Ianadmin

ANDRITZ Nonwoven presents latest technologies for nonwovens and textiles at Hightex/ITM 2016

International technology Group ANDRITZ will present comprehensive nonwovens and textile production technologies at Hightex/ITM 2016 in Istanbul (June 1-4, 2016, hall 11, booth no. 1124 A). ANDRITZ Nonwoven – comprising ANDRITZ Asselin-Thibeau, ANDRITZ Küsters, and ANDRITZ Perfojet – has been active successfully on the Turkish market for many years and provides full lines and individual solutions for spunlace, wetlaid, needlepunch, bonding and finishing for spunbond applications, and textile calenders.

New milestones in ANDRITZ spunlace technology

In the spunlace sector, whether for direct or crosslapped lines, ANDRITZ focuses on highest performance with regard to productivity, fabric quality, process reliability, and energy consumption. For high capacities and the production of lightweight fabrics (with a minimum of 20 gsm at a remarkably low MD/CD ratio), the combination of TT card and Jetlace Essentiel hydroentanglement process has been well accepted in the market.

The in-house expertise of ANDRITZ in through-air dryer technologies and in developing high-performance systems brings new and efficient process solutions to the spunlace industry. ANDRITZ customers now have the opportunity to reduce energy consumption in their lines consistently thanks to the new ANDRITZ drying solution neXecodry.

ANDRITZ neXline spunlace: high productivity, fabric quality, and process reliability – low energy consumption

Continuous innovation in needlepunch technology

In the needlepunch sector, innovative ANDRITZ nonwovens products generate high added value. For both light and heavy fabrics, ANDRITZ neXline needlepunch optimizes the production rate of every individual machine along the line, providing higher tensile strength, better MD/CD ratios, or greater evenness. Delivering equal strength performance in both directions, with excellent fabric resilience, will generate fiber savings by further reducing the fabric’s average weight. This can shorten payback times and increase return on investment for ANDRITZ’s customers.

ANDRITZ neXline needlepunch: innovation for both light and heavy fabrics production

Versatile ANDRITZ wetlaid technology

ANDRITZ is also a system supplier of complete wetlaid nonwoven lines for innovative and versatile end-uses in hygiene, medical, and technical product ranges.

ANDRITZ neXline wetlaid: benchmark in the production of specialty nonwovens

Finishing for nonwovens and textiles

In finishing of nonwovens, ANDRITZ provides high-performance neXcal calenders for thermobonding, embossing, laminating, and calibrating. For wet finishing with functional chemicals, ANDRITZ supplies padders and kiss roll systems with suitable dosing stations. The textile calender product line is complemented by the high-performance teXcal trike, specially designed for technical textiles.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 24,500 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ to supply evaporation plant to Södra Cell Mörrum in Sweden

ANDRITZ Oy, member of international technology Group ANDRITZ, has received an order from Södra Cell AB to supply a new evaporation plant for the pulp mill in Mörrum. Start-up is scheduled for fourth quarter of 2017.

ANDRITZ Oy, member of international technology Group ANDRITZ, has received an order from Södra Cell AB to supply a new evaporation plant for the pulp mill in Mörrum. Start-up is scheduled for fourth quarter of 2017.

The new 7-effect high dry solids evaporation plant will replace existing evaporation lines and significantly enhance energy efficiency at the Mörrum mill. Based on state-of-the-art technology provided by ANDRITZ, the evaporation plant also produces a considerable amount of district heat to be supplied to the Karlshamn municipality. The plant will also produce very clean condensates, all of which can be reused in other processes of the pulp mill.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 24,500 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

Toscotec obtains a repeat order from Celupaper S.A. for a new tissue machine PM4 in Buenos Aires, Argentina.

Toscotec will supply a new MODULO-PLUS tissue line to Celupaper S.A., part of Grupo Vual, South American leading regional player for the production of high quality tissue products.

The new line will be installed at Papelera Nicaragua. This is the third order in 2 years: previously Toscotec has been chosen to reconfigure the existing Fourdrinier machine PM2 with the installation of the TT DOES package (Drying Optmization for Energy Saving) already started up in 2015 and to supply a new PM3 MODULO line that will start up in May, this year.

Toscotec’s MODULO-PLUS will be delivered with a design for the production of high quality tissue products featuring a gross daily production of 65 tonn. The tissue machine is equipped with single layer headbox, one press configuration, TT SYD-3200MM, TT Milltech-MYH Monosystem Hood fed by natural gas and steam and condensate removal system. Approach flow system, electrification & control, as well as erection supervision, start up assistance and training programs are also included in the scope of supply.

“With this series of investments we believe to play an important role in South American market. Today the group has already three manufacturing plants (Jose Juan Yapur, Celupaper and Papelera Nicaragua), one pulp manufacturing plant (Celulosa Alto Vale) and many distribution centers located in Santa Fe, Córdoba, Bahia Blanca and Buenos Aires employing more than 700 people.” - confirms Mario Speranza, CEO of Celupaper S.A..

“It's an honor for us to continue the good cooperation with Celupaper. Our aim is to reach significant results in terms of productivity and of drying energy saving. The TT DOES continues to be a key technology of our lines to bring concrete benefits to our customer and take their performance forward."- says with great satisfaction Alessandro Mennucci, CEO of Toscotec S.p.A..

The PM4 will be started up within the end of 2017.

About Toscotec S.p.A.

Toscotec is a turnkey supplier to the global tissue industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects, and individual machineries. Headquartered in Lucca, the nerve center of the Italian paper district, with offices in China and North America, the Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities. Key to the Group’s success is the engineering and R&D department, run by a team of highly qualified engineers. Toscotec currently employs approx. 180 people.

Valmet to supply a new screening and washing plant to Smurfit Kappa Cellulose Du Pin Biganos in France

Valmet will supply Smurfit Kappa Cellulose Du Pin Biganos pulp and paper mill in France with a new screening and brown stock washing plant for kraft liner pulp production. The new plant will replace old equipment and make the mill meet today's environmental requirements. The delivery is scheduled for the beginning of 2017, and the start-up for later the same year.

Valmet will supply Smurfit Kappa Cellulose Du Pin Biganos pulp and paper mill in France with a new screening and brown stock washing plant for kraft liner pulp production. The new plant will replace old equipment and make the mill meet today's environmental requirements. The delivery is scheduled for the beginning of 2017, and the start-up for later the same year.

The order was included in Valmet's fourth quarter 2015 orders received. The value of the order will not be disclosed. The value of an upgrade of this scope is usually valued below EUR 10 million.

"Valmet has proven technology for high kappa pulp production, based on a unique cooking, refining and washing concept. This order is a token of our leading position within the area of fiber lines for kraft liner. We are looking forward to an interesting project together with Smurfit Kappa," says Peter Rummel, Sales Manager, Valmet.

Technical information of the delivery

The order includes a new screening plant with a reject refiner and a washing stage consisting of a filter stage followed by two TwinRoll presses. The screening and brown stock washing plant will have a capacity of 1250 adt/d.

About the customer Smurfit Kappa

Smurfit Kappa Cellulosedu Pin, is one of the leading Europeanproducers ofpaper made fromvirgin fiberfor packaging. Based in Facture, Aquitaine(South-Westof France), its production unitis specializedin the manufacture ofcoverageKraft papercorrugated board.

For further information, please contact:

Peter Rummel, Sales Manager, Pulp and Energy Business Line, Valmet, tel. +46 70 653 3802

Yannick Duperrier, Senior Mill Sales Manager, EMEA Sales, Valmet, tel. +33 6 85 67 24 24

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Verso Announces Sterling® Ultra TrueJet®

Verso Corporation (OTCPink: VRSZQ), a leading producer of digital coated papers, has just introduced Sterling® Ultra TrueJet®, a specialized line of digital coated papers for production inkjet presses.

Verso Corporation (OTCPink: VRSZQ), a leading producer of digital coated papers, has just introduced Sterling® Ultra TrueJet®, a specialized line of digital coated papers for production inkjet presses.

"Sterling® Ultra TrueJet® is designed to meet the growing need for a high-quality inkjet coated paper for high-speed, personalized print runs," said Verso Senior Vice President of Sales, Marketing and Product Development Mike Weinhold. "The offset-like coating of Sterling® Ultra TrueJet® meets market expectations with proven runnability and durability on some of the best-known, high-speed inkjet presses with the added benefit of delivering significant ink cost savings."

Sterling® Ultra TrueJet® optically matches Verso's Sterling® Ultra coated paper line for commercial offset printing applications. Weinhold adds, "Expanding the commercial Sterling® Ultra line to include a matching inkjet product provides our customers the flexibility to choose the right product from the Sterling® family of brands for the right technology."

The Sterling® Ultra TrueJet® line includes 80 lb. and 100 lb. gloss and matte text, 75 lb. (7 pt.) and 92 lb. (9 pt.) gloss cover and 75 lb. (9 pt.) and 92 lb. matte cover for a variety of print applications. The 7 pt. and 9 pt. are caliper guaranteed and meet the United States Postal Service minimum requirements for direct mail.

Along with the Sterling® Ultra TrueJet® inkjet product, Verso offers premium digital products including Futura®, Sterling® Premium Digital™, Sterling® Premium Digital™ for HP Indigo, Blazer Digital®, along with Productolith Pts. Digital® for heavier-weight packaging and applications requiring a caliper guarantee.

From coated digital to coated inkjet papers, Verso can meet a broad range of digital paper needs. To learn more about Verso's entire product portfolio, including digital, sheetfed, web and specialty papers, visit us at Booth No. 249, April 14 to 16 at DSCOOP 11, San Antonio, Texas or at versoco.com.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.

SOURCE Verso Corporation

UPM's PM3 is officially inaugurated in Changshu, China

UPM have just announced the official inauguration of the Paper Machine 3 (PM3) in Changshu, China. As an important milestone for the development of UPM in China, the new paper machine will further increase production capacity while implementing the Biofore strategy. With this investment UPM will continue to provide environmentally friendly, safe and broad product portfolios for customers in China and the Asia-Pacific region.

"In UPM Changshu we will focus on value added, advanced paper products for growing segments in China and worldwide. On this site, we are also introducing totally new, innovative manufacturing technology - not only for China, but for the paper industry worldwide," said President and CEO Jussi Pesonen in his opening speech.

In 2012, in order to meet the growing demand for paper from China and the Asia-Pacific region, UPM began to implement the PM3 Project with a total cost of EUR 277 million. The PM3 production line and process has been designed to be very flexible with a wide range of different products from uncoated woodfree papers to advanced specialty products. This swing concept of PM3 also greatly improves the efficiency of paper production and also helps to reduce energy consumption. The product portfolio of Changshu has been extended into labelling material and other specialty products to better fit customer needs. These segments are still seeing and are forecasted to see significant growth globally, but especially in this part of the world.

UPM first invested in China in 1998 and has since invested more than USD 2 billion in the region. The Changshu site is a proof of UPM's consistent and steady commitment in China. Today, the site boasts a fully integrated production and converting capability that incorporates a paper mill, labelstock factory, Asia R&D Centre as well as an APAC Supply Chain Centre. With the new investment, UPM is able to produce 1.4 million tonnes of labelling material and fine papers for customers across the Asia Pacific region, and beyond.

UPM attaches great importance to the sustainable development of the economy, society and environment. UPM's Biofore strategy emphasizes environmental friendliness and sustainable development for the full life cycle of paper production. Currently the share of certified fibres is at 84 per cent. In addition, UPM has developed a biodiversity program for forest management, to increase biodiversity, improve natural ecosystems, carbon cycles, and vitalize the forest. In the paper production process, UPM values the protection and recycling of water resources. At UPM's Changshu Mill, the recycling rate for the white water has reached 97 per cent.

"The completion of PM3 Project in Changshu is another strong example of our long-term commitment to sustainable development in Chinese market. In the future, through UPM's Biofore strategy, the company will continue to raise industry standards to achieve a more sustainable and safer way of production," said Jussi Pesonen.

For further information please contact:

Bernd Eikens, Executive Vice President, UPM Paper Asia, tel. +86 139 1366 2828

Mary Ma, Director, Marketing, Communications and Environmental Affairs, UPM Paper Asia, tel. + 86 21 644 855 44

UPM Changshu Mill

UPM Changhu mill located in Jiangsu Province, China produces high quality office and printing papers, and labelling materials. The annual production capacity of the three production lines is 1.4 million tons. UPM Changshu employs around 1,400 people.

UPM Paper Asia

UPM Paper Asia produces fine papers to Asian markets and label and packaging materials to global markets. Our products and services are developed to provide our customers' the right solutions. We are a recognized industry leader in sustainability and environmental excellence. Our responsibly produced and high performance papers are manufactured in China and Finland. www.upmpaper.com

UPM

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 19,600 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM - The Biofore Company - www.upm.com

Kotkamills consumer boards organisation news

To ensure the continued smooth development of the new Consumer Boards business unit, we are pleased to announce that Pirjo Eteläinen has been appointed Director, Consumer Boards. She takes responsibility for the operating result of the business unit and will continue to develop the sales and support network ready for the launch of the new board machine at the end of June this year. In addition, David Ingham has been appointed Global Sales Director, Consumer Boards, and will take responsibility for the sales organisation and sales overall.

Both appointments are made with immediate effect.

Christian Höglund, previously Director, Consumer Boards Business Unit, has left the company to pursue other opportunities. We would like to take this opportunity to thank him for his work in developing the business unit to date and wish him every success with his future challenges.

For further information, please contact Mr. Markku Hämäläinen, CEO of Kotkamills Oy, tel. +358 40 721 0548, This email address is being protected from spambots. You need JavaScript enabled to view it..

About Kotkamills

Kotkamills is a responsible partner that delivers renewable products and performance to its customers’ processes via product innovations created from wood, a renewable raw material. Our key brands include Absorbex® and Imprex®, both innovative laminating paper products for the laminate, plywood and construction industries. Moreover, Kotkamills offers ecological, technically sound and visually attractive wood products for demanding joinery and construction. In summer 2016, Kotkamills will start-up a new cartonboard machine designed to produce folding boxboard and food service boards for consumer markets, including the capability to add barriers on-machine. All Consumer Boards material solutions will be fully recyclable and repulpable.

Kotkamills has two production sites in Finland, located in Kotka and Imatra, and a subsidiary L.P. Pacific Films for Imprex® production in Malaysia. The majority shareholder of Kotkamills is MB Funds, a Finnish private equity firm.

www.kotkamills.com

Acelli - We will participate at IDEA 2016

From 3 to 5 May, a A.Celli Nonwovens S.p.A. will participate at IDEA 2016, the most importantinternational event for 2016 in the world of nonwovens, organised and promoted by INDA (Association of theNonwoven Fabrics Industry).

IDEA is a must for anyone involved in nonwovens. An exhibition of technologies, conferences, and an innovationaward are the highlights of this trade show that every three years calls together the most brilliant minds in the field,hundreds of exhibitors, thousands of participants coming from all over the world, and lots & lots of… ideas!

The 2016 edition moves from its traditional venue in Miami, Florida, to the Convention and Exposition Center inBoston, Massachusetts.

A.Celli Nonwovens invites all visitors to its stand no. 1541, where it will be pleased to illustrate its broadproduction range and dedicated technical solutions: winding and rewinding lines, lines for packaging, palletizingand reel handling for nonwovens, printing technologies for different supports including nonwovens, PP/PE film andtissue in a wide range of grammages and much more.

A.Celli’s offer is completed by a reliable 24/7 post-sales service and by MySp@res®, the service born to be able toidentify, localise and request an estimate for what concerns all spare parts components.

For further information and/or to fix an appointment at the A.Celli stand, please contact:

This email address is being protected from spambots. You need JavaScript enabled to view it. – This email address is being protected from spambots. You need JavaScript enabled to view it. – This email address is being protected from spambots. You need JavaScript enabled to view it.

Come and see us at stand number 1541

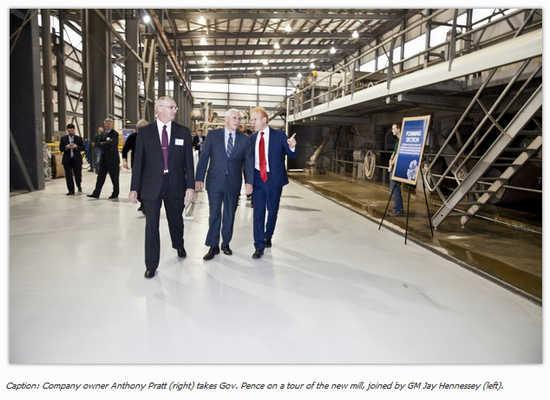

Pratt Celebrates Grand Opening of Fourth 100 Percent Recycled Paper Mill in Valparaiso

Pratt Industries officially opened its fourth, 100 percent recycled paper mill in Valparaiso, Indiana, last week with a gala luncheon attended by more than 300 guests including Indiana Govenor Mike Pence.

Our company has now built three of the last 4 paper mills constructed in the U.S., which is an amazing achievement!

The new mill, which will produce 500,000 tons of the industry’s best recycled paper at capacity, will supply our rapidly-best expanding Midwest box-making operations.

“This is the most environmentally friendly and modern containerboard mill in the world,” said company chairman Anthony Pratt. “We’re proud that we are the only major paper company that produces only 100 percent recycled paper and these days this is very important to our customers. In doing so we save 68,000 trees a day or enough to cover 120 football fields.

“What’s also important to our customers is cost effective packaging and this technologically advanced mill will produce lightweight papers that produce boxes that work at lower cost.”

But even more important than that, he said, was that the mill created more than 100 new jobs, bringing the company total nationwide to 5800.Governor Mike Pence, who officially opened the mill with a ceremonial ribbon cutting, said: “I applaud Pratt for investing in Indiana’s future and creating quality jobs for Hoosiers for generations to come.”

He also hailed Anthony as “a man of your word…thank you for believing in Indiana.”

The mill, located 50 miles southeast of Chicago, is on the same site as Pratt’s corrugated box plant, the world’s largest.

Before the official program began guests were given tours of the mill and the adjoining box factory and a sit down lunch.

Valpariaso major Jon Costas said after touring the site: “One thing is for sure, the next time an Amazon box shows up on my doorstep, I’m probably going to be more amazed at the box than what’s inside the box.”

Guizhou Chitianhua Paper Industry (Taison Group) chooses A.Celli Paper.

The Chinese company, part of the Taison Group since the beginning of 2016, has decided to place its total trust in the Italian excellence of A.Celli Paper in the development of high-level technology in paper/cardboard and tissue rewinders.

An important project that includes a total order for 3 tissue Rewinders and an additional agreement for other 9Rewinders. The first 3 Rewinders, whose start-up is scheduled for January 2017, will be delivered to GuizhouChitianhua Paper Industry, at the Chishui facilities, in the province of Guizhou (China).

The additional 6 Rewinders are scheduled for the second half of next year, while the remaining last 3 Rewinders willbe delivered at the end of 2017.

The rewinders are all Model AC882 shaftless for tissue production, with grammages ranging between 13 to 42g/m2; they are all in a 5,600 mm format and can run up to 1,000 m/min. The 12 plants are part of the ambitiousdevelopment plan that the Chinese Group has designed for its tissue division with the aim of attaining importantproduction goals throughout the East.

A.Celli Paper will be at the complete disposal of the Taison Group, flanking the growth of Guizhou ChitianhuaPaper Industry in an extremely dynamic and continuously evolving scenario that is China's Tissue market.