Displaying items by tag: Xerium Technologies

Xerium's New TransForm Forming Fabric Delivers Cost Reduction and Operational Improvements for Paperboard and Packaging Manufacturers

Xerium Technologies, Inc. (NYSE:XRM), introduces TransForm, a revolutionary new generation of forming fabrics designed specifically for paperboard and packaging machines that lowers energy consumption and extends fabric life, among other considerable benefits.

“Utilizing new proprietary polymers and structural designs, our new TransForm line is already helping customers reduce energy consumption by more than 15 percent while extending fabric life between 15 and 25 percent.”

“Our board and packaging customers continuously demand improvements in uptime efficiency and reduced operating costs while delivering higher product quality at maximum output,” said Bill Butterfield, EVP and CTO of Xerium. “Utilizing new proprietary polymers and structural designs, our new TransForm line is already helping customers reduce energy consumption by more than 15 percent while extending fabric life between 15 and 25 percent.”

![]()

Representing half of the global tonnage produced, paperboard and packaging grades continue to grow globally compared to other paper grades. TransForm forming fabrics have been tailor-made for every type of board and packaging former: fourdriniers, twin wire formers, top formers, gap formers, and multiply formers.

“We trialed these new TransForm products in select board and packaging mills with excellent results of improved drainage rates and sheet quality. The performance continues to exceed our customers’ expectations,” adds Butterfield.

TransForm technology is applicable for machines producing: paperboard, containerboard, fluting/corrugating, linerboard, kraft bag, liquid packaging board, food and beverage containers, bleach board, white top paperboard, boxboard, and other related subgrades.

About Xerium Technologies, Inc.:

Xerium is a leading producer of fabrics and roll covers used in the production of paper and packaging, nonwovens, and other industrial manufacturing processes. Xerium’s technology portfolio also includes integrated machine monitoring and automation applications that analyze and deliver real-time machine performance data. With a breadth of patented and proprietary products and services, Xerium provides customers with tailored solutions all designed to reduce their operational costs and optimize their machine’s performance. Xerium is headquartered in Youngsville, NC and has 28 manufacturing facilities in 13 countries with approximately 2,900 employees.

Michael Zirm wins Huyck.Wangner's Talent Award 2016

Earns highest marks in Engineering in Paper Technology basic studies program at Munich University of Applied Sciences

On July 29, Xerium Technologies Inc., one of the world's leading suppliers of paper machine clothing and roll technology, awarded its 1500-euro Huyck.Wangner talent prize for the seventeenth time at the Munich University of Applied Sciences. The grant was presented for the seventeenth time in conjunction with the closing ceremonies for the school's Master of Engineering in Paper Technology program, which is headed by Prof. Dr. Stephan Kleemann. The winner, Michael Zirm, received the traditional award for having achieved the highest marks in the basic studies program.

From left to right: Professor Stephan Kleemann, Munich University of Applied Sciences, Head of the Engineering in Paper Technology program, Michael Zirm, winner of the 2016 Huyck.Wangner Talent Award and Ernst Kerschhofer, Vice President Sales & Services Xerium EMEA

After receiving a vocational college certificate in conjunction with a dual study program at Schoeller Technocell GmbH & Co. KG in Günzach, Germany, Michael Zirm enrolled in the Engineering in Paper Technology program at the University of Munich for the 2015 winter semester, with the help of a scholarship from his employer. During his apprenticeship, he also earned an advanced technical college certificate at the Gernsbach papermaker school. This year's award winner had no difficulty choosing Munich as the place to study. For one, the university's paper technology faculty has gained an outstanding global reputation thanks to its practice oriented and increasingly international approach. In addition, former apprentices at Schoeller Technocell who had also studied in Munich and serve as excellent role models recommended this path. And of course, fellow students he knows from his apprenticeship days, the appeal of the Bavarian capital, with its countless recreational opportunities, and naturally, the proximity to his home in the Allgäu, were also all key factors that influenced his decision.

As the top graduate of the "Engineering in Paper Technology" basic studies course, Michael Zirm beat out his nearest rival by just five one-hundredths, earning an average grade of 1.71 and thereby capturing the Huyck.Wangner Talent Award valued at 1500 euro. The award not only tops up the student's bank account, but above all serves as motivation to tackle the second half of his studies with equally strong enthusiasm. Furthermore, as seen at the closing ceremonies, former award recipients have the set the bar quite high: Marcel Prinz, Huyck.Wangner prize winner in 2013, had the highest marks of all graduates of the Bachelor's program; after winning the 2011 basic studies award, Lars Gaida received the Palm Award this year for top Master's graduate, and Sebastian Porkert, who received the Huyck.Wangner award in 2006 and was honored as the top graduate of the class of 2009, added a doctorate to the list of winners' degrees.

In his speech at the award ceremony, Ernst Kerschhofer, Vice President Sales & Services Xerium EMEA, emphasized the importance of the paper engineering program in view of the high demand for recruits in the paper industry. But he also stressed that all of the paper technology knowledge the students have acquired so far is only the kick-off for their careers. Ever-advancing digitization and the associated papermaking complexity (ref: paper mill 4.0) makes it essential for graduates to familiarize themselves with changes in the sector, new technologies and products and to continuously further their education. He recommends that budding papermakers also pay considerable attention to a harmonious work environment, excellent team spirit, a collegial approach and responsible employee management, all of which are equally important success factors. In his closing remarks, he thanked Professor Kleemann and his faculty colleagues for not only providing their students with a solid foundation in paper technology, but also offering them outstanding prerequisites for a promising start to their careers thanks to the school's established networks with industry and trade associations.

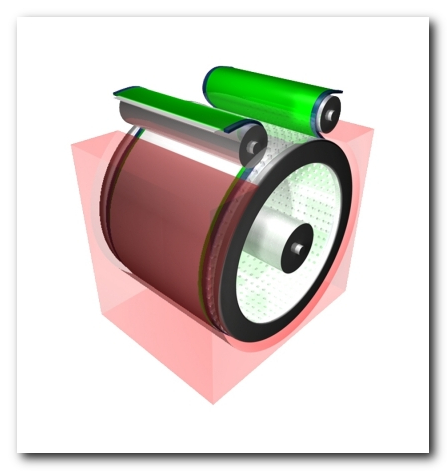

Xerium Introduces 2 New Roll Cover Technologies; EnerSoft TS for Tissue Machines and ProGloss for Calender Roll Applications

Xerium Technologies, Inc., a leading global provider of industrial consumable products and services, recently launched 2 new roll cover product families; EnerSoft TS – a new generation polyurethane roll cover technology specifically engineered for demanding tissue pressure rolls positions, and ProGloss – a new advanced technology composite roll cover for calender applications.

New ProGloss Composite Calender Roll Technology Engineered for Improved Gloss and Longer Life (Graphic: Business Wire)

EnerSoft TS combines advanced polyurethane materials technology, innovative venting patterns, and proprietary roll manufacturing techniques to deliver maximum machine performance and reduced energy consumption, with consistent performance over the life of the cover. EnerSoft TS is available in several hardnesses for virtually any pressure roll application.

ProGloss composite roll covers utilize the latest innovative composite technology to deliver the industry’s leading combination of wear resistance, impact resistance, and durability while generating best-in-class gloss levels for all calender applications. ProGloss covers incorporate newly developed epoxy matrix and filler materials enabling improvements in gloss sustainability, cover life, and barring resistance while maintaining extreme resistance to damage.

New EnerSoft TS Roll Cover Technology for Tissue and Toweling Machines provides Enhanced Machine Performance with Reduced Energy Consumption (Graphic: Business Wire)

More information about EnerSoft TS and ProGloss technology is available at http://www.xerium.com/.

“We are very pleased to introduce these two new roll technologies. EnerSoft TS - builds upon our highly successful Rebel polyurethane technology with yet another pace-setting innovation for demanding tissue applications,” said Mr. Bill Butterfield, EVP and CTO of Xerium. “And our new ProGloss portfolio of composite calender roll covers provide the ideal set of options for our customers that depend on critical calender operations. Once again, our roll cover development team has demonstrated its leadership in roll cover technology and have delivered high-performance covers that help our customers run their machines more reliably, and more efficiently, with improved product quality and reduced energy consumption.”

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 30 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Xerium Schedules Second Quarter 2016 Earnings Conference Call

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has just announced that it plans to release its financial results for the second quarter of 2016 after the close of regular market trading on Tuesday, August 2, 2016.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has just announced that it plans to release its financial results for the second quarter of 2016 after the close of regular market trading on Tuesday, August 2, 2016.

The Company will hold a conference call on August 2 following the release:

- Date: Tuesday, August 2, 2016

- Start Time: 4:30 p.m. Eastern Time

- Domestic Dial-In: 1-844-818-4921

- International Dial-In: 1-484-880-4582

- Passcode: 49430194

Webcast: www.xerium.com/investorrelations

To participate on the call, please dial in at least 10 minutes prior to the scheduled start.

A live audio webcast, in addition to the materials used in the presentation, will be available in the investor relations section of the company's website at www.xerium.com/investorrelations. To access the live audio webcast, please click on the earnings call event link that will appear on the investor relations home page.

An archive of the webcast and presentation materials will also be available after the call by clicking on the "Archived Webcasts" link that appears on the left hand side of the company's investor relations homepage at www.xerium.com/investorrelations

ABOUT XERIUM TECHNOLOGIES

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 30 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Source: Xerium Technologies, Inc.

Xerium Technologies, Inc.

Clifford Pietrafitta, 001-919-526-1403

This email address is being protected from spambots. You need JavaScript enabled to view it.

Xerium Announces the Promotion of Mr. Robert Burke to the Position of Xerium - President of Asia

Harold Bevis, the President and CEO of Xerium Technologies, Inc., a leading global provider of industrial consumable products and services, has just announced the promotion of Mr. Robert Burke to the position of Xerium - President of Asia.

Mr. Burke will be based in Xerium - Asia headquarters located in Kunshan, China. Mr. Burke will have full responsibility for the Asia region and be responsible for delivering Xerium-Asia’s long-term and short-term business plans while maintaining and strengthening customer relationships.

Mr. Burke will be based in Xerium - Asia headquarters located in Kunshan, China. Mr. Burke will have full responsibility for the Asia region and be responsible for delivering Xerium-Asia’s long-term and short-term business plans while maintaining and strengthening customer relationships.

Harold Bevis said “Xerium has a very successful and growing business in the Asia region and we have significantly increased our competitive position with our strategic initiatives over the past 3 years. We have even bigger plans over the next 3 years. We have a great team and are closely aligned with key customers throughout Asia. Bob will be taking over a great business for Xerium and taking it to the next level. He is a seasoned leader both within Xerium and in the industry with significant strengths and established relationships. He adds a lot to our Asian business and to our top executive team. Bob will shape the team under him, refine the company’s product offerings, expand our production capabilities, and deepen our go-to-market strategies.”

“Xerium is committed to leveraging its customer relationships, best practices and cost optimization across the globe and is an expert at creating value for our customers and we have an arsenal of patented solutions,” continued Mr. Bevis. “Asia is an extremely important market for Xerium and it is imperative that we continue to profitably grow, enhance our lead times and diversify our Asian business.”

Mr. Robert Burke said, “Xerium is a market leader in the region and we are committed to the continued growth of the business while further executing our strategic business plans. It is my goal to ensure alignment with the company’s long-term strategy, address future market demands and opportunities while further developing our strong relationships with critical regional customers.”

Mr. Robert Burke Background Highlights

- 30+ years of sales, operational, development, managerial and executive leadership experience within the industry.

- Seasoned international leader with 20+ years residing and operating in China and the USA.

- Joined Xerium as an Executive leader in 2009. Most recently held the position of Vice President of Sales and Marketing for Xerium – Asia.

- Many years of full P&L responsibility with functional leadership experiences including manufacturing, project management, business development, sales and marketing.

- Experience in establishing and maintain manufacturing and sales operations in China, Malaysia, India, Korea, Japan, Indonesia and Australia.

- Instrumental in the start-up and business development for our Kunshan, China Greenfield operation.

- BS in Industrial Engineering from the University of Massachusetts - Dartmouth

ABOUT XERIUM TECHNOLOGIES

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 30 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

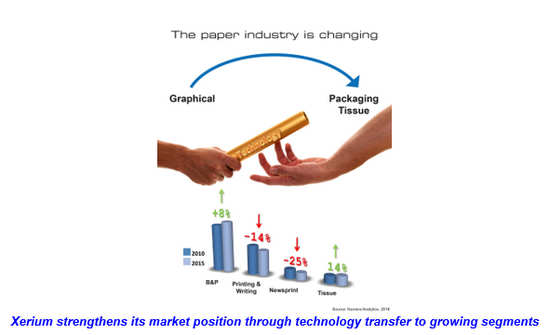

Strategic foundation based on investment, innovation and close customer relationships

Long-term strategy focuses on optimizing growth rather than growing sales

Xerium Technologies, Inc. is one of the paper industry's leading global suppliers of paper machine clothing and roll covers. Its corporate strategy for the next five years is to optimize growth instead of aiming to generate higher sales. The strategy will be based mainly on investments targeting growth markets, a high innovation rate for game changing product technologies in the Huyck.Wangner (PMC) and Stowe Woodward (rolls covers and spreader rolls) divisions, together with the group's traditional strong customer focus, which will be further expanded by adding new offices and sales organizations. In the EMEA region, Xerium has also been able to further expand its market share over the past few quarters, and was selected as the supplier for countless paper machine expansion projects.

The unrelenting transformation of the paper industry, with significant declines in the newsprint and graphic papers segments, presents suppliers with ever greater challenges. Since 2010, production in these important Xerium target segments has shrunk by twenty-five and fourteen percent respectively. This market situation, together with currency exchange factors, is reflected in Xerium's 2015 earnings. Overall revenues were down about four percent year over year, coming in at 477 million US dollar. Having foreseen these developments, the company launched strategic initiatives, and was able to not only hold its EBITDA percentage steady, but even boost it slightly.

In contrast, tissue and packaging papers continued to be reliable businesses marked by steady growth. Tissue paper production rose fourteen percent from 2010 to 2015, while the packaging papers segment was up eight percent. Industry associations are forecasting growth for packaging papers in the EMEA region of 5.6 million tons between now and 2020.

Overall, it is estimated that 65 percent of EMEA paper production is on a growth track. Xerium's priority is therefore to boost its market share in these markets and at the same time limit declines in the newsprint and graphic paper sectors as much as possible.

Investment focus on strategically important market and growth segments

Xerium has initiated a long-term investment program focused on strategically important market growth segments. The plan is supported by the resources the company has made available for new offices, factories and product development. A strong customer focus and solid advisory services play as great a role as does the enhancement of key technologies in all product segments. The company's new sites in Kunshan, China, and Çorlu, Turkey have successfully started operations. But the strategic aim is clear: Europe is to manufacture for Europe, or the EMEA region, and China for Asia and Australia. This will guarantee close proximity to customers and faster service, as well as greater flexibility, shorter lead times, lower logistics costs and efficient supply chain management.

The European factories in Reutlingen and Gloggnitz were a high priority and here the company invested heavily: 12 million US dollar in 2015/16 for new seaming technologies, four new looms, a new needling machine and an additional finishing machine. This not only boosts capacity and manufacturing, but also reinforces the company's claim that it is able to quickly and flexibly deliver all products in line with customary European top-quality standards. In parallel, a number of operational continuous improvement projects were rolled out, including in the area of process systems, procurement management, data collection and the all-important employee development.

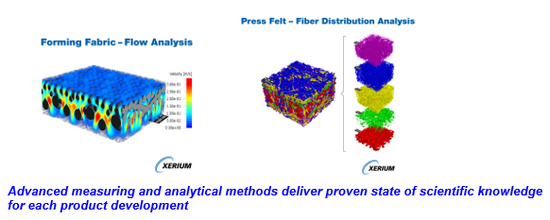

Basic research – valuable asset and competitive advantage

The strong capital spending for basic research is a testament to the importance that Xerium attaches to this corporate asset. It impacts both enhancement of its core competencies, as well as key technologies and new product concepts. For example, in 2014 alone, Xerium's spending on R&D projects for innovative analysis and simulation tools totaled close to 1 million US dollar. The entire product portfolio of every segment has been revamped over the past three years. The rate of innovation has never been this high: twenty-five new patented products introduced to market, often including groundbreaking new material or design concepts.

Products form the foundation. If this foundation is not solid, products will not work properly on a paper machine. In the past, the successful launch of a product was based to a large extent on the experience and specialized knowledge of the engineers and those responsible for the product, in addition to risky empirical half-knowledge.

In order to determine whether current performance parameters are still valid, Xerium examines every application to see if efficiency could potentially be improved by changing one or more criteria. It is how the company ensures that Xerium products successfully run on paper machines. Designers also use unique digital measuring and analytic processes developed in-house in order to clearly and understandably present to customers the pros and cons of the structural and performance attributes of various applications.

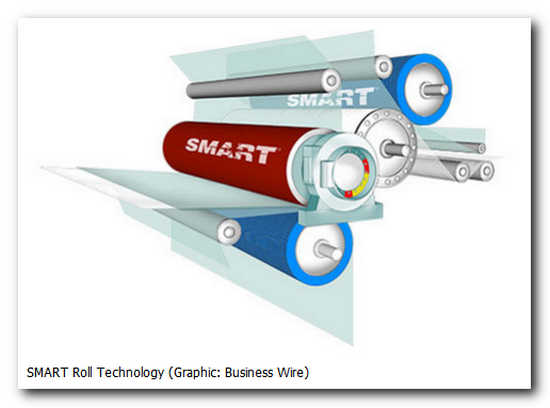

Expanding market share by pacesetting innovations

Xerium can easily justify its claim to being the pioneer and technology leader when it comes to paper machine clothing. The company aims to meld its technical knowledge with more than 200 years of market experience since its founding. Since 2014, patent applications have been submitted for 100 developments and 65 inventions have been announced – a clear indicator of the rising pace of innovation. Thanks to this research and development drive, the company has set new benchmarks: the SSB and EDC technologies, the QS and Booster technologies and the SMART® technology for roll covers to name just a few. These patented developments not only testimonialize Xerium's expertise, but are also the basis for developing various products, adapting and enhancing them, and introducing new performance features, all in accordance with customer and market requirements.

Exclusively from Xerium: Game changing paper machine clothing and roll cover technologies

Key technologies and innovative product solutions secure sustainable growth

This approach fundamentally differentiates Xerium from the competition. New, future-proof forming fabrics and felt technologies, combined with unique material and design concepts – especially for tissue and packaging applications in proven growth markets, as well as for the nonwovens/industrial textile product range – offer significant value added: exclusively from Xerium. At the same time, it reinforces the company's high demands of not only providing customers with products that function flawlessly, but also working with them in close partnership to supply individually tailored product solutions, which in turn enables papermakers to develop the right strategies for the future, seize new market opportunities and ensure long-term success.

Furthermore, the decision to continue to conduct research and development on basic technologies for its core competencies at its European locations and to supply products to customers in the EMEA region from there is an added plus. It means that the company is obliged to continue to offer the paper industry top-quality innovative products.

Xerium Technologies Inc. at a glance:

Xerium Technologies Inc. is located in the United States in Youngsville, North Carolina, and incorporates the leading paper industry brands Huyck.Wangner, Weavexx, Stowe Woodward and Mount Hope. In 2015, the company generated consolidated sales of about 477 million US dollars. About 64% was attributable to paper machine clothing and 36% to rolls. Xerium has approximately 3,000 employees at 30 manufacturing facilities in 13 different countries. Its established technology leadership is reflected in intensive research and development work, as well as hundreds of patented, registered product inventions, all of which serve to improve customers' papermaking processes.

The Xerium Podium:

• Ernst Kerschhofer, Vice President Sales & Marketing Xerium Europe

• Oliver Baumann, Global Vice President Machine Clothing Technology

• DI Dr. Robert Marchhart, Global Product Manager

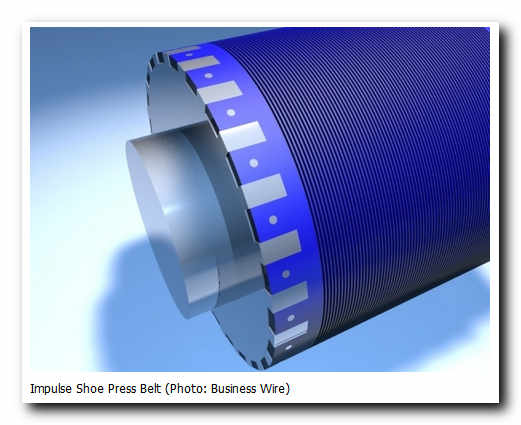

Xerium Introduces Impulse Shoe Press Belt Technology

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched the new Impulse family of shoe press belt technology.

Impulse shoe press belts combine the latest in specially developed polyurethane materials, state-of-the-art manufacturing technology, and global application expertise which are already delivering world-class performance on modern shoe press positions. Impulse technology is available in a variety of proprietary venting patterns for optimized performance on virtually every grade of paperboard, tissue, paper, and pulp. More information about Impulse technology is available at http://www.xerium.com.

“We are very excited to launch Impulse - a new generation shoe press belt technology,” said Mr. Bill Butterfield, EVP and CTO of Xerium. “Our roll cover technology team, which has been responsible for every major polyurethane breakthrough in roll cover technology in the last two decades, has now delivered a unique high-performance polymer shoe press belt with an expanded product portfolio especially for demanding machines. Impulse is already running very successfully on numerous machines around the world and we are extremely delighted in the growth potential for this new class of product Xerium now supplies.”

About Xerium (NYSE:XRM)

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 30 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Xerium to Acquire J.J. Plank Corporation, Maker of Spencer Johnston Spreader Rolls, Advancing Strategy in High-Growth Market Segments

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has just announced that it has acquired the business of J.J. Plank Corporation, including its Spencer Johnston brand spreader roll line and related family of product lines for $18 million, comprised of $16.25 million in cash at closing, and the rest in future obligations. Spencer Johnston and the other J.J. Plank divisions supply equipment used in the production of paper, nonwoven fabrics, flexible packaging, tissue converting, and food packaging. The addition of these product lines will add strength and diversity to Xerium’s products, customers, and markets served. The combined company will have one of the broadest sets of capabilities with respect to spreader rolls, dandy rolls, and tissue embossing rolls in the world.

- Expands rolls product offering and service capabilities

- Diversifies customer base into tissue embossing, flexible packaging and nonwoven production

- Positions Xerium to be one of the leading global suppliers for spreader rolls, tissue embossing rolls, and dandy rolls

- Post synergy, pro-forma EBITDA contribution of $6 million

- Immediately de-leverages the company, on a pro-forma basis

The transaction furthers Xerium’s strategic plan to expand into product categories with the strongest growth opportunities. Through the acquisition, Xerium will expand its current product offerings and service capabilities, its markets served, and strengthen its financial profile and grow its customer base.

Harold Bevis, President and CEO of Xerium Technologies, Inc., said, “Incorporating Spencer Johnston’s and the other divisions' strengths in spreader rolls, dandy rolls, and tissue embossing rolls with our existing portfolio of products is a strategically and financially compelling advancement opportunity. These product lines will strengthen our product and service offerings, add new customers to our roster, and accelerate revenue diversification. Importantly, this acquisition furthers the Company’s strategy of realigning its market presence and future sales opportunities by onboarding existing customer references and special-purpose manufacturing assets.”

Harold Bevis, President and CEO of Xerium Technologies, Inc., said, “Incorporating Spencer Johnston’s and the other divisions' strengths in spreader rolls, dandy rolls, and tissue embossing rolls with our existing portfolio of products is a strategically and financially compelling advancement opportunity. These product lines will strengthen our product and service offerings, add new customers to our roster, and accelerate revenue diversification. Importantly, this acquisition furthers the Company’s strategy of realigning its market presence and future sales opportunities by onboarding existing customer references and special-purpose manufacturing assets.”

Bevis continued, “The acquisition is expected to produce post-synergy Adjusted EBITDA of $6 million, which will bolster the company’s de-leveraging efforts and immediately improve Xerium’s leverage ratios on a pro-forma basis.”

Spencer Johnston and the other J.J. Plank divisions generated 2015 revenue of $18.5 million, and are expected to be immediately accretive. Including integration and synergies, Xerium expects the acquisition to provide an Adjusted EBITDA contribution in 2016 of $2 to $3 million, excluding transaction related costs. When fully integrated, EBITDA contribution is expected to be $6 million annually, assuming no unexpected changes to market conditions.

ABOUT XERIUM TECHNOLOGIES

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 30 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Xerium Announces New Rolls & Services Plant in Concepción, Chile

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, announced plans to establish a new roll cover and mechanical services facility located in Concepción, Chile. The Company is continuing to reposition assets from low-growth to high-growth markets. This new project is very capital efficient in that the Company already owns the majority of the equipment that will be installed in the new Concepción plant. The remaining spend will cross 2 calendar years and is already included in the capex guidance previously given by the Company.

Xerium's facility will be the first major rolls and service facility established in Concepción, Chile, by any of the industry's major global suppliers. From this location, Xerium will be able to provide regional customers with dramatically quicker and more cost effective service. Importantly, these products and services will be delivered through a local workforce familiar and respectful of local customs.

The facility will be state-of-the art and is expected to be fully in production Q2 2017. From this strategic geographic location, Xerium will provide its full suite of patented, performance-enhancing roll solutions to customers in the surrounding region. Xerium will perform roll grinding, roll recovering and mechanical services on site. Xerium is also increasing its field sales and service staff for the region for machine clothing, roll services, mechanical services and machine automation through its SMART® roll sensor solutions.

The facility will contain state-of-the-art rolls and service machines. Xerium will transfer all of its best practices and all of its global patented technology solutions to the region. The plant will also have state-of-the-art information systems and supply chain interfaces. This new facility will serve customers in Chile, Peru, Ecuador and Colombia.

This new operation will be under the regional direction of Mr. Eduardo Fracasso, President of Latin America. The Concepción, Chile greenfield implementation will be led by Luis Vitti; Project Manager. Luis has been with Xerium for 32+ years and brings significant leadership and customer focused expertise to this role.

Harold Bevis, President and CEO of Xerium Technologies, Inc., said, “For the first time ever, customers in the immediate Chilean region will receive locally provided & locally optimized state-of-the-art rubber extrusion technology. The Chile plant will be able to service large rolls from any industry or application.”

Mr. Bevis continued, “The commercial objective is to provide machine optimization solutions with world-class technology, short lead times, and a local cost structure. The customers in the region deserve this world-class approach and we are proud to provide it. Customers will immediately receive better lead times, better technology, better service and better costs. This new business start-up is part of Xerium’s investment strategy to realign its global business model and global factory locations to line up with growth markets in the world.”

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 26 manufacturing facilities in 13 countries around the world, Xerium has approximately 2,900 employees.

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 26 manufacturing facilities in 13 countries around the world, Xerium has approximately 2,900 employees.

Source: Xerium Technologies, Inc.

Xerium Introduces Drysoft Through-Air-Drying Fabric Technology for Tissue Machine

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched Drysoft fabric technology for tissue machines that utilize the through-air-drying process.

“We are delighted to introduce Drysoft fabrics for the global tissue market”

The Drysoft T.A.D. fabric portfolio includes designs with the ideal topography options to optimize sheet softness, maximize sheet bulk, and improve machine efficiency. Drysoft is also engineered with an exceptionally strong seam design and enhanced edge reinforcements for dependability, stability, and long economic life. More information is available about Drysoft at http://www.xerium.com.

“We are delighted to introduce Drysoft fabrics for the global tissue market,” said Mr. Bill Butterfield, EVP and CTO of Xerium. “In direct response to our T.A.D. customers’ requests, our research team has delivered an outstanding product portfolio to help tissue makers overcome some historical challenges with T.A.D. fabrics. Unlike some conventional T.A.D. fabrics, Drysoft seams do not use glues, coatings, or welds which can negatively influence performance and sheet quality. And with successful trials and orders in process, we are excited to see its adoption rate grow.”

About Xerium (NYSE:XRM)

Xerium Technologies, Inc. is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to the production of paper, paperboard, tissue, pulp, building products, nonwoven fabrics, and variety of industrial applications. Xerium products are specifically designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Contacts

Xerium Technologies, Inc.

Steve Cole, Director, Global Marketing

This email address is being protected from spambots. You need JavaScript enabled to view it.