Ianadmin

Celupaper starts up the new MODULO tissue machine supplied by Toscotec at Papelera Nicaragua, Argentina.

Celupaper S.A. started up the new PM3, the first of the two tissue machine that the South American producer has commissioned to the Italian leading supplier in the last 2 years. This start-up follows the rebuilding of PM2 that Toscotec also carried out in February 2015.

The new line is installed at Papelera Nicaragua mill, Argentina.

Based on an intensive energy-saving concept, PM3’s delivery included the approach flow system featuring ultimate Toscotec technology TT SAF®, a MODULO tissue machine with single-layer headbox, single press configuration and TT SYD-2500MM featuring TT Milltech-MYH (monosystem gas heated hood). The supply also comprised an electrification and controls package and steam & condensate system.

The excellent cooperation between the two teams has allowed to get immediately the target of productivity, optimizing the production cycle, both in terms of flexibility and energy costs. This project will increase the mill daily tissue production of 50 tons of different grades of high-quality tissue.

“A new era for Celupaper has just began. We believe to play an important role in South American market according to our vision: to meet the demand with high quality products following the market growth and retaining the customers. Now we are waiting for the next Toscotec PM4 that will be started up within the end of 2017.”says Mario Speranza , owner of Celulpaper S.A..

About Toscotec

Toscotec is a turnkey supplier to the global tissue industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects, and individual machineries. Headquartered in Lucca, the nerve center of the Italian paper district, with offices in China and North America, the Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities. Key to the Group’s success is the engineering and R&D department, run by a team of highly qualified engineers. Toscotec currently employs approx. 180 people.

Xerium Schedules Second Quarter 2016 Earnings Conference Call

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has just announced that it plans to release its financial results for the second quarter of 2016 after the close of regular market trading on Tuesday, August 2, 2016.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has just announced that it plans to release its financial results for the second quarter of 2016 after the close of regular market trading on Tuesday, August 2, 2016.

The Company will hold a conference call on August 2 following the release:

- Date: Tuesday, August 2, 2016

- Start Time: 4:30 p.m. Eastern Time

- Domestic Dial-In: 1-844-818-4921

- International Dial-In: 1-484-880-4582

- Passcode: 49430194

Webcast: www.xerium.com/investorrelations

To participate on the call, please dial in at least 10 minutes prior to the scheduled start.

A live audio webcast, in addition to the materials used in the presentation, will be available in the investor relations section of the company's website at www.xerium.com/investorrelations. To access the live audio webcast, please click on the earnings call event link that will appear on the investor relations home page.

An archive of the webcast and presentation materials will also be available after the call by clicking on the "Archived Webcasts" link that appears on the left hand side of the company's investor relations homepage at www.xerium.com/investorrelations

ABOUT XERIUM TECHNOLOGIES

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 30 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Source: Xerium Technologies, Inc.

Xerium Technologies, Inc.

Clifford Pietrafitta, 001-919-526-1403

This email address is being protected from spambots. You need JavaScript enabled to view it.

Verso Successfully Emerges from Bankruptcy

Highly De-levered Capital Structure Positions Verso to Successfully Compete and Profitably Grow

Class A Common Stock Listed on NYSE; Trading to Begin on July 18, 2016

Verso Corporation (NYSE:VRS) has just announced that the company and its subsidiaries have emerged from bankruptcy following a successful financial restructuring and confirmation of its Chapter 11 plan of reorganization by the U.S. Bankruptcy Court for the District of Delaware on June 23, 2016.

Verso Corporation (NYSE:VRS) has just announced that the company and its subsidiaries have emerged from bankruptcy following a successful financial restructuring and confirmation of its Chapter 11 plan of reorganization by the U.S. Bankruptcy Court for the District of Delaware on June 23, 2016.

"Our emergence from bankruptcy less than six months after our Chapter 11 filings would not have been possible without the support of our lenders, whose willingness to invest in Verso demonstrates their confidence in our prospects for long-term growth and value creation," said Verso President and Chief Executive Officer David J. Paterson. "We also appreciate the hard work and dedication of our employees, who continued to serve our customers without interruption throughout the restructuring process. Lastly, we thank our customers, vendors and other stakeholders for their loyalty. We believe Verso is poised for sustainable profitability, and we are excited about the opportunities that lie ahead."

Verso's restructuring reduced the company's debt by $2.4 billion and includes $595 million in exit financing to support ongoing operations and capital investment. The exit financing consists of an asset-based lending facility with borrowing capacity of up to $375 million led by Wells Fargo Bank, National Association, and a $220 million term loan facility with available loan proceeds of $198 million led by Barclays Bank PLC.

"Verso emerges from bankruptcy as a much stronger company with significantly reduced debt and a unified capital structure that position us to fully realize and leverage the benefits of our prior operational improvements, explore opportunities for strategic growth, successfully compete in the global marketplace, and deliver on our corporate mission to create value for all of our stakeholders," Paterson said.

As provided in Verso's plan of reorganization, all shares of Verso's common stock issued prior to the commencement of Verso's bankruptcy proceeding were cancelled upon emergence, and Verso has issued new shares of common stock to the holders of its previously outstanding funded debt in return for their allowed claims against the company. There is no majority stockholder, and no single entity owned more than 10 percent of Verso's outstanding shares at the time of emergence.

In connection with its emergence, Verso also received approval from the New York Stock Exchange for Verso's Class A common stock to be listed for trading on the NYSE. The Class A common stock will begin trading on the NYSE on July 18, 2016. The trading symbol for the Class A common stock is "VRS," which is the same trading symbol used for Verso's common stock when it previously was listed on the NYSE.

In accordance with Verso's Chapter 11 plan of reorganization, the term of Verso's previous board of directors expired upon emergence and a new board of directors provided for in the plan of reorganization is effective immediately. As previously announced, Paterson will serve as Chairman of the Board and will remain as President and Chief Executive Officer until his replacement is named. The other directors of Verso are Robert M. Amen, Alan J. Carr, Eugene I. Davis, Jerome L. Goldman and Jay Shuster. Verso's senior management team is unchanged and continues to lead the company.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at www.versoco.com

ANDRITZ receives repeat order for sludge dewatering line from SAICA, Spain

International technology Group ANDRITZ has received an order from S.A. Industrias Celulosa Aragonesa (SAICA) in El Burgo de Ebro, Spain, to supply a gravity table GT and a sludge screw press SCS. SAICA already has two ANDRITZ dewatering lines of the same type and size operating to its full satisfaction. This repeat order confirms the trust that SAICA places in sludge dewatering technology from ANDRITZ.

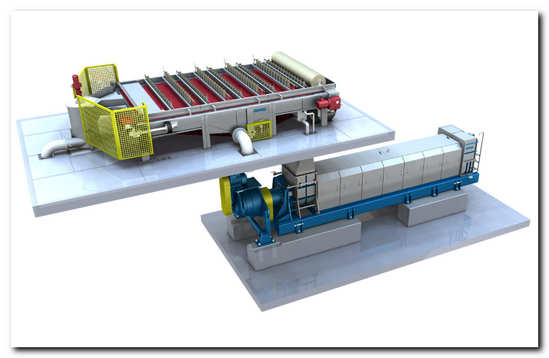

Schematic diagram of ANDRITZ sludge dewatering line with gravity table GT and sludge screw press SCS Photo Andritz

The new sludge dewatering system will process mixed sludge from stock preparation, deinking, and waste water treatment. The scope of supply also includes erection supervision, start-up and commissioning, and training. Start-up is planned for November 2016.

SAICA Group is the leading European company for the production of recycled paper for corrugated cardboard, with an annual production of 2.5 million tons of paper. With locations in Spain, Italy, Portugal, the UK, Ireland, and Turkey, the group has more than 8,000 employees and is divided into four business areas: recycled paper production for corrugated cardboard (Paper), recyclable materials recovery (Natur), production of corrugated packaging (Pack), and flexible packaging (Flex). In 2015, consolidated sales of the multinational group amounted to 2,378 million euros.

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 24,200 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

Verso Introduces GlazeSil™ Lightweight Release Liner Papers for Hygiene and Medical Applications

Verso Corporation, a leading producer of flexible packaging, technical, and label and converting papers, today introduced GlazeSil™, a specialized family of lightweight uncoated, machine glazed release liner papers specifically designed for hygiene and medical applications.

"This exciting addition to Verso's industry leading release liner product portfolio gives producers of hygiene, medical and personal care products more options than ever to meet their unique converting performance, reliability and silicone coating requirements," said Mike Weinhold, Verso Senior Vice President of Sales, Marketing and Product Development. "You can count on GlazeSil™ to deliver the functionality and features required to innovate and differentiate in these markets."

Verso is proud to offer the largest portfolio of pressure sensitive papers in North America, featuring a comprehensive range of label and release liner base papers designed for specific end uses. Available in a wide variety of light basis weights, GlazeSil™ is engineered for healthcare applications such as diaper tape release, feminine care, incontinence and personal care products. GlazeSil™ offers a smooth, uniform surface for excellent silicone coating and release liner characteristics.

The GlazeSil™ product line is produced on paper machine No. 5 at Verso's Androscoggin Mill in Jay, Maine, and offers basis weights (3000 sq. ft.) ranging from 17 lb. to 43 lb., each optimized for specific end uses. According to Jason Handel, Verso Group Vice President of Product Development and Technical Sales, "The No. 5 paper machine has an outstanding reputation for producing high quality papers with excellent surface characteristics and reliable performance. GlazeSil™ is just one example of Verso's commitment to delivering innovative and reliable solutions as the leading provider of pressure sensitive papers in North America."

For more information on GlazeSil™ or other products in Verso's broad specialty papers offering, email This email address is being protected from spambots. You need JavaScript enabled to view it. or visit versoco.com/specialtypapers.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.

ANDRITZ to supply reject equipment to the Ji'An Group, China

International technology Group ANDRITZ has received an order from Ji’An Group Co. Ltd. to supply a set of reject handling equipment for paper production lines PM11, PM12, and PM13 at its mill in Jiaxing City, Zhejiang province, China. This order is part of Ji'An's ongoing activities to upgrade the OCC reject handling lines. Start-up is scheduled for September 2016.

Four ANDRITZ Reject Compactor ReCo units will be delivered to the Ji'An Group “Photo: ANDRITZ”.

The reject handling equipment encompasses four ANDRITZ Reject Compactors ReCo that will compact rejects to the required dryness needed for further processing. The ANDRITZ scope of supply also includes erection supervision, start-up and commissioning, and training. This order once again confirms the expertise of ANDRITZ in reject handling equipment.

The Ji'An Group manufactures various liner grades as well as corrugated papers.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 24,200 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

Valmet to supply advanced process controls and analyzers for Nippon Paper in Japan

Valmet has received repeat orders of advanced process control (APC) systems and analyzers from Nippon Paper in Japan. The solutions will be delivered to three of the Nippon Paper mills and consist of Valmet Advanced Process Control (APC) systems and Valmet Kappa Analyzers for the mills bleaching and lime kiln processes. The solutions will provide Nippon Paper with savings in chemicals and in energy consumption, as well as reduce end product quality variability. The new, latest technology kappa analyzers replace Nippon Paper's existing analyzers. The new advanced process controls and kappa analyzers will be in operation in 2016.

Valmet has received repeat orders of advanced process control (APC) systems and analyzers from Nippon Paper in Japan. The solutions will be delivered to three of the Nippon Paper mills and consist of Valmet Advanced Process Control (APC) systems and Valmet Kappa Analyzers for the mills bleaching and lime kiln processes. The solutions will provide Nippon Paper with savings in chemicals and in energy consumption, as well as reduce end product quality variability. The new, latest technology kappa analyzers replace Nippon Paper's existing analyzers. The new advanced process controls and kappa analyzers will be in operation in 2016.

Additionally, Valmet will provide Nippon Paper with performance services which will sustain the results and savings long term. The services contain expert support and consultation, and the processes will be improved further in in close cooperation with the customer as part of the services.

The order was included in Valmet's first quarter 2016 orders received.

Excellent results from an earlier delivery

The order is based on excellent results from an earlier delivery to Nippon Paper's Akita mill. In 2015, a performance improvement project was successfully delivered for Nippon Paper Akita mill.

"The highlight of the project is the speed in which Akita mill was able to achieve significant savings," comments Mr. Kameda, Senior technical manager of automation department, Akita Mill, Nippon Paper. This was achieved by delivering a holistic solution consisting of APC, analyzers as well as process consultation. The savings were delivered on schedule and clearly exceeded all targets.

The Akita mill now enjoys bleaching chemical savings of 7 %, 28% decrease in final brightness standard deviation, 5.5% saving in specific energy at the lime kiln, and has entered into Performance Sustainability agreement with Valmet to maintain and improve those savings long term.

"Through our proven automation and analyzer technology, and with our global and local professionals, we deliver concrete benefits and move the customers operations to a whole new level," says Atsushi Yamamoto, Sales Manager, Japan, Automation, Valmet.

Record high kappa analyzer deliveries in the past 12 months

In the past 12 months, Valmet has received a record number of orders for kappa analyzers. This has further strengthened Valmet's leading position on the global kappa analyzer market and increased its market share.

All greenfield pulp mills started up in the 2000s are equipped with Valmet's kappa analyzers. Since its introduction in 1992, Valmet has installed over 430 Valmet Kappa Analyzers in pulp mills around the world. Today, all leading chemical pulp producers worldwide use this technology in their processes.

Read more about the kappa analyzer market trends on valmet.com: Valmet's kappa analyzer deliveries hit record high in the past 12 months

Proven performance solutions through advanced process control and optimization

Valmet's performance solutions are part of comprehensive services offering and are designed to provide sustained performance improvement to pulp and paper producers. Valmet is a market leader of advanced process control (APC) with its 320 installations globally. The solutions combine advanced process control and optimization technology and expertise, and utilize Valmet's process measurements and analyzers. The solutions are scalable from one department to a line or mill level optimization.

Read more about Valmet Process optimization services and solutions at valmet.com.

Information about the customer Nippon Paper

Nippon Paper Group is one of the leading producers of paper and cardboard in the world. Nippon Paper Akita is the leading Japanese producer of paper, cardboard and pulp.

Södra grants SEK 1.7 million to new research projects

In recent years, the Södra Foundation for Research, Development and Education has distributed SEK 10-12 million per year to new research and development projects. Pulp grade, conservation values and seed cultivation are now the focus as a further SEK 1.7 million is distributed. To date in 2016, research projects for SEK 4.2 million have been approved.

The mission of the Södra Foundation for Research, Development and Education is to promote research and education of significance to forestry, and forest industry operations, in Southern Sweden. At the most recent Board meeting, support was approved for three new projects. The projects being granted funding comprise relevant and important research and development areas for both forestry and the pulp industry, as well as support for the arrangement of an international conference on seed cultivation.

Projects granted funding

“Higher pulp yield without additives in cooking,” Elisabeth Brännvall och Anna Jacobs, Innventia AB, Stockholm, SEK 662,000

This project is aimed at increasing understanding of the impact of process conditions impact on reactions that lead to carbon dioxide losses during chemical pulp production. The aim is to achieve a higher pulp yield without additives in cooking by controlling the process conditions so that carbohydrate losses are minimised.

“Nature conservation management of general consideration in conjunction with first thinning,” Per Westerfelt, the Forestry Research Institute of Sweden, Uppsala, SEK 971,000

This project will document the need for nature conservation management in accordance with general consideration in conjunction with first thinning as submitted earlier. Furthermore, there will be a study of how conservation values are strengthened by nature conservation management and proposals will be made for future routines regarding nature conservation management in areas of special consideration and edge zones.

"Funding application for the conference project Seed Orchards – The Key to a Sustainable Bio-based Economy,” Thomas Funda, Swedish University of Agricultural Sciences (SLU), Umeå and Curt Almqvist, the Forestry Research Institute of Sweden, Uppsala, SEK 50,000

The Research Foundation is contributing in this manner to the establishment of an international conference on research into seed cultivation and seed orchards. This conference is scheduled for 2017 and is being arranged by the Swedish University of Agricultural Sciences (SLU) and the Forestry Research Institute of Sweden in partnership.

In recent years, the Foundation has distributed SEK 10-12 million per year to various projects.

Facts

The mission of the Södra Foundation for Research, Development and Education is to promote research and education of significance to forestry, and forest industry operations, in Southern Sweden.

The projects that are granted funding include fields of research and development that are relevant and important for both forestry and the forest industry. Since the inception of the Foundation in 1995, some 150 research projects have been awarded grants. The findings of the research projects have been significant both from a social perspective, and for the forest industry.

The Foundation holds four Board meetings per year, at which grant applications are considered.

ANDRITZ to supply new sludge dewatering line to Norske Skog Halden, Norway

International technology Group ANDRITZ has received an order from Saugbrugs Bioenergi AS – a part of the Norske Skog Group – to supply a new sludge dewatering line for thickening and dewatering of fibrous sludges for its mill in Halden, Norway.

The sludge dewatering line is a part of the upgrade to the effluent plant at the Halden mill. The goal of the investment is to increase the capacity for anaerobic treatment in order to produce marketable biogas that is used for vehicles in public transport. Start-up of the new ANDRITZ line is scheduled the first quarter of 2017.

ANDRITZ Gravity Table GT and

Sludge Screw Press SCS Phot Andritz

The order comprises the delivery of a Gravity Table GT and a Sludge Screw Press SCS, which will process up to 58 tons of mixed sludge per day. The sludge to be dewatered consists of a mixture of fibrous and biological sludges from primary and secondary clarifiers, the TMP plant, the paper machine, and from the effluent treatment plant.

The ANDRITZ sludge press dewaters the mixed sludge to the highest possible dryness that can be achieved by mechanical means today. This will enable Saugbrugs Bioenergi to feed the power boiler with sludge dewatered to the maximum possible and thus operate the boiler with higher efficiency.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 24,200 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

Valmet inaugurates new logistics center in Brazil

On July 7, 2016 Valmet inaugurated its logistics center in the city of Araucária, in Paraná state in Brazil. The center is Valmet's fifth logistics center globally and serves the pulp, paper, fiber board and other industries across South America with spare parts and components produced by Valmet and its local suppliers.

The inauguration ceremony was attended by local authorities, customers and Valmet's management. From left Marcos Ozório, Vice-Director of Codar, Celso Tacla South America Area President, Valmet, Marcelo Lupparia Vice President, Abimaq, Rui Souza Araucária Vice Mayor, and Elio Krummenauer Services Director, Valmet.

The inauguration ceremony was attended by local authorities, customers and Valmet's management. "This is an important milestone for Valmet in South America and offers a concrete contribution to moving our customers' performance forward," stated Celso Tacla, Area President for South America at Valmet in his inauguration speech.

The new logistics center will help to secure the reliability and efficiency of customers' processes in South America by supplying the required spare parts and components from the same continent, saving on freight costs and cutting delivery times.

"We'll be delivering just-in-time services to our customers, and we will reduce their dependency on spare parts imports. In addition, our customers will not have to invest in inventories, as Valmet is prepared to take care of their inventory management," says Jukka Tiitinen, Business Line President of Services at Valmet.

By securing a presence close to its customers' operations, Valmet's new logistics center in Araucária takes Valmet closer to its vision of becoming the global champion in serving its customers. Valmet's other logistics centers are located in Beloit (USA), Wuzi (China), Sundsvall (Sweden), and Helsinki (Finland).

"We want to deliver the best service experience to our customers worldwide. One part of that is being close and available whenever needed," states Elio Krummenauer, Valmet's Services Director in South America.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com