Ianadmin

SCA publishes Annual Report and Sustainability Report

SCA has just published its Annual Report and Sustainability Report for 2015. The reports are available at www.sca.com.

SCA has just published its Annual Report and Sustainability Report for 2015. The reports are available at www.sca.com.

Digital versions of the reports are available via the following links:

Annual Report:http://reports.sca.com/2015/annual-report

Sustainability Report: http://reports.sca.com/2015/sustainability-report

Distribution of printed versions of the reports to shareholders and other stakeholders will commence on March 30.

NB: SCA discloses the information provided herein pursuant to the Securities Markets Act. Submitted for publication on March 22, 2016, at 17:45 CET

For additional information please contact:

Johan Karlsson, Vice President Investor Relations, 46 8 788 51 30

Karl Stoltz, Media Relations Manager, 46 8 788 51 55

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo, Vinda and Zewa. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2015 amounted to approximately SEK 115bn (EUR 12.3bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Kemira expands its sodium chlorate production capacity in Joutseno, Finland

Kemira will invest approximately EUR 50–60 million in its Joutseno site in Finland to implement its growth strategy. Kemira is planning to build a completely new sodium chlorate production line and cell-room based on Kemira’s in-house technology that will significantly increase the Joutseno site’s current sodium chlorate capacity. The construction is expected to start in June 2016, after fulfillment of certain regulatory requirements. During the construction phase, the indirect employment impact is about 200 persons.

Kemira will invest approximately EUR 50–60 million in its Joutseno site in Finland to implement its growth strategy. Kemira is planning to build a completely new sodium chlorate production line and cell-room based on Kemira’s in-house technology that will significantly increase the Joutseno site’s current sodium chlorate capacity. The construction is expected to start in June 2016, after fulfillment of certain regulatory requirements. During the construction phase, the indirect employment impact is about 200 persons.

The new chlorate production unit is expected to be in operation during the fourth quarter of 2017. Sodium chlorate is the raw material for chlorine dioxide (ClO2), which is produced on-site at the pulp mills and it is the primary bleaching agent for kraft pulp.

“The consumption of bleaching chemicals is increasing due to the recent pulp mill expansions and the announced greenfield projects in the Nordics. We want to invest in our sodium chlorate capacity to ensure our ability to effectively serve our customers. This investment supports our strategy to grow faster than the market and to strengthen Kemira’s position as a leading supplier for the pulp & paper industry”, says Kim Poulsen, President, Pulp & Paper segment.

Kemira’s Joutseno site is currently employing 67 persons and produces a wide range of chemicals for pulp and paper industry.

For more information, please contact

Kemira Oyj

Antti Matula, Head of Marketing & Product Management

Pulp & Paper segment

Tel. +49 171 196 1641

Tero Huovinen, SVP, Communications and Corporate Responsibility

Tel. +358 10 862 1980

Olli Turunen, VP, Investor Relations

Tel. +358 10 862 1255

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers’ water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2015, Kemira had annual revenue of EUR 2.4 billion and around 4,700 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd.

www.kemira.com

Hands-on Circular Economy - An inspiring paper mill visit with permanent representation officials

The Dutch Presidency of the Council of the European Union organised a field trip for Industry and Environment Council working group members to illustrate the Circular Economy, one of the Presidency’s top priorities. The Presidency chose the state-of the-art paper mill in Roermond, The Netherlands. The mill is operated by Smurfit Kappa and its raw material is 100% recycled paper, making it the perfect example of circularity. The visit was co-organised with the Confederation of European Paper Industries (CEPI) and the Royal Dutch papermaking association VNP.

The Dutch Presidency of the Council of the European Union organised a field trip for Industry and Environment Council working group members to illustrate the Circular Economy, one of the Presidency’s top priorities. The Presidency chose the state-of the-art paper mill in Roermond, The Netherlands. The mill is operated by Smurfit Kappa and its raw material is 100% recycled paper, making it the perfect example of circularity. The visit was co-organised with the Confederation of European Paper Industries (CEPI) and the Royal Dutch papermaking association VNP.

“We are very happy to be given the opportunity to demonstrate that paper is at the heart of the Circular Economy”, said CEPI Acting Director General Jori Ringman. “The paper industry champions many aspects of circularity from reusing water to industrial symbiosis, from including the whole value chain in advancing circularity to working towards clean and safe cycles. Whilst the recycling starts already at homes and offices and is a chain of many important actors, it is vital that EU legislation acknowledges the final recycling where the material is physically transformed to start a new cycle; this is what the participants saw today in practice”, he added.

Europe is a world champion when it comes to paper recycling, achieving a 72% recycling rate in 2014.

The Roermond mill is a great example of Circular Economy. It processes 600,000 tonnes or one million bales of waste paper into new paper rolls every year, which is more than 25% of the annual collected amount of paper for recycling. “The companies in our sector produce products in a very high tech and sustainable way, products that play a very important role in everyday life. The participants of the field trip could closely experience that in Roermond,” said Gerrit Jan Koopman, Director of Royal VNP.

For more information, please contact

Jori Ringman, CEPI Acting Director General at This email address is being protected from spambots. You need JavaScript enabled to view it., mobile: +32 478 25 50 70

Rutger van Dijk, VNP Communication and PR at This email address is being protected from spambots. You need JavaScript enabled to view it., mobile +31 6 45 79 02 60

CEPI aisbl - The Confederation of European Paper Industries

The Confederation of European Paper Industries (CEPI) is a Brussels-based non-profit organisation regrouping the European pulp and paper industry and championing industry’s achievements and the benefits of its products. Through its 18 member countries (17 European Union members plus Norway) CEPI represents some 505 pulp, paper and board producing companies across Europe, ranging from small and medium sized companies to multi-nationals, and 920 paper mills. Together they represent 23% of world production. For further information see www.cepi.org

Royal VNP – Koninklijke Vereniging van Nederlandse Papier- en Kartonfabrieken

The Dutch paper and board association represents the interests of the Dutch paper and board industry with an active lobbying focused on solutions, on current policies, legislation and sustainability. They provide services to their members and initiate policy-supporting studies. In this way they help to connect the companies’ needs and developments in society (customers, employees, government, NGOs and society in general). For further information see www.vnp.nl.

Global Forest and Paper Industry Celebrates International Day of Forests

On March 21st 2016, the International Council of Forest and Paper Associations (ICFPA) celebrated the United Nations International Day of Forests. ICFPA is proud to represent the contributions of the global forest products industry to sustainable development, ensuring that environmental, social and economic benefits are available to current and future generations.

On March 21st 2016, the International Council of Forest and Paper Associations (ICFPA) celebrated the United Nations International Day of Forests. ICFPA is proud to represent the contributions of the global forest products industry to sustainable development, ensuring that environmental, social and economic benefits are available to current and future generations.

Forests are essential to life on our planet. They provide clean air and water, and regulate climate. As renewable and recycable resources, forests are an important part of the solution to meeting global needs for foods, fuel, fiber, medicine and other products important to our daily lives.

The global forest products industry is inherently renewable. ICFPA members are commited to sustainable forest management with some 300 million hectares of certified areas from which a significant amount of wood fiber used by the industry is sourced.

“By following best practices, well-managed forests of all types are a positive contribution to the provision of distinct products and services that are essential for human well-being and development. Thus, our industry is helping to mitigate climate change while providing social inclusion,” said ICFPA president Elizabeth de Carvalhaes.

The ICFPA’s 5th Sustainability Progress Report (2015) highlights the industry’s advancements on a range of sustainability indicators and focuses on the industry’s contributions toward a green economy, including the reduction of greenhouse gas emissions intensity, the increase in sustainable forest management, and a high paper recycling rate.

The ICFPA represents more than 30 national and regional forest and paper associations around the world. Together, ICFPA members represent over 90 percent of global paper production and half of global wood production.

For more information about the sustainability of the global forest and paper industry, visit icfpa.org.

For more information:

Milena Serro

+ 55 11 3018-7829

This email address is being protected from spambots. You need JavaScript enabled to view it.

Sonoco Expands Fiber Certification Program to Brazil and Mexico

Sonoco (NYSE:SON), one of the largest global diversified packaging companies, has expanded its fiber certification program into Brazil and Mexico, as of mid-February 2016. Although most of the raw material used in our mills is 100 percent recycled fiber, this certification also requires that Sonoco select suppliers of virgin fiber and virgin fiber components that avoid trading or sourcing raw material that is: a) illegally harvested, b) harvested in violation of traditional and civil rights and c) harvested where global conservation priorities are threatened.

Sonoco (NYSE:SON), one of the largest global diversified packaging companies, has expanded its fiber certification program into Brazil and Mexico, as of mid-February 2016. Although most of the raw material used in our mills is 100 percent recycled fiber, this certification also requires that Sonoco select suppliers of virgin fiber and virgin fiber components that avoid trading or sourcing raw material that is: a) illegally harvested, b) harvested in violation of traditional and civil rights and c) harvested where global conservation priorities are threatened.

“Fiber certification is a demonstration of Sonoco’s commitment to recycling, healthy forests and responsible resource management,” said Laura Rowell, global sustainable packaging manager.

In Brazil, Sonoco’s paper mill in Londrina and rigid paper converting operation in Araras were both chain-of-custody certified to the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification Schemes (PEFC). In Mexico, its Atizapan paper mill and Mexico City rigid paper converting operation were also chain-of-custody certified to the FSC and PEFC, plus the North American-based Sustainable Forestry Initiative (SFI).

These operations join the company’s 12 previously certified paper mills and four previously certified converting operations located in the U.S., Canada and Europe.

As the leader in high-quality, innovative, value-creating packaging solutions that “Satisfy the Customer,” Sonoco is prepared to help its global brand customers meet their sustainability goals related to deforestation and responsible sourcing. For more information about its sustainability targets and programming, visit www.sonoco.com/sustainability.

About Sonoco

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging, and displays and packaging supply chain services. With annualized net sales of approximately $5.0 billion, the Company has 21,000 employees working in more than 330 operations in 34 countries, serving some of the world’s best known brands in some 85 nations. Sonoco is a proud member of the 2015/2016 Dow Jones Sustainability World Index. For more information on the Company, visit our website at www.sonoco.com.

Contact: Hilary Culbertson

+843/383-7859

This email address is being protected from spambots. You need JavaScript enabled to view it. A.Celli Nonwovens'1st "Lamination Workshop"

Don't miss A.Celli Nonwovens'1st "Lamination Workshop" brought to you by The A.Celli Nonwovens Winding School!

Two 1-day course dates to choose from: 18th or 19th May 2016, in Lucca.

![]() Developed in cooperation with Nordson Engineering GmbH and with the participation of Henkel, and Savaré Specialty Adhesives, the workshop will offer in-depth information on the lamination process, as well as the opportunity to see a live demonstration of a high speed (800 m/min) lamination line (2200 mm wide).

Developed in cooperation with Nordson Engineering GmbH and with the participation of Henkel, and Savaré Specialty Adhesives, the workshop will offer in-depth information on the lamination process, as well as the opportunity to see a live demonstration of a high speed (800 m/min) lamination line (2200 mm wide).

Need further info? You can address your inquiries to This email address is being protected from spambots. You need JavaScript enabled to view it. and we will get back to you with all the details you require.

Interested in participating? Click here to redirect to our website to fill out the Registration Form.

Make sure to register before Friday, 15th April 2016 to ensure a place at the Workshop!.

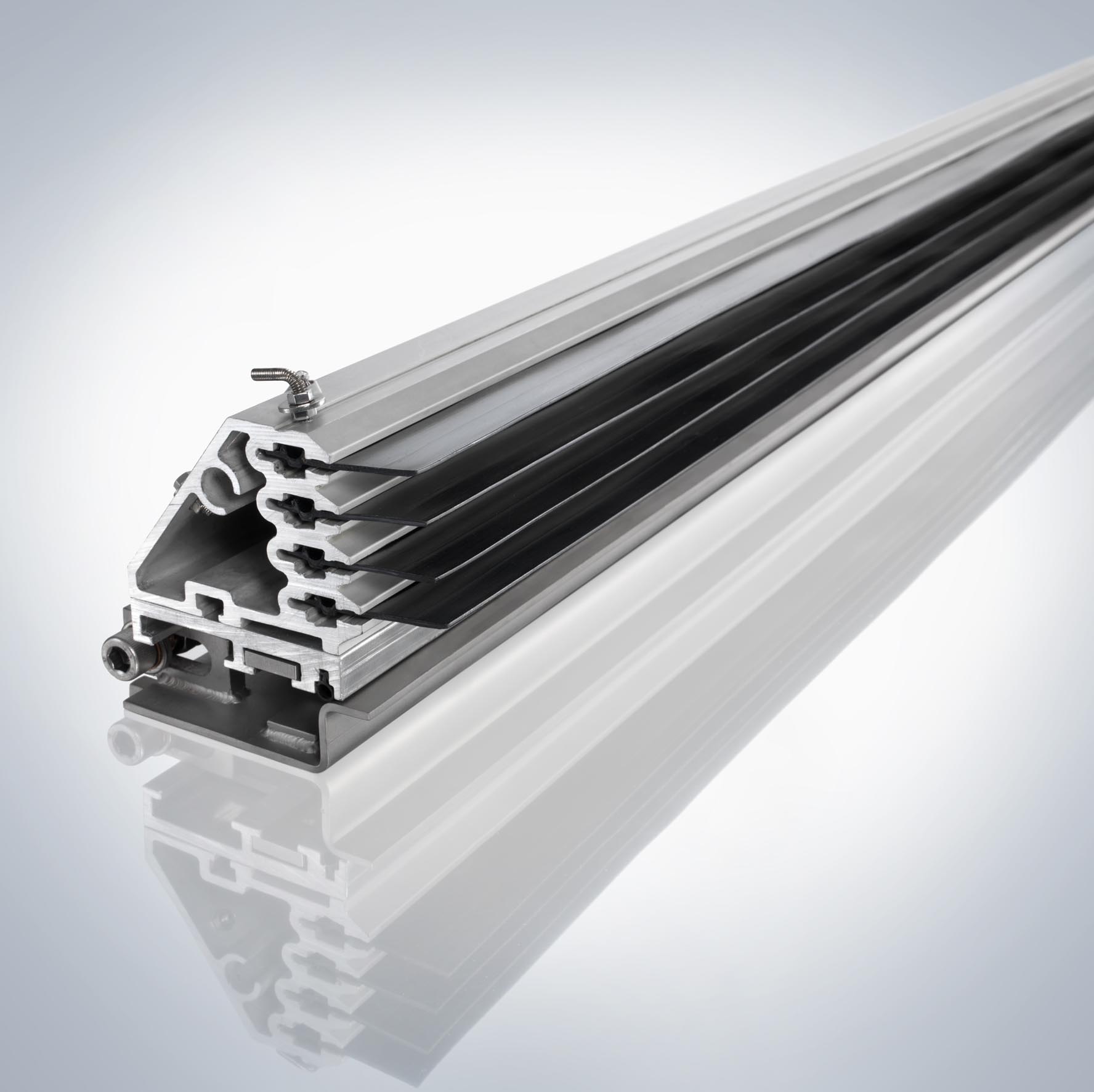

New sealing technology from Voith: upgrade for ProRelease+

Voith’s new MultiSeal Plus sealing technology improves processes in the dryer section of paper machines. Thanks to a shorter high-vacuum zone, the fabric deflection is significantly reduced and fabric wear is decreased. In addition, the adjustable SkySeal Plus sealing strips consistently optimize fabric runs and extend maintenance intervals. The entire sealing technology upgrades the web stabilization system ProRelease+ and results in better performance and an increase in machine speed.

- Reduced fabric wear thanks to minimized deflection

- Faster production speeds through an optimized vacuum zone

- Greater durability of sealing strips and easier servicing

The MultiSeal Plus is the carrier system for the SkySeal sealing strips. A key innovation is the horizontal adjustability of the new strips, which can be re-adjusted by up to 12 millimeter depending on the amount of wear. As a result, the correct distance between fabric and sealing system is guaranteed at all times. The SkySeal is available in two models with different hardness levels, which makes it easier to accommodate the characteristics and requirements of the respective paper machine. As a result the sealing strips suffer less abrasion.

The MultiSeal Plus carrier systems can be adjusted to provide an optimum seal of the release zones in the ProRelease+ sealing systems. Thanks to the new technology, the high-vacuum zone can be shortened overall. This results in an increase in runnability and reduced energy costs. The entire upgrade for ProRelease+ should be suitable for all fast-running paper machines.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith industrial Services.

Cham Paper Group Full year 2015: Progress and headwind

The Cham Paper Group has closed another transformative year with a small profit. The financial year was challenging for the paper division on several levels. Extensive investment in upgrading machinery to increase capacity and efficiency in Carmignano and the relocation of coating operations from Cham to Italy resulted in greater restrictions on capacity and higher start-up costs than originally planned. The appreciation in the US dollar against the Euro also led to sharply increased cellulose costs, which could not be offset directly via higher prices. In the newly created real estate division, preparations for the transformation of the industrial site into a new quarter proceeded according to plan.

The Cham Paper Group has closed another transformative year with a small profit. The financial year was challenging for the paper division on several levels. Extensive investment in upgrading machinery to increase capacity and efficiency in Carmignano and the relocation of coating operations from Cham to Italy resulted in greater restrictions on capacity and higher start-up costs than originally planned. The appreciation in the US dollar against the Euro also led to sharply increased cellulose costs, which could not be offset directly via higher prices. In the newly created real estate division, preparations for the transformation of the industrial site into a new quarter proceeded according to plan.

- Rising revenues in local currency thanks to good market conditions and successful products

- Higher costs of pulp due to currencies reduce operating profit

- Challenging transfer of Digital Imaging production

- Investmens implemented to increase productivity and capacity

- Planning dossier submitted for redesign of the Papieri site

- Payment of a dividend of CHF 3.00 per share

In 2015, the Group achieved revenue of CHF 194.3 million. This is 10.4% less than in 2014 (CHF 216.8 million), however, revenue grew by 2.4% in local currency. The operating profit came to a modest CHF 2.4 million (previous year: CHF 5.9 million), while the net result was just positive, at CHF 0.5 million (CHF 1.8 million). The profit has therefore improved slightly in the traditionally weaker second half thanks to the reduction in costs.

The paper division presented a contrasting picture

The trend in the paper division's revenue and profits did not match the opportunities presented by the market. The extensive investment in paper machine 4 in Carmignano to increase capacity and efficiency was completed on schedule, however, the start-up processes following the modifications turned out to be more difficult than expected and there was a delay in exploiting the increased production potential. The gains in efficiency are not yet apparent in the results because of the 10% increase (caused by movements in exchange rates) in the cost of cellulose, which accounts for around 50% of manufacturing costs. The challenges involved in the relocation of coating operations for the manufacture of complex digital imaging products to Italy were underestimated; it was not possible to keep to the budget or the timetable and this depressed profitability. However, demand for the Cham Paper Group's speciality papers was satisfactory to good in all segments. The three divisions Consumer Goods, Industrial Release and Digital Imaging are well positioned strategically and their products are appreciated in the market. Tonnage sold increased by 2.3% despite the restrictions mentioned previously, and the paper division's net revenue reached CHF 193.4 million. The gross profit decreased from CHF 28 million to CHF 18.4 million as a consequence, in particular, of the increase of approximately CHF 9 million in the cost of cellulose. Thanks to the reduction in the cost base, a marginally positive operating profit (EBIT) before restructuring of CHF 0.7 million was achieved (previous year: CHF 8.6 million); the figure after restructuring was CHF 2.5 million (CHF 5.6 million).

The real estate division developed as planned

Development of the Papieri site again made major progress in the financial year 2015: the municipality of Cham submitted the planning dossier, which had been produced jointly with the Cham Paper Group, to the responsible cantonal offices for preliminary review. The aim is to carry out the ballot on the development plan and the environmental impact assessment in autumn 2016. A possible scheduling concept was devised parallel to the development planning process. The space that has been released on the factory site is already being used on a short-term basis in a variety of ways by over 50 different tenants. The first contracts for new long-term tenants in the commercial area have also been signed. The relevant construction work has started and the real estate division generated revenue with third parties of CHF 0.8 million (previous year: CHF 0.7 million) and an operating profit (EBIT) of CHF 0.2 million (CHF 0.2 million). The development expenses for the Papieri project were capitalised.

Strong balance sheet and constant dividend

Despite the dividend payment, the abolition of the minimum EUR/CHF exchange rate and the associated reduction in the value of Italian assets in CHF, the Cham Paper Group still has a strong balance sheet. At the end of the reporting year, the equity ratio amounted to 50.6% (previous year: 52.8%). The Group is almost free from debt and has cash reserves of CHF 41.4 million. The site in Cham is still valued at acquisition cost. The Board of Directors will propose to the General Meeting of Shareholders that a dividend of CHF 3.00 (previous year: CHF 3.00) is paid per share, which will be exempt from capital gains tax for Swiss private investors.

New Delegate of the Board of Directors

Preparations are being made for a transfer of responsibilities in the Board of Directors of the Cham Paper Group: Susanne Oste, the previous Head of International Sales at Ziegler Papier, will be proposed for election to the Board of Directors at the General Meeting of Shareholders on 4 May 2016. She is to replace Urs Ziegler, who will continue to make himself available as a member of the Board of Directors, as Delegate of the Board of Directors. Susanne Oste has been being introduced to her responsibilities by Urs Ziegler since January 2016. Peter Schmid will not stand for re-election. The Board would like to thank Mr Schmid for his tremendous commitment since 2011.

A cautiously positive outlook

The Board of Directors and the Executive Board are of the opinion that the Group is well positioned for the future. In all its three areas of operations, the paper division covers attractive and expanding markets. The modernised mills produce more efficiently than ever before and have built up additional capacity. As a result, the lengthy, demanding transformation process is drawing to a close. Assuming that the cost of raw materials stabilises, we are expecting a clear improvement in the operating profit in the ballpark of the EBIT achieved in 2014). The Real Estate Division will develop into a strong second pillar for the Group over the next decade.

Annual Report 2015

The complete annual report (in German) is available on our website in the Investor Relations section (see «Financial Reports») or directly under the following link: http://ir.champaper.ch/cgi-bin/show.ssp?id=310&companyName=champaper&language=German

Key Figures

in CHF million, unless otherwise specified 2015 2014

Sales in tonnes 146,274 142,981

Net revenue 194,258 216,762

EBITDA 9,187 18,800

As a % of net revenue 4.7% 8.7%

EBIT before restructuring 627 8,930

As a % of net revenue 0.3% 4.1%

Restructuring income / (restructuring expenses) 1,795 -3,059

EBIT after restructuring 2,422 5,871

Profit 480 1,841

Earnings per share (in CHF) 0.65 2.48

Free Cash Flow -5,695 -5

Shareholders' equity 102,088 107,900

As a % of total assets 50.6% 52.8%

(Net debt) / Net cash -1,432 3,095

Investments in tangible and intangible assets 12,073 13,384

Number of employees (FTE) 389 417

Cham Paper Group

The Cham Paper Group is a leading manufacturer of coated speciality papers. Surface finishing lends papers properties that generate value added for its customers. The company, which was founded in 1657, has three sites, one in Switzerland (Cham) and two in Italy (Carmignano and Condino), and a global sales network.

The decision to focus on development and sales and discontinue paper manufacturing in Switzerland has made way for a new project on the factory site in the centre of Cham. The Cham Paper Group is developing an eleven-hectare quarter there called the Papieri site.

The Cham Paper Group (ticker symbol: CPGN) is listed on the SIX Swiss Exchange.

ANDRITZ to upgrade Flash Drying for Rottneros Bruk AB

ANDRITZ to upgrade Flash Drying for Rottneros Bruk AB, Sweden: Drying capacity increase of more than 50%

International technology Group ANDRITZ has received an order from Rottneros Bruk AB to upgrade the CTMP pulp drying line at its Rottneros mill, Sweden. After the modernization, the Flash Dryer’s capacity will be increased by more than 50% while at the same time specific heat consumption will be reduced. Start-up is scheduled for the fourth quarter of 2016.

International technology Group ANDRITZ has received an order from Rottneros Bruk AB to upgrade the CTMP pulp drying line at its Rottneros mill, Sweden. After the modernization, the Flash Dryer’s capacity will be increased by more than 50% while at the same time specific heat consumption will be reduced. Start-up is scheduled for the fourth quarter of 2016.

ANDRITZ will deliver a customized upgrade solution including a new drying stage as well as new cyclones, including complete mechanical erection. The newly designed cyclones will meet highest environmental standards, thus minimizing emissions.

“The target of this investment is to increase the production capacity and at the same time reduce the use of energy in our CTMP Flash Dryer. We’ve been having a long-lasting and very good cooperation with ANDRITZ for many years now, and this has been a strong reason to choose ANDRITZ as a supplier in this project”, says Nils Hauri, Production Manager at Rottneros mill.

Rottneros AB operates two pulp mills in Sweden with a total production capacity of almost 350,000 tons. The modernization will enable the company to raise its output at the Rottneros mill substantially.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 24,500 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

Preston paper products manufacturer plans expansion

Paper Innovation, a Preston-based manufacturer of paper products, is set to expand into new markets and launch its first online store after increasing its turnover by 15 per cent over the past three years.

Founded by husband and wife team Steve and Wendy Johnston in 1994, the company creates bespoke and personalised paper products for companies across the UK.

The company will be launching an online platform to expand its customer base both at home and overseas, with support from Lloyds Bank Commercial Banking which has supplied a £710,000 funding package.

The move will create four new jobs, and is expected to boost the company’s turnover by a further 25 per cent over the next two years.

Steve Johnston, director of Paper Innovation, said: “To stay competitive within our sector it is vital that we remain innovative, and we are constantly looking for new ways to expand our customer base and improve the services on offer to clients.

“The new online site will enable us to increase our presence in new markets, and we will be looking to expand our customer base across the corporate and hospitality sector over the next 12 months”

Lloyds Bank Commercial Banking provided the funding package after the business was introduced to the team by Johnny Abraham at J9 Advisory, Paper Innovation’s business finance advisor.

Steve added: “We switched our day-to-day banking relationship late last year, after looking for a banking partner which shared our enthusiasm for growth.

“Our relationship team and J9 Advisory has worked very closely with us to understand our business and objectives, and were able to provide the tailored suite of products that was required to achieve our expansion plans.”

Charlotte Jackson, regional manager for Lloyds Bank Commercial Finance, worked with relationship manager, Richard Hargreaves, to provide the support.

She said: “It is vital that firms explore different ways which they can expand their customer base, so when Steve and Wendy approached us for funding we recognised how launching an online store would benefit the business.

“We provided a bespoke funding package that gave them the flexibility to invest quickly in the firm, allowing them to capitalise on businesses increased appetite to purchase products and place orders online.

“According to our latest Business in Britain research, businesses in the North West are expecting their business activity levels to increase over the next 12 months. To help small businesses, like Paper Innovation, capitalise on these expansion opportunities, we have pledged to grow our net lending to them by £1 billion each year until 2017.”

Johnny Abraham, managing director at J9 Advisory, said: “Paper Innovation is an excellent example of a company that is constantly looking at innovative new products together with ways to improve the service it offers to its clients.

“It was clear from the first meeting that Steve and Wendy had formed a great relationship with the team at Lloyds Bank Commercial Banking, and by delivering a significant increase in working capital, together with a reduction in monthly commitments, the company is now well positioned to achieve its growth plans.”