Ianadmin

Sofidel reconfirms A.Celli technology.

A.Celli Paper has recently concluded an order for a latest-generation rewinder model E-WIND® with the Italian Group Sofidel, a world market leader in the production of tissue for hygienic and domestic use.

Sofidel, that has just celebrated 50 years of business activity, is present in Europe and the United States with 19 companies that each year produce more than one million tons of paper and employ over 5,500 people.

The new tissue rewinder model E-WIND®T200 commissioned to A.Celli Paper of Lucca will have a 5600-mm format and a working speed of 1600 mpm. The machine, highly evolved from the point of view of design and equipped with sophisticated technological innovations, will guarantee the Lucchese Group Sofidel the opportunity to work and handle structured webs. The rewinder is scheduled for delivery in May 2017, and will be installed in one of Sofidel’s facilities in Europe.

Just a few months from the order of the first tissue rewinder by Sofidel, this new order is yet a further confirmation that A.Celli Paper is a reliable, expert and professional partner capable of walking side by side with its customers, building important relationships.

A hundred-year perspective on sustainability

The brownish water and dead seabeds are gone. This year Iggesund Paperboard, manufacturer of the paperboards Invercote and Incada, can look back on a century’s unique performance record on sustainability. Iggesund Mill opened its first pulp mill in 1916, which was expanded to become an integrated pulp and paperboard mill in 1963.

“I’m proud to have the privilege of working for a company whose environmental efforts are characterised by both a long-term approach and a sense of responsibility,” comments Anna Mårtensson, Environmental Manager at Iggesund Paperboard’s Swedish production facility, Iggesund Mill. “Today our environmental impact is almost non-existent compared with the situation just over 50 years ago.”

“From the 1960s and onwards we have steadily reduced our local environmental impact even though our production has increased,” comments Anna Mårtensson, Environmental Manager at Iggesund Paperboard’s Swedish production facility, Iggesund Mill. “Iggesund has every reason to be proud of this development as well as the fact that the mill now runs almost exclusively on fossil-free energy.” © Iggesund

When Iggesund built its first pulp mill in 1916, environmental legislation did not exist and companies were basically free to release fibre waste and chemicals into the air and water. During the mill’s first 50 years this caused a significant negative effect on the local environment. The first emissions limits were set in 1963, symbolically the same year that biologist Rachel Carson’s famous book about the influence of pesticides on nature, Silent Spring, was published and became the alarm clock that laid the foundation of today’s environmental movement.

“By the mid-1960s the combined emissions of process chemicals and cellulose fibres had turned the seabed around the mill into a desert,” Mårtensson continues. “The water smelled bad and was a brownish colour. Sensitive species at the top of the marine ecosystem’s nutrient chains had disappeared from the mill’s vicinity.”

Since the 1960s the mill’s effect on the local environment has continually been improved, driven by both economic and environmental demands. Today’s processes make more efficient use of the timber raw material, leading to a better use of resources and less release of organic material. Today having chemical emissions at the levels of the 1950s would be inconceivable; instead, more than 99 per cent of the process chemicals are recycled. Since the 1970s, Iggesund’s water purification measures have been built up into a three-stage process: mechanical, biological and finally chemical purification almost identical to that used to produce drinking water.

“Experts say the solution we have at Iggesund Mill is the best available technology,” Mårtensson adds. “Above all, it has radically reduced our emissions of sulphur and phosphorus, which are particularly important since our water goes out into the Baltic Sea, which is threatened by eutrophication.”

The mill’s airborne emissions have developed in the same direction – the levels of acidifying sulphur or eutrophying nitrogen are down to levels where their local environmental impact is hard to document.

“People can catch edible food fish in the water surrounding the mill,” Mårtensson says. “Using chemical analysis it is impossible to distinguish those fish from fish caught in reference areas far from industrial sites. We are very pleased to see how species like sea eagles and seals, which had disappeared from near the mill, have now returned.”

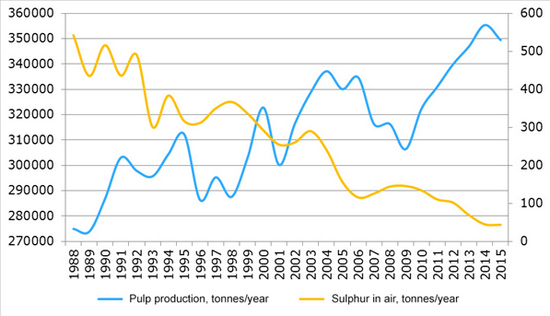

Sulphur emissions are one example of how the systematic environmental work has developed over time. In 1988 Iggesund Mill emitted 1.98 kilos of sulphur per tonne of pulp produced. Today’s emissions are just over six per cent of that, at 0.13 kilos per tonne. The corresponding value for the total amount of sulphur emitted per year has gone down from 540 annual tonnes to about 44 annual tonnes. This means that total sulphur emissions have fallen by 92 per cent despite a 25 per cent production increase over the same period.

In the past five years Iggesund Paperboard has also invested SEK 3.4 billion (EUR 360 million, GBP 225 million) to make its facilities in Sweden and the UK almost entirely fossil free by switching the energy source at the mills in Iggesund and Workington to bioenergy.

In the summer of 2016 Iggesund applied for a new permit for its operations. As a first step the company wants to increase its pulp production by 40,000 annual tonnes. In a later step, Iggesund Mill wants to increase its pulp production by another 40,000 tonnes and its paperboard production from today’s 400,000 tonnes to 450,000 tonnes per year.

“We’re now starting discussions with the authorities and I believe we have a number of good arguments going into the negotiations,” Mårtensson concludes. “Not least because we can point to half a century of continual improvements.”

The Fundamental Research Symposia Final Call for Papers

The Fundamental Research Symposia are held every four years at the English universities of Oxford and Cambridge. For the sixteenth symposium we will, for the first time, have the sym- posium at Pembroke College, Oxford. The title of the symposium is, ‘Advances in Pulp and Paper Research, Oxford 2017’. The Fundamental Research Committee is pleased to announce the review topics and authors:

• Fiber-fiber bonds. Ulrich Hirn and Robert Schennach, Graz University of Technology

• Forming of advanced structures in paper. Sören Östlund, KTH Royal Institute of Technology

• Barrier coatings for packaging. Lars Järnström and Magnus Lestelius, Karlstad University

• Non-woven structures. Joel Pawlak, North Carolina State University

• Creasing and folding. Dough Coffin, Miami University and Mikael Nygårds, Innventia

The committee now invites authors of research articles to submit an extended abstract for con- sideration for the symposium. Abstracts should be no more than four pages long, including all figures, diagrams, equations, etc. Session titles will be determined from the abstracts submitted, not by the review topics. The deadline for submission of abstracts is Monday 10th October 2016. Late submissions will not be accepted.

As a result of the IPCCS/IPPC event in Tokyo 2015 an alignment between these events and the Fundamental Research Symposia was made. Therefore we would like to emphasise that the Fundamental Research Symposium has a wide scope and submissions from scientists and engineers from all areas of paper science and technology as well as related areas are encouraged.

There are two stages to the refereeing process. Authors will be advised of the outcome of the first stage towards the end of November 2016; those who are successful will be invited to submit full papers by the end of January 2017 for the second stage of refereeing. Comments will be provided to authors towards the middle of March 2017. The deadline for the final fully refereed versions of all papers will be 7th May 2017.

We receive many more submissions for the Fundamental Research Symposia than may be included in the programme. In light of this, a subsidiary event consisting of a poster session, preceded by an introductory and very brief presentation, will be held during the week of the symposium. Contributions to this event, ‘Fundamental Research Communications’, will consist of no more than four typeset pages and will be published separately from the symposium proceedings. Abstracts submitted for the main symposium and considered by the referees to be of good quality but that are not included in the symposium programme may be considered for inclusion in this event. Authors willing to have their work considered for inclusion in Fundamen- tal Research Communications should indicate this in the email accompanying their abstracts. This information will not be available to referees.

Abstracts should be sent by email in Adobe PDF format to: This email address is being protected from spambots. You need JavaScript enabled to view it.

For enquiries, contact Dr. Daniel Söderberg: This email address is being protected from spambots. You need JavaScript enabled to view it. Groundbreaking of the new plant in Circleville

Sofidel breaks ground for its new integrated plant in Circleville (OH), in the US.

The plant enters its first building phase with a ceremony that draws dozens of elected officials. They include, among others, Ohio Lt. Governor Mary Taylor, Congressman Steve Stivers, State Senator Bob Peterson, and State Representative Gary Scherer.

“Today, we celebrate the commencement of construction of the first Sofidel integrated paper mill to be built from the ground up in the United States,” said our CEO Luigi Lazzareschi. “It’s going to be a very big project for us.”

“Today, we celebrate the commencement of construction of the first Sofidel integrated paper mill to be built from the ground up in the United States,” said our CEO Luigi Lazzareschi. “It’s going to be a very big project for us.”

“This is a very good location for us. Two hundred and eighty acres of relatively flat land,” Mr Lazzareschi added. “A good rail system connected to water and gas, a good airport, good logistically, lots of customer distribution centers, and a potential workforce of hard-working people.”

“For our 50th anniversary, we summarize our attention to The Future in a sentence: Sofidel, 50 years of growth into the future. If Ohio is the State where the future is happening, then evidently, we share the same interest – the future” Mr Lazzareschi said in ending his speech.

"The collaboration and determination of local and state officials and community stakeholders made it possible for Sofidel to break ground today for a facility that not only attests to the strong economic potential of Pickaway County, but brings hundreds of job opportunities for Ohioans," said State Senator Bob Peterson. "Today's groundbreaking was an opportunity to welcome Sofidel to Pickaway County and thank their CEO for making an important investment in our community and in our workforce."

The Circleville plant is expected to become operational by 2018.

As you know US President Barack Obama himself recently mentioned Sofidel in reference to its investment in Ohio. He declared at SelectUSA summit in Washington D.C.: “…at last year’s summit an Italian tissue company started a conversation with folks from central Ohio and next month they are breaking ground in the town of Circleville on a manufacturing facility that will create hundreds of jobs in a part of the American Midwest that needs them. It will be the largest private sector investment in Circleville in decades and it started right here at SelectUSA”.

Mohawk MakeReady Celebrates Fifth Anniversary at Graph Expo 2016

Mohawk, North America’s largest privately-owned manufacturer of fine papers, envelopes and specialty substrates for commercial and digital printing, celebrates the fifth anniversary of Mohawk MakeReady, an online community for digital print service providers at Graph Expo 2016, September 25-28 in Orlando, Florida.

Mohawk MakeReady, which launched at Graph Expo 2011, is designed to give digital printers practical tools and actionable guidance to help them meet their business objectives. Visitors to the site can easily browse content by relevant topic or type including a popular downloads section. Mohawk’s goal in creating the site was to provide straightforward strategies that printers can implement immediately for their customers.

Mohawk MakeReady, which launched at Graph Expo 2011, is designed to give digital printers practical tools and actionable guidance to help them meet their business objectives. Visitors to the site can easily browse content by relevant topic or type including a popular downloads section. Mohawk’s goal in creating the site was to provide straightforward strategies that printers can implement immediately for their customers.

Content on Mohawk MakeReady varies from perspectives from industry leaders, case studies about marketing a successful printing business, concise videos on topics such as operational efficiency, and presentations and articles that showcase solutions to maximizing social media efforts and identifying sales opportunities. Additionally, the site offers design-ready die-lines and templates and equipment compatibility charts to support Mohawk’s broad line of specialty digital substrates. All content is designed to be concise and practical, and new topics are added weekly.

“When we launched MakeReady in 2011, our goal was to leverage Mohawk’s knowledge, relationships and experience as a leader in digital substrates to help digital printers make more efficient use of their time, materials, people and entrepreneurial spirit,” says Joe Schember, Product Manager, Digital Specialty & Paper, Mohawk.

The site has experienced significant growth since its inception, showing increases in page views and visitors, including an impressive 60% increase in visitors and 1,300% increase in membership since 2011.

“Five years later, we’re pleased that the community has expanded to include paper merchants, graphic designers, marketing professionals, brand owners, students and educators, and we’re pleased that the site’s content continues to receive positive feedback from the graphic arts industry worldwide. We encourage anyone who may not be familiar with the Mohawk MakeReady community to join us as we continue to grow and deliver valuable industry insight,” Schember continues.

Print Service providers and members of the graphic arts industry describe how MakeReady has helped their businesses grow and thrive:

“MGI Digital technology marketing, sales and technical teams have all learned more about paper & substrate application opportunities from Mohawk MakeReady than from any other source.”

- Jack Noonan, Marketing Coordinator, MGI Digital Technology

“Mohawk continues strengthening their industry position as a highly valuable resource for information and creative inspiration for the graphic arts supply chain through MakeReady. Their dedicated team is always on trend with what’s next in printing and marketing, and the site provides a wealth of free knowledge that consistently inspires me.”

- Deborah Corn, Print Media Centr

“Comprehensive, informative and fun, is how I would describe Mohawk MakeReady. In our environment, where digital media and workflows are converted into physical products, Mohawk MakeReady has become a go-to resource as I navigate an ever-expanding market of new products and technologies.”

- Matt Rees, Sr. Strategy Development Manager, Vistaprint Corporate Solutions

“Mac Papers has found MakeReady to be an excellent resource and I highly recommend printers utilize the Equipment Compatibility section. This is an easy reference guide to verify the wide selection of substrates for their digital press. As this segment of digital paper expands, Mohawk keeps current with the new technologies in qualifying substrates, so it is always up to date. In addition, there are many educational tools that print service providers can reference to generate ideas for their customers thus creating new revenue streams. If you have not already done so, bookmark MakeReady.”

- David Schaffer, Product Manager, Digital Papers and Substrates, Mac Papers

“Mohawk MakeReady provides an easy-to-use avenue for inspiration and application ideas that help Konica Minolta digital press users grow their business and leverage their technology investment. Konica Minolta also uses MakeReady to download templates to produce great looking samples at all of our open houses and trade shows.”

- Dawn Nye, Solutions and Services Marketing Manager, Konica Minolta Business Solutions

“Mohawk MakeReady was truly the first of its kind. A valuable, no-nonsense resource giving real world tips and information that its readers can easily put to use.”

- Lisa DiBacco, DiBacco + Company

“Mohawk MakeReady provides great information on digital printing. My favorite section of the site focuses on case studies demonstrating innovative uses of substrates across a range of applications. Any service provider will benefit from a close look at this and other materials on the site, including videos with industry thought leaders.”

- Jim Hamilton, Group Director, InfoTrends

Mohawk will exhibit in booth #2413 within the Material Matter pavilion at Graph Expo 2016. Mohawk’s presence in the pavilion aligns with the brand’s Maker Campaign, celebrating the role that well-crafted materials play in the print ecosystem, and supports the brand’s leadership position in the digital print industry.

Members of the graphic arts industry interested in learning more about Mohawk MakeReady or joining the community should visit https://www.mohawkconnects.com/makeready/.

ABOUT MOHAWK

Mohawk is North America’s largest privately-owned manufacturer of fine papers and envelopes which are preferred for commercial and digital printing, photo specialties, packaging and high-end direct mail.

Mohawk fine papers and envelopes include the signature brands Mohawk Superfine® and Strathmore®, as well as proprietary treatments Inxwell® and i-Tone®. With a culture of innovation, Mohawk’s business model now extends beyond paper manufacturing into new areas of growth, including specialty digital substrates and wide format ink jet materials. Mohawk remains committed to an 85 year heritage of bringing the most innovative and beautiful materials to the design and print communities.

As a leader in environmentally and socially responsible business practices, Mohawk was the first U.S. manufacturer of commercial printing papers to match 100% of its electricity with wind power renewable energy credits and the first U.S. premium paper mill to shift toward carbon neutral production. Many products within Mohawk’s portfolio of recycled papers are certified by Green Seal and the Forest Stewardship Council (FSC).

Mohawk is a fourth-generation, family-owned and operated business based in Cohoes, New York, with global sales and operations located throughout North America, Europe and Asia. For more information, please visit www.mohawkconnects.com.

Grand slam at Pentawards for BillerudKorsnäs innovation and design agency NINE

BillerudKorsnäs innovation and design agency NINE wins gold and bronze in the concept category at Pentawards, the packaging world's finest award. NINE is a subsidiary of BillerudKorsnäs and offers services within packaging innovation and design to brand owners, primarily within fast moving consumer goods.

The gold is awarded to a packaging concept for travel size organic beauty products, made by the extremely stretchable paper FibreForm from BillerudKorsnäs. This introduces a renewable material as an alternative to a product area today completely dominated by fossil materials. The bronze is awarded to a concept paper bottle for carbonated beverages, which is an ongoing innovation project within BillerudKorsnäs and an example of how the company is challenging conventional packaging for a sustainable future.

What if carbonated drinks could be packaged in paper! BillerudKorsnäs challenges conventional packaging with new solutions and innovation projects.

- NINE works on the forefront of our packaging solutions offer with deep consumer insights and an ear to the market. It is a strength to BillerudKorsnäs to be in this position in the value chain and very pleasing that Pentawards once again confirms NINE’s ideas and innovative approach within our industry, says Henrik Essén, Senior Vice President Communication and Sustainability.

BillerudKorsnäs has clear goals for sustainable and profitable growth, which in part is created by strengthening its position in the value chain. Therefore the company's sustainable materials are gradually and increasingly complemented with offering packaging solutions based on many years of expertise on packaging's role in society and their life cycle from manufacture to recycling. The orientation towards solutions is a natural development as new markets often demand comprehensive solutions when new materials are introduced.

Pentawards Gold: Renewable packaging for organic beauty products. Each origami-inspired container consists of a single sheet that is folded and pressed into shape, a tear-off corner reveals a wood twist cap.

NINE is an innovation and design-oriented agency with clear focus on strategic business development and packaging design. BillerudKorsnäs is its principal owner. Its vast experience within fast moving consumer goods has given NINE an in-depth understanding of packaging innovation and a unique position in the market. www.nine.se

BillerudKorsnäs provides packaging materials and -solutions that challenge conventional packaging for a sustainable future. We are a world leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4 200 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Domtar Optimizing Fluff Pulp Production, Streamlining Plymouth Mill Operations

Domtar Corporation have just announced a plan to optimize fluff pulp manufacturing at its Plymouth mill. The streamlining measures will strengthen the mill's position in the global fluff pulp markets.

The restructuring, which is expected to be completed by mid-2017, includes the permanent closure of the small pulp dryer and idling of related assets, in addition to a workforce reduction of approximately 100 positions. The streamlining process will also right-size the mill to an annualized production target of approximately 380,000 metric tons of fluff pulp. The Plymouth mill will continue to produce LighthouseTM Fluff, the benchmark grade for high-quality fluff pulp.

The restructuring, which is expected to be completed by mid-2017, includes the permanent closure of the small pulp dryer and idling of related assets, in addition to a workforce reduction of approximately 100 positions. The streamlining process will also right-size the mill to an annualized production target of approximately 380,000 metric tons of fluff pulp. The Plymouth mill will continue to produce LighthouseTM Fluff, the benchmark grade for high-quality fluff pulp.

"This action at Plymouth along with the start-up of fluff pulp production at Ashdown will optimize Domtar's fluff pulp manufacturing network and strengthen our position in the growing fluff-pulp market," said Domtar President and Chief Executive Officer John D. Williams. "We remain committed to the Plymouth mill, where we have made significant investments in the past several years. These changes will prepare the mill for long-term, sustainable success."

Fluff pulp is bleached softwood cellulose fiber used worldwide in absorbent applications such as baby diapers, feminine hygiene and adult incontinence products.

About Domtar

Domtar is a leading provider of a wide variety of fiber-based products including communication, specialty and packaging papers, market pulp and absorbent hygiene products. With approximately 10,000 employees serving more than 50 countries around the world, Domtar is driven by a commitment to turn sustainable wood fiber into useful products that people rely on every day. Domtar's annual sales are approximately $5.3 billion and its common stock is traded on the New York and Toronto Stock Exchanges. Domtar's principal executive office is in Fort Mill, South Carolina. To learn more, visit www.domtar.com.

Cham approves the development of the Papieri site

On occasion of the public voting on September 25, 2016, the Cham voters approved both proposals for the development of the Papieri site (partial change of building legislation and zoning plan with 63% yes-votes as well as development plan with 57% yes-votes).

With this, the general public has created the prerequisite to create a new, mixed residential and working district on the site of the former paper factory. For the development plan and rezoning to take legal effect, the approval of the Zug Cantonal council is still required.

With this, the general public has created the prerequisite to create a new, mixed residential and working district on the site of the former paper factory. For the development plan and rezoning to take legal effect, the approval of the Zug Cantonal council is still required.

Cham Paper Group

The Cham Paper Group is a leading manufacturer of coated speciality papers. Surface finishing lends papers properties that generate value added for its customers. The company, which was founded in 1657, has three sites, one in Switzerland (Cham) and two in Italy (Carmignano and Condino), and a global sales network.

The decision to focus on development and sales and discontinue paper manufacturing in Switzerland has made way for a new project on the factory site in the centre of Cham. The Cham Paper Group is developing an eleven-hectare quarter there called the Papieri site.

The Cham Paper Group (stock exchange symbol: CPGN) is listed on Switzerland's SIX Swiss Exchange.

Take-Over of Renkum PM 2 signed: Successful conversion from newsprint to packaging paper

The PM 2 of Parenco in Renkum, Netherlands, was successfully started up just 14 months after contract signing. After a short optimization phase the customer signed the official take-over document. This rebuild increases the mill's capacity by approximately 385,000 metric tons annually.

“We are very pleased that the take- over has been signed. In the next months, we will proof that Parenco has arrived as a new supplier in the packaging paper industry” says Geert Wassens, CEO of Parenco. The conversion from newsprint to packaging paper grades will help to position Parenco as a highly competitive supplier in the packaging paper market, and broadens its paper making activities. Since 2012, Parenco is an independent company under the ownership of H2. Beside the converted PM 2, Parenco operates also the PM 1 in Renkum, which produces magazine paper (SCB) for the European market.

“We are very pleased that the take- over has been signed. In the next months, we will proof that Parenco has arrived as a new supplier in the packaging paper industry” says Geert Wassens, CEO of Parenco. The conversion from newsprint to packaging paper grades will help to position Parenco as a highly competitive supplier in the packaging paper market, and broadens its paper making activities. Since 2012, Parenco is an independent company under the ownership of H2. Beside the converted PM 2, Parenco operates also the PM 1 in Renkum, which produces magazine paper (SCB) for the European market.

Just after start-up the rebuilt PM 2 already proved that the produced paper quality reaches the market demands on all points.

With a wire width of 8.4 m the paper machine was equipped with a new two-layer MasterJet Pro M2 headbox, a DuoFormer D II, a DuoCentri NipcoFlex press, a SpeedFlow sizing unit and a new CombiDuoRun after dryer section. The PM 2 produces Testliner and Fluting in a basis weight range of 70-160 g/m².

Voith did not only rebuild the paper machine itself: Within the Process Line Package scope, Voith as general contractor also adjusted and rebuilt all adjacent processes and utilities. This also included a new OCC stock preparation and the Wet End Process. Based on the results of a pre-engineering, the scope of supply also covered all necessary adaptions on the steam, water and power supply as well as civil works.

About Voith Paper

Voith Paper is a Group Division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

Pankaboard launches new cartonboard for luxury packaging

Following recent investment at the mill in Finland, and as a result of extensive product development, Pankaboard is delighted to introduce a new Folding Boxboard to the product portfolio.

PANKALUX, is a new GC1 Folding Boxboard that has been engineered with the demands of the luxury packaging market in mind, and the luxury beverage sector in particular. The result of the development can be seen as outstanding printing quality, an improved surface for lamination, and improved runnability on high speed packaging lines.

Makings of PANKALUX are immediately available in the substance range of 285 to 560 gsm.

The new product will be officially introduced to the market at the FachPack exhibition in Germany, where Pankaboard will be present.

Pankaboard is a global leading producer of special cartonboards with a capacity of 110,000 t/a. The product portfolio consists of high thickness FBB as well as various uncoated speciality boards. The company serves globally a wide range of end uses, including luxury beverage and food packaging, picture framing, capseals and visual communication.