Ianadmin

The Swedish Court of Patent Appeals has revoked Andritz's Swedish Patent on which Andritz had filed a summons application against Valmet in 2015

As Valmet announced by stock exchange release on February 20, 2015, Andritz Oy had filed a summons application with the Stockholm District Court against Valmet AB, a subsidiary of Valmet Corporation, regarding patent infringement. In the claim Andritz is asking that Valmet under a penalty ceases to utilize the system allegedly infringing Andritz's patent and to impose royalty and damages on Valmet AB with EUR 54 million and interest for the alleged infringement. Valmet has not made any provisions concerning the claim.

As Valmet announced by stock exchange release on February 20, 2015, Andritz Oy had filed a summons application with the Stockholm District Court against Valmet AB, a subsidiary of Valmet Corporation, regarding patent infringement. In the claim Andritz is asking that Valmet under a penalty ceases to utilize the system allegedly infringing Andritz's patent and to impose royalty and damages on Valmet AB with EUR 54 million and interest for the alleged infringement. Valmet has not made any provisions concerning the claim.

The validity of Andritz's patent has been challenged by Valmet, and this matter has been awaiting a decision from the Swedish Court of Patent Appeals. The Swedish Court of Patent Appeals has on March 23, 2016 decided to revoke Andritz's patent.

An appeal of the decision now made by the Swedish Court of Patent Appeals can be filed to the Supreme Administrative Court by May 23, 2016.

Further information, please contact:

Rasmus Oksala, General Counsel, Valmet, tel. +358 10 672 0026

Hanna-Maria Heikkinen, Vice President, Investor Relations, Valmet, tel. +358 10 672 0007

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

HiTec Papers from Mitsubishi at Drupa 2016

Mitsubishi HiTec Paper is exhibiting a broad portfolio of high-quality coated speciality papers at Drupa 2016 (Hall 8B, Stand D24). Amongst other things, the German speciality papers manufacturer is showing papers designed for various digital printing technologies and innovative solutions for the packaging and label area. A new product is being launched: Giroform DIGITAL - ONE FOR ALL.

Mitsubishi HiTec Paper is exhibiting a broad portfolio of high-quality coated speciality papers at Drupa 2016 (Hall 8B, Stand D24). Amongst other things, the German speciality papers manufacturer is showing papers designed for various digital printing technologies and innovative solutions for the packaging and label area. A new product is being launched: Giroform DIGITAL - ONE FOR ALL.

"Quality paper is the foundation. Incomparable added value is created by excellent coating." This is the maxim according to which Mitsubishi HiTec Paper produces, in Germany, its coated speciality papers for a variety of applications and to meet a variety of demands. All product areas are represented at Drupa 2016:

Inkjet Papers JETSCRIPT

Mitsubishi HiTec Paper offers a wide range of coated inkjet media for the B2B sector. Small format, large format or high-speed inkjet printing - the applications are endless. Highlights at the stand are:

- jetscript DL 2584, a 248 g double-sided matt coated inkjet paper for high-speed inkjet printing (direct mail)

- jetscript MH 1484 CCB, a 134 g premium matt coated inkjet paper with a unique safety feature. A coloured base paper allows for easy verification by tearing. Ideal for coupons, entrance tickets and lottery tickets. Suitable for desktop ticket printers, large format or high-speed inkjet printing machines.

- jetscript MH 7084, a 70 g lightweight matt coated premium inkjet paper for use as face paper for demanding self-adhesive labels

Thermal Papers THERMOSCRIPT

The broad spectrum of thermoscript standard products for POS, ticket and label applications is supplemented by various specialities: Thermal paper with our proven security features, two-colour or rewritable thermal papers or anti-fade grades. Highlights at Drupa:

- Thermal papers with special security features such as coloured centre, security fibres, coating marks or an anti-counterfeit thermal coating

- Thermal paper for linerless labels

- HP Indigo certified thermal papers

Label Papers SUPERCOTE

The cast-coated label paper supercote range meets all the demands made of an excellent label paper. Also in moisture and alkali resistant versions. Ranging from 80-170 g, the products are optimised to meet the needs of the drinks industry and are also ideal for composite cans and shoulder boxes. Supercote has particularly good processing properties which give premium products the appearance that they deserve at point of sale.

Carbonless Papers GIROFORM

The world-famous classic Giroform range of products including numerous standard and special grades is the reliable carbonless paper. In 2006 Mitsubishi was the first manufacturer to develop a carbonless paper for digital printing. A new universal carbonless paper for a wide range of digital printing systems is being exhibited at Drupa:

- Giroform DIGITAL - ONE FOR ALL, an 80g high quality carbonless paper for the digital production of individual, personalised forms and documents. It is available as CB, CFB and CF in up to 6 colours, in reels and sheets, and is suitable for use on toner printing systems of leading manufacturers, copiers and printing systems in the Business Solutions sector.

Our sales team is looking forward to your visit in Hall 8B, Stand D24, and will be pleased to supply you with further information.

Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's leading manufacturers of speciality paper. The roughly 700 employees at Mitsubishi HiTec Paper Europe produce high-quality thermal, digital imaging, carbonless and label papers at two tradition-rich locations in Bielefeld and Flensburg. Each factory stands out for own base paper production, state-of-the-art production machinery and innovative coating technologies. Through its dense global sales network, Mitsubishi HiTec Paper Europe supplies a full range of speciality papers featuring a modular system for every application and printing technology – and is a highly capable partner whenever customized coated paper solutions are required.

Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's leading manufacturers of speciality paper. The roughly 700 employees at Mitsubishi HiTec Paper Europe produce high-quality thermal, digital imaging, carbonless and label papers at two tradition-rich locations in Bielefeld and Flensburg. Each factory stands out for own base paper production, state-of-the-art production machinery and innovative coating technologies. Through its dense global sales network, Mitsubishi HiTec Paper Europe supplies a full range of speciality papers featuring a modular system for every application and printing technology – and is a highly capable partner whenever customized coated paper solutions are required.

Environmental trends and diverging product performance drive innovation in tissue production, according to Smithers Pira

Smithers Pira publishes a new report entitled, The Future of Tissue Manufacturing to 2021, which provides an in-depth, long-term assessment of the rapidly evolving tissue manufacturing processes.

Operating environment trends and diverging product performance levels will push alternative manufacturing technologies. Tissue manufacturers occupying economy segments compete primarily on price. This requires increased focus on productivity and cost control. Premium level product performance will drive increased adoption of structured sheet technologies supported by chemicals and fibres.

Operating environment trends and diverging product performance levels will push alternative manufacturing technologies. Tissue manufacturers occupying economy segments compete primarily on price. This requires increased focus on productivity and cost control. Premium level product performance will drive increased adoption of structured sheet technologies supported by chemicals and fibres.

Changes are well underway as the standardisation of crescent former configurations and sizes have allowed machines to be built in auto assembly line fashion in workshops at much lower costs than the traditional engineered custom machines. Steel Yankee assembly is rapidly joining this disruptive approach to machinery sourcing.

“Product focus is moving toward a two level strategy with economy and premium performance products.” states Bruce W. Janda, author of the report.

“Middle of the road products will increasingly be left behind.”

Recycled fibre for tissue making will see shortages as tissue demand grows and the supply of recyclable papers decreases in the electronic media conversion. This will have a disruptive effect, particularly in North America over the period to 2021. Tree-free tissue products are poised to take off in North America and this period will show if consumers will respond with interest. Sustainable pulping where fibre is a by-product of non-fossil energy or feedstock production is moving forward in Northern Europe.

Tissue manufacturing is growing in allregions, albeit at distinctly different rates. The two undeveloped tissue markets remain Africa (excluding South Africa) and India. These are unlikely to change the market balance in the next five years. Improved hot air hand dryers will continue to take business away from paper hand towels with substitution rates above 30% expected in Western Europe and North America by the end of this period.

The operating environment for tissue manufacturers will increasingly be constrained by uncertain water and energy access and costs. Sustainability measures will become a greater factor as consumer and government requirements increase. The growth of non-wood fibre sources has opened up new possibilities for simplified and sustainable pulping processes. New approaches to dry strength additives show potential to increase tissue softness and productivity. Enzyme applications for fibre modification and process management will offer potential sustainable improvements to tissue manufacturing.

The Future of Tissue Manufacturing to 2021 focuses on the market and manufacturing processes for hygienic tissue and towel products made from natural cellulosic fibre, along with packaging and other applications of tissue paper.Trends in manufacturing processes, cutting-edge machinery developments, fibre technologies, and tissue end-use are examined both on a globaland regional basis. Additionally new product trends, the current operating environment, and technology developments are assessed for potential disruptive changes to tissue manufacturing.

The Future of Tissue Manufacturing to 2021 is available for £4,200. For more information, please contact:

Europe/Asia

Stephen Hill / This email address is being protected from spambots. You need JavaScript enabled to view it.

+44(0)1372 802025

North/South America:

Josh Rabb / This email address is being protected from spambots. You need JavaScript enabled to view it.

330-762-7441 ext. 1206

Smithers Pira is the worldwide authority on packaging, paper and print industry supply chains. Established in 1930, Smithers Pira provides strategic and technical consulting, testing, intelligence and events to help clients gain market insights, identify opportunities, evaluate product performance and manage compliance. For more information please visit www.smitherspira.com

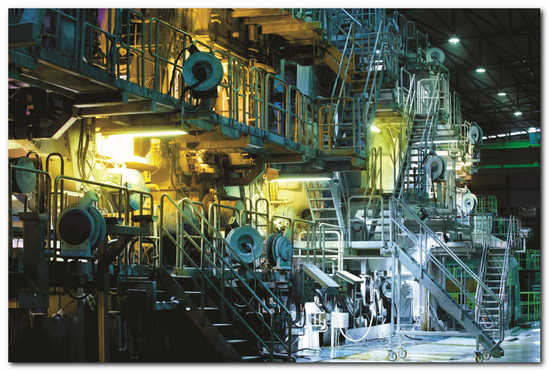

Full speed ahead at Iggesund’s Workington Mill

Production at Iggesund Paperboard’s mill in the UK is now fully operational again. At the beginning of March the board machine was shut down for a rebuild, in which its oldest part, the press section, was replaced with cutting-edge technology. The rebuild will increase the machine’s capacity by 20,000 annual tonnes from 200,000 up to 220,000 and will also enable further quality improvements in the future.

Iggesund Paperboard’s paperboard mill at Workington is up and running again after almost a month-long stoppage to install a new press section, which will give more consistent quality and an additional 20,000 annual tonnes of production. © Iggesund

“These are the immediate effects but in the longer term the new press section means we have a more advanced platform for our continued development work, which will be decisive for our future competitiveness,” comments Bengt Löfroth, technical strategy officer at Workington Mill.

A rebuild of a huge paper machine is a race against time. The high capital costs mean that the loss of every hour’s earnings is significant. The rebuild must therefore be planned down to the smallest detail so that all the contractors know precisely what they must do and when. Planning for a stoppage like that at Workington starts more than a year in advance.

After the rebuild is finished, uncertainties still remain: will the machine restart and how quickly can production get back to the quality that existed prior to the stoppage?

“Looking back, this was a superb job by both our own staff and the contractors involved,” says Ulf Löfgren, Managing Director of Workington Mill. “They worked night and day to give us the best possible results.”

Prior to this year’s rebuild, Iggesund Paperboard had invested more than £200 million in Workington Mill since the turn of the millennium. Today Workington is the only remaining paperboard mill using virgin fibre in the British Isles. The mill has a high technological standard and is a good demonstration of paperboard’s environmental advantages over other packaging materials. In 2013 the mill switched overnight from using fossil natural gas to using biomass as its energy source. The change meant an instant reduction of the mill’s fossil carbon emissions by 190,000 tonnes per year, the equivalent of taking 65,000 cars off the road. The investment that made this possible cost £108 million.

The new press section, combined with other measures implemented during the rebuild period, also increases the mill’s energy efficiency.

“We’re constantly looking for ways to become more efficient and save on the resources we use,” Bengt Löfroth says. “What we’ve just done now means that we will reduce our energy consumption by almost 10 per cent – which is an achievement in itself.”

Incada is the name of the folding box board produced at Workington. It is made of virgin fibre and is built to have a stiffness that makes it a preferred packaging material among companies wanting to give their products good protection with low weight while still getting the best possible print results on their packaging.

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Further information:

Staffan Sjöberg

Public Relations Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

Iggesund Paperboard

SE-825 80 Sweden

Tel: +4665028256

Mobile: +46703064800

www.iggesund.com

Kemira's new production plant in Ortigueira, Brazil successfully started up

Kemira Oyj has successfully started up production in its new sodium chlorate plant located in Ortigueira, Paraná, Brazil. The sodium chlorate produced at the plant is used for on-site generation of chlorine dioxide, a key bleaching agent in bleached pulp production.

Kemira Oyj has successfully started up production in its new sodium chlorate plant located in Ortigueira, Paraná, Brazil. The sodium chlorate produced at the plant is used for on-site generation of chlorine dioxide, a key bleaching agent in bleached pulp production.

Kemira's plant is built adjacent to Klabin SA's new pulp mill securing a long-term partnership between the two units. This concept is a good example of sustainable circular economy where the production facilities make use of renewable energy from the pulp mill, Kemira providing the pulp production sodium chlorate it needs. Electricity is the main raw material for sodium chlorate.

"Kemira is a global leader in the production and supply of chemicals for the pulp and paper industry and has the most comprehensive offering for pulp production. The new plant strengthens our capabilities to serve the growing demand for pulping chemicals in the South American market", says Billy Ford, Senior Vice President, Pulp & Paper, The Americas.

The new pulp mill in Brazil (Puma Project) is the largest investment in Klabin's history and will almost double the company's production capacities. The unit has a capacity of 1.5 million tons of pulp, with 1.1 million tons of bleached hardwood pulp (eucalyptus) and 400,000 tons of bleached softwood pulp (pine). The new mill will also generate a renewable and sustainable bioenergy surplus of 150 MWh/h.

For more information, please contact

Kemira Oyj

Billy Ford, SVP, Pulp & Paper, Americas

Tel. +1 404 661 9336

Olli Turunen, VP, Investor Relations

Tel. +358 10 862 1255

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2015, Kemira had annual revenue of EUR 2.4 billion and around 4,700 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd.

www.kemira.com

Dramatic Advance in Packaging – 30% cheaper board

You don’t have to be an expert to know that E-Commerce or “distance retail” is experiencing compound growth. The statistics are significantly out of date by the time they are published. Previously growth of between 3.7 to 4.0 percent was expected. DHL’s website is reporting 10.7 percent growth for the sector and that you can bet is already dated; quoting DHL “In 2013 the global distance selling market was worth €616 billion, but will grow annually by 10.7 percent until 2018.”

So, plain, robust, transport friendly, consignment packaging is replacing plastic shopping bags, fancy printed boxes and shopping trolleys to get consumer goods home.

So, plain, robust, transport friendly, consignment packaging is replacing plastic shopping bags, fancy printed boxes and shopping trolleys to get consumer goods home.

What is the material of choice to satisfy the Amazon.coms and FedExs of this world – naturally it’s corrugated cardboard. It is light, sufficiently robust, fulfilment house compatible, transport efficient, readily available and economic.

Now imagine on top of those credentials there is a new board that is 30% lighter; 30% cheaper; offering increased stiffness, to eliminate corrugated board’s problem of bending in line with the flutes; and facilitates boxes being stamped out of sheets in any orientation to minimise waste.

And it doesn’t stop there. The developers are currently assessing the production savings in energy, water, and transport which will lower the board’s CO² profile. The manufacturing process only requires one pass through the high speed lines, so these savings will also reflect high values.

This is big. It is believed that this new patented board is the most significant advance in the mechanical efficiency in the corrugated sector for 140 years. A new organisation is being set up to deploy the Design Technology worldwide. Based in the Netherlands, with Scandinavian paper engineers, the developers say that a final block of shares is still available to industry players.

Apart from the enormous savings the new board is expected to penetrate the market very quickly due to its unique and distinctive appearance. Brands that use this board will be seen as environmentally conscience, as consumers will readily identify with the best of breed “green” packaging.

It’s a game changer. If you currently manufacture corrugated medium, either close shop or get a license to manufacture. Watch this space.

Fibria contracts new services for expansion of Três Lagoas Unit in Mato Grosso do Sul

New package includes electromechanical assembly of interconnections of all process areas at the company’s new pulp production line

Fibria, a Brazilian forestry company and the world’s leading eucalyptus pulp producer, has contracted the execution of electromechanical assembly, known as Balance of Plant (BoP), to interconnect all the process areas at the Horizonte 2 Project, which involves expansion of the pulp production line at the Três Lagoas Unit in the state of Mato Grosso do Sul.

In this first stage, the electrical and mechanical assembly will focus on installing pipe racks, which are metal structures used to support pipelines that transport the inputs used in the pulp production process, such as chemicals, water and compressed air, among others, as well as in the manufacture of chimney ducts and water sourcing and wastewater treatment pipes.

The electromechanical assembly will be executed by Imetame Metalmecânica, while Pöyry will be responsible for the engineering and management of the package.

“The BOP is going according to schedule. Starting this phase is essential to meet the goals of the project, which will make Fibria’s Três Lagoas Unit one of the world’s largest pulp plants,” says Maurício Miranda, general manager of engineering at the Horizonte 2 Project.

With an investment of R$8.7 billion, Fibria's expansion project will create 40,000 jobs during construction and 3,000 direct and indirect jobs once the project is completed. The Três Lagoas Unit will have its annual pulp production capacity expanded by 1.75 million tons, which will take its total annual pulp production capacity to 3.05 million tons.

About Fibria

The world leader in eucalyptus pulp production, Fibria strives to meet the growing global demand for forestry products in a sustainable manner. With production capacity of 5.3 million tons of pulp per year, it has industrial units in Aracruz (Espírito Santo), Jacareí (São Paulo) and Três Lagoas (Mato Grosso do Sul), as well as in Eunápolis (Bahia), where it operates Veracel in a joint operation with Stora Enso. Fibria has 969,000 hectares of forests, with 568,000 hectares of planted forests, 338,000 hectares of environmental preservation and conservation areas and 63,000 hectares destined for other uses. The pulp manufactured by Fibria is exported to more than 40 countries. In May 2015, Fibria announced the expansion of its Três Lagoas unit, which will receive a new line with annual pulp production capacity of 1.75 million tons and is slated for startup in the fourth quarter of 2017.Learn more at www.fibria.com.br

ABB to deliver new drive system for Kruger Packaging’s PM 10 rebuild in Trois-Rivières, Quebec

Engineered solution and services for paper machine conversion from newsprint to containerboard production will improve energy efficiency and equipment reliability

ABB will deliver a complete engineered solution to Kruger Packaging for a paper machine rebuild project at Kruger’s Trois-Rivières Mill in Quebec, Canada. The project is part of Kruger’s $250-million investment to rebuild its No. 10 Newsprint Machine (PM10) to manufacture 100%-recycled, lightweight and high-strength linerboard. Once the conversion is complete, PM 10 will produce 360,000 metric tonnes of linerboard annually for use in Kruger’s box plants and for the global packaging market.

ABB will deliver and install drive systems for PM 10 and its winder. The scope of supply for this rebuilding project includes ACS880 MultiDrive Line ups, AC motors, System 800xA control system, supervisory systems, remote diagnostic services, high-speed data logging system, spare parts and local engineering, commissioning, installation supervision and start-up service.

ABB provides reliable and efficient solutions for the pulp and paper industry

Kruger Packaging opted for the latest state-of-the-art AC Drive System, which will replace the existing DC drive system currently on PM 10. Kruger chose ABB because of their deep paper industry application knowledge, comprehensive technical and engineering solutions, and close working relationship with Kruger on other projects.

“We have chosen ABB for their excellent engineering and service team, as well as their extensive knowledge and experience in delivering proven technology for a number of our projects,” said Christian Lemay, Kruger Project Manager.

ABB’s ACS880 Drive technology, coupled with ABB’s Direct Torque Control (DTC) technology, provides unsurpassed motor control performance, supported with best in class uptimes. This ensures energy efficient, highly reliable systems that maximize process uptime and minimize production downtime.

“The ABB project delivery and engineering team has a strong, trusted relationship and great working history with Kruger,” said Jim Fisher, Head of ABB’s Pulp & Paper business. “We look forward to delivery of yet another successful project which will produce energy efficiencies and reduced maintenance costs for Kruger.”

Kruger Packaging L.P. (http://www.kruger.com) is a Canadian manufacturer of containerboard and packaging products made from recycled fibers. Its parent company, family-owned Kruger Inc. founded in 1904, is also a major producer of publication papers, tissue products, renewable energy, cellulosic biomaterials, and wines and spirits. The Company is also a leader in paper and paperboard recycling in North America.

ABB (http://www.abb.com) is a leading global technology company in power and automation that enables utility, industry, and transport & infrastructure customers to improve their performance while lowering environ-mental impact. The ABB Group of companies operates in roughly 100 countries and employs about 135,000 people.

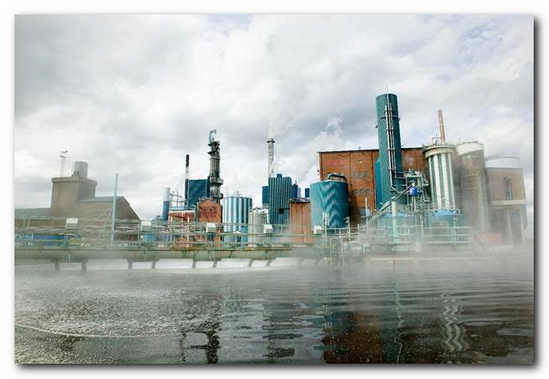

Valmet to deliver a new white liquor filter to Rottneros Vallvik pulp mill in Sweden

Valmet will deliver a white liquor filter to Rottneros Vallvik pulp mill located on the east coast of Sweden. White liquor filter is part of the pulp mill's chemical recovery process.

This investment is part of Rottneros AB's larger rebuild project called Agenda 500, which aims to increase availability and the total production volume at both of Rottneros AB's pulp mills, Rottneros Mill and Vallvik Mill, and with a target to reach a capacity of 500,000 tons per year.

Rottneros' Vallvik pulp mill. Photo: Rottneros image bank

The new white liquor filter will replace an existing filter delivered by Valmet in 1990. A larger filter is needed to handle the capacity increase at the mill. Start-up of the new filter is scheduled for autumn 2016.

The order is included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. A white liquor filter is usually valued below EUR 5 million.

"Vallvik has great confidence in Valmet as a supplier and despite a very tough schedule, we have a good reason to assume that Valmet will deliver on time. In addition, I personally look forward to working with Valmet again because this is my third project with Valmet regarding installation of pressurized disc filter," says Per-Arne Nilsson, Project Manager at Vallvik mill.

"Despite being a trusted partner with Vallvik for more than 40 years in the white liquor area, the tight schedule of this project was a challenge when pursuing this project. All people involved in the sales phase participated in the strategic and proactive work to compress the delivery time, and they deserve big thanks for their efforts. We are very pleased and look forward to a good and safe project implementation phase," says Thomas Malmqvist, Sales Manager at Valmet.

Valmet will also deliver a new bleach plant to Rottneros pulp mill, which was published earlier this year.

Technical details about the delivery

Valmet's delivery includes a new PDW-type white liquor filter, erection, start-up services, basic engineering for piping, for instrument and for electrical and process control. The PDW pressure disc filter produces completely clear white liquor and washes the lime mud. The very high white liquor yield increases upstream capacity and eliminates the potential process disturbances that increased amount of dregs and other non-process elements (NPE's) in the white liquor can cause.

About the customer Rottneros and the Vallvik mill

The Rottneros Group produces paper pulp at two pulp mills. Chemical pulp is produced at the Vallvik Mill, while mechanical pulp is produced at the Rottneros Mill. Vallvik mill produces two grades of long-fiber sulphate pulp: fully bleached sulphate pulp - ECF (Elemental Chlorine Free) and unbleached sulphate pulp - UKP (Unbleached Kraft Pulp). The mill has recently received a permission to produce 255 000 tons per year.

For further information, please contact:

Thomas Malmqvist, Sales Manager, Pulp & Energy Business Line, Valmet tel. +46 54 14 23 87

Paper for Recycling Quality Control guidelines

The European Standard EN 643, European list of standard grades of paper and board for recycling, is the basic document to be used by industry professionals in the buying and selling of paper for recycling. Interested parties should order the EN 643 from their respective national standardisation body . The standard was revised in 2013. It defines what the different grades of paper for recycling can and cannot contain as well as defining prohibited materials and unwanted materials. It also sets maximum tolerance levels by grade for unwanted materials.

The European Standard EN 643, European list of standard grades of paper and board for recycling, is the basic document to be used by industry professionals in the buying and selling of paper for recycling. Interested parties should order the EN 643 from their respective national standardisation body . The standard was revised in 2013. It defines what the different grades of paper for recycling can and cannot contain as well as defining prohibited materials and unwanted materials. It also sets maximum tolerance levels by grade for unwanted materials.

Specific agreements between buyer and supplier for grades with special specifications might still be necessary to meet individual requirements. However, general recommendations are needed to facilitate a common understanding of the standard.

To achieve greater harmonisation, to improve the implementation of the EN 643 Standard and to facilitate commercial relationships between paper mills and paper for recycling suppliers, these guidelines contain recommendations regarding paper for recycling quality controls for paper for recycling suppliers and paper mills.