacity of Valmet's operations or are incurred outside its normal course of business. Valmet discloses alternative performance measures to describe the underlying business performance and to improve comparability between reporting periods.

January-March 2016: Orders received, net sales and profitability increased

- Orders received increased to EUR 803 million (EUR 580 million).

- Orders received increased in the Pulp and Energy, Paper, and Services business lines.

- Automation contributed to orders received with EUR 66 million.

- Orders received more than doubled in EMEA (Europe, Middle East and Africa) and South America.

- Net sales increased to EUR 652 million (EUR 561 million).

- Net sales increased in the Paper and Services business lines and decreased in the Pulp and Energy business line.

- Automation contributed to net sales with EUR 58 million.

- Comparable earnings before interest, taxes and amortization (Comparable EBITA) were EUR 31 million (EUR 19 million), and the corresponding Comparable EBITA margin was 4.8 percent (3.5%). Earnings per share were EUR 0.08 (EUR 0.05).

- Profitability improved due to the higher level of net sales in Paper and Services business lines, improved gross profit, and the acquisition of Automation.

- Items affecting comparability amounted to EUR -2 million (EUR 0 million).

- Cash flow provided by operating activities was EUR 3 million (EUR -20 million).

Valmet reiterates its guidance for 2016

Valmet is reiterating its guidance presented on February 9, 2016 in which Valmet estimates that net sales in 2016 will remain at the same level with 2015 (EUR 2,928 million) and Comparable EBITA in 2016 will increase in comparison with 2015 (EUR 182 million).

Due to new regulation by the European Securities and Market Authority, Valmet has decided to replace the performance measure 'EBITA before non-recurring items' with 'Comparable EBITA'. The content of items affecting comparability, i.e. items previously disclosed as non-recurring, remain unchanged and therefore 'Comparable EBITA' equals previously disclosed 'EBITA before non-recurring items' (EUR 182 million in 2015). Items affecting comparability consist of income and expenses arising from activities that amend the capacity of Valmet's operations or are incurred outside its normal course of business.

Short-term outlook

General economic outlook

The baseline projection for global growth in 2016 is a modest 3.2 percent, broadly in line with last year, and a 0.2 percentage point downward revision relative to the January 2016 World Economic Outlook Update. The recovery is projected to strengthen in 2017 and beyond, driven primarily by emerging market and developing economies, as conditions in stressed economies start gradually to normalize. But uncertainty has increased, and risks of weaker growth scenarios are becoming more tangible. The fragile conjuncture increases the urgency of a broad-based policy response to raise growth and manage vulnerabilities. (International Monetary Fund, April 12, 2016)

Short-term market outlook

Valmet reiterates the good short-term market outlook for board and paper, and the satisfactory short-term market outlook for services, automation, pulp, energy, and tissue.

President and CEO Pasi Laine: Solid start of the year with increase in orders received, net sales and profitability

Valmet had a solid start of the year 2016 with an increase in orders received, net sales and profitability. Orders received increased in Pulp and Energy, Paper, and Services business lines. As a result of both customer activity and good work in all parts of the organization, the orders received development has been trending upwards in all business lines. The orders received were at an all-time high level in the Services business line. Profitability improved in the first quarter of the year compared to the first quarter of 2015.

Automation has now been a part of Valmet for a full year, and I am very pleased with the development. Summing up the year from the Automation perspective, the integration was a success. Both customers and employees are pleased and energized, we launched new automation products during the year, strengthened Valmet's position in Industrial Internet and, in financial terms, we can be satisfied with the development of the Automation business line. Furthermore, our four business lines have found a good and continuously improving way to cooperate in the customer interface and to bring benefits of our unique and market's widest offering to our customers.

News conference and webcast for analysts, investors and media

Valmet will arrange a news conference in English for investment analysts, investors, and media on Wednesday, April 27, 2016 at 2:00 p.m. Finnish time (EET). The news conference will be held at Valmet Head Office in Keilaniemi, Keilasatama 5, 02150 Espoo, Finland. The news conference can also be followed through a live webcast at www.valmet.com/webcasts.

It is also possible to take part in the news conference through a conference call. Conference call participants are requested to dial in at least five minutes prior to the start of the conference, at 1:55 p.m. (EET), at +44 1452 560304. The participants will be asked to provide the following conference ID: 82571086.

During the webcast and the conference call, all questions should be presented in English. After the webcast and the conference call, media has a possibility to interview the management in Finnish.

The event can also be followed in Twitter at www.twitter.com/valmetir.

Further information, please contact:

Hanna-Maria Heikkinen, Vice President, Investor Relations, Valmet, tel. +358 10 672 0007

Kari Saarinen, Chief Financial Officer, Valmet, tel. +358 10 672 0031