Ianadmin

Cohoes-Based Manufacturer Continues to Lead Nation in Renewable Energy Use and Green Initiatives

Mohawk Walks the Talk: Cohoes-Based Manufacturer Continues to Lead Nation in Renewable Energy Use and Green Initiatives

EPA Names Mohawk to National ‘Top 100 List’ of Environmental Green Power Users

Environmental commitment, social responsibility and corporate stewardship are woven into the fabric of Mohawk’s culture and business practices.

Cohoes-based Mohawk, North America’s largest privately-owned manufacturer of fine papers, envelopes and specialty substrates for commercial and digital printing, continues to lead the paper industry in environmental and sustainable practices, and has been recognized by the U.S. Environmental Protection Agency ‘National Top 100 List’ of Green Power Users for the eleventh year in a row.

11 Years of EPA Recognition on ‘National Top 100 List’

As of April 8, 2016, Mohawk ranks 77th in the nation for green power use, and has been named to the EPA 100% Green Power Users list for using wind power to meet 100 % of the company’s electricity use.

Since 2007, 100% of electricity used in Mohawk’s operations is matched with Green-e certified Renewable Energy Certificates (RECs). Mohawk ranks among other leading renewable energy purchasers including Google, REI, American Express, JP Morgan Chase, The Estee Lauder Companies, Starbucks, Herman Miller and Apple.

The National Top 100 list represents the largest green power users within the EPA Green Power Partnership, which is a voluntary program that encourages organizations to use green power as a way to reduce the environmental impacts associated with conventional electricity use. Partners include a wide variety of leading organizations such asFortune 500® companies, small and medium sized businesses,local, state and federal governments, as well as colleges and universities.

“As a paper manufacturer, we have always understood that our dependence on basic resources such as water, wood fiber and energy creates a unique responsibility for environmental stewardship. We continue to examine each aspect of our business with the objective of minimizing our environmental footprint in every way practicable. Environmental responsibility is at the core of Mohawk’s company culture,” said Michelle Carpenter, Vice President, Environmental and Energy Stewardship, Mohawk.

Mohawk has also qualified for the U.S. EPA SmartWay Partnership, a program of the U.S. EPA designed to reduce transportation-related emissions by creating incentives to improve supply chain efficiency.

Mohawk efficiently transports paper products across the country on a regular basis, and the company’s logistics team is recognized for optimizing shipping methods and routes, and using biodiesel in the Mohawk truck fleet.

Longstanding environmental alliances and partnerships

Mohawk takes pride in the company’s numerous environmental partnerships and certifications, including longstanding alliances with:

• US Environmental Protection Agency (EPA) Green Power Partnership

• EPA SmartWay Transport Partnership

• Center for Resource Solutions Green-e Marketplace

• Green Seal (celebrating a 22-year affiliation)

• The Rainforest Alliance

• The Forest Stewardship Council (FSC)

As a leader in environmentally and socially responsible business practices, Mohawk was the first U.S. manufacturer of commercial printing papers to match 100% of its electricity with wind power renewable energy credits and the first U.S. premium paper mill to shift toward carbon neutral production. Mohawk’s portfolio of recycled papers is certified by Green Seal and the Forest Stewardship Council (FSC).

Engaging Employees and Community

From a community standpoint, Mohawk encourages its employees to volunteer in their communities and participate in the company’s annual Earth Day clean-up. Employees at all Mohawk locations (Cohoes, Waterford and Albany, NY; South Hadley, MA, and Saybrook, OH) are encouraged to clean up parks, sidewalks, and other community areas in the vicinity of their workplaces on Earth Day each year. Employees are incentivized to pitch in, and educate themselves about responsible use of energy, water and other natural resources.

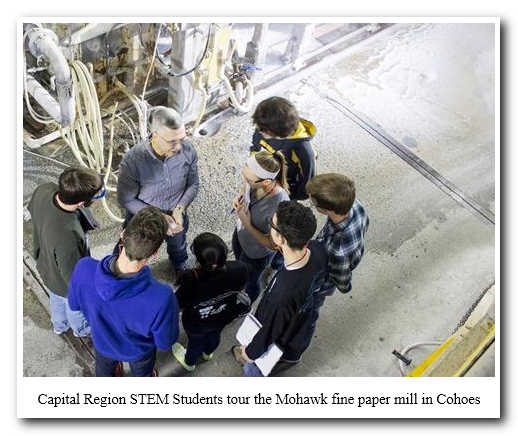

Supporting STEM Education

Mohawk is engaging students in the New York State New Visions STEM (Science, Technology, Engineering & Math) Questar III program in an effort to foster a new generation of leaders in renewable energy.

Mohawk provides real world, practical experiences for high school seniors participating in STEM programs through Rensselaer Polytechnic Institute. The students participate in laboratory experiments as well as interact with scientific professionals.

Most recently, Mohawk hosted several STEM student presentations exploring innovative clean energy technologies and carbon reduction projects that could appeal to Mohawk. Students from around the Capital Region presented projects to Mohawk executives spanning topics such as harnessing wind and wave energy, maximizing use of solar and fusion technologies, exploring biofuel and geothermal energy sources and exploration of solid oxide fuel cells for energy.

For more information about Mohawk’s environmental and sustainable business practices, visit http://www.mohawkconnects.com/company/environment.

ABOUT MOHAWK

Mohawk is North America’s largest privately-owned manufacturer of fine papers and envelopes which are preferred for commercial and digital printing, photo specialties and high-end direct mail. Mohawk fine papers and envelopes include the signature brands Mohawk Superfine® and Strathmore®, as well as proprietary treatments Inxwell® and i-Tone®. With a culture of innovation, Mohawk’s business model now extends beyond paper manufacturing into new areas of growth, including non-paper substrates for digital printing.

Mohawk is a fourth-generation, family-owned and operated business based in Cohoes, New York, with global sales and operations located throughout North America, Europe and Asia. For more information, please visit www.mohawkconnects.com.

Supplier for billion-krona investment selected for Södra Cell Mörrum

In February 2016, Södra’s Board of Directors decided to invest SEK 1 billion in a new evaporator and modernisation of the brown stock washing system in the dissolving pulp line, where textile pulp is produced. Södra is now awarding ANDRITZ Oy, a subsidiary of the international technology Group ANDRITZ, the contract to supply the evaporator.

Södra is growing together with its customers. During the 2014-2020 strategy period, Södra Cell Mörrum will gradually begin to offer larger volumes and increase production capacity from 380,000 tonnes to 500,000 tonnes, of which 200,000 tonnes will consist of high-quality dissolving pulp.

On 18 March, Södra awarded ANDRITZ Oy, a subsidiary of the international technology Group ANDRITZ, the contract to supply a new evaporation plant for the pulp mill in Mörrum. The start-up is planned for the fourth quarter of 2017.

“We are looking forward to increasing the volume of Södra Cell Mörrum’s leading-edge products. Together with Andritz, we will build a highly technological evaporator that not only reinforces the energy efficiency of our pulp mill, but also strengthens and improves the process as a whole,” said Stefan Sandberg, Mill Manager, Södra Cell Mörrum

A new evaporator will make it possible for Södra to increase its production rate while also enabling larger deliveries of energy products, such as electricity, district heating and biofuels. The new investment will increase production capacity by 45,000 tonnes, bringing the total production of paper and dissolving pulp to 470,000 tonnes.

The new 7-effect evaporator represents an important step in Södra Cell Mörrum’s strategy plan to expand its production capacity. The evaporation plant will produce lye with a high content of dry solids, and replace the existing evaporation lines while considerably improving the energy efficiency of the mill. This will lead to a significant energy surplus at the mill, in turn enabling increased energy supplies.

Read more: major investment in Morrum

For further comments:

Stefan Sandberg, Site Manager at Södra Cell Mörrum,

+46 (0)70-638 78 78

Metsä Board's new folding boxboard machine at Husum mill inaugurated

In early April, Metsä Board, part of the Metsä Group, had its new folding boxboard machine at Husum in Sweden inaugurated with the Swedish Minister for Enterprise and Innovation, Mikael Damberg, attending the ribbon-cutting ceremony. Among others, project partners, as well as local authorities and businesses, were also invited to the inauguration ceremony.

After considerable structural changes Husum mill is now an integrated site concentrating on paperboard and pulp manufacturing. It is also a significant local employer. The EUR 170 million investment programme included a folding boxboard machine BM1 supplied by Valmet as well as enhancements to the pulp mill and the mill site’s own port. The capacity of the new machine is 400,000 t/a. The company is targeting the volume at the Americas and at food service end-uses globally.

“The Husum mill site has the best available technology, people with extensive know-how and access to an ideal location by the sea where the mill has its own port. These important success factors will also support our customers in their businesses,” says Mika Joukio, CEO of Metsä Board.

Last November, Metsä Board announced an additional EUR 38 million investment in a new extrusion coating line and related infrastructure at Husum. This line will be taken into use during the first half of 2017. With this investment the company will be able to further improve its offering to food and food service end-uses.

Metsä Board is a leading European producer of folding boxboards and white linerboards made from fresh forest fibres. Its lightweight paperboards are developed as the perfect fit for consumer goods, retail-ready and food service packaging. The pure fresh forest fibres Metsä Board uses are a renewable resource, traceable to origin in northern forests.

Metsä Board is a leading European producer of folding boxboards and white linerboards made from fresh forest fibres. Its lightweight paperboards are developed as the perfect fit for consumer goods, retail-ready and food service packaging. The pure fresh forest fibres Metsä Board uses are a renewable resource, traceable to origin in northern forests.

The global sales network of Metsä Board supports customers worldwide, including brand owners, converters and merchants. In 2015, the company’s sales totalled EUR 2.0 billion, and it has approximately 2,600 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

www.metsagroup.com

Metsä Group is a forerunner in bioeconomy utilising renewable wood from sustainably managed northern forests. Metsä Group focuses on tissue and cooking papers, fresh forest fibre paperboards, pulp, wood products, and wood supply and forest services.

Metsä Group’s sales totalled EUR 5 billion in 2015, and it employs approximately 9,600 people. The Group operates in some 30 countries. Metsäliitto Cooperative is the parent company of Metsä Group and is owned by approximately 116,000 Finnish forest owners.

Global Forest Products Industry is Part of the Solution to Climate Change

The International Council of Forest and Paper Associations (ICFPA) and its members welcome the signing of the landmark United Nations agreement to tackle climate change, set to take place on April 22. The agreement urges countries to implement policies that would allow them to keep a global temperature rise below 2 degrees Celsius. The global forest products industry has a highly significant role to play in the implementation of these targets.

The International Council of Forest and Paper Associations (ICFPA) and its members welcome the signing of the landmark United Nations agreement to tackle climate change, set to take place on April 22. The agreement urges countries to implement policies that would allow them to keep a global temperature rise below 2 degrees Celsius. The global forest products industry has a highly significant role to play in the implementation of these targets.

“The global forest products industry has made significant strides in reducing its carbon footprint, stocking carbon, and generating greenhouse gas removals – all helping to mitigate climate change”, said ICFPA President and Brazilian Tree Industry (Ibà) President Elizabeth de Carvalhaes. “This agreement is crucial to implementing some of the policies that consider biomass as carbon neutral when harvested from sustainably managed forests and to further recognize all positive contributions that forests and forest products provide in combating climate change.”

The inherently-renewable global forest products industry remains committed to mitigating climate change for the benefit of the green economy and society at large. ICFPA members have achieved an impressive 5% reduction in their greenhouse gas emissions intensity since 2010/2011 and 17% since the 2004-2005 baseline year (2015 ICFPA Sustainability Progress Report).

The European pulp and paper industry has been a global champion in mitigating greenhouse gas emissions. It has set itself in 2011 a clear vision of becoming carbon neutral by 2050 and since then, taken concrete steps to reach that goal,” said Jori Ringman, Acting Director General of Confederation of European Paper Industries (CEPI). “Thanks to responsible sourcing practices and sustainable forest management, the forest area is growing in Europe by an area of over 1,500 football pitches per day. CEPI is pleased to see development in the same direction globally”, he added.

The forest industry’s significant role in mitigating climate change was highlighted in the ICFPA-commissioned report Analysis of Forest Contributions to the INDCs by acclaimed researcher Paulo Canaveira. Having looked at the contributions of forests in the national targets of ICFPA member countries (INDCs) and global mitigation effort from 2020 onwards, the report concludes that many countries identify forests and the land-use sector as relevant to policies and measures implemented to meet their targets. Reducing emissions from deforestation, but also sustainable forest management, afforestation and reforestation are commonly mentioned as key mitigation practices. In some developing countries, they even constitute the country’s main contributions.

Other climate change mitigation efforts of the global forest products industry include supporting national and regional climate policies and programs; investing in technologies with low carbon footprints and ones that improve carbon sequestration; and developing bio-based technologies to find innovative ways to use wood fiber and substitutes for goods traditionally made from fossil fuels.

The ICFPA represents more than 30 national and regional forest and paper associations around the world. Together, ICFPA members represent over 90 percent of global paper production and more than half of global wood production.

For more information about the global forest and paper industry, visit www.icfpa.org

Resistant ECO2 Air Actuators Open Up New Applications

ContiTech has extended its air actuator product range: The company is the first manufacturer in the world to offer air actuators made of an ECO compound with improved resistance to chemicals and environmental influences. The new ECO2 air actuators can now also be used in applications in which they are exposed to lubricating oils, corrosive vapors, and alkalis. One potential area of application, among many, is the paper industry. „Our ECO2 air actuators are ideally suited to the specific demands of this environment,” explains Verena Weiss, head of the Industry segment at ContiTech Air Spring Systems.

- New and improved ECO air actuators are now lead-free

- Improved resistance to chemicals and environmental influences allows for extensive use in the paper industry

- Acid- and corrosion-resistant stainless steel plates offer increased safety in challenging areas of application

The new ECO2 air actuators are resistant to chemicals and environmental influences and can now also be used in applications in which they are exposed to lubricating oils, corrosive vapors, and alkali compounds. Photo: ContiTech

ECO2 air actuators are made of the elastomer epichlorohydrin and are particularly suited to high-temperature applications. Depending on the design, they can be used at ambient temperatures of up to +130°C. ContiTech's new ECO2 compound is also lead-free, in response to the European Union's REACH regulation, as lead oxide is suspected of being harmful to health. This makes it a candidate for the hazardous chemical substances black list. „That's why we switched to a lead-free ECO2 compound, to ensure we would still be able to supply our products even if lead oxide is banned,” says Weiss.

The new and improved ECO2 air actuators are now part of ContiTech's product range and are available for almost all the models in the C, D, and R series. Further product development remains a possibility.

Acid- and corrosion-resistant: with new V4A stainless steel plates, ContiTech air actuators meet the specific requirements of the chemical industry. Photo: ContiTech

Solutions for demanding industry sectors

ContiTech has also adapted the air actuators' connections in order to meet the specific requirements of particularly sensitive industry sectors. The air actuator models 40 to 530 in the C series now also come with stainless steel plates that are resistant to most acids. Instead of the widely used V2A stainless steel, ContiTech uses high-grade, acid-resistant V4A stainless steel. An additional alloy means that the material is even more resistant to corrosion, especially when exposed to chemicals and environments containing chloride. „This particular feature makes our new development suitable for many industries in which corrosive chemicals and environments are encountered,” says Weiss.

For example, the air actuators with the new stainless steel plates can be used in the chemical and pharmaceutical industries, where components often come into direct contact with chemicals. Especially in areas in which heavy-duty cleaning agents are used, acid-resistant steel is a must. At the same time, in many applications the components also need to be resistant to the flow of liquids and gases. „The new connections meet both requirements fully,” says Weiss.

The paper industry makes similar demands: high humidity and extreme heat combined with chemicals pose a challenge to the materials. Stainless steel helps to avoid downtimes and their associated costs. Corrosion prevention is also extremely important in the food and beverage industry, in order to meet all the hygiene standards of the U.S. Food and Drug Administration (FDA), for example. Therefore only materials with high resistance to chemicals and environmental influences are used in this sector.

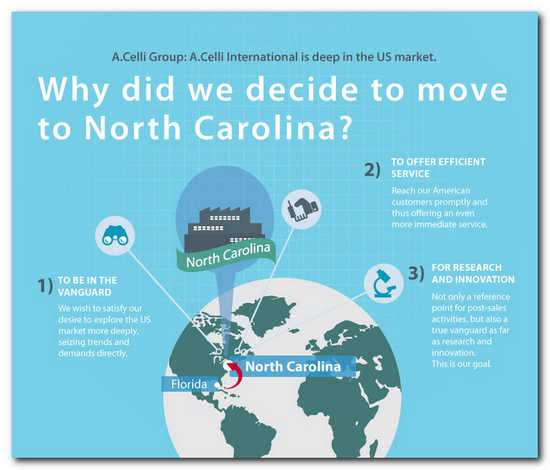

A.Celli International is deep in the US market

The Lucca Group is announcing the transfer of the US A.Celli International facilities from Florida to North Carolina. The offices are operational from the first week of April.

This decision is in part tied to the need to be closer location-wise to what are considered the neuralgic areas of the nonwovens market and hence to its American customers in order to be able to reach them promptly and thus offer an even more immediate service. This move also gives the team the opportunity to explore the US market more deeply and attentively and seize trends, demands and needs directly based on the daily experience of customers and partners.

Through this initiative, the A.Celli International’s customer assistance structure strives to be not only a reference point for post-sales activities, but also a true vanguard as far as research and innovation is concerned, capable of predicting future needs and identifying solutions useful to improve the work of production facilities.

The address of the new offices in North Carolina is:

A Celli International Inc.

1930 Derita Road, Concord, NC 28027 – U.S.A.

Phone +1 704 817 3922 – Fax +1 704 820 6020

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Our best wishes to A.Celli International Inc.!

Vinda orders Futura lines for continued growth in China

Vinda has signed an agreement with Futura for the supply of multiple high-performance converting lines for tissue roll products.

One of the leading players in China’s fast-expanding tissue market, Vinda is investing in new capacity to meet demand while improving its competitive position through quality products made on cutting-edge equipment.

One of the leading players in China’s fast-expanding tissue market, Vinda is investing in new capacity to meet demand while improving its competitive position through quality products made on cutting-edge equipment.

Vinda’s choice of partner for growth was influenced by its positive experience with Futura technology already installed within the Group.

Futura Head of Sales and VP of International Operations, Piero Ceccon, said: “It has been a very positive experience working with Vinda and we are delighted that our partnership is entering a new phase of intensity. The tissue market in China is evolving strongly and all of us at Futura are highly motivated to be growing together with such an important player in this market.”

The first complete lines ordered are scheduled to start up in 2017.

Stable markets and stable performance despite slow ramp-up

CEO Per Lindberg comments on the development during Q1 2016:

”We have again had a tough quarter with production lower than expected, due to last year’s rebuilds. Production improved during the quarter and I anticipate production to reach target run rate at the end of the second quarter. Even if we did not reach our own growth expectations I still think we deliver a solid and satisfactory financial result. Our markets continue to be stable and we expect that growth will materialise as production stabilises.”

THE RESULT

Net sales and EBITDA were down from the same quarter last year due to the divestment of Latgran in the third quarter 2015. For comparable units, Net sales was on the same level as last year and the EBITDA has actually improved. We saw improvements in results in both Consumer Board and Corrugated Solutions business areas.

Net sales and EBITDA were down from the same quarter last year due to the divestment of Latgran in the third quarter 2015. For comparable units, Net sales was on the same level as last year and the EBITDA has actually improved. We saw improvements in results in both Consumer Board and Corrugated Solutions business areas.

MARKET OUTLOOK

The overall market has been stable and we expect this to continue with normal demand patterns.

Business area Packaging Paper experienced, as anticipated, a lower than normal brown sack market with lower prices in local currencies. Also the pulp price was down compared to Q1 last year. The remaining segments in Packaging Paper saw a stable market development with stable pricing with slight increases on MG paper.

For the first quarter Consumer Board did not manage to deliver sales volume growth. This is due to the problems in production in the fourth quarter. But we expect growth rates to start pick-up again in the second half of the year as the market has not changed and our production stabilises. In spite of the production problems during the quarter and the associated tight delivery situation the business area has managed to deliver a solid profit in line with previous year.

Business area Corrugated Solutions shows a continued strong performance. Corrugated markets continued to be stable during the quarter and our solution sales continued to grow successfully and take on-board new business.

STRATEGY

For our industry, sustainability has historically meant to minimise our impact on the environment. Sustainability is part of our core business and we see sustainability as a business opportunity. We are proud to be the only company in Sweden and the only one in our industry on the CDP's (previously Carbon Disclosure Project) A-list of companies that demonstrate leadership in measures to improve the climate. But we are also pleased for every customer that switches from plastics to BillerudKorsnäs’ paper or board because that is when we have a tangible positive impact. As an example, an independent life cycle analysis shows that a paper bag results in half the emission of carbon dioxide compared to a plastic bag. Based on our products from renewable raw materials we can contribute to increased sustainability along the value chain by replacing other materials and solutions. As a result of the increasing interest for sustainable consumption, we also see an increasing interest in sustainable packaging among both brand owners and converters. With sustainability as part of our core business we consider our strategic position to be very strong.

For further information, please contact:

Per Lindberg, President and CEO +46 (0)8 553 335 00

Susanne Lithander, CFO, +46 (0)8 553 335 00

The information is such that BillerudKorsnäs AB (publ) is obligated to publish under the Swedish Securities Market Act. Submitted for publication at 07.02 CET, 21 April 2016.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4 200 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

PMP successfully completed PM#4 wet end rebuild for Smurfit Kappa, Saillat, France

In April 2015, PMP (Paper Machinery Producer) was awarded by Smurfit Kappa Saillat (France) a PM#4 wet end rebuild. Thus it is our pleasure to announce that on January 8th 2016 at 7:00 p.m. local time, PM#4 was successfully brought on stream at the Saillat mill in France. At the same time, saleable paper parameters has been achieved just 1.5 hour later.

In April 2015, PMP (Paper Machinery Producer) was awarded by Smurfit Kappa Saillat (France) a PM#4 wet end rebuild. Thus it is our pleasure to announce that on January 8th 2016 at 7:00 p.m. local time, PM#4 was successfully brought on stream at the Saillat mill in France. At the same time, saleable paper parameters has been achieved just 1.5 hour later.

The main goals of the project were: paper quality improvement (Basis Weight CD profile, TSO profile and 2 sigma COV), as well as PM capacity increase.

PMP’s scope of delivery included a 4 channel Intelli-Jet V® (hydraulic head-box) for a top ply, a pressure pulsation attenuator system, a temperature control system and a wire rebuild (top ply mini-Fourdinier). The new hydraulic head-box assures significant improvement of basis weight profile, uniform paper web structure and significantly better formation. The temperature control system minimizes CD slice open deviations due to thermal, pressure and gravity forces, but also minimizes production loses. PMP was responsible also for a Vacuum System, on site erection and start-up supervision.

The delivery was divided into two stages:

1st stage – during August 2015: erection of a Top Mini-Fourdrinier including a Vacuum System installation and a Save-all System.

2nd stage – during January 2016: erection of a Top Ply Intelli-Jet V® Hydraulic Head-box with Consistency Profiling and a new turning roll, followed by commissioning and start-up supervision.

Main project achievements are: The TSO profile of top ply range increased significantly. The dry basis weight profile 2 sigma in cross machine direction (CD) was also improved. Top layer formation have been also improved.

Formation improvement can be seen in a much better top side smoothness. Final product formation has been improved as well. As a result of a better tuning allowed, operating machine speed increased as well.

About PMP Intelli-Jet V® Technology:

PMP Intelli-Jet V® Hydraulic Headbox Technology has become iconic – it is today a leading solution in the Pulp & Paper industry. It is a part of PMP Intelli-Paper® platform for papermakers. There are over 130 units working successfully on 6 continents.

About Smurfit Kappa:

Smurfit Kappa - one of the leading providers of paper-based packaging solutions in the world with over 43,000 employees across 33 countries. Smurfit Kappa is located in 21 countries in Europe, and 12 in the Americas, and is the only large-scale pan-regional player in Latin America. Smurfit Kappa’s pro-active team relentlessly uses its extensive experience and expertise, supported by its scale, to open up opportunities for its customers. This is enhanced through the benefits of the integration, with optimal paper design, logistics, timeliness of service, and packaging plants sourcing most of their raw materials from own paper mills. Smurfit Kappa products, which are 100% renewable and produced sustainably, improve the environmental footprint of customers. (learn more: www.smurfitkappa.com)

Smurfit Kappa Saillat is a flag mill located in Saint-Junien, in central France, with nearly 130 employees.

About PMP:

PMP – a global provider of tissue, paper & board technology, has been supporting pulp and paper industry for over 160 years, executing projects on 6 continents, in 29 countries. Company owns 6 facilities in 4 countries (Poland, USA, China, Italy). PMP is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching new logo & visual identity. (learn more: www.pmpgroup.com)

PMP is represented in France by Gérard Cottet Consulting (This email address is being protected from spambots. You need JavaScript enabled to view it.)

Former MEP Lena Ek takes on leadership to strengthen the role of the forest-based sector in the European bioeconomy

Chair of the Board of Södra and former Swedish Minister of Environment, she is the new Chairperson of the Board of the Forest-based Sector Technology Platform

Lena Ek, former Member of the European Parliament (MEP) and Chairperson of the Board of the Södra Skogsägarna, is named the new Chair of the Board of the Forest-based Sector Technology Platform (FTP). She replaces Kaija Pehu-Lehtonen, Senior Vice President for Business Development in Metsä Fibre, who has been chairing FTP’s Board for the last two and half years.

Lena Ek, former Member of the European Parliament (MEP) and Chairperson of the Board of the Södra Skogsägarna, is named the new Chair of the Board of the Forest-based Sector Technology Platform (FTP). She replaces Kaija Pehu-Lehtonen, Senior Vice President for Business Development in Metsä Fibre, who has been chairing FTP’s Board for the last two and half years.

“Our objective is to advance the competitiveness of the whole sector by supporting European innovation and research”, stated Lena Ek after recognizing the substantial progress of the sector within the European research framework programmes, particularly Horizon 2020. “The forest-based sector will help to unlock Europe’s potential to make the transformation towards a biobased society. This fact should not be overlooked on the decisions about application of funding for research, innovation and technological development”, she added.

“It has been a privilege to work with such a competent Chair and strong industry representative as Kaija. We are truly grateful for her work and happy to see increased cooperation among industry, forest owners and researchers, as well as elevated success rates of proposals submitted by the sector,” stated FTP Managing Director Johan Elvnert. “We are excited with the new directions that FTP will take chaired by Lena Ek”, he concluded.

Lena Ek holds an honorary doctorate degree in Law and a distinct reputation in public affairs. Formerly, Lena served as Minister for the Environment of Sweden, Member of the European Parliament, Member of the Swedish Riksdag and hold prominent positions at the board of renowned political, scientific and industrial organisations. //FTP

About FTP – FTP is the European Technology Platform for the Forest-based Sector. Since 2005, when FTP was established, more than EUR 1 billion of public funding have been invested in cooperative research and innovation projects addressing the vision and improving the competitiveness and sustainability of the forest-based sector in Europe. The long-term strategy of FTP is established in its Vision 2030 to be implemented through the Strategic Research and Innovation Agenda for 2020. These documents were revised in 2013 and updated according to changing realities. The Confederation of European Paper Industries (CEPI), Confederation of European Forest Owners (CEPF), European State Forest Association (EUSTAFOR) and European Confederation of Woodworking Industries (CEI-Bois) are FTP shareholders.

About the European forest-based sector – The forest-based sector is one of Europe’s largest business sectors. It includes woodworking industries, pulp and paper industries as well as forest owners. It contributes some 8% of the EU’s total manufacturing added value, and sustainably manages forests covering 37% of the EU’s land area. It supports 3-4 million industrial jobs in sectors including transport, machinery, construction, instrumentation, information technology, chemicals and energy. The sector is also Europe’s biggest producer and user of bio-based energy.