Ianadmin

Minerals Technologies Signs Commercial Agreement With Major North American Papermaker For Fulfill® High-Filler Technology

Agreement is 27th for Unique High-Filler Technology to Provide Significant Cost Savings in Reduced Fiber Consumption by Increasing PCC Filler Usage 20%

Minerals Technologies Inc., has just announced that it has entered into a commercial agreement with a premier North American paper company to provide Fulfill® E-325 higher filler technology. Minerals Technologies (MTI) now has 27 agreements with paper mills worldwide for adoption of the Fulfill® technology, which allows papermakers to reduce costs by replacing higher-cost pulp with increased loading levels of precipitated calcium carbonate (PCC). The agreement with this papermaker, which wishes to remain unnamed for competitive reasons, marks MTI's ninth in North America.

Minerals Technologies Inc., has just announced that it has entered into a commercial agreement with a premier North American paper company to provide Fulfill® E-325 higher filler technology. Minerals Technologies (MTI) now has 27 agreements with paper mills worldwide for adoption of the Fulfill® technology, which allows papermakers to reduce costs by replacing higher-cost pulp with increased loading levels of precipitated calcium carbonate (PCC). The agreement with this papermaker, which wishes to remain unnamed for competitive reasons, marks MTI's ninth in North America.

"The widespread adoption of our Fulfill® technology is further evidence that MTI's solutions-oriented R&D efforts continue to yield valuable innovations for our customers. Technological innovation is a key driver in the company's growth strategy." said Joseph C. Muscari, chairman and chief executive officer.

The Fulfill® E-325 series allows papermakers to replace higher-cost pulp by increasing PCC loading levels three to five percentage points, from a typical level of approximately 20 percent up to 25 percent.

"In addition to the 27 commercial agreements we now have, MTI is also actively engaged with 17 additional paper mills that are interested in FulFill®." said W. Rand Mendez, senior vice president & managing director, Paper PCC.

PCC is a specialty pigment for filling and coating high-quality paper. By substituting PCC for more expensive wood fiber, papermakers are able to produce brighter, higher quality paper at lower cost. Minerals Technologies originated the satellite concept for making and delivering PCC on-site at paper mills, and the concept was a major factor in revolutionizing North American papermaking from an acid to an alkaline-based technology. Minerals Technologies constructed its first PCC satellite plant in 1986. Today, the company has 64 satellite plants in operation or under construction around the world and continues to lead the industry with consistent quality and technical innovation.

New York-based Minerals Technologies Inc. is a resource and technology based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral based and synthetic mineral products and related systems and services. MTI serves the paper, foundry, steel, construction, environmental, energy, polymer and consumer products industries. The company reported sales of $1.798 billion in 2015.

For further information about Minerals Technologies Inc. look on the internet at http://www.mineralstech.com/

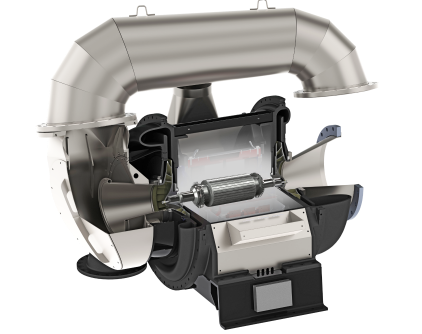

The Switch direct-drive, high-speed turbo technology becomes industry standard

Finland-based Runtech Systems has placed its largest multi-million-euro order for high-speed turbo motors from The Switch for use in its turbo vacuum blower systems for paper machines. Using direct-drive technology developed jointly by both companies since the early 2000s, these turbos have now become widely accepted in the paper industry thanks to their superior advantages. Along with being a reliable, long-lasting solution, they bring customers unmatched simplicity and energy efficiency.

Years of product development and unrelenting sales work are now paying back for Runtech Systems with their unique turbo vacuum pump systems specifically designed to replace the poorly performing water ring pumps in paper mills. Runtech has superior competence in analyzing and designing efficient paper manufacturing processes. Together with The Switch, the company harnessed the built-in power of direct-drive, high-speed turbo technology to create a radical solution that has recently become the new industrial standard. The turbo vacuum blower is now a key component in the optimum solution when retrofitting existing paper machines or designing new ones.

Runtech Systems placed its largest multi-million-euro order with The Switch for turbo motors to be used in their vacuum pump systems that have now become the papermaking industry standard.

Breaking through to standard

“We’ve finally made an industrial breakthrough with our turbo vacuum blower systems, which are fully and widely accepted as a viable, long-lasting solution in the papermaking industry. Today, our customers see us a trusted and preferred supplier when it comes to providing energy efficiency,” says Jukka Lehto, President and CEO of Runtech Systems.

“Another major step for us in attaining this position has been in strengthening our global sales network. We can now be in closer touch with local paper mills through our sales representatives. Although Europe still represents the largest market for us in total, China and Asia in general are growing the fastest for these products,” he says.

Exceptional savings

The undisputable main benefit of Runtech’s vacuum blower system is its power savings. Results show that mills can save between 30–60% in energy while increasing vacuum speed. Additionally, the solution is water-free, giving mills a 100% savings in water costs, which are exceptionally high in papermaking. Payback time is normally one to three years.

“Environmental savings are also important benefits as regulations are becoming more stringent,” Jukka adds. “A recent study proves that electrical machines can increase system efficiency as well as reduce CO2 emissions in both energy production and energy consumption.”

Simplicity facilitates uptake

“Now we have an optimum and proven solution that works at the natural speed of the blowers of up to 10,000 rpm to achieve the optimum vacuum for the process,” says Jukka-Pekka Mäkinen, President and CEO of The Switch. “The simplicity of the solution means that extra parts like the gearbox can be avoided, along with any associated cooling and lubrication. The motor offers a much smaller and lighter footprint. And it is all self-contained; only minimum on-site installation is required.”

“With Runtech, we have had a dedicated partner that truly understands the applications and complete paper mill process. Now it is exciting to see them break through with great results,” he continues. “In the future, we see that that our turbo technology can bring advantages to a wider range of industrial applications, such as oil and gas, where we already have experience with high-speed solutions.”

Latest high-performance turbo models

Deliveries of the newest motors will start in September 2016 and include higher power motors that match Runtech’s new models.

“In certain cases, there has been a clear need for greater capacity. Instead of delivering five vacuum pumps for a paper machine, these new higher-performing units allow us to deliver only four. What’s more, we do not need to dimension the capacity too tightly for the prevailing conditions with these new units,” Jukka states.

The new turbo models are exactly the same physical size as the current ones, which enables Runtech to offer a more powerful turbo solution rebuilt for some of their existing units.

About Runtech

Runtech Systems provides energy-efficient and innovative solutions for the global paper industry. The majority of business comes from vacuum systems for the paper industry, where Runtech is globally one of the leading suppliers with its very energy-efficient Ecopump technology. The other main businesses are in doctoring products and tail threading products for paper, board, tissue and pulp machines. Since being founded in 1989, Runtech has provided the best and most innovative solutions for its customers with many cutting-edge technologies. For more information, visit www.runtech.fi.

About The Switch

The Switch, a Yaskawa company, is a pioneer in advanced drive train technology. The company has an installed base of over 11 GW of megawatt-class permanent magnet machine and converter packages. The main focus areas are wind, marine and special industrial solutions. The company’s innovative drive trains make an impact on profitable power generation and energy use, with the ultimate goal of lowering the cost of energy and operations. Starting in 2006, The Switch reported net sales of EUR 37.1 million in 2014. The company employs approximately 175 persons. The Switch is headquartered in Helsinki, Finland. For more information, visit: www.theswitch.com.

ABB's new test laboratory helps customers find their ideal combination of motor and drive

ABB has inaugurated a new customer drives test laboratory at its factory in Helsinki, Finland. The facility now enables customers to have their own motors tested with ABB’s variable speed drives (VSDs) to verify their impact on performance and energy consumption.

ABB’s new customer drives test laboratory has been established to enable customers to evaluate the capability of their own motors when operating in combination with the new generation of ABB drives. The facility incorporates independent equipment for high-precision measurements of drive/motor dynamic performance, load capability and efficiency that enables customers to find the optimal drive system for their application, helping reduce costs, equipment size and energy consumption.

The test laboratory is an entirely new concept that is aimed primarily at high-volume drives customers and ABB partners such as technology companies in the machine building industries and system integrators. It now offers an easy and reliable way for customers to test various motor/drive combinations before introducing a new ABB product into volume production.

The test laboratory is an entirely new concept that is aimed primarily at high-volume drives customers and ABB partners such as technology companies in the machine building industries and system integrators. It now offers an easy and reliable way for customers to test various motor/drive combinations before introducing a new ABB product into volume production.

”This investment really supports the process of establishing the ideal drive/motor combination and demonstrates how we can help customers test their equipment up to 400 kilowatts (kW) with a minimum amount of effort to verify that ABB’s solution is the best choice for their application,“ explains Morten Wierod, Managing Director of ABB’s Drives and Controls business unit.

ABB’s global drives business also has customer laboratories in the United States, China and India that provide local support. Morten Wierod continued, “This new laboratory in Helsinki is the center of excellence for our business unit from where we support global customers with the most demanding requirements. The main advantage of these laboratories is how we connect them together in a global chain so that all customers always receive the best support available from the most appropriate ABB unit.”

The decision to make the investment to create the new facility was based on ABB’s successful experience with the customer application laboratory for crane and winch applications that opened in 2011. This facility, also located at the drives factory in Helsinki, provides facilities for OEMs to test ABB’s drive compatibility in cranes and winches in a simulated environment corresponding to actual application conditions. The laboratory has played a significant role in helping ABB to grow its business in this sector and it has recently been upgraded to increase its test capacity to cover a wider range of application areas.

The decision to make the investment to create the new facility was based on ABB’s successful experience with the customer application laboratory for crane and winch applications that opened in 2011. This facility, also located at the drives factory in Helsinki, provides facilities for OEMs to test ABB’s drive compatibility in cranes and winches in a simulated environment corresponding to actual application conditions. The laboratory has played a significant role in helping ABB to grow its business in this sector and it has recently been upgraded to increase its test capacity to cover a wider range of application areas.

Morten Wierod acknowledges that customers are increasingly demanding and ABB wants to offer even better service and application know-how by bringing customers into its own facilities. “We are dedicated to our customers and want to help them achieve the right features and performance in their applications by investing in these facilities. Being able to test the customer’s own equipment together with our drives gives them the confidence that ABB really can support our partners and customers in their day to day operations,” Wierod said.

ABB is the leading drives manufacturer supplying drives and software tools for all applications and industries worldwide. ABB’s drives business employs 6,000 people in over 80 countries.

ABB (www.abb.com) is a leading global technology company in power and automation that enables utility, industry, and transport & infrastructure customers to improve their performance while lowering environmental impact. The ABB Group of companies operates in roughly 100 countries and employs about 135,000 people.

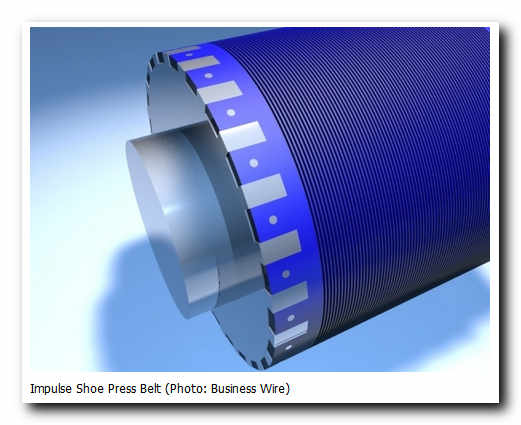

Xerium Introduces Impulse Shoe Press Belt Technology

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched the new Impulse family of shoe press belt technology.

Impulse shoe press belts combine the latest in specially developed polyurethane materials, state-of-the-art manufacturing technology, and global application expertise which are already delivering world-class performance on modern shoe press positions. Impulse technology is available in a variety of proprietary venting patterns for optimized performance on virtually every grade of paperboard, tissue, paper, and pulp. More information about Impulse technology is available at http://www.xerium.com.

“We are very excited to launch Impulse - a new generation shoe press belt technology,” said Mr. Bill Butterfield, EVP and CTO of Xerium. “Our roll cover technology team, which has been responsible for every major polyurethane breakthrough in roll cover technology in the last two decades, has now delivered a unique high-performance polymer shoe press belt with an expanded product portfolio especially for demanding machines. Impulse is already running very successfully on numerous machines around the world and we are extremely delighted in the growth potential for this new class of product Xerium now supplies.”

About Xerium (NYSE:XRM)

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 30 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Minerals Technologies Signs Commercial Agreement For Fulfill® High-Filler Technology With Major South American Papermaker

26th Agreement for FulFill® Technology that Reduces Papermaking Costs by Replacing Fiber with Precipitated Calcium Carbonate

Minerals Technologies Inc., (NYSE: MTX) has just announced that it has entered into a commercial agreement with a leading South American paper company to provide Fulfill® E-325 higher filler technology. This is the company's 26th commercial agreement for the technology that allows papermakers to produce quality paper at lower cost by replacing higher-cost fiber with precipitated calcium carbonate (PCC). The papermaker wishes to remain unnamed for competitive reasons.

Minerals Technologies Inc., (NYSE: MTX) has just announced that it has entered into a commercial agreement with a leading South American paper company to provide Fulfill® E-325 higher filler technology. This is the company's 26th commercial agreement for the technology that allows papermakers to produce quality paper at lower cost by replacing higher-cost fiber with precipitated calcium carbonate (PCC). The papermaker wishes to remain unnamed for competitive reasons.

"We are extremely pleased that this prominent South American papermaker is adopting our cost-saving technology," said Joseph C. Muscari, chairman and chief executive officer. "The continued acceptance of our FulFill® product portfolio by paper companies worldwide further validates the value-added technology developed by MTI."

Minerals Technologies now has 10 agreements with paper companies in Asia; eight in North America; six in Europe; and two in South America. The Fulfill® E-325 series allows papermakers to replace higher-cost pulp by increasing PCC loading levels three to five percentage points, from a typical level of approximately 20 percent up to 25 percent.

"In addition to the 26 commercial agreements we now have, MTI is actively engaged with 18 additional paper mills that are interested in FulFill®." said W. Rand Mendez, senior vice president & managing director, Paper PCC. "We are also working with numerous other paper producers to advance our NewYield® technology that saves costs and reduces environmental impact."

PCC is a specialty pigment for filling and coating high-quality paper. By substituting PCC for more expensive wood fiber, papermakers are able to produce brighter, higher quality paper at lower cost. Minerals Technologies originated the satellite concept for making and delivering PCC on-site at paper mills, and the concept was a major factor in revolutionizing North American papermaking from an acid to an alkaline-based technology. Minerals Technologies constructed its first PCC satellite plant in 1986. Today, the company has 64 satellite plants in operation or under construction around the world and continues to lead the industry with consistent quality and technical innovation.

New York-based Minerals Technologies Inc. is a resource and technology based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral based and synthetic mineral products and related systems and services. MTI serves the paper, foundry, steel, construction, environmental, energy, polymer and consumer products industries. The company reported sales of $1.798 billion in 2015.

For further information about Minerals Technologies Inc. look on the internet at http://www.mineralstech.com/

Minerals Technologies, Sun Paper and Tsinghua University Form One of Six New EcoPartnerships

Minerals Technologies, Sun Paper and Tsinghua University Form One of Six New EcoPartnerships Announced in Beijing During Recent U.S.-China Strategic and Economic Dialogue

EcoPartnership Aimed at Reducing Pollution Through Minerals Technologies' NewYield(TM) Integrated Process Technology

Minerals Technologies Inc. (NYSE: MTX) have just announced that it has formed a partnership with the Sun Paper Group and Tsinghua University's School of Environment to pilot innovation with its NewYield(TM) process technology aimed at reducing soil and ground water pollution by converting a waste stream from the papermaking process into a useable filler pigment for paper. The announcement was made on June 6 in Beijing during the China-U.S. Climate Leaders Summit held in conjunction with the eighth annual U.S.-China Strategic and Economic Dialogue. The partnership signing, sponsored by the U.S. State Department and China's National Development and Reform Commission (NDRC), was witnessed by John Kerry, U.S. Secretary of State, and Yang Jiechi, China State Councilor.

Minerals Technologies Inc. (NYSE: MTX) have just announced that it has formed a partnership with the Sun Paper Group and Tsinghua University's School of Environment to pilot innovation with its NewYield(TM) process technology aimed at reducing soil and ground water pollution by converting a waste stream from the papermaking process into a useable filler pigment for paper. The announcement was made on June 6 in Beijing during the China-U.S. Climate Leaders Summit held in conjunction with the eighth annual U.S.-China Strategic and Economic Dialogue. The partnership signing, sponsored by the U.S. State Department and China's National Development and Reform Commission (NDRC), was witnessed by John Kerry, U.S. Secretary of State, and Yang Jiechi, China State Councilor.

"We are very pleased to partner with two of China's leading institutions--Sun Paper and Tsinghua University--to help reduce the impact on the environment through our NewYield(TM) process technology that eliminates the cost of disposal and remediation of certain papermaking waste streams," said Joseph C. Muscari, chairman and chief executive officer. "With the leadership of Sun Paper, with which we have an operating NewYield(TM) facility, and Tsinghua University, as well as the support of China's NDRC, we expect increased interest in this technology in China."

The U.S.-China EcoPartnership program was established in 2008 to help address environmental challenges shared by both the U.S. and China. The program was created to highlight U.S.-China environmental cooperation pilot projects.

Through their new EcoPartnership, Minerals Technologies, Sun Paper and Tsinghua University will demonstrate the capability to repurpose essentially 100 percent of the lime mud waste stream generated in the papermaking process, providing a roadmap for the Chinese pulp and paper industry to reduce the adverse impact on soil and groundwater. The partnership will work to pilot the new technology, innovate ways to localize the technology to China, evaluate the results of the technology deployment, recommend policy and regulatory action, and assess the steps necessary to drive change throughout the Chinese pulp and paper industry.

In addition to NewYield(TM), Minerals Technologies also exhibited three additional families of technologies aimed at reducing environmental impact at the two-day Climate Leaders Summit. These included solutions for containment and remediation of pollutants, eco-friendly buildings, and enhancement of crop yields. The company provides a variety of technologies such as geosynthetic clay linings, groundwater treatment, solidification and stabilization, and sediment remediation for commercial, industrial and infrastructure construction. The company's technologies for eco-friendly buildings include green roof systems, geothermal drilling solutions and advanced waterproofing. Minerals Technologies also exhibited its Enersol(TM) crop enhancement product line, which improves plant health, soil bioavailability and crop yield.

New York-based Minerals Technologies Inc. is a resource and technology based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral based and synthetic mineral products and related systems and services. MTI serves the paper, foundry, steel, construction, environmental, energy, polymer and consumer products industries. The company reported sales of $1.798 billion in 2015.

For further information about Minerals Technologies Inc. look on the internet at http://www.mineralstech.com/

Sappi’s Magno Plus products certified for HP Indigo digital presses

Sappi’s Magno Plus Gloss and Plus Silk high bulk products deliver more value and outstanding print results. In addition to high performance offset printing they are now fully certified for use on HP Indigo digital presses.

Flavio Froehli, Sales Director for Sappi’s commercial print products said; “We are delighted that Magno Plus products have received this certification, the entire Magno range of products are already extensively used on all types of digital presses but this certification for HP Indigo presses provides additional quality assurance by the market leader”

Flavio Froehli, Sales Director for Sappi’s commercial print products said; “We are delighted that Magno Plus products have received this certification, the entire Magno range of products are already extensively used on all types of digital presses but this certification for HP Indigo presses provides additional quality assurance by the market leader”

“Sappi Magno supports the overall efficiency of printed media by offering multi-use products that avoid the need for duplicated stocks, ensuring production flexibility between offset and digital processes whilst retaining the high quality and consistency Magno is renowned for.”

Further information:

The Magno graphic paper range offers seven products including gloss, silk, matt in standard or hi-bulk options and uncoated surfaces, basis weights range from 80g/m² to 400g/m² with all products having an aligned high white shade.

For further information, samples or to organize a trial please contact your local Sappi sales office.

About Sappi

Sappi Europe SA is the leading European producer of coated fine paper used in premium magazines, catalogues, books and high-end print advertising. Headquartered in Brussels, Belgium, Sappi Europe is recognised for innovation and quality. Its graphic paper brands include Magno™, Quatro™, Vantage™, Royal, Galerie™ and GalerieArt™ ranges. Algro®, Fusion®, Leine® and Parade® are the brands for speciality labelling, topliner, packaging papers and boards. Sappi papers are produced in mills accredited with ISO 9001, ISO 14001 and OHSAS 18001 certification and EMAS registration for all our mills in the EU. Sappi European mills hold chain-of-custody certification under the Forest Stewardship Council (FSC®) and/or the Programme for the Endorsement of Forest Certification (PEFC™) schemes.

Sappi Europe SA is a division of Sappi Limited (JSE), a global company headquartered in Johannesburg, South Africa, with over 13,500 employees and manufacturing operations on three continents in seven countries, sales offices in 50 countries, and customers in over 100 countries around the world. Learn more about Sappi at www.sappi.com.

BillerudKorsnäs invests for growth and efficiency in packaging paper

The BillerudKorsnäs board has just approved a SEK 1 280 million investment program to strengthen the leading position of the company in kraft papers for packaging applications. The investment will enable further growth in attractive market segments and at the same time streamline the company’s production structure.

The investment program will result in the Skärblacka production unit in Sweden being developed into a world leading center for machine glazed, MG, kraft paper production. The program includes relocating the BillerudKorsnäs MG paper machine in Tervasaari, Finland, to Skärblacka and investing in surface treatment capacity on the existing paper machine 7 in Skärblacka. The Tervasaari machine is one of the largest MG paper machines in the world. In Skärblacka it will be fully integrated to pulp production which will give it a highly competitive position in the white MG paper market. The surface treatment capacity at Skärblacka PM7 will allow further functionality to be added for applications within food packaging, medical packaging and release liners.

The investment program will result in the Skärblacka production unit in Sweden being developed into a world leading center for machine glazed, MG, kraft paper production. The program includes relocating the BillerudKorsnäs MG paper machine in Tervasaari, Finland, to Skärblacka and investing in surface treatment capacity on the existing paper machine 7 in Skärblacka. The Tervasaari machine is one of the largest MG paper machines in the world. In Skärblacka it will be fully integrated to pulp production which will give it a highly competitive position in the white MG paper market. The surface treatment capacity at Skärblacka PM7 will allow further functionality to be added for applications within food packaging, medical packaging and release liners.

“Packaging solutions based on renewable raw materials are parts of the solution to some of the challenges we face in society. In order to contribute to the sustainable future we believe in, we need to constantly develop ourselves and our assets. This investment gives us a production platform for continued growth and increased efficiency within our business area Packaging Paper”, says Per Lindberg, President and CEO, BillerudKorsnäs.

The investments will be carried out between 2016 and early 2018 and start-ups of the relocated machine and the rebuilt PM7 are expected during Q4 2017 to Q1 2018. BillerudKorsnäs underlying investment level is approximately SEK 1 300 million per year. With the decision announced today, the total investment level is expected to increase to approximately SEK 1 420 million in 2016 and approximately SEK 1 900 million in both 2017 and 2018.

More than 40 new jobs will be created in Skärblacka as a result of the investments. In addition to this, there is significant positive employment effect among suppliers and contractors during the implementation phase.

As announced earlier, BillerudKorsnäs is also working on a feasibility study regarding the potential investment in a new board machine at the Gruvön production unit for further volume growth within business area Consumer Board. No decision has been made yet regarding this potential investment. The study is currently in an intense phase and is expected to be completed by the end of 2016.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4 200 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Valmet to supply two spray moisturizer systems to SAICA's corrugated board converting plants in Spain and France

Valmet will supply two Valmet IQ Moisturizer systems to SAICA's corrugated board converting plants in El Prat, Spain, and Beaulac, France. By installing Valmet's advanced moisturizing technology in their corrugators, SAICA's plants will be able to reduce corrugated board warping and consequently reduce waste and improve productivity in their converting processes.

The order was included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. A moisturizer is usually valued below EUR 1 million. The deliveries will take place during the third quarter of 2016.

The order was included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. A moisturizer is usually valued below EUR 1 million. The deliveries will take place during the third quarter of 2016.

"After many years of successful experiences working together with Valmet's automation solutions on paper production, Saica Group celebrates Valmet movement towards the introduction of automation technology on corrugators to ensure board quality as well as line production efficiency. The collaboration of the two companies' innovation technology teams is resulting on reliable control systems working on line and this order is a proof of our satisfaction," says Federico Asensio, Saica Group, Director, R&D and innovation.

"Entering paper and board converting with the Valmet IQ quality control solutions is one of Valmet's growth initiatives. We have earlier supplied a moisturizer system to SAICA's converting plant in Viana, Spain. A repeat order from SAICA is now proof that we are on the right track for delivering proven, value-adding quality control solutions also for the converting industry," states Jari Almi, Director, Quality Management Solutions, Automation, Valmet.

Technical information about Valmet IQ Moisturizer

Valmet's delivery includes two Valmet IQ Moisturizers that are part of the Valmet IQ product family for monitoring and optimizing process performance and end product quality.

Valmet IQ Moisturizer is a moisturizing system with applications for moisture cross-direction profiling, warp (curl) control and smooth moisture level increase. It features an air atomized micro droplet spray nozzle, a linear water control valve and excessive spray mist removal system.

Information about the customer SAICA

SAICA Group has three business areas: paper mills (Paper), collection of recyclable materials (Natur) and corrugated paper pack containers (Pack). The consolidated sales figures of the Spanish company for year 2015 were EUR 2,378 million. SAICA Group is a leading company in Europe in the manufacturing of containerboard paper, corrugating board with a capacity of almost 2.5 million tons of paper and more than 2.400 million square meters of corrugated board. The company has more than 8,800 employees at present in Spain, France, Italy, Portugal, United Kingdom, Ireland and Turkey.

Stora Enso increases its fluff pulp capacity at Skutskär Mill in Sweden

Stora Enso will invest EUR 26.5 million in Skutskär pulp mill to increase its fluff capacity to meet the growing demand in the hygiene market.

The investment will enhance Skutskär Mill’s profitability and long-term competitiveness by increasing fluff production by approximately 160 000 tonnes annually. The mill’s softwood capacity is expected to be reduced by 160 000 tonnes, starting from year 2018. The total fluff pulp capacity of the mill after the investment will amount to 415 000 tonnes.

The investment will enhance Skutskär Mill’s profitability and long-term competitiveness by increasing fluff production by approximately 160 000 tonnes annually. The mill’s softwood capacity is expected to be reduced by 160 000 tonnes, starting from year 2018. The total fluff pulp capacity of the mill after the investment will amount to 415 000 tonnes.

The investment supports Stora Enso’s strategy of transforming into a customer-focused renewable materials growth company. The aim is to develop further the current market pulp business and to focus more on growth segments.

“Both hygiene and non-woven products are a fast-growing market. This investment will enable us to support the growth of our customers and further develop this business together with them,” says Juan Carlos Bueno, EVP, Stora Enso’s Biomaterials division.

The investment is expected to be completed during the second quarter of 2018, and it falls within the group’s capital expenditure guidance given earlier. The investment includes the necessary changes to one of the drying machines.

Stora Enso’s Skutskär Mill produces Northern bleached kraft softwood pulp (NBSK), softwood fluff pulp and bleached hardwood pulp (birch). The total annual capacity of the mill is 540 000 tonnes. The fluff pulp is mainly used in airlaid hygiene products such as diapers, feminine care products and adult incontinence products. It is also used in tabletop products and wipes.

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Our aim is to replace fossil based materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 26 000 people in more than 35 countries, and our sales in 2015 were EUR 10.0 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market. storaenso.co