Ianadmin

Toscotec provides a Steel Yankee Dryer to Fujian Jinmin Tobacco

Fujian Jinmin Reconstituted Tobacco Development Co., Ltd. has chosen Toscotec’s TT SYD-18FT Steel Yankee Dryer, in order to benefit from high energy efficiency and drying capacity. The start-up is scheduled for June 2017.

Following a similar application in the US, Toscotec consolidates its position in the segment of tobacco in Asia. As market leader of Steel Yankee Dryers worldwide, Toscotec is now well established also in the application of tobacco papermaking, offering the most comprehensive range of sizes and face lengths, up to a diameter of 22FT and 6 mt of width.

For its new project Fujian Jinmin Tobacco has chosen the Steek Yankee Dryer with the best production performances and energy efficiency, relying on Toscotec’s extensive experience in the field of energy savings and drying optimization.

About Toscotec Toscotec is a turnkey supplier to the global tissue industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects, and individual machineries. Headquartered in Lucca, the nerve center of the Italian paper district, with offices in China and North America, the Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities. Key to the Group’s success is the engineering and R&D department, run by a team of highly qualified engineers. Toscotec currently employs approx. 180 people.

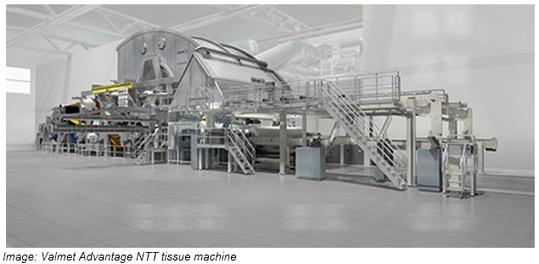

Valmet to supply an Advantage NTT tissue production line to Sofidel S.p.A in Poland

Valmet will supply a complete automated tissue production line to Sofidel's Delitissue mill in Ciechanóv, Poland. The delivery includes an Advantage NTT 200 tissue production line, stock preparation equipment and automation system.

The order was included in Valmet's 2015 orders received. The value of the order is not disclosed.

Sofidel and Valmet have a long history in working together and Valmet has previously delivered eleven tissue lines to Sofidel mills in various countries in Europe. The up-coming new line in Poland is the first Valmet Advantage NTT tissue technology based line in Sofidel's machine fleet. Start-up of this new line is scheduled for fourth quarter 2017.

"We see this as an investment of the future for several reasons. Sustainable production with low energy and fiber consumption is a success factor where the new line fits well in line with our targets to reduce environmental impact. The energy and fiber saving Valmet Advantage NTT technology will support Sofidel's environmental strategy. The Advantage NTT technology also allows us to take next step into the premium quality segment and differentiate our product offering in the tissue market," says Luigi Lazzareschi, CEO of Sofidel

"We share a long history with Sofidel, and are proud that they have selected our Advantage NTT technology for their path forward. We are facing an increasing interest in this technology from all markets, due to its flexibility to produce both conventional and premium products with low energy and fiber consumption. And we are convinced that it will be a success also for Sofidel," says Jan Erikson, Vice President, Sales, Valmet.

Technical information of the delivery

The new tissue machine will have a design speed of 1,800 m/min in textured mode and 2,000 m/min in plain mode. The production line is optimized to save energy and fiber as well as add possibilities for product differentiation and increased capacity of premium quality products.

Valmet's scope of supply comprises a complete tissue production line including an Advantage NTT tissue machine, with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including, an AirCap hood with Air system, WetDust system and a SoftReel B reel. Valmet will also deliver detailed mill engineering, stock preparation equipment as well as an automation package including DCS (distributed control) and QCS (quality control) systems.

About the customer Sofidel S.p.A

The Sofidel Group is the second largest European manufacturer of tissue paper (paper products for sanitary and domestic use) and the sixth largest in the world. It was founded 50 years ago and today boasts 27 subsidiaries in 13 countries - Italy, Spain, Sweden, The United Kingdom, Belgium, France, Croatia, Germany, Poland, Romania, Greece, Turkey and the USA. It has about 5500 employees and a consolidated turnover of € 1,809 million (2015) and a capacity of over a million tonnes a year.

For further information, please contact:

Jan Eriksson, Vice President Sales Valmet Tissue Mills Business Unit, tel. +46 705 17 14 90

Johan Björn, Sales Manager, Valmet Tissue Mills Business Unit, tel. +46 703 17 12 16

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

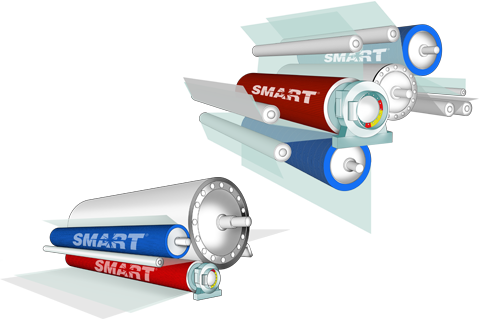

Xerium Introduces New SMART Connect Technology with Mobile Device Support, Enhanced Collaboration, and Real-time Value Opportunities Functionality

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched SMART(R) Connect Technology, further extending functionality of the company’s patented SMART Technology platform.

SMART Connect now includes seamless connectivity to existing site computer systems with automatic data backup. In addition, SMART Connect’s innovative new mobile monitoring capabilities provide the ability to monitor nip analytics from smartphones and tablets, at anytime, and from anywhere. The system also provides the ability for collaborative review of the analytics with the customers’ and Xerium’s engineers.

SMART Connect can also estimate a machine’s financial cost savings opportunities by comparing the actual nip conditions to an ideal condition based on key performance parameters.

More information is available about SMART Connect at http://www.xerium.com/SMART.

“We are very proud to release this next generation functionality for SMART Technology,” said Mr. Bill Butterfield, EVP and CTO of Xerium. “We continue to develop this unique platform to deliver more value to our customers, and continue to be excited to see them gain new insights into their complex operations enabling significant improvements to machine performance. SMART Connect technology is revolutionizing the way our customers manage their nipped roll positions in a wide variety of industrial applications. Customers continue to report benefits such as; reduced problems with roll crown issues, improved machine productivity, reduced energy consumption, and better product quality. And even with over 650 SMART Technology systems around the world, we still believe we’re just at the beginning stages for this innovative platform.”

About Xerium (NYSE:XRM)

Xerium Technologies, Inc. is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to the production of paper, paperboard, tissue, pulp, building products, nonwoven fabrics, and variety of industrial applications. Xerium products are specifically designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Source: Xerium Technologies, Inc.

Xerium Technologies, Inc.

Steve Cole, This email address is being protected from spambots. You need JavaScript enabled to view it.

Director – Global Marketing

Södra raises price for softwood pulp in Europe from April 1st

Following a period of downward price pressure last year, the softwood pulp market stabilized in early 2016 and the outlook is now improving. As a result, a number of global price initiatives have already been announced.

"We know from experience that the spring is typically characterized by stronger demand than the start of the year, and that this is also a time for maintenance stoppages in Europe. That's why we anticipate that the market will tighten even further", said Magnus Björkman, President of Södra Cell International.

"We know from experience that the spring is typically characterized by stronger demand than the start of the year, and that this is also a time for maintenance stoppages in Europe. That's why we anticipate that the market will tighten even further", said Magnus Björkman, President of Södra Cell International.

In the expectation of a stronger global market and solid demand, Södra will increase its market price for NBSK deliveries in Europe to USD 810/tonne, effective from April 1st 2016.

For further information, please contact:

Magnus Björkman, President of Södra Cell International,

+46 70 265 75 22

Henrik Wettergren, Sales Director Europe,

+46 73 069 70 12

Stora Enso is further investing in the competitiveness of Consumer Board and Biomaterials

Stora Enso is investing a total of approximately EUR 63 million to further improve competitiveness in strategic growth areas in China and Sweden in the Consumer Board and Biomaterials divisions.

Stora Enso will invest EUR 31 million in a new polyethylene (PE) coating line in the new consumer board mill in Beihai, China. The Beihai Mill is expected to be in operation during the second quarter of 2016, as communicated earlier. The investment will enhance Stora Enso’s strategy for profitable growth and supports competitiveness by enabling short lead-times and full quality control for PE-coated prime Food Service Board (FSB). The investment is expected to be completed in mid-2017.

Stora Enso will invest EUR 31 million in a new polyethylene (PE) coating line in the new consumer board mill in Beihai, China. The Beihai Mill is expected to be in operation during the second quarter of 2016, as communicated earlier. The investment will enhance Stora Enso’s strategy for profitable growth and supports competitiveness by enabling short lead-times and full quality control for PE-coated prime Food Service Board (FSB). The investment is expected to be completed in mid-2017.

Stora Enso is also investing EUR 16 million in a new chemical plant at the consumer board mill in Skoghall, Sweden to further improve the environmental performance of the mill. The investment is expected to be completed by the end of 2017.

In the Biomaterials division, Stora Enso is investing EUR 16 million to improve the environmental performance by reducing sulphur emissions of its mill in Skutskär, Sweden. The investment is expected to be completed by the end of 2017.

The investments will further enhance Stora Enso’s transformation into a global renewable materials growth company. EUR 31 million of these investments are part of the group’s 2016 capital expenditure forecast, which amounts to EUR 680–720 million as communicated earlier.

For further information, please contact:

Ulrika Lilja, EVP, Communications, tel. +46 1046 71668

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Our aim is to replace non-renewable materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 26 000 people in more than 35 countries, and our sales in 2015 were EUR 10.0 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market. storaenso.com

IQ Color dress rocks Cracow Fashion Show

On February 7th, the Junk Fashion Show took place in Cracow, Poland. Students of the School of Art and Fashion Design again proved their creativity working with paper and other materials. The idea behind the initiative is to create art using sustainable and recycled materials. The event was sponsored by Europapier Poland. Mondi’s fancy IQ Color dress opened the fashion show impressing with its bright and intense colours.

On February 7th, the Junk Fashion Show took place in Cracow, Poland. Students of the School of Art and Fashion Design again proved their creativity working with paper and other materials. The idea behind the initiative is to create art using sustainable and recycled materials. The event was sponsored by Europapier Poland. Mondi’s fancy IQ Color dress opened the fashion show impressing with its bright and intense colours.

We are Mondi: In touch every day

At Mondi, our products protect and preserve the things that matter.

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are located in central Europe, Russia, North America and South Africa. We offer over 100 packaging and paper products, customised into more than 100,000 different solutions for customers, end consumers and industrial end uses - touching the lives of millions of people every day. In 2015, Mondi had revenues of €6.8 billion and a return on capital employed of 20.5%.

The Mondi Group is fully integrated across the packaging and paper value chain - from managing forests and producing pulp, paper and compound plastics, to developing effective and innovative industrial and consumer packaging solutions. Our innovative technologies and products can be found in a variety of applications including hygiene components, stand-up pouches, super-strong cement bags, clever retail boxes and office paper. Our key customers are in industries such as automotive; building and construction; chemicals; food and beverage; home and personal care; medical and pharmaceutical; packaging and paper converting; pet care; and office and professional printing.

Mondi has a dual listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc, under the ticker code MNDI.

For us, acting sustainably makes good business sense and is part of the way we work every day. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is a business unit of Mondi’s Europe & International Division. In 4 paper mills in Austria, Slovakia, and Russia Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

Kimberly-Clark Europe chooses Futura JOI Embosser

Kimberly-Clark Europe has specified the latest generation Futura JOI Embosser for an existing tissue converting line at its Niederbipp facility in Switzerland.

![]() The new JOI Embosser started up in October 2015 and is being used to produce Kimberly-Clark’s high quality multi-ply toilet tissue. The JOI Embosser can operate in various modes, including nested, decorated embossing and point-to-point, including random point-to-point.

The new JOI Embosser started up in October 2015 and is being used to produce Kimberly-Clark’s high quality multi-ply toilet tissue. The JOI Embosser can operate in various modes, including nested, decorated embossing and point-to-point, including random point-to-point.

The JOI embosser symbolises Futura’s transformational influence on tissue converting. Kimberly-Clark will benefit from patented features such as the Zero Deflexion embossing rolls and supreme flexibility in terms of embossing pattern and configuration changes. JOI has also been designed with optimum safety in mind through guarding and reliable automation of all its main parameters, including nip adjustment.

The JOI Embosser in Niederbipp features the unique Futura Steel Marrying Roll which ensures no re-embossing effect and perfect inner ply definition. It also offers reduced maintenance and simplified cleaning.

Vinda invests in three new Toscotec’s tissue lines.

Two AHEAD-2.0M will be installed at its Sanjiang facility in Guangdong province, where Vinda already has eight Toscotec-supplied tissue machines running, to attain a total mill capacity of 250,000 t/y. This also represents a record-breaking achievement for the Italian manufacturer, who will accomplish start-up of its tenth tissue line on the same production base over the course of just four years.

The third machine will be installed in Vinda Shandong, where Toscotec has already supplied three lines in three years. This AHEAD-1.5M is identical to the machine fired up last August in Laiwu mill, with design speed of 1700 m/min and a production capacity of 30,000 t/y, same as the Guangdong tissue lines.

Vinda Group has once again confirmed its choice of the best available technology with top energy savings, as the winning choice for its unprecedented growth on the market. Toscotec’s successful solution TT DOES (Drying Optimization for Energy Saving) delivers the greatest advantages for the mill: highest performances with the lowest operating costs, by skilfully tapping on cost-effective energy sources such as steam and benefiting from Toscotec’s signature technology, its second generation Steel Yankee Dryer.

About Toscotec

Toscotec is a turnkey supplier to the global tissue industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects, and individual machineries. Headquartered in Lucca, the nerve center of the Italian paper district, with offices in China and North America, the Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities. Key to the Group’s success is the engineering and R&D department, run by a team of highly qualified engineers. Toscotec currently employs approx. 180 people.

Brazils new forest code: guide 2016

The Forest Code in Brazil is a piece of legislation on land management that legally requires that landowners in the Brazilian Amazon should permanently maintain a proportion of the land (80%) as forest. It was passed in 1965 but with little implementation until it was revised in 2012. Since then new legal instruments have been introduced which should lead to better environmental management and land use planning in Brazil including the reforestation, restoration or offset of historically illegally deforested areas.

The Forest Code in Brazil is a piece of legislation on land management that legally requires that landowners in the Brazilian Amazon should permanently maintain a proportion of the land (80%) as forest. It was passed in 1965 but with little implementation until it was revised in 2012. Since then new legal instruments have been introduced which should lead to better environmental management and land use planning in Brazil including the reforestation, restoration or offset of historically illegally deforested areas.

Produced by WWF-Brazil, this guide provides an overview of the updated Forest Code in Brazil and gives recommendations for decision makers in supply chain companies, financial institutions and Governments on how to take action to implement and ensure compliance to the Forest Code. It is particularly important for those in the supply chain who promote, regulate, produce, consume, export or import Brazilian agricultural and forest commodities.

Brazils new forest Code: guide 2016 PDF

WWF Guide to the Forest Code:

With the Forest Code serving as a first step towards fully legal and responsible agricultural production, cattle ranching and forestry production in Brazil it is important for companies sourcing from Brazil to ensure compliance with it. WWF has produced a new guide providing information on the Forest Code law, and outlining some recommendations to ensure effective implementation of the law. It also highlights precisely why we need to go even further to protect forests in Brazil, particularly if we are to achieve zero net deforestation and forest degradation (ZNDD) by 2020.

TheForest Code is the law that regulates land management and the protection of native vegetation on Brazilian properties. It came into force in 2012 and was revised in 2014 to include new regulations and new legal instruments for implementation.

Our guide to the code:

- Explains the main components of the law, with a supplement that explains the law in more detail, for example examining how compensation for incompliance can work, and how it can benefit biodiversity.

- Gives short case studies on how the sugarcane, beef, pulp and paper, soybean industries might implement the code (pages 32-35)

- Provides recommendations for the international community, buyers and producers, financiers, and public sector

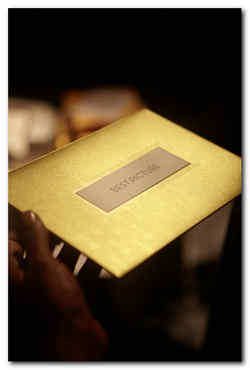

Voith and the Oscars® – a Short Story about the Night’s Glamorous Envelopes

Los Angeles. “And the Oscar goes to…“ – these magic words will once again make 24 movie stars very happy at the 88th presentation of the Academy Awards®. The famous stage at the Dolby Theater® will also feature a little piece of Voith, when the world’s entertainment industry is looking excitedly at the golden envelopes. Because the paper for the envelopes, which currently contain the presumably 24 best kept secrets of the film industry, originates from a paper machine made by Voith.

Gmund Treasury – this is the name of the award-worthy paper used for the Oscar® envelopes. Gmund Papier (Gmund Paper) produces the glamorous paper on its paper machine PM 407 from Voith. In 1979, the first high-quality papers made on PM 407 rolled off the production line at the Gmund paper makers. Voith originally built the machine for a Swiss paper manufacturer. After a rebuild, it was brought to Gmund at Lake Tegernsee, where it continues to make its special contribution to the Oscar® ceremony for the fifth time.

Gmund Treasury – this is the name of the award-worthy paper used for the Oscar® envelopes. Gmund Papier (Gmund Paper) produces the glamorous paper on its paper machine PM 407 from Voith. In 1979, the first high-quality papers made on PM 407 rolled off the production line at the Gmund paper makers. Voith originally built the machine for a Swiss paper manufacturer. After a rebuild, it was brought to Gmund at Lake Tegernsee, where it continues to make its special contribution to the Oscar® ceremony for the fifth time.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith industrial Services.