Ianadmin

Visit Voith at the Zellcheming-Expo 2016 in Frankfurt, Germany

The focus of the three-day exhibition with congress is the pulp and paper production as well as the range of fiber based materials for the paper industry.

![]() Voith presents innovative products, latest references and developments for paper machine optimization, energy and raw material savings. Dr. Christian Naydowski, Vice President Technology 4.0, will present his speech “Optimized paper manufacturing processes using the Internet of things” during the Business Forum.

Voith presents innovative products, latest references and developments for paper machine optimization, energy and raw material savings. Dr. Christian Naydowski, Vice President Technology 4.0, will present his speech “Optimized paper manufacturing processes using the Internet of things” during the Business Forum.

Visit Voith at Zellcheming-Expo in Hall 11.0, Booth C10 at the fairgrounds in Frankfurt a. M., 28.-30. June 2016.

Watson-Marlow delivers vital dosing operations and maintenance savings to tissue manufacturer

One of Europe’s largest manufacturers of toilet tissue and paper towels is now using an extensive range of peristaltic hose pumps from Watson-Marlow Fluid Technology Group in its production processes. The pumps, which include numerous APEX and Qdos models, are today performing vital dosing operations, typically on a 24 hour basis. Both the robustness and reduced maintenance requirements of Watson-Marlow pumps have proved attractive to this manufacturer, while their inherent accuracy has also seen the company reduce its chemical consumption significantly.

-

Diaphragm pumps replaced with peristaltic pumps for dosing sodium hydroxide

-

Chemical consumption reduced significantly thanks to greater pump precision

-

Maintenance is now quick and tool-free – and production downtime is minimised

The main mill at this high technology plant consists of two machines for the production of paper and eight converting machines.

The production machines comprise numerous dosing stations, where since 2011 the company has been enjoying the benefits of Watson-Marlow 521F/RC close-coupled pumps. These were selected by its Methods and Processes Project Manager, in response to a request for a reliable system that could dose enzyme at the pulp preparation stage.

Successful trials

Trials showed that Watson-Marlow’s peristaltic pump technology was extremely robust, thus minimising any maintenance requirements – a principal factor considering the pumps would be required to run 24 hours a day. Now, the enzyme dosing station is equipped with two 521F/R2C pumps, on which the Watson-Marlow MarpreneTM tubing is very rarely changed. 521F/R2C models offer flow rates up to 250 litre/h at 2 bar peak pressure, and feature 520 LoadSure elements. Moreover, the 520REL pumphead delivers large swept volume with sprung rollers for high accuracy.

A year later the company was facing another challenge and once more turned to Watson-Marlow for the solution. In the company's offset printing production process, the transfer of sheet paper is performed using a rubber 'mat'. In short, images on metal plates are transferred (offset) to rubber blankets, or mats, and then on to the toilet tissue. Rubber is used because it readily conforms to the surface of the tissue, however, the company was finding that the mat was becoming subject to increasing levels of fouling.

To address the problem, a dosing station for sodium hydroxide was installed and Watson-Marlow was called upon once more for this application. After consultation, a Bredel APEX 20 hose pump was selected, not simply for its advantageous peristaltic operating technology, but its ability to run dry, as well as its high extraction rate. The APEX 20 is capable of delivering flow rates of 8.7-870 litre/hr and pressures up to 8 bar.

Diaphragm pumps replaced

Most recently, electromagnetic diaphragm pumps on the company's coating stations started to prove problematic.

Not only were there issues of back-pressure, which meant valves were getting blocked, engineers reported that maintenance was becoming long, complicated and dangerous.

The three diaphragm pumps at this station were replaced with three Qdos30 Universal+ chemical metering pumps for the necessary coating chemicals. The advantages of Qdos30 Universal+ pumps include the absence of valves and the fact that the chemicals remain completely confined within the ReNu pumphead, thus delivering total operator safety. Maintenance is also quick and tool-free, which means production downtime is minimised.

With flow rates up to 500 ml/min and 7 bar pressure, the Qdos30 Universal+ is enhanced by offering the flexibility for automatic and manual control together with configurable 4-20 mA input and output, thus allowing connection directly to the process controller.

Cost savings

The company has reported that it is “very happy” with the Qdos pumps as they provide complete peace of mind, safety and cost savings. Use of coating chemicals has reduced significantly.

The performance of the Qdos pumps has been so impressive, that the company has also adopted six further Qdos models on the dryer protection station serving the two paper production machines, and three coagulant dosing pumps for treating water in the company’s flotation units.

The factory is booming and a third production line is now planned, with the goal of producing 90,000 tonnes of paper per year. The plan is for the new line to be equipped Watson-Marlow dosing pumps to ensure continued dosing accuracy.

Howden American Fan Company Announces BCS Backwardly Inclined Fan for Air Purification Applications

Fan delivers non-overloading horsepower characteristics over entire pressure curve

Howden American Fan Company, the leading manufacturer of high-quality industrial fans and blowers, announces that it offers the BCS Backwardly Inclined Fan for air purification in applications like woodworking, chemical mixing, welding, dry storage, and more. The BCS fan delivers non-overloading horsepower characteristics and stable performance over the entire pressure curve for maximum efficiency.

The Howden American Fan BCS Backwardly Inclined Centrifugal Blower Fan is quieter and more efficient than radial bladed fans for air purification applications, and delivers better performance due to its non-overloading design. The BCS fan is typically installed on the clean side of an air purification system’s dust collection bag or cartridge, thereby reducing maintenance needs and improving overall product life.

Unique in the industry, the BCS fan is independently tested and certified by the Air Movement and Control Association (AMCA) for air and sound. It is proven to be stable throughout the entire performance curve, and can be dampened back to approximately 40% of maximum flow. It is suitable for use in a variety of air purification applications, including in outdoor installations.

The fan is available with both high temperature and spark free construction designs, as well as with corrosion-resistant or other special alloys according to the needs of individual customers. It is available in 18 different fan sizes, from 12-1/4" through 66" diameter wheels, in Class I, II, or III construction. With the available percentage widths of the BCS fan product line, nearly any flow range can be met with the direct drive fan.

For more information, visit www.americanfan.com

About Howden American Fan Company

Howden American Fan Company is the leading manufacturer of high quality industrial fans and blowers that set the standard within the industry. Howden supplies axial fans, centrifugal fans, and blowers for a wide range of industries, including marine, industrial manufacturing, and building and construction. Located near Cincinnati, OH, Howden American Fan is part of the Howden Industrial Fan Group, made up of American Fan, Joy Fan, and Garden City Fan. For more information, please visit http://www.americanfan.com/ or call 866-771-6266 toll-free.

Lucrative ‘power balancing’ schemes can help the pulp and paper industry generate £90,000 per Megawatt

Wriiten by Micheal Phelan, CEO at Endeco Technologies which is a national grid and eirgrid approved aggregator

Many in the pulp and paper sector may not be aware that there is a significant new revenue stream available to progressive and forward-thinking plants. It focusses on the use of energy, and how by turning the power down for a relatively short period each year in line with National Grid and EirGrid’s requirements, manufacturers can enjoy considerable financial rewards.

High Energy Consumption

Pulp and paper plants are intensive users of energy, with equipment such pumps, fans, pulpers, chippers, grinders, dryers commonplace in such facilities. Unfortunately this represents a problem in the UK, where only the most oblivious will be unaware that there exists a somewhat precarious electricity supply situation. According to a Guardian newspaper report earlier in 2016, UK electricity demand is expected to outstrip supply by over 40% within 10 years.

Many thought renewables would deliver the answer, but in reality the inflexibility of renewable energy sources in conjunction with the difficulty of controlling grid stability in real-time, represents a major challenge for grid operators. In simple terms, when generation and energy demand are imbalanced, a change of frequency in the grid system is created, which is made worse by the intermittent nature of wind and solar sources. The requirement for quicker grid balancing and frequency is why the National Grid (in the UK) and EirGrid and SONI in Ireland now offer a number of opportunities for energy-intensive businesses, with very lucrative rewards for those able to offer real-time response.

Ofgem, the industry regulator, is also on-board, recently laying out five priority areas of focus, central to which is a pledge to make the UK energy system more flexible. With this in mind, Ofgem is actively encouraging businesses to engage in demand-side response.

Demand-Side Response

Firm frequency response (FFR) and the new Dynamic FFR, as well as the forthcoming (2017) Enhanced FFR, are schemes that all form part of the system operators’ broad DSR (Demand-Side Response) suite of solutions. In essence, these schemes involve removing sufficient load from the grid to stabilise frequency.

To help boost uptake, the National Grid and EirGrid are offering those that participate the potential to earn extra income from assets by adjusting power consumption in real-time. As a result, grid operators can reduce the requirement for coal and gas-fired reserves to be ready to supply power at short notice.

This is where the pulp and paper industry can accrue significant financial rewards. To provide an indication, in the UK sums of up to £90,000 are currently achievable for every megawatt (MW) of average onsite energy consumption turn down. In Ireland, the latest scheme – DS3 System Services – also offers very significant sums per megawatt.

Any pulp and paper company expecting to endure weeks if not months of blackouts to see financial savings on such levels would be wrong. In the first instance, the requirement is for ‘turn-down’ not ‘turn-off’, and secondly, the sums stated are in return for around 10 (on average) ‘turn-down’ events per year, lasting for a maximum of just 30 minutes each. In total, this adds up to – on average - around 5 hours a year.

For those thinking there must be a catch, there isn’t. The grid operators are prepared to pay such high rewards as it is obliged to control frequency within the limits specified in the 'Electricity Supply Regulations', i.e. ±1% of nominal system frequency (50.00Hz) except in abnormal or exceptional circumstances. It must therefore ensure that sufficient generation and/or demand is reserved in automatic readiness to manage all credible eventualities that might produce frequency variations.

Virtual Power Plant

As every pulp and paper processing facility will have its own array of assets and requirements, comprehending and choosing the optimum DSR scheme is vital. With this in mind, partner companies known as aggregators provide the critical elements that enable participating companies to make the best selection and optimise returns.

Aggregators take a central role in this new power-balancing arena. In essence, they act as intermediaries between the Grid operators and large energy users. They create a ‘virtual power plant’ where the assets of hundreds of companies are aggregated. This provides a grid-balancing mechanism helps the system operators to deliver on their vision for a more sustainable, flexible power infrastructure.

All of this combines to help National Grid (UK) and EirGrid (Ireland) to minimise the operational costs of making the grid ‘smart’ because the aggregators deliver a technical solution to the challenge of grid balancing.

Essential Partnership

From the point of view of the end user, an aggregator is an essential partner for any pulp and paper company that wishes to take advantage of the long-term lucrative opportunities. They take care of the necessary hardware and software installation, as well as the online monitoring and reaction systems, and the day-to-day running of the system.

From the point of view of the end user, an aggregator is an essential partner for any pulp and paper company that wishes to take advantage of the long-term lucrative opportunities. They take care of the necessary hardware and software installation, as well as the online monitoring and reaction systems, and the day-to-day running of the system.

All of this is offered without any capex requirement, with the aggregator instead taking a percentage of the scheme pay-out. As a point of note, the aforementioned sum per megawatt is the amount payable after the aggregator has taken payment.

Pulp and paper companies are in prime position to benefit from this offer. In this first instance, energy consumption is reduced on selected equipment after an audit of the plant, before energy strategies to reduce cost are adapted and agreed with the plant’s operations team.

The chosen aggregator will connect the manufacturer’s principal assets to its proprietary on-site optimisation platform, which enables the automated control of energy consumption via wireless smart sensors and actuators. One part of the aggregator’s job is to ensure pulp and paper producers are ready and able to turn down their energy use when the grid operators require it, and check that the response works correctly. Facilities employing an aggregator simply relax and concentrate on day-to-day business.

Aggregate to accumulate

The answer to the question of which aggregator is best depends on many factors. However, pulp and paper manufacturers should be mindful to only select a ‘National Grid Approved Aggregator’, and preferably one with hundreds of existing sites under its belt. A further vital factor is to choose an aggregator that offers a platform which can future-proof against better schemes being introduced. Response schemes are always likely to change over time and plants participating in the scheme must be technology-ready to access more financially attractive tariffs.

Ultimately, DSR schemes represent a no-risk route to generous additional income for pulp and paper manufacturers willing to help the UK better manage its challenging electricity requirements.

1.IDENTIFY: An approved National Grid or EirGrid aggregator will assess your available assets and calculate revenue potential.

2. DEFINE: Your aggregator will work with you to establish parameters for response, define constraints and operational priorities.

3. IMPLEMENTATION: Your aggregator will install and configure its technology platform to connect your energy intensive assets. This is often at no cost to the end user*.

4. RESPOND: Once you’re connected, you’re ready to respond when required, without risk or impact on your productivity.

5. EARN: You start receiving monthly payments from the energy market.

* Endeco Technologies makes no charge for the implementation of the technology platform. Other aggregators might take a different approach.

Rolland Recycled Kraft Paper

Rolland continues to be a strong provider of recycled kraft paper with high environmental attributes in the North American market.

Rolland KraftTM is an interesting hybrid sheet that has the natural earthy color and the opacity of kraft paper, while having a true fine paper base sheet which enables an enhanced printing quality and color output, as well as a smoother feel. The paper is ideal for any promotional material, high-end bags and envelopes, and performs well on both commercial and digital printing equipment.

Rolland KraftTM is an interesting hybrid sheet that has the natural earthy color and the opacity of kraft paper, while having a true fine paper base sheet which enables an enhanced printing quality and color output, as well as a smoother feel. The paper is ideal for any promotional material, high-end bags and envelopes, and performs well on both commercial and digital printing equipment.

Part of the Rolland fine paper portfolio, recycled kraft is a perfect environmentally friendly medium for remarkable design. It contains 50% post-consumer fiber, is certified FSC® and EcoLogo, and is made using renewable biogas energy.

"Rolland Kraft allows customers to emotionally connect and identify with the handcrafted look of the paper and the vibrant and contrasting colors. Paper will always have a sweet spot in people's heart when it is well made and well printed", said Robert Ferragina, Vice-President, Commercial Sales USA.

Rolland Enterprises is the market leader in the production of specialty uncoated fine papers with the undisputed highest standards for environmental sustainability. The Company produces fine papers with biogas energy and up to 100% recycled content for many sectors including security printing as well as the commercial, office, government and education markets. Rolland's facilities include the Paper Mill and Converting Center in St-Jérôme, as well as deinking facility in Lévis, Quebec and De Pere, Wisconsin.

Voith rebuilds Hedemora disc filter at Sappi in Kirkniemi, Finland

At Sappi Finland Operations Oy in Kirkniemi, Finland, Voith has successfully converted the existing Hedemora disc filter in the stock preparation unit to the latest BaglessPlus filter technology. As the number of discs could be reduced, the disc filter will be well prepared for future increase capacity. The rebuild has also substantially improved the performance of fiber material removal and reduced maintenance costs. Filtrate quality is now more stable due to no more leakage in filter plastic bags.

![]() With the newly installed BaglessPlus disc filter sectors with knock-off nozzles the number of sectors could be reduced from 18 to 16 discs. With full assembly a capacity increase by 30 percent can be achieved, when future upgrade of the production line is necessary. The conversion to BaglessPlus has allowed stable and good filtrate quality. And this filtrate quality will remain constant over the entire service life of the sectors of more than ten years, as the BaglessPlus sectors are maintenance-free and do not suffer from any kind of leakage. Thanks to the consistent process conditions, the operation is more stable.

With the newly installed BaglessPlus disc filter sectors with knock-off nozzles the number of sectors could be reduced from 18 to 16 discs. With full assembly a capacity increase by 30 percent can be achieved, when future upgrade of the production line is necessary. The conversion to BaglessPlus has allowed stable and good filtrate quality. And this filtrate quality will remain constant over the entire service life of the sectors of more than ten years, as the BaglessPlus sectors are maintenance-free and do not suffer from any kind of leakage. Thanks to the consistent process conditions, the operation is more stable.

Impressed by the concept for the new filter technology with BaglessPlus, Sappi decided to also commission Voith to rebuild an Ahlström disc filter at its mill in Kirkniemi during this year’s scheduled summer shutdown.

Sappi is a leading global producer of premium quality fine paper. In Europe, Sappi Fine Paper Europe has a production capacity of 3.5 million metric tons of fine paper and 1.1 million metric tons of pulp per year. At Sappi Finland Operations Oy in Kirkniemi, 70 km from Helsinki, 760,000 metric tons of coated writing and printing paper is produced annually from locally sourced wood.

About Voith Paper

Voith Paper is a Group Division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

Pulp-and-Paper Industry in Canada: Business Report 2016 - Research and Markets

Research and Markets has announced the addition of the "Pulp-and-paper industry in Canada: Business Report 2016" report to their offering.

![]() This report is a comprehensive research of pulp-and-paper industry in Canada.

This report is a comprehensive research of pulp-and-paper industry in Canada.

The first two chapters of the report feature the country profile by giving general information on Canada and by thoroughly studying its economic state (including key macroeconomic indicators and their development trends).

The third chapter covers common business procedures in the country: from starting a project to closing a business. This chapter elucidates the country's fiscal system, existing labour practices, property rights regulation peculiarities and other issues vital for running business in this country.

Further the report analyses pulp-and-paper industry in the country. This key chapter tells about main trends in the industry, identifies key market players (including major producers, traders, etc.), and evaluates trade operations within the sector in the recent years.

Related news bulletins update adds the finishing touch to an overview of economic situation in Canada.

Key Topics Covered:

1. CANADA: COUNTRY PROFILE

1.1. Geographical position

1.2. Historical background

1.3. Demography

1.4. Administrative divisions

1.5. Political situation

1.6. Economic situation

1.7. Foreign relations

1.8. Social environment and culture. Cultural differences and their impact on business negotiations

2. CANADA: FINANCIAL AND ECONOMIC PROFILE

2.1. Country's Gross Domestic Product (GDP): historical trends and projection

2.2. Industrial production outlook

2.3. Canada foreign trade

2.4. Current investment climate

2.5. Labor market overview. Current employment state

2.6. Ratings by major rating agencies

3. PECULIARITIES OF DOING BUSINESS IN CANADA

3.1. Procedures for starting a business

3.2. Routine for building permits obtaining

3.3. Registration of ownership rights

3.4. Basic terms of providing business loans by banks

3.5. Measures for investments protection

3.6. Tax system

3.7. Foreign trade transactions

3.8. Debt collection

3.9. Business liquidation

4. CANADA PULP-AND-PAPER INDUSTRY OVERVIEW

5. CANADA ECONOMY NEWS AND ANALYSIS DIGEST

For more information visit http://www.researchandmarkets.com/research/xxlxcn/pulpandpaper

Neenah Packaging Announces Significantly Expanded Box Wrap Portfolio and Custom Design Solutions

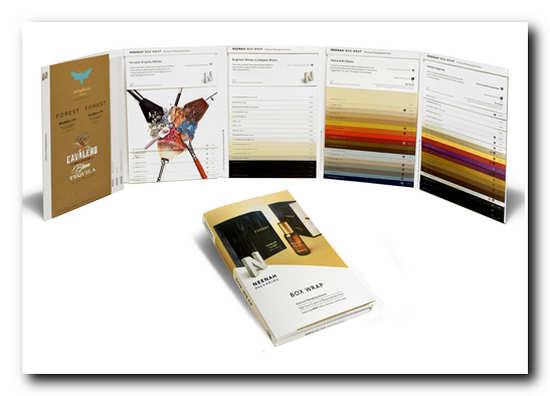

Neenah Packaging announces the significantly expanded offering of its Box Wrap portfolio, with new additions to its Premium Packaging Solutions, and the introduction of its Luxury Packaging Solutions.

Together, these two expansive collections create an elevated line of packaging papers for national and multi-national retail, beauty, alcohol, electronics and entertainment media brands.

“This expansion has elevated our box wrap offering to the level where we can address key end users who are looking for differentiated packaging solutions, from mid-range to premium, and up to the most luxurious decorative papers. The breadth of this offering, and the custom opportunities now available — from the largest range of whites and durable graphic papers, to the feel of nubuck leather, and high-end exotic finishes — are unmatched in the marketplace,” said Mark Sng, Director of Marketing, Neenah Packaging.

The ability to create custom packaging solutions is the cornerstone of Neenah’s new Box Wrap portfolio. The portfolio now offers a broad range of standard color palettes, an impressive array of whites and neutrals, and an extensive library of embossing options. And, beyond that, lies Neenah’s newly advanced custom capabilities — creating endless possibilities for designers and brand owners.

“The value of our custom capabilities is immense for brands looking to create unique, one-of-a-kind at shelf recognition with a color, texture, finish combination designed specifically for that brand. Or, for global brands with a need to maintain color and texture consistency across all packaging pieces, no matter what country the converting is being done in, we can provide assurance with custom box wrap papers,” said Sng.

The two portfolios are overviewed in a new, two-book specification program, each showcasing the breadth and range of the line. “We consider these tools a springboard for every designer and brand manager’s imagination. Open these books to understand just how endless the possibilities are,” said Sng.

Neenah Packaging Box Wrap Premium Packaging Solutions

An already expansive portfolio, Neenah Packaging has added 26 new items including offset-printable, uncoated and lightweight C1S premium box wrap papers with a wide variety of whites, colors, and environmental papers.

Neenah Packaging Box Wrap Luxury Packaging Solutions

This collection of one-of-a-kind papers exudes luxury with every look and touch. From realistic metal-like finishes, to plush textures, to authentic-looking fine leathers and high-end exotic skins, Neenah Packaging Luxury Box Wrap offers endless combinations. This collection is about building a unique design. Start with color, select an embossed texture, and further enhance the visual with a print pattern and/or specialty finish. Or, go beyond the offerings presented in the book, and work with Neenah Packaging to create a custom color or design solution.

“As our Box Wrap portfolio continues to evolve, we remain committed to providing superior service, with low minimums, fast turnarounds, color and texture consistency, durability, and unrivaled on-press, converting and finishing performance for all of our Neenah Packaging papers,” said Sng.

Contact your local Neenah Packaging rep to request a special presentation of the new Neenah Packaging Box Wrap specification books.

About Neenah Packaging

Neenah Packaging, http://neenahpackaging.com, provides unique and sustainable packaging papers and custom solutions for premium packaging. Its range of colors and textures—for bags, box wraps, gift cards, gift card carriers, hangtags, labels, folding board and fragrance strips—inspire visually and create a high touch tactile connection. Neenah Packaging enables leading and emerging brands in cosmetics and fragrances; wine, spirits & craft beer; retail and more to deliver on their brand’s promise. Neenah was the first in the packaging industry to offer a premium100% PCW board. Neenah Packaging welcomes custom inquiries. Neenah is now proud to offer a portfolio of 100% paper based flexible and rigid wide format products perfect for retail, tradeshow and many other end-use applications.

For more than 100 years, Neenah Paper (NYSE: NP) has been an innovative leader in the creation and manufacturing of papers for premium writing, text, cover, digital, packaging and specialty needs. The Neenah signature portfolio includes market leading brands such as CLASSIC®, ENVIRONMENT®, and ROYAL SUNDANCE® Papers. The company also offers envelopes in thousands of unique colors, finishes and styles. Neenah is now proud to offer a portfolio of 100% paper based flexible and rigid wide format products perfect for retail, tradeshow and many other end-use applications.

With multiple manufacturing facilities in Wisconsin and the Northeast, prime importance is placed on recycled and alternative fiber products through the Neenah Green initiative. For more information on Neenah call (800) 558-5061. Follow Neenah on Twitter: @neenahpaper; subscribe to the Neenah Facebook page; or visit Against the Grain, Neenah’s design blog.

Twin Rivers Announces Plans to Position Business for the Future

Twin Rivers Paper Company Limited has just announced that it will invest approximately $12 million at its Madawaska facility as part of a strategic realignment to focus on growth-oriented market segments and maximize productivity.

“Our industry has undergone a great deal of change in the past decade, and we must continue to innovate and position Twin Rivers for the future,” said Chief Operating Officer John Reichert. “As part of our strategic repositioning, we have reviewed our papermaking assets and have initiated a substantial upgrade to the largest machine in the system, PM8, which will be completed in 2017. Additionally, this repositioning will result in the permanent closure of PM3 at the end of July, improving productivity across our operations.”

“Our industry has undergone a great deal of change in the past decade, and we must continue to innovate and position Twin Rivers for the future,” said Chief Operating Officer John Reichert. “As part of our strategic repositioning, we have reviewed our papermaking assets and have initiated a substantial upgrade to the largest machine in the system, PM8, which will be completed in 2017. Additionally, this repositioning will result in the permanent closure of PM3 at the end of July, improving productivity across our operations.”

Twin Rivers plans to invest approximately $12 million in PM8 to dramatically enhance the machine’s capabilities and broaden the markets served by the largest asset in the Twin Rivers paper mill system. The rebuild will establish PM8 as one of the largest producers of lightweight technical specialties in North America, ideally positioned to support strategic growth initiatives while strengthening the company’s industry-leading lineup of hybrid and freesheet lightweight publishing grades. The machine to be shut down, PM3, is one of the mill’s higher-cost machines – an older, slower and smaller machine that produces a variety of coated and uncoated grades.

“Twin Rivers does not take these decisions lightly, and we recognize they will impact employment for approximately 49 of our valued associates. We will work closely with these individuals and the unions to facilitate this transition, and provide whatever resources are available to assist them,” says Reichert. “At the same time, we have a responsibility to make strategic decisions for the future of the Company, our approximately 1000 associates and the 5,800 people who rely on Twin Rivers’ operations across the regions in which we operate.”

The proposed capital investment announced today brings to over $47 million the level of strategic capital investments to date since the transition of mill ownership in 2013. Twin Rivers operates three additional paper machines that manufacture a range of specialty packaging, label and publishing papers with options in fiber content, functional characteristics, aesthetics and sustainability. The company is known for rapid innovation and its commitment to co-development.

Twin Rivers is a vital part of the region’s economy. An economic impact study conducted in 2014 by Gardiner Pinfold Consultants Inc. (of Sackville, NB) showed that Twin Rivers is responsible for $268 million (CAD) in economic output at its New Brunswick operations each year, and app. $344 million (USD) at its operations in Maine.

Twin Rivers Paper Company Limited

Canada:

Paul Black, 506-737-2602

This email address is being protected from spambots. You need JavaScript enabled to view it.

or

U.S.:

Dave Deger, 207-523-2355

This email address is being protected from spambots. You need JavaScript enabled to view it.

Catalyst Paper Named One of Canada's Top Corporate Citizens, 10th Year in a Row

Catalyst Paper has just announced that it has been named for the 10th consecutive year as one of the Best 50 Corporate Citizens in Canada by Corporate Knights Magazine, which reports on corporate sustainability and transparency.

"We are proud to be acknowledged for the 10th consecutive year as one of Canada's Best Corporate Citizens," said Joe Nemeth, President & Chief Executive Officer. "This designation acknowledges the investments we have made to put our sustainability values and commitment into practice."

"We are proud to be acknowledged for the 10th consecutive year as one of Canada's Best Corporate Citizens," said Joe Nemeth, President & Chief Executive Officer. "This designation acknowledges the investments we have made to put our sustainability values and commitment into practice."

The Best 50 Corporate Citizens in Canada are selected by Corporate Knights Magazine on the basis of their performance against 12 key sustainability indicators, including greenhouse gas production, percentage of taxes paid, health and safety performance, and pension fund quality.

The award recognizes Catalyst's ongoing focus on strengthening its leadership role in sustainable business practices and its commitment to building respectful and constructive relationships with stakeholders. In 2015, Catalyst demonstrated its environmental sustainability commitment through ongoing achievements, including maintaining certified fibre sourcing and chain of custody transparency, supporting the Great Bear Rainforest Land Use Objectives Order, investing in green-energy generation and implementing carbon reduction policies and practices.

Catalyst is proud of its performance and track record, and its commitment to transparently sharing information in its annual Sustainability Reports. The company's 2015 Sustainability Report, which is presented according to the Global Reporting Index, provides a transparent record of Catalyst's performance across multiple dimensions, including environmental results, as well as the social and economic contribution of its operations in the communities where the company's employees live and work.

About Catalyst Paper

Catalyst Paper manufactures diverse printing papers such as coated freesheet, C1S, coated and uncoated groundwood, newsprint, directory, as well as market pulp. Customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada, and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.