Ianadmin

Temporary Suspension of One of Resolute's Two FSC Certificates in Quebec Extended

Resolute Forest Products Inc. (NYSE: RFP) (TSX: RFP) recently learned from a Forest Stewardship Council® (FSC®) Canada press release that FSC has requested that the Rainforest Alliance certification body extend the temporary suspension of one of Resolute's two certificates in Quebec's Lac-Saint-Jean region for six months, until July 2, 2015.

Resolute Forest Products Inc. (NYSE: RFP) (TSX: RFP) recently learned from a Forest Stewardship Council® (FSC®) Canada press release that FSC has requested that the Rainforest Alliance certification body extend the temporary suspension of one of Resolute's two certificates in Quebec's Lac-Saint-Jean region for six months, until July 2, 2015.

"I am quite surprised by FSC Canada's last-minute intervention, which to my knowledge is unprecedented," said Richard Garneau, president and chief executive officer of Resolute. "I note that FSC Canada has indicated that it has identified possible solutions to avoid 'unfairly penalizing' Resolute, according to its president, François Dufresne, quoted in the December 21, 2014 edition of the newspaper Le Progrès Dimanche. We are eager to meet with Mr. Dufresne and discuss solutions for reinstating our FSC certificates."

The extension of the temporary suspension is intended to give the Quebec government time to settle its dispute with the Cree First Nation, which dates back to 2002, and to resolve issues with its caribou conservation plan, the two issues that led to the temporary suspension of Resolute's certificates in the Lac-Saint-Jean area.

"Naturally, we would prefer to have our certificates reinstated, but it is clear that Resolute cannot resolve the two major stumbling blocks, and in view of the auditors' interpretations that led to these temporary suspensions, we question whether it is possible for the government to fully address the concerns without major socio-economic impacts on employment and the well-being of communities," added Garneau.

It is also interesting to note that only the Lac-Saint-Jean certificate has been extended, while the Mistassini-Péribonka certificate, which expired on December 3, 2014, is not treated with the same measure of flexibility even though it was alleged to suffer the same defect related to the caribou conservation plan.

"We look forward to clear proposals from FSC Canada for resolving the two issues that are responsible for the temporary suspension of the two certificates, while maintaining the viability of our company and the communities in which we operate," said Richard Garneau. "We are also asking FSC Canada to reconcile the regional and provincial caribou conservation action plans, and on implementation of Motion 65, introduced by Greenpeace and adopted at the FSC's last General Assembly, held in September in Seville, Spain. The motion, which calls for preservation of 80% of intact forest landscapes, is scheduled to come into effect at the end of 2016."

In light of recent events, Resolute believes it is important for FSC Canada to establish an independent comparative analysis of all the audits conducted in recent years in Quebec and Ontario, according to the FSC boreal standard, in order to compare auditors' interpretations and requirements, as well as the efforts made by certificate holders to meet these requirements. FSC Canada should proceed with this exercise for the sake of fairness and transparency for all certificate holders; this goes to the credibility of the standard itself.

"We remain convinced that such an analysis would clearly demonstrate to our employees, communities, governments and customers, that Resolute is a leader in sustainable forest management and would underscore our ongoing commitment to balancing the three sustainability pillars: environmental, social and economic," added Garneau.

Resolute remains committed to the voluntary certification of 100% of the forests it manages to one or more of three internationally recognized sustainable forest management standards used in Canada and recognized world-wide, namely, Sustainable Forest Initiative® (SFI®), FSC and the Canadian Standards Association (CSA). In addition, the company continues to be one of the largest holders of FSC sustainable forest management certificates in Canada and recently successfully renewed its certificates in the Mauricie, Abitibi and North Shore regions of Quebec.

About Resolute Forest Products

Resolute Forest Products is a global leader in the forest products industry with a diverse range of products, including newsprint, specialty papers, market pulp and wood products. The Company owns or operates nearly 40 pulp and paper mills and wood products facilities in the United States, Canada and South Korea, and power generation assets in Canada. Marketing its products in close to 90 countries, Resolute has third-party certified 100% of its managed woodlands to at least one of three internationally recognized sustainable forest management standards. The shares of Resolute Forest Products trade under the stock symbol RFP on both the New York Stock Exchange and the Toronto Stock Exchange.

Resolute and other member companies of the Forest Products Association of Canada, as well as a number of environmental organizations, are partners in the Canadian Boreal Forest Agreement. The group works to identify solutions to conservation issues that meet the goal of balancing equally the three pillars of sustainability linked to human activities: environmental, social and economic.

Resolute is proud to be ranked by Corporate Knights as one of Canada's Best 50 Corporate Citizens for 2014. Corporate Knights is an organization recognized globally for its transparent and objective approach to measuring corporate sustainability performance. Resolute Forest Products and Richard Garneau, president and chief executive officer, have also been named to Canada's Clean50, recognizing leaders who have made the greatest contributions to sustainable development or clean capitalism in Canada.

SOURCE Resolute Forest Products Inc.

For further information: Investors: Rémi G. Lalonde, Vice President and Treasurer, 514 394-2345, This email address is being protected from spambots. You need JavaScript enabled to view it.; Media and Others: Karl Blackburn, Director, Canadian Public Affairs and Government Relations,514 250-4364, This email address is being protected from spambots. You need JavaScript enabled to view it.

Verso Settles With U.S. Department of Justice Regarding Pending Acquisition of NewPage

Settlement Enables Completion of Acquisition in Early January 2015

Verso Paper Corp. (NYSE: VRS), a leading North American producer of printing and specialty papers and pulp, has announced that it has reached a settlement with the United States Department of Justice that will permit Verso to proceed with its acquisition of NewPage Holdings Inc. The transaction, valued at approximately $1.4 billion, originally was announced on January 6, 2014. Upon the completion of the NewPage acquisition, Verso will have approximately $3.5 billion in annual sales and approximately 5,800 employees in eight mills across six states.

As part of the settlement process, the United States today filed a civil antitrust lawsuit in the U.S. District Court for the District of Columbia alleging that Verso's proposed acquisition of NewPage would violate the antitrust laws. At the same time, the United States filed a proposed settlement that, if approved by the court, will resolve the lawsuit and enable the transaction to proceed. The transaction remains subject to customary closing conditions.

The proposed settlement requires the divestiture of NewPage's paper mills in Biron, Wisconsin, and Rumford, Maine, as previously announced on October 30, 2014. The proposed settlement will be published in the Federal Register and will be subject to public comment, as required by the Antitrust Procedures and Penalties Act (known as the Tunney Act).

Verso expects to complete the NewPage acquisition in early January 2015. NewPage is expected to complete the divestiture of the Biron and Rumford mills to a subsidiary of Catalyst Paper Corporation in connection with Verso's acquisition of NewPage.

"The combination of Verso and NewPage will create a stronger, more stable company that will be better positioned to serve our customers and compete in a competitive global marketplace," said David J. Paterson, Verso's president and chief executive officer. "We are pleased that we were able to address the concerns of the Justice Department while preserving the benefits of the transaction for our stockholders and customers."

"Although this transaction has been among the most challenging and complex, the resulting combination will create value for all of our constituents, particularly our shareholders," said Mark Angelson, the chairman of NewPage. "We would not have come this far without critical input from the Justice Department and the advisors, key shareholders and directors of both companies."

Following the completion of the NewPage acquisition, Verso's existing senior leadership team will continue to lead the combined company.

About Verso

Verso Paper Corp. is a leading North American producer of coated papers, including coated groundwood and coated freesheet, and specialty products. Verso is headquartered in Memphis, Tennessee, and owns and operates two paper mills located in Maine and Michigan. Verso's paper products are used primarily in media and marketing applications, including magazines, catalogs and commercial printing applications such as high-end advertising brochures, annual reports and direct-mail advertising. Additional information about Verso is available on its website at www.versopaper.com .

Forward-Looking Statements

In this press release, all statements that are not purely historical facts are forward-looking statements within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934. Forward-looking statements may be identified by the words "believe," "expect," "anticipate," "project," "plan," "estimate," "intend" and other similar expressions. Forward-looking statements are based on currently available business, economic, financial and other information and reflect management's current beliefs, expectations and views with respect to future developments and their potential effects on Verso. Actual results could vary materially depending on risks and uncertainties that may affect Verso and its business. For a discussion of such risks and uncertainties, please refer to Verso's filings with the Securities and Exchange Commission. Verso assumes no obligation to update any forward-looking statement made in this press release to reflect subsequent events or circumstances or actual outcomes.

Contact

Verso Paper Corp.

Robert P. Mundy

Senior Vice President and Chief Financial Officer

001-901-369-4128

Email Contact

www.versopaper.com

Source: Verso Paper Corp.

Konecranes has every stage of the pulp and paper industry process covered

The paper manufacturing is characterized by a long and complicated process. From the transformation of wood into pulp, over the winding paper web into rolls, and subsequently the rewinding and cutting of these giant rolls into smaller ones, through the automatic storage for converting, sheet cutting, or customer delivery. The paper mill works fast, and the products need to be shipped on time to meet demanding customer schedules. Unexpected downtime can’t be afforded.

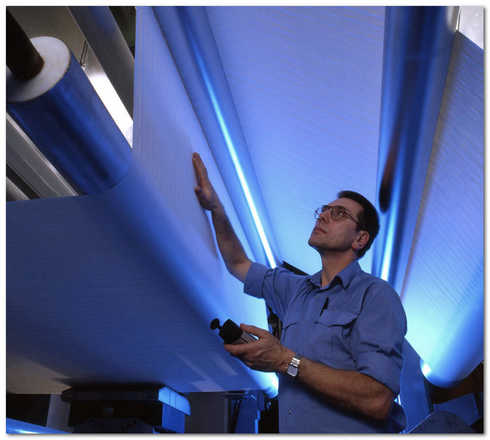

Konecranes develops paper mill cranes to help boost long-term reliability and minimize ownership costs. © Konecranes

Konecranes understands the processes of the pulp and paper – from wood handling to recycling - and has been meeting the needs of this industry for decades by providing cranes and other lifting solutions that help to increase productivity, maximize efficiency, as well as avoid downtime and costly problems right from the start.

Selecting from an unmatched portfolio of superior products, Konecranes can deliver integrated solutions – starting with the unloading of raw materials and continuing every step of the way to the shipping of the finished paper products. The company has end-to-end expertise covering planning, engineering, delivering, commissioning, and servicing lifting solutions for all pulp and paper operations. The know-how offered by Konecranes can start with a feasibility study and extend to cover the complete maintenance of lifting equipment and tools throughout their lifecycle.

Konecranes offers specialized service for the pulp and paper industry that helps to improve safety and decrease the cost of downtime. © Konecranes

Paper mill cranes and material handling system

Konecranes has designed paper mill cranes to help boost long-term reliability and minimize ownership costs for pulp and paper industry. The solutions are based on long experience and know-how of the industry environment, and the process. This know-how is based on Konecranes’ own resources and close collaboration with machine suppliers and engineers. Konecranes provides cranes and material handling systems for all lifting applications in the pulp and paper industry, such as process duty cranes, maintenance cranes, parent roll handling cranes, paper roll storage systems, workshop cranes, as well as maintenance services. Cranes used in the pulp and paper industry are used as an integrated part of the production process and maintenance.

Moreover, the applications provided vary and cover the fields of wood handling, pulp production lines, paper and paperboard production, deinking plants, tissue paper mills and converting plants, intermediate storage, and shipping.

Paper Roll Storage Solutions

Konecranes’ warehouse management system (WMS) and the automatic paper roll handling crane design for unpacked and wrapped storage rolls help to save space and time. The automated vacuum lifter economizes the warehouse capacity of the available space. Furthermore, software for the storage administration system and crane automation with purpose-built machineries form an integrated handling system. Mechanical roll grippers can handle wrapped rolls and multiple rolls at a time for higher input/ output of smaller roll sizes.

In addition, Autostore helps paper mills operate more efficiently by eliminating capital and labor costs. Storage automation keeps the inventory fresh, clean, and current and provides up-to-date information.

Excellent, proactive service

Konecranes provides an extensive range of services for the pulp and paper industry that can cover a single item or all lifting equipment. The offered specialized service helps to improve safety, decrease the cost of downtime, and increase the productivity of uptime. With a global network of maintenance professionals working from more than 600 service depots around the world, Konecranes can service any make of crane and hoist. Services include inspections, repairs, maintenance, and modernizations of cranes and other lifting equipment worldwide.

In addition, Konecranes offers the unique TRUCONNECT® Remote Monitoring and Reporting service, which provides actual crane usage data. TRUCONNECT® periodic data reporting and real-time diagnostics allow customers to optimize crane maintenance activities and give visibility to crane maintenance and application compliance.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity-enhancing lifting solutions as well as services for lifting equipment and machine tools of all makes. In 2013, Group sales totaled EUR 2,100 million. The Group has 11,800 employees at 600 locations in 48 countries. Konecranes is listed on the NASDAQ OMX Helsinki (symbol: KCR1V).

Further information:

Konecranes

Lena Ansorge, Marketing & Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone +49 6103 7333-235 | Mobile +49 162 2824233

Clearwater Paper Announces Sale of Specialty Mills to Dunn Paper, Inc

Clearwater Paper Corporation (NYSE:CLW)(the "Company") has announced the Company has sold its specialty products business and mills to Dunn Paper, Inc. The Company intends to reinvest the net proceeds of the sale into capital projects within its Consumer Products Division.

Clearwater Paper Corporation (NYSE:CLW)(the "Company") has announced the Company has sold its specialty products business and mills to Dunn Paper, Inc. The Company intends to reinvest the net proceeds of the sale into capital projects within its Consumer Products Division.

The transaction, which closed today, includes the sale of five Clearwater Paper subsidiaries with facilities located at East Hartford, Conn., Menominee, Mich., Gouverneur (Natural Dam), N.Y., St. Catharines, Ontario, and Wiggins, Miss.

"The sale of the specialty products business sharpens our Consumer Products Division's focus on the core retail business," said Linda Massman, president and CEO. "It's about improving our approach and efficiencies in all parts of our business while meeting or surpassing our customers' expectations, and our Company financial goals. We believe that the capital projects in which we will invest the proceeds of this sale can yield a 300 to 400 basis point improvement in the Consumer Product Division's EBITDA margins over the next three years."

"On behalf of Clearwater Paper, we sincerely thank the specialty products team for their hard work and commitment to providing our customers with high-quality products and services," said Massman.

Effective today, 470 specialty products employees are now employees of Dunn Paper.

"We are very pleased to welcome the exceptional people who lead and work at these specialty mills to the Dunn Paper team," said Brent Earnshaw, CEO of Dunn Paper. "Combining the unique assets, capabilities and products of these mills with Dunn Paper's Port Huron mill will lead to a specialty paper company with unmatched product offerings for our diverse customer base."

FBR Capital Markets & Co., led by Matthew Spain, advised Clearwater Paper on the sale of the specialty products business. Pillsbury Winthrop Shaw Pittman LLP acted as legal advisor to Clearwater Paper.

ABOUT CLEARWATER PAPER

Clearwater Paper manufactures quality consumer tissue, away-from-home tissue, hard roll tissue, bleached paperboard and pulp at manufacturing facilities across the nation. The Company is a premier supplier of private label tissue to major retailers and wholesale distributors, including grocery, drug, mass merchants and discount stores. In addition, the Company produces bleached paperboard used by quality-conscious printers and packaging converters. Clearwater Paper's employees build shareholder value by developing strong customer partnerships through quality and service.

ABOUT DUNN PAPER

Dunn Paper, Inc. is a leading specialty paper manufacturer with customers worldwide. Dunn Paper produces a wide array of specialty waxed, coated and uncoated machine-glazed papers used in various food packaging and specialty label applications. Dunn Paper is located in Port Huron, Mich., approximately 60 miles north of Detroit.

FORWARD-LOOKING STATEMENTS

This press release contains certain forward-looking statements within the meaning of the Private Litigation Reform Act of 1995 as amended, including, but not limited to, statements regarding the Company's reinvestment of proceeds, improved efficiencies, customer expectations, Company financial goals and EBITDA margins. These forward-looking statements are based on current expectations, estimates and assumptions that are subject to change, and actual results may differ materially from the forward-looking statements. Factors that could cause actual results to differ materially include, but are not limited to customer acceptance and quantity and timing of purchases of the Company's new TAD products; competitive pricing pressures for the Company's products, including as a result of increased capacity as additional manufacturing facilities are operated by the Company's competitors; difficulties with the optimization and realization of the benefits expected from the Company's TAD paper machine and converting lines in North Carolina; the loss of or changes in prices in regards to a significant customer; manufacturing or operating disruptions, including IT system failures, equipment malfunction and damage to the Company's manufacturing facilities; changes in the cost and availability of wood fiber and wood pulp; changes in transportation costs and disruptions in transportation services; labor disruptions; changes in costs for and availability of packaging supplies, chemicals, energy, and maintenance and repairs; changes in customer product preferences and competitors' product offerings; changes in expenses and required contributions associated with the Company's pension plans; environmental liabilities or expenditures; changes in the U.S. and international economies and in general economic conditions in the regions and industries in which the Company operates; cyclical industry conditions; or inability to successfully implement the Company's expansion strategies; and other risks and uncertainties described from time to time in the Company's public filings with the Securities and Exchange Commission. The forward-looking statements are made as of the date of this press release and the Company does not undertake to update any forward-looking statements.

For additional information on Clearwater Paper, please visit our website at www.clearwaterpaper.com.

News media

Clearwater Paper Corporation

Matt Van Vleet, 509-344-5912

Vice President, Public Affairs

This email address is being protected from spambots. You need JavaScript enabled to view it.

or

Investors

Clearwater Paper Corporation

Robin Yim, 509-344-5906

Vice President, Investor Relations

This email address is being protected from spambots. You need JavaScript enabled to view it.

Source: Clearwater Paper Corporation

Xerium Named by Triangle Business Journal as One of the Top 35 Healthiest Employers for 2014

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently was honored by Triangle Business Journal as one of the top 35 Healthiest Employers for 2014.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently was honored by Triangle Business Journal as one of the top 35 Healthiest Employers for 2014.

In recent years, Xerium initiated its corporate-wide wellness programs which offers incentives on medical plan premiums aligned with employee participation in biometric screenings, weight loss and fitness programs along with gym membership reimbursements. In addition, the state-of-the-art gym at the Youngsville headquarters gives employees on-site access to quality fitness equipment and activities. Xerium also sponsors Wellness Fairs and free flu shots throughout our locations while communicating with participants through monthly wellness newsletters.

"We value each of our employees and believe that their health and that of their family is one of our top priorities. We also recognize that our employees' health and well-being is important to the health of our business. I have always been a strong advocate of wellness programs within the businesses I have been fortunate to lead. At Xerium, we wanted to build on this commitment and implement our wellness programs to also help offset rising medical claims expenses, especially when coupled with the changes in U.S. health care reform," said Mr. Harold Bevis, President and CEO of Xerium. "We knew it was time to inspire proactive changes to the wellness of our employees, and are pleased with the progress we have made together."

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 27 manufacturing facilities in 12 countries around the world and employs approximately 3,200 employees.

De La Rue Invests in QiSOFT Manufacturing intelligence key to operational excellence

QiSOFT, a leading provider of manufacturing intelligence software, announces a major business expansion with De La Rue, the world’s largest integrated commercial banknote printer and passport manufacturer.

QiSOFT, a leading provider of manufacturing intelligence software, announces a major business expansion with De La Rue, the world’s largest integrated commercial banknote printer and passport manufacturer.

Established in 1813, De La Rue is a trusted partner of governments, central banks and commercial organisations around the world. It also produces a wide range of security products, including banknotes, passports, tax stamps, authentication labels and identity documents and manufactures high speed cash sorting and banknote inspection equipment. Listed on the London Stock Exchange, De La Rue operates globally and its diverse operations, combined with ever increasing quality considerations from customers put growing pressure on the company’s data analysis capabilities, as Peter Hall, De La Rue’s Quality Director explains.

“Our biggest challenge is the need to monitor accurately all the available information on the production floor to support our strategy of continuous improvement.” He continues, “It was essential to have a solution that not only helps identify opportunities to reduce waste, rework and raw material usage, we also need to be able to monitor trends and identify potential issues before they impact product quality, helping us ensure the highest level of customer satisfaction.”

After a thorough evaluation of alternatives De La Rue invested in QIS manufacturing intelligence software, from QiSOFT, a pioneer in this sector. John Abson, De La Rue, Quality Manager, explains why QIS was the solution of choice. “We wanted a proven system with a good pedigree, implemented and supported by people who genuinely understand our industry in general and our business in particular. QIS provides the visibility and flexibility we need as well as seamlessly integrating with our other IT systems – we anticipate the same considerable benefits that we know many other QIS users enjoy.”

Kevin Luxton, CEO of QiSOFT, commented on the business win. “QIS has been trusted in the process manufacturing sector for over 27 years and has proved its ability here to take all the available shop-floor data and turn this into meaningful and actionable intelligence. This combined with the unparalleled implementation and support expertise means that De La Rue can have maximum confidence in their investment, today, tomorrow and into the future.”

A company-wide roll-out is currently underway, with minimal impact to the business. QIS is expected to be in full use across De La Rue sites globally by early 2015.

About QiSOFT

QiSOFT has been a leading provider of manufacturing intelligence software since 1986, helping hundreds of sites around the world to improve product quality, reduce waste and optimise process efficiency. With offices in the USA, UK and Europe, supported by a global network of distributors and partners, QiSOFT is a truly international company. They have an established and loyal customer base, from large blue-chip manufacturing organisations to smaller, local family run businesses across a variety of industries. Although a software company at the core, QiSOFT’s ultimate aim is to help establish quality as a key strategic focus, supporting their customers in the drive to deliver continuous improvement and operational excellence.

AstenJohnson acquires Eagle Nonwovens business

AstenJohnson, a premier supplier of paper machine clothing, filaments, specialty and filtration fabrics, and equipment for the paper industry, has completed the acquisition of Eagle Nonwovens, Inc. in the USA.

AstenJohnson, a premier supplier of paper machine clothing, filaments, specialty and filtration fabrics, and equipment for the paper industry, has completed the acquisition of Eagle Nonwovens, Inc. in the USA.

Eagle Nonwovens is known for producing consistent, high-quality products and delivering them with fast service. The company has also gained a reputation for creative problem solving by developing innovative needlepunch solutions for the aerospace, automotive, healthcare, filtration, and home furnishings industries. It manufactures products in its 170,000 square-foot facility in St. Louis, Missouri. The plant utilizes state-of-the-art Dilo Systems production equipment with in-line calendering, heat setting, singeing, glazing, etc. The facility is capable of processing more than 30 million pounds of synthetic fiber each year.

The Eagle Nonwovens business unit reports to Steve Polston, Senior Vice President and Chief Financial Officer of AstenJohnson. Gregg Badami, Founder of Eagle Nonwovens, will continue with the company throughout a transition period.

“We are excited to welcome Eagle Nonwovens into our family of businesses,” says Dan Cappell, President and Chief Executive Officer of AstenJohnson. “This is yet another opportunity to offer customers an array of high performance products, technical expertise, and innovative solutions. The workforce at Eagle Nonwovens is highly engaged and professional, and shares our commitment to Lean Manufacturing and Quality.”

AstenJohnson is a global manufacturer of paper machine clothing, advanced and filtration fabrics, filaments, paper machine equipment, and custom rebuild solutions. As a supplier to the paper industry since 1790, privately held AstenJohnson has a thorough knowledge of equipment and processes, with the expertise to help customers be more profitable. The company employs more than 2,000 people. Locations include a corporate office in Charleston, SC, and six manufacturing plants in the USA, three in Canada, three in Europe, one in China, and one in Thailand. The company’s R&D centers are in Canada and Belgium.

For more information, please contact:

Steve Polston

Senior Vice President and Chief Financial Officer

+1 843 202 6259

This email address is being protected from spambots. You need JavaScript enabled to view it.

Pöyry awarded engineering assignment for Metsä Board Husum new folding boxboard machine project in Sweden

Metsä Board has awarded Pöyry with the assignment for engineering consultancy, laser scanning, 3D modelling, detail engineering and site services for the new folding boxboard machine project at their Husum Mill in Sweden. The assignment is a continuation of the pre-feasibility and the pre-engineering services performed by Pöyry and it covers the majority of the required engineering services related to the implementation of the project.

Metsä Board has awarded Pöyry with the assignment for engineering consultancy, laser scanning, 3D modelling, detail engineering and site services for the new folding boxboard machine project at their Husum Mill in Sweden. The assignment is a continuation of the pre-feasibility and the pre-engineering services performed by Pöyry and it covers the majority of the required engineering services related to the implementation of the project.

The assignment will be executed during the autumn of 2015 and the new board machine scheduled to start up in the first quarter of 2016. The capacity of the new board machine is approximately 400 000 tonnes per year of folding boxboard.

"This project is a continuation of the long co-operation between Metsä Board and Pöyry, and strengthens Pöyry's position as the world's leading pulp and paper engineering consultancy, having delivered projects for 80% of the world's major pulp and paper companies", says Nicholas Oksanen, President, Industry Business Group.

The value of the order is not disclosed. The order will be recognised within the Industry Business Line order stock in Q4 2014.

Additional information by:

Nicholas Oksanen

President, Industry Business Group.

Tel: +358 10 33 22294

Johan Ehrnrooth

Vice President, Industry Pulp and Paper Europe

Tel: +358 10 33 22570

Pöyry is an international consulting and engineering company. We serve clients globally across the energy and industrial sectors and locally in our core markets. We deliver strategic advisory and engineering services, underpinned by strong project implementation capability and expertise. Our focus sectors are power generation, transmission & distribution, forest industry, chemicals & biorefining, mining & metals, transportation and water. Pöyry has an extensive local office network employing about 6,000 experts. Pöyry's net sales in 2013 were EUR 650 million and the company's shares are quoted on NASDAQ OMX Helsinki (Pöyry PLC: POY1V).

Toscotec to supply a new ahead tissue line to JSC Syassky Pulp & Paper Mill in Russia

Syassky Pulp and Paper Mill, based in St. Petersburg, Russia has signed a contract with the Italian manufacturer Toscotec for the supply of a new tissue line at its mill in Syasstroy, in the Leningrad region of Russia.

Syassky Pulp and Paper Mill, based in St. Petersburg, Russia has signed a contract with the Italian manufacturer Toscotec for the supply of a new tissue line at its mill in Syasstroy, in the Leningrad region of Russia.

The new Toscotec AHEAD tissue machine, designed for production of high quality tissue products, will replace the existing PM3 after its dismantling and will come on stream in first half of 2016.

In line with a huge investment process put in progress in the last years and to better expand its growing market in terms of quantity and quality, Syassky Pulp and Paper Mill has decided to invest in the new PM3 line adopting Toscotec’s state of the art latest technology with the aim of improving products offer and reduce the mill's energy costs.

The scope of supply of the new PM3 includes AHEAD-1.5M crescent former tissue machine with a single layer headbox, single press configuration with suction pressure roll TT SPR1045, a 12 FT diameter Steel Yankee Dryer TT SYD-12FT and a reel section TT Reel-P.

The delivery will also include the approach flow system, stock preparation plant, gas heated hood and steam & condensate system from Toscotec associate Milltech, as well as electrification & control system. Engineering and services (erection supervision, commissioning & start up assistance, training) complete the package. Machine speed will be up to 1400 mpm with a trim width of 4200 mm, for a daily production of 125 tons both from dry and slush pulps.

This new order from the Russian Company to Toscotec confirms the successful cooperation between the two companies begun in 2009. The Syasstroy’s site already houses a AHEAD-1.5M tissue machine supplied by the Italian manufacturer in 2012 to replace the existing PM2 as well as two rewinders TT WIND-H (for PM2 and PM3 lines) that came on stream in 2010 and 2012 respectively.

Syassky Pulp and Paper Mill is actually one of the most modern enterprises of the north west Russian region and the only integrated tissue producer in this area having in line pulp mill, tissue production (PM2, PM3 and PM5) and converting & packaging facilities. Founded in 1928 with the unique aim to cover the needs of the domestic market, the Company has been reorganized as joint stock company with the result to be able to satisfy the growing demand for domestic but also for AFH export markets.

SCA Conversion of shares

According to SCA’s articles of association, owners of Class A shares have the right to have such shares converted to Class B shares. Conversion reduces the total number of votes in the company. When such a conversion has occurred, the company is obligated by law to disclose any such changes in this manner.

According to SCA’s articles of association, owners of Class A shares have the right to have such shares converted to Class B shares. Conversion reduces the total number of votes in the company. When such a conversion has occurred, the company is obligated by law to disclose any such changes in this manner.

In December, at the request of shareholders 117 Class A shares were converted to Class B shares. The total number of votes in the company thereafter amounts to 1,479,559,401.

The total number of registered shares in the company amounts to 705,110,094 of which 86,049,923 are Class A shares and 619,060,171 are Class B shares.

NB: This information is such that SCA must disclose in accordance with the Financial Instruments Trading Act. The information was submitted for publication on December 30, 2014, at 10.00 CET.

For additional information please contact:Karl Stoltz, Press and Media Officer, + 46 8 788 51 55

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2013 amounted to approximately SEK 93bn (EUR 10.7bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.