Ianadmin

Metsä Board recognised as world leader for corporate action on climate change by CDP

Metsä Board has been identified as a global leader for its actions and strategies in response to climate change and has been awarded a position on the Climate A List by CDP (formerly Carbon Disclosure Project), the international not-for-profit organisation that drives sustainable economies. Metsä Board is among 9% of corporations participating in CDP’s climate change programme to be awarded a position on the list, in recognition of its actions to reduce emissions and mitigate climate change in the past reporting year.

“A position on CDP’s Climate A List is welcome recognition to our work. By investing in bioenergy, as well as energy and material efficiency, our fossil CO2 emissions have decreased by 42% since 2009. In 2015 more than 80% of the fuels we used were bio-based. We are continuously looking for new areas of improving energy efficiency at our production units, “ says Mika Joukio, CEO of Metsä Board. “In addition, our fresh fibre paperboards are lightweight, safe and recyclable, and therefore benefit the whole packaging value chain.”

Thousands of companies submit annual climate disclosures to CDP for independent assessment against its scoring methodology. 193 ‘A Listers’ appear on the list, which has been produced at the request of 827 investors with assets of US$100 trillion. The Climate A List, along with the climate scores of all companies publicly taking part in CDP’s climate change programme this year, is available on CDP’s website.

Thousands of companies submit annual climate disclosures to CDP for independent assessment against its scoring methodology. 193 ‘A Listers’ appear on the list, which has been produced at the request of 827 investors with assets of US$100 trillion. The Climate A List, along with the climate scores of all companies publicly taking part in CDP’s climate change programme this year, is available on CDP’s website.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of folding boxboards and white linerboards made from fresh fibres. Its lightweight paperboards are developed as the perfect fit for consumer goods, retail-ready and food service packaging. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in northern forests.

The global sales network of Metsä Board supports customers worldwide, including brand owners, converters and merchants. In 2015, the company’s sales totalled EUR 2.0 billion, and it has approximately 2,600 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

6 Ways that Thermal Receipt Paper can Act as a Marketing Tool (Infographic)

Gone are the days when the use of thermal receipts is only to act as proof of purchase. With the ever evolving technology within our grasp, modern point-of-sale printers now have the capability to print custom text, images, and messages, making it possible for marketers to leverage receipts as a low-cost yet powerful marketing collateral.

Gone are the days when the use of thermal receipts is only to act as proof of purchase. With the ever evolving technology within our grasp, modern point-of-sale printers now have the capability to print custom text, images, and messages, making it possible for marketers to leverage receipts as a low-cost yet powerful marketing collateral.

Below, we give you six ways thermal receipt paper rolls can help you market to your customers, boost business profitability, and encourage consumer loyalty.

Embedded from Panda Paper Roll

Global pulpwood prices were up in the 2Q/16 after having declined for seven consecutive quarters

Wood fiber costs currently account for almost 60% of the cash costs when manufacturing wood pulp. Prices for both wood chips and pulplogs have trended downward for a long time, but this came to an abrupt halt in the 2Q/16 when the softwood price index rose 2.3% and the hardwood price index increased 3.7% from the 1Q/16, according to the latest Wood Resource Quarterly.

The wood fiber costs for the world’s pulp industry had trended downward for almost five years until this year when both the softwood and hardwood fiber price indices jumped in the 2Q/16. The two indices rose because price increases were seen for wood chips and pulplogs in practically every major market around the world.

The wood fiber costs for the world’s pulp industry had trended downward for almost five years until this year when both the softwood and hardwood fiber price indices jumped in the 2Q/16. The two indices rose because price increases were seen for wood chips and pulplogs in practically every major market around the world.

The Softwood Wood Fiber Price Index (SFPI) was up 2.3% from the 1Q/16 to US$89.63/odmt in the 2Q/16, as reported in the Wood Resource Quarterly (WRQ). This was the first quarter-over-quarter increase since early 2014. A combination of a weaker US dollar and higher wood fiber prices in the local currencies in Western Canada, France, Brazil and Germany, were the main reasons for the higher SFPI this quarter.

The Hardwood Wood Fiber Price Index (HFPI) was up 3.7% from the 1Q/16 to US$86.86/odmt, which was also the first increase in almost two years. The biggest price increases (in US dollars) occurred in Russia, Brazil, Chile, Australia and Eastern Canada.

Despite the recent price increase, current price levels for wood fiber are close to the lowest they have been in almost ten years in nominal terms. Wood fiber costs currently account for approximately 58% of the cash costs when manufacturing pulp on a global basis, according to Fisher International. Of the 16 major pulp-producing regions around the world tracked by the WRQ, pulpmills in Japan have the highest wood fiber cost percentage of close to 70%, while Russian mills have the lowest wood cost share of just below 40%.

The historically low wood fiber costs are, of course, very good news for the world’s pulp and paper industry. With market pulp prices currently being slightly below their ten-year averages, the wood costs as a percentage of the market pulp price (NBSK and EBK) are close to their lowest levels in almost 15 years.

Note. The Global Wood Fiber Price Index is a weighted average of delivered wood fiber prices for the pulp industry in all regions tracked by the publication Wood Resource Quarterly. These regions together account for 85-90% of the world’s wood-based pulp production capacity. The price is based on current quarter average prices, and country/regional wood fiber consumption data. The global average price for softwood and hardwood is calculated in nominal US$ per oven-dried metric ton (odmt) of wood fiber.

Global lumber, sawlog and pulpwood market reporting is included in the 52-page quarterly publication Wood Resource Quarterly (WRQ). The report, which was established in 1988 and has subscribers in over 30 countries, tracks sawlog, pulpwood, wood chip, lumber and pellet prices, trade and market developments in most key regions around the world. To subscribe to the WRQ, please go to www.woodprices.com

Firm performance in line with plans

CEO Per Lindberg comments on the development during Q3 2016:

”Once again we show a stable performance and I am happy to see that we deliver results as expected. Our production has stabilized and we have been producing in line with planned levels. The one issue for me is the lack of growth in Consumer Board. This is due to the production problems we suffered in previous quarters, but our view on the Consumer Board market has not changed and we expect to see the growth coming back as we catch up on inventory levels.”

”Once again we show a stable performance and I am happy to see that we deliver results as expected. Our production has stabilized and we have been producing in line with planned levels. The one issue for me is the lack of growth in Consumer Board. This is due to the production problems we suffered in previous quarters, but our view on the Consumer Board market has not changed and we expect to see the growth coming back as we catch up on inventory levels.”

THE RESULT

Net sales and adjusted EBITDA in Q3 are on par with previous year’s performance and in line with our expectations which is very satisfactory. We are not satisfied with our current lack of growth in the Consumer Board segment, but we have put the production disturbances related to last year’s rebuilds behind us, and the anticipated improvements will come as we now are able to run our capacity on higher levels to match market demand and growth. Unfortunately, at the end of the quarter the recovery boiler in Frövi experienced serious problems and we were forced to stop it before our planned maintenance shutdown. We can run the board machine on lower capacity on external pulp but as a consequence we will see additional costs for pulp and the repair of the recovery boiler in the coming quarter beyond our previous estimates.

MARKET OUTLOOK

Overall the markets in all three business areas were stable and we anticipate that to continue.

The brown sack paper market improved compared to previous quarter. The market demand and local pricing for NBSK pulp also remained stable in the quarter.

Our view on the Consumer Board market continues to be very positive. Local pricing has been stable and we are not expecting any changes.

Within Business area Corrugated Solutions the demand for fluting has strengthened throughout the quarter and local pricing was unchanged. Managed Packaging sales have continued to deliver good progress.

STRATEGY

Our company has high sustainability ambitions and performance, hence it makes us proud when it is recognized and verified. During the quarter, we have been awarded the Gold of EcoVadis for the third consecutive year, and we have been included in one of the world's most prestigious sustainability indexes, the Dow Jones Sustainability Europe Index. BillerudKorsnäs is the only European company in its category to be included.

BillerudKorsnäs wants to be a positive force in the development towards a sustainable future by challenging conventional packaging. One way of doing that is to find and invest in attractive companies in the early stages to eventually generate new business and solutions later on in the packaging value chain. "Internet of Packaging" is one of several areas of focus, and through our venture company it now includes the investment in Kezzler.

Our innovation and design agency NINE recently achieved great success at Pentawards, the packaging world's finest award, through gold and bronze in the concept category. Yet another example of how we challenge conventional packaging.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4 200 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Energy efficient pumping and gentle handling of sensitive process fluids

Cutting energy use while safeguarding product quality

Proven performance and reliability

Alfa Laval SRU rotary lobe pumps are carefully engineered to provide reliable performance, trouble-free operation and superior energy efficiency for demanding applications in the dairy, food, beverage, personal care and pharmaceutical industries.

It is an excellent choice for duties that require contamination-free pumps to meet high standards of hygiene, low-shear and low-pulsation operation. This pump handles both Cleaning-in-Place and Sterilization-in-place, and can be supplied with thorough documentation to support rigorous validation requirements.

Consistency with minimal risk of contamination

Alfa Laval SRU rotary lobe pumps are designed with features that maximize performance and minimize the risk of contamination. These include a defined compression front cover sealing, rotor nut retention design, drainable pump head and ultra-clean surface finishes.

Understanding of flow patterns is vital to ensure high efficiency fluid transfer with low pulsation, low shear and low noise characteristics. Alfa Laval employs Computational Fluid Dynamics (CFD) to establish exact geometry for the rotors and rotor case.

Robust construction – low maintenance

To deliver reliable operation and low maintenance the SRU features a robust gearbox construction with heavy-duty shafts, torque locking assemblies and taper roller bearings throughout.

Certification, specification and standards

Alfa Laval SRU rotary lobe pumps comply with EHEDG, 3-A, 3.1 and FDA hygienic standards and have ATEX approval for use in explosive environments.

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena.

Alfa Laval is listed on Nasdaq OMX, and, in 2014, posted annual sales of about SEK 35.1 billion (approx. 3.85 billion Euros). The company has about 18 000 employees.

Stora Enso Imatra – Web Inspection / Defect Detection System Upgraded to Improve the Quality of Board Machine #4

Stora Enso Imatra Mills introduced the Procemex web inspection and web monitoring system. The system helps Stora Enso to better investigate the root causes of web breaks, reduce the number of breaks and increase production efficiency.

Stora Enso Imatra Mills is the largest manufacturer of liquid packaging board in the world. Consumer packaging board used in contact with food and liquids must meet strict quality requirements set for food safety. What is more, no flavours can dissolve from the board into food products, and the products must be first-rate in terms of visual cleanliness.

For several years, systems supplied by Procemex have been used in Stora Enso's board machine 4 (BM4) to indicate any defects in board quality and to reduce web breaks. In March 2016, Stora Enso Imatra Mills made a system modernisation investment to improve the quality of food packaging board and increase the efficiency of the board machine.

Why did you decide to upgrade your system?

“We compared three different suppliers and ended up with Procemex, first of all, because we have had positive experiences with the previous system and, secondly, because we were able to upgrade the previous system – without needing to acquire a completely new one. We also investigated what benefits we can gain from the upgrade. In the end, the decision was an easy one; after all, we obtained a wholly new system by simply upgrading the old one,” says Mr. Riku Suurnäkki, Production Manager of BM4.

“Both web break and web inspection/defect detection systems are critical elements in order to be able to operate these machines: web inspection in terms of the final cleanliness and the web break system in terms of production efficiency. If we encounter any problems with efficiency, the web break system allows us to identify the root cause of breaks, enabling us to resolve, or even eliminate, the problems.”

Stora Enso Imatra Mills defined new locations for cameras, together with machine operators, and, now, cameras indicate the locations where pulp starts to pile up. “Of course, it is essential to listen to users,” Suurnäkki says.

“The new system became a necessity after we identified that we need to improve the classification of defects and the usability of the system. The previous system was unable to reliably classify a certain common defect, and there were situations in which defects in board ended up in our plastic coating,” says Suurnäkki.

What benefits did the upgrade produce?

The new upgraded Procemex cameras have a significantly higher resolution, defects are now classified more closely, the detection of defects is now more visual and the system is easier to configure for each user.

The new upgraded Procemex cameras have a significantly higher resolution, defects are now classified more closely, the detection of defects is now more visual and the system is easier to configure for each user.

“We can better detect any dirt and impurities,” says Vesa Koskinen, system specialist at Efora, who is responsible for the maintenance of the BM4 system.

Project management at the core

“On our part, the project did not get off to a textbook start, and we were forced to speed up the process. Procemex did an excellent job, even though the order-delivery schedule was very tight. The installation period was also tightly regulated and brief, but Procemex was able to ensure the resources required,” says production manager Riku Suurnäkki. “Commissioning, adjustments and links to mill systems – everything was done on time.”

User experiences

“The experience we have had so far indicate that the detection of defects is now much more visual than in the previous system, and the classification of defects has improved. Operators have already given us direct positive feedback, saying that the image quality is on a completely different level and, therefore, there are fewer web breaks,” Riku Suurnäkki says.

Usability and maintainability

“When acquiring new systems, usability and maintainability are among the most important criteria in order to keep our expensive machines and systems up and running. Cameras need to remain clean and the image quality must be high. The supplier must be quick and easy to reach,” Suurnäkki says, listing the criteria set for the new system.

“The new system improved overall reliability. We acquired new PCs and upgraded our cameras. Shifting to the new system was a simple process,” Vesa Koskinen says. “These Procemex Pinhole cameras are excellent, and they practically require no cleaning. The Pinhole cameras are in challenging locations, where pulp keeps flying every which way, but they are easy to keep clean. The new Procemex cameras offer an HD quality, the images they produce are on a whole different level, and lighting has been improved by using new Procemex LEDs. These new lights are much easier to control than the old ones.”

“It is easy to call Procemex whenever we need help, and it quickly responds to our questions,” Vesa Koskinen says.

Remote maintenance reporting

Stora Enso is using the Procemex remote reporting system, which offers preventive information, for example, about system performance, camera image quality, the operation of IT hardware and backups – it is a maintenance tool. The system produces monthly reports, creating comprehensive information about maintenance and raising a need for various tasks. “Procemex has very short delivery times for spare parts; of course, with the help of the preventive remote reporting system,” Koskinen says.

Continuous development

“We have new development projects in progress all the time, but we cannot say anything more about them at this stage. As requirements are becoming tighter and tighter, there is always something to improve. Procemex is an excellent partner in these projects.”

Stora Enso Imatra:

Stora Enso Imatra Mills is the largest manufacturer of liquid packaging board in the world. Imatra Mills consists of two mill units: Kaukopää and Tainionkoski. Together, these units employ approximately 1,000 people. The annual capacity of Imatra Mills is more than one million tonnes of board and paper. More than 90% of production is exported. The company's main market areas are located in Europe, while Southeast Asia forms another significant region.

Imatra Mills produces board and paper. Stora Enso manufactures liquid packaging board for milk and juice cartons, among others. Food packaging board is used to manufacture cups and different food packages. Packaging board is used in food, candy and cigarette packages. Package covers, cards and luxury packages are made from graphic board. Imatra Mills also manufactures packaging paper.

New steam turbine repair facility in Piedmont expands Sulzer’s network capability

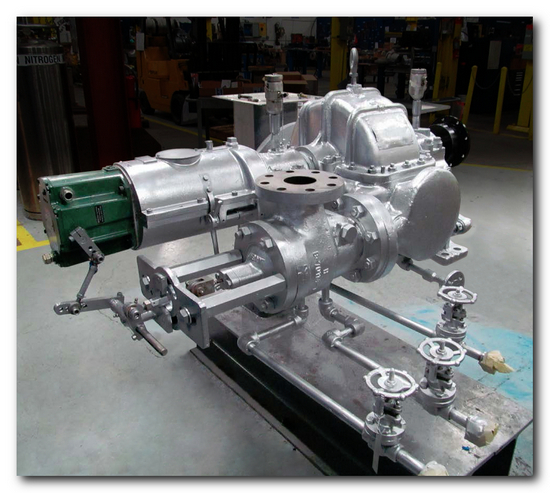

Sulzer’s extensive repair facilities have been further enhanced with the ability to refurbish small steam turbines in Piedmont, South Carolina. This additional service complements the existing range of repairs for electric motors, pumps, compressors and generators. In addition to mechanical repairs and welding services, the service center has an experienced field services team that delivers on-site repairs around the clock.

Sulzer’s extensive repair facilities have been further enhanced with the ability to refurbish small steam turbines in Piedmont, South Carolina.

As part of the investment made by Sulzer to improve local repair facilities, the service center in Piedmont has been equipped to carry out complete refurbishments of small steam turbine packages in addition to the services already delivered. The service center can now handle steam turbines up to 750 hp and repairs include balancing as well as overhaul of the governor and trip unit.

The service center in Piedmont has been equipped to carry out complete refurbishments of small steam turbine packages including overhauls of governor and trip units.

The experienced project team of engineers, designers and field service technicians is able to deliver repairs to small steam turbines and other turbomachinery for customers involved in power generation, paper, and petrochemical, steel as well as more general industries. This most recent addition in the Sulzer portfolio minimizes transport time for steam turbine repairs in the South East USA and ensures a cost effective repair.

Repairs to steam turbomachinery such as compressors and expanders up to 750 hp are delivered by the Service Center.

Sulzer service centers act as the local point of contact for a repair of any scale, even if the equipment has to be sent to another facility for the work to be completed. In this way every service center can offer the complete range of repair services to its customers. By delivering an efficient and reliable service, Sulzer is able to minimize downtime and increase productivity for each customer.

About Sulzer:

Sulzer is the leading worldwide, independent service provider for the repair and maintenance of rotating machines including turbomachinery, pumps and electro-mechanical equipment. With a global network of over 150 technically advanced manufacturing and test facilities, Sulzer offers a collaborative advantage that delivers high-quality, cost-effective, customized and turnkey solutions, providing its customers with the peace of mind to focus on their core operations.

Sulzer Rotating Equipment Services, a division of Sulzer, can accommodate all brands of rotating equipment including turbines, compressors, generators, motors and pumps. With an enviable track record, dedicated teams of on-site engineers provide best-in-class solutions to ensure that the most effective service is delivered.

Sulzer is dedicated to providing superior service solutions to a range of industries including power generation, oil and gas, hydrocarbon and chemical processing, water and air separation. Every solution is customized to suit the business needs of each application – whenever or wherever that may be.

With a long history of providing engineering service support, Sulzer is headquartered in Winterthur, Switzerland where it began in 1834. Today, with sales over US$ 3 billion and with approximately 15,000 employees, the Sulzer footprint spans across the globe. The core aim is to deliver a flexible and cost-effective service that optimizes customer operational efficiency and minimizes downtime.

For more information on Sulzer, visit www.sulzer.com

The image(s) posted with this press release may only be used to accompany this copy, and are subject to copyright. Please contact DMA Europa if you wish to license the image for further use.

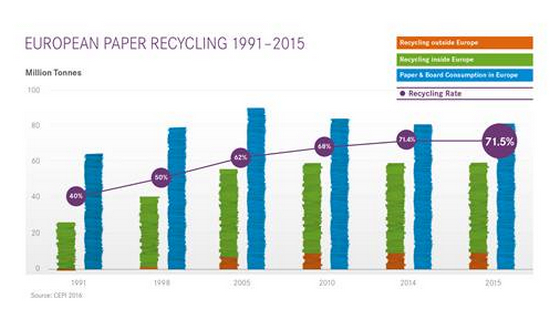

Paper recycling in Europe now at 71.5% - exceeding voluntary commitment

Paper Recycling Chain exceeds its voluntary commitment

European Paper Recycling at 71.5% in 2015

The paper recycling rate in Europe reached an impressive 71.5% as announced by the European Recovered Paper Council (ERPC) in their final monitoring report for 2015. Compared to 2010, collection and recycling has increased by almost one million tonnes of paper. This is due in part to the excellent work of the ERPC.

The 2015 European paper recycling rate of 71.5% is 1.5% higher than the target set by the ERPC in the 3rd European Declaration on Paper Recycling for the period 2010-2015. We are proud to report on the impressive work completed, following the pledge it first made in 2000 to expand paper recycling in Europe.

“The efforts of the ERPC perfectly complement EU policy on Circular Economy. The paper fibre loop can serve as the perfect model for circularity”, says ERPC Chairman Henri Vermeulen. “All 13 ERPC associations are proud to be part of a value chain ‘Made in Europe’, prolonging value creation and job opportunities”, he added.

In addition to the quantitative progress, a lot of qualitative work was done, particularly with initiatives to facilitate the recycling process and increase recycling activity. These notably include collection and applying ecodesign to paper products.

For the commitment period of 2011 to 2015, EY has independently verified the recycling rate calculations.Currently, a new ambitious commitment for 2016-2020 is being prepared. This will keep the industry moving on its path towards ever-higher recycling rates.

For more information, please contact the ERPC Secretariat, Ulrich Leberle, at

+32 2 627 49 23, This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.paperforrecycling.eu

- Download link for the 2015 Monitoring Report: http://www.paperforrecycling.eu/uploads/Modules/Publications/MonitoringReport2015final.pdf

- The European Recovered Paper Council (ERPC) was a self-initiative set up in November 2000 to monitor progress towards meeting the paper recycling targets set out in the 2000 European Declaration on Paper Recycling. Since then the commitments in the Declaration are renewed every five years. In 2011 the ERPC committed itself to meeting and maintaining both a voluntary recycling rate target of 70% in the EU27 plus Switzerland and Norway by 2015 as well as reaching qualitative targets in areas such as waste prevention, ecodesign, and R&D.

- As of 2016, ERPC’s signatories are ACE, CEPI, CITPA, EMFA, ERPA, ETS, FEPE, INGEDE, INTERGRAF. The supporters are AFERA, EuPIA, FINAT and RADTECH Europe. The European Commission (DG Environment and DG Grow) are permanent observers to ERPC.

SKF technology keeps Metsä Group’s pioneering bioproduct mill moving forward

With SKF providing cutting edge lubrication technology, the world's first next generation bioproduct mill from Metsä Group will operate reliably and efficiently, as well as sustainably.

SKF’s industry leading lubrication technology and system engineering support is being used to help ensure optimal operational performance on the world's first next generation bioproduct mill. The groundbreaking mill, which is being built by Metsä Fibre, part of Metsä Group, in the Finnish town of Äänekoski, will use 100 per cent of the raw materials and run solely on renewable energy.

The new mill is the largest ever single investment in the nation’s forest industry at approximately €1.2 billion and it is a major step forward in the development of sustainable production processes as it will produce significantly more electricity than it will need. It is expected to process 6.5 million cubic metres of wood into 1.3 million tonnes of pulp, with the remaining biomass and side streams being used to make high value bioproducts, including tall oil, turpentine, bioelectricity, process steam, district heat and wood fuel.

SKF was selected to supply lubrication systems – mainly dual-line grease lubrication devices – for about 3,000 lubrication points on the bioproduct mill. It is also providing specially developed, new generation lubrication control centres with mobile access to ensure maximum efficiency and reliability when the mill goes into operation in the third quarter of 2017.

Ossi Puromäki, Project Services Director at Metsä Fibre, said: “The new bioproduct mill is a step towards a world that is no longer dependent on fossil resources. Thanks to innovative technologies and support from trusted partners like SKF, we have been able to realise that ambition and satisfy the growing global demand for softwood pulp through sustainable means.”

Erkki Kemppainen, OEM Sales Manager at SKF’s Lubrication Business Unit, said: “Building on a relationship that already spans decades, we are proud to see our proven lubrication technologies in this state-of-the-art bioproduct mill that is transforming the face of the pulp, paper and wood production industry. Getting involved early in the process has allowed us to deliver a high performance, user friendly system that will support the mill as it manufactures products and produces energy.”

SKF is a leading global supplier of bearings, seals, mechatronics, lubrication systems, and services which include technical support, maintenance and reliability services, engineering consulting and training. SKF is represented in more than 130 countries and has around 17,000 distributor locations worldwide. Annual sales in 2015 were SEK 75 997 million and the number of employees was 46 635. www.skf.com

® SKF is a registered trademark of the SKF Group.

ANDRITZ to upgrade woodyard systems at Sappi North America’s mill in Skowhegan, Maine, USA

International technology Group ANDRITZ has received an upgrade order from Sappi North America for a high-capacity debarking line and woodyard equipment to be installed at Sappi’s Somerset Mill in Skowhegan, Maine. The new line will further reduce wood losses and enhance the mill’s reliability and performance. Commissioning of the new line, which has a design capacity of 300 t/h of hardwood chips and 270 t/h of softwood chips, is scheduled for the fourth quarter of 2017.

Over 100 HHQ-Chippers have been sold worldwide since being introduced to the market in 2001. The delivery to Sappi Somerset includes an extra-large (XXL) size chipper. This order is the second order for ANDRITZ in North-America in 2016 for a high-capacity debarking line with HHQ chipping technology.

ANDRITZ’s scope of supply includes upgrade of the log infeed, delivery of a new 38-m long debarking drum with energy-efficient steam de-icing, an extra-large (XXL) HHQ-Chipper with ANDRITZ TurnKnife and ChipperEKG condition monitoring systems, installation of a new scalping screen, and upgrade of the chip handling equipment. ANDRITZ will also deliver an advanced Automation & Industrial Internet package, including optical systems for scanning wood, chips, and bark to optimize the debarking and chip production processes, as well as data acquisition and analysis tools to improve the mill’s operational performance.

ANDRITZ and Sappi North America have had a good business relationship for many years. Recently, ANDRITZ completed a successful project to convert the Somerset Mill’s lime kiln from oil to gas firing, which resulted in significant savings in energy costs for the mill.

About The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,700 employees. ANDRITZ operates over 250 sites worldwide.

About ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), and recycling plants are also allocated to the business area.

About Sappi North America

Sappi North America, headquartered in Boston, is a market leader in converting wood fiber into superior products that customers demand worldwide. The success of our four diversified businesses – high quality Coated Printing Papers, Specialised Cellulose, Release Papers and Specialty Packaging – is driven by strong customer relationships, best-in-class people and advantaged assets, products and services. Our high quality Coated Printing Papers, including McCoy, Opus, Somerset and Flo, are the key platform for premium magazines, catalogs, books and high-end print advertising. We are a leading manufacturer of Specialised Cellulose used in a wide range of products, including textile fibers and household goods, and one of the world's leading suppliers of Release Papers with our Ultracast, PolyEX, Classics and Neoterix lines for the automotive, fashion and engineered films industries. OurSpecialty Packaging products, such as LusterPrint and LusterCote, represent an important asset in the food packaging and labeling industries. Customers rely on Sappi for high technical, operational and market expertise; products and services delivered with consistently high quality and reliability; and, state-of-the-art and cost-competitive assets and innovative spirit.

Sappi North America is a subsidiary of Sappi Limited (JSE), a global company headquartered in Johannesburg, South Africa, with more than 13,000 employees and manufacturing operations on three continents in seven countries and customers in over 100 countries around the world. Learn more about Sappi at: www.sappi.com/na.