Displaying items by tag: abb

Sappi uses the ABB Optical Caliper Sensor and QCS to improve reel-building quality for its customers.

Sappi’s Somerset Mill is on a mission to continually improve its reel building quality, and the ABB Optical Caliper Sensor has helped Sappi to effectively manage optimum reel-building conditions in real-time.

Uniform caliper is extremely important for good roll-building on coated and calendered papers. Because the paper is so dense and smooth, very little caliper profile deviation can be tolerated before the effect is seen on the hardness profile of the reel, and subsequently in the quality of the rolls coming off the winder. PM2 at Sappi’s Somerset Mill used to rely on manual off-line testing of reel hardness profiles using a hand-held hardness tester to assist with the process of troubleshooting reel-building. While this approach was sufficient to enable Sappi to meet its quality targets, the infrequency of these hardness tests represented an opportunity for Sappi to further optimize reel-building conditions, and their available manpower.

“The stability and repeatability of the Caliper Sensor allows the operator to trust the profile shape and make reel-building corrections in real-time rather than wait for an off-line hardness profile test,” says Dave Moore, Senior Process Engineer at Sappi Somerset Mill.

The Optical Caliper Sensor contacts the sheet on one side using a smooth ceramic stabilizing plate with vacuum applied by concentric rings. On the other side of the sheet is a unique optical (confocal) measurement. The confocal measurement is combined with a magnetic reference measurement, and the result is caliper measurement. The simplicity of this design provides reliable performance day after day in the harsh paper mill environment.

Even with the sensor applied very soon after the calendering process on high-gloss grades, Moore adds that, “We have not seen any sheet marking issues with this design.”

Caliper correlation within ±1% between the laboratory and the Optical Caliper Sensor was one goal of the project: “The optical sensor has met our requirement of reproducible CD profile correlation without marking the sheet surface,” reports Moore.

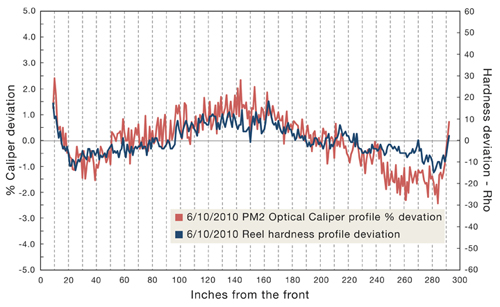

Equally important for Sappi was the correlation to the hand-held hardness instrument. Figure 1 shows that the correlation was good enough to allow operators to make corrections before out of specification limits were reached.

ABB has been working with the Sappi Somerset Mill to implement service and evolve its Quality Control Systems (QCS) for more than 25 years on its three paper machines. Over that period of time, ABB and Sappi have worked together to evolve the systems in a step-wise approach, with manageable capital investments.

TAPPI Honors ABB Staff for Exceptional Achievement

Shin-Chin Chen, Åke Hellström and Keith Masters are recognized during PAPERCON 2011

Three ABB staff members, Shin-Chin Chen, Åke Hellström and Keith Masters, were recently honored by TAPPI, one of the industry’s leading associations, for their outstanding achievements and service.

Chen, a corporate executive engineer with ABB’s Pulp and Paper Division in Westerville, Ohio, USA, was named a TAPPI Fellow for 2011. TAPPI Fellows are an elite group who have each made extraordinary contributions to the industry.

Chen, who has worked for ABB since 1984 and has a Ph.D. from Case Western Reserve University in systems engineering, holds 10 patents and has published more than 40 technical papers. His recent paper on “VAP and new indices for quantifying sheet quality and trouble shooting” won the 2009 Jasper Mardon Award.

Hellström won TAPPI’s Process Control Division Technical Award. He retired from ABB in 2009 as a chief engineer with the company’s Pulp and Paper Division in Columbus, Ohio, USA,

During his four decades with ABB, Hellström played a key role in developing the scanner and sensor technology that is still widely used today. He worked as the chief engineer on ABB’s Measurement Platform, launched in 1986. Hellström holds 13 U.S. and many international patents.

Masters, a business manager with ABB’s Pulp and Paper Division in San Antonio, Texas, USA, was awarded TAPPI’s Division’s Leadership and Service Award.

Masters, who has over 30 years of leadership in the pulp and paper industry, worked at Honeywell, Bailey, and Measurex before joining ABB in 2006. He has worked on project, product and quality management, and chaired PAPERCON panels on process control.

Chen, Hellström and Masters were recognized during the PAPERCON 2011 conference held May 1 – 4, 2011, in Covington, KY, USA.

Swedish paper mills can easily save 1- 2.5 million kronor with ABB optimization

Every Swedish krona invested in improved quality can yield 5-10 kronor in payback

For years ABB has offered its optimization service, Paper Machine Fingerprint, to the paper industry. This solution gives papermakers an assessment of their entire production process so mills can precisely identify areas with improvement potential. Based on the ABB diagnosis, the mill obtains appropriate recommendations for improvement, along with an ROI calculation.

“We have seen that a typical paper mill, by implementing the improvement measures that we suggest, can earn 5-10 times the money it costs to implement them via more efficient and optimized paper production,” said Jonas Warnqvist, an ABB process optimization and QCS specialist. “A mid-sized Swedish paper mill can typically save 1-2.5 million kronor, just by improving those areas that we identify through the Fingerprint diagnosis.”

When making the diagnosis ABB assesses every part of the production process, looking for improvement potential from a mechanical as well as a control engineering perspective. The diagnosis may point at process, instrument or automation-related issues. ABB can assess any paper machine, regardless of its automation system.

“We always offer continuous follow-up after the completed diagnosis and implementation, in order to ensure sustained improvements and payback on the customer’s investment,” said Warnqvist.

The Fingerprint diagnosis provides both a basis for future comparisons and analysis of the mill’s performance. The Fingerprint also includes a plan for improvements that identifies the improvement potential and ranks the measures in terms of best saving opportunities. The ROI calculation is a very important tool for showing, in a simple way, how the improvements generate cost savings.

To be capable of performing this fully comprehensive assessment, a company needs to have a deep understanding of the process and of every part of the mill – which is something that ABB has built up through its extensive experience and leading-edge expertise within the paper industry.

ABB's Listening for red flags

A new early-warning system finds problems with large induction motors before disaster can strike.

Motors and generators manufacturer ABB is offering a new condition monitoring service for large induction motors, ABB MACHsense-P, that acts like a skilled doctor with a stethoscope, detecting trouble before it can lead to crisis. The key to its early-warning capabilities is ABB's intelligent software, which analyzes vibrations and other data collected from the motor with remarkable accuracy.

MACHsense-P, based on years-long intensive research, represents a major leap forward. "ABB's analysis system uses algorithms that pick out specific signals," says Cajetan Pinto, R&D Manager for ABB Motors and Generators, Service and Vice President for ABB in Mumbai, India. "If you're concerned about bearings, our system can isolate the signals coming from the bearings itself."

“No one in the past has looked at data the way we do,” explains Pinto. “We recently filed three patents for our methodology.”

Older monitoring systems generated too many errors – both false positives and false negatives. In part, that's because noises from non-essential parts of the motor tended to confuse the readings.

Since May 2010, customers can order the ABB MACHsense-P service in one of two ways: ‘Standard’ service comes as part of a regular six-month maintenance plan, while ‘advanced’ service refers to a one-time intervention to troubleshoot a specific problem. Next year, ABB plans to expand the service from large induction motors to synchronous motors and wind generators.

ABB MACHsense-P can save a customer from major headaches. Pinto recalls, “At a power plant recently, the in-house maintenance team did not detect any defects in its motor bearings – but we picked up defects, and they were verified.”

In fact, more than 60 percent of failures in squirrel-cage motors occur in the bearings. When bearings develop faults, said Pinto, "they can lead to catastrophic failure.”

Besides trouble with bearings, ABB MACHsense-P also detects a wide range of other problems, including rotor winding defects, imbalance, looseness, internal misalignments and voltage abnormalities.

Technicians at ABB service centers in 35 countries are now being trained to use ABB MACHsense-P. “We have gotten very positive responses from our customers so far,” said Pinto. “This service could extend the working life of thousands of motors, running in critical applications worldwide.”

ABB MACHsense-P is only one example from a complete portfolio of services for motors and generators offered by ABB. The service organization has long experience in electrical motors and generators and their applications, enabling it to deliver improved operational availability and life-cycle profitability to ABB’s customers.

ABB MACHsense-P

- Provides accurate diagnosis

- Reports quickly, with a summary delivered on-site

- Includes integrated analysis for current, voltage and vibration

- Rates defects clearly, by severity

- Recommends specific repairs

- Considers machine design in judging defect severity

- Reduces unplanned downtime

Issues early warnings, allowing time for planning maintenance

ABB's Flowmeter with advanced diagnostic functions now on the market

Electromagnetic flowmeter ProcessMaster FEP500 for more precision and safety

ABB introduces the ProcessMaster FEP500, its latest electromagnetic flowmeter for the process industry, to enlarge its well-proven product family. In addition to its enhanced diagnostic information, higher measuring accuracy and explosion protection to ATEX, IEC, FM, CSA and NEPSI, the ProcessMaster FEP500 offers various communication protocols: HART, Profibus PA or FOUNDATION Fieldbus. This allows for comfortable access to all device and process status information.

Using its advanced diagnostic functions, the ProcessMaster FEP500 monitors its own operability, e.g. by detecting gas bubbles or deposits on its electrodes, and your process. Gradual changes are recorded and stored in the device as trends. The integral conductivity monitoring function further extends these possibilities. Access to the status information and trends is obtained via the easy-touse ScanMaster verification and evaluation software that cyclically monitors the measuring values and functionality of the instruments installed.

The determined test results are stored in a database and can be retrieved and printed at any time. Cyclic monitoring of the installed instrumentation is a main customer concern to meet the increasing requirements in terms of quality management and quality auditing. ABB’s ScanMaster is the optimum solution for this challenge.

ProcessMaster FEP300 is the flowmeter with basic functionality. In addition to the high-end electromagnetic flowmeter ProcessMaster FEP500, ABB offers the standard model ProcessMaster FEP300 with basic functionality.

ABB’s ProcessMaster series of flowmeters is successfully used in the chemical, power, water and waste water, oil and gas, pulp and paper, metal and machine construction industries. The instrument design offers the industry’s widest range of sizes, liners, materials and process connections. The ProcessMaster series provides maximum safety and reliability and very short response times. The especially powerful transmitter can be intuitively operated even by inexperienced users, due to its product-spanning operating concept. Additionally, it has a bright, backlit display.

When integrated into an asset management system like the Asset Master from ABB by using the FDT/DTM technology, the ProcessMaster considerably contributes to optimal monitoring of your plant to improve the productivity and profitability and helps you get the most out of your investment over the entire product lifecycle.

ABB launches drive series with integrated safety features

The new drive series is based on a common architecture, specifically designed to simplify the process, increase performance and maximize output.

ABB has developed a new series of drives, ACS880, for low voltage applications. The integrated safety functions minimize the need for external safety components. The new architecture also enables control for practically any AC motor, with information transfer via the most common fieldbus protocols and various remote monitoring solutions.

The new drive series represents the start of a new industrial era, with intuitive control displays that make navigation easy. Many flexible data visualization features help the user analyze the processes. Menus and messages can be customized to correspond to the specific application terminology in question. An integrated USB port makes it easy to connect PC tools.

The PC tool Drive Composer can, from now on, be used for any type of drives. This tool offers fast and effective process commissioning, start-up and monitoring. The control diagrams save users from browsing long lists of parameters and help to set the drive’s logic easily and quickly.

The new integrated safety functions in ABB’s industrial drives – that minimize the need for external safety components, simplify the configuration and reduce the commissioning footprint – could be named a paradigm shift. The safety features include Safe Torque-Off (STO), used for preventing unexpected start-up and solving other stoppage-related issues, as well as Safe Stop 1, Safe Stop Emergency, Safely-Limited Speed, Safe Brake Control and Safe Maximum Speed. ABB’s safety function solution also meets the requirements of the EU Machinery Directive 2006/42/EC.

ABB drives are designed for maximum energy efficiency and productivity. The built-in energy calculators provide essential information, including used and saved kWh and MWh, CO2 reduction and cost savings, that help the user fine tune the processes to ensure optimum energy use.

“This is the largest product launch we will do in ten years. Drives that can reduce energy use by up to 80 percent are attractive to companies throughout the entire Swedish industry, especially within the pulp and paper, steel and mining sectors,” said Lars Lithner, product manager, ABB Svensk Försäljning.

ABB’s proprietary motor control technology DTC (Direct Torque Control) is at the heart of every industrial drive in the ACS880 series. The drives can be customized to suit the specific needs in any industry sector, for example pulp and paper, metal, marine, material handling, mining, cement, energy production, chemical and oil and gas.

ACS880-01 is designed for the control of a broad range of applications, such as extruders, cranes, winches, paper machines, conveyors, mixers, compressors, pumps and fans.

ABB to update automation systems at Arjowiggins Creative Papers mill in Scotland

Comprehensive automation and collaborative production management systems will increase product quality and overall efficiency at Arjowiggins Creative Papers Stoneywood Mill

Arjowiggins is a leading manufacturer of creative and technical paper, the company’s Stoneywood mill produces papers for corporate communication and promotion, luxury packaging, industrial release papers and other creative papers and specialty applications. The mill’s two manufacturing sites collectively produce 200 metric tons of paper per day.

The delivery includes ABB’s award-winning System 800xA Extended Automation to control the central boiler house and integrate with other mill systems. System 800xA will protect Stoneywood Mill’s paper machines’ steam and electrical supplies by replacing older, less reliable equipment, while helping to optimize energy efficiency. Its unique operator interface will give workers clear visibility into mill status information at all times.

The delivery includes ABB’s award-winning System 800xA Extended Automation to control the central boiler house and integrate with other mill systems. System 800xA will protect Stoneywood Mill’s paper machines’ steam and electrical supplies by replacing older, less reliable equipment, while helping to optimize energy efficiency. Its unique operator interface will give workers clear visibility into mill status information at all times.

The new Quality Control System integrated with the 800xA control system for PM10 will maximize product quality and help sustain the Arjowiggins Creative Papers’ high-quality brands. ABB’s integrated control system significantly improves mill productivity by increasing operator effectiveness and reducing transition times during shade and grade changes.

ABB’s delivery also includes several collaborative production management solutions. cpmPlus, Smart Client information management software will provide users with easy access to real time and historical process data. With Smart Client, Arjowiggins Creative Papers supervisors can make better decisions and improve mill management. cpmPlus Loop Performance Manager has tuning and auditing tools that will keep the mill running at peak levels with minimal engineering staff effort.

ABB (www.abb.com) is a leader in power and automation technologies that enable utility and industry customers to improve performance while lowering environmental impact. The ABB Group of companies operates in around 100 countries and employs about 124,000 people.

Shin-Chin Chen of ABB Inc. Named TAPPI Fellow for 2011

Shin-Chin Chen has been named a TAPPI Fellow for 2011. He is currently Corporate Executive Engineer with ABB Inc. in Westerville, Ohio, USA. Fellow is an honorary title bestowed upon a very small percentage of TAPPI’s membership. It is given to individuals who have made extraordinary technical or service contributions to the industry and/or the Association.

“Dr. Chen’s contributions to TAPPI and its Process Control Division have been most noteworthy over the years,” said Larry N. Montague, president and CEO of TAPPI. “He continues to interface on many levels with volunteers and is an innovator in generating ideas for the benefit of the organization.”

A graduate of National Cheng-Kung University in Taiwan with a bachelor of science degree in Mechanical Engineering, Dr. Chen earned his master of science degree in Power Mechanical Engineering from the National Tsing-Hua University in Taiwan. He holds a Ph.D. in Systems Engineering from Case Western Reserve University.

He has held various positions at ABB Inc. since joining the company in 1984, currently serving as Corporate Executive Engineer. He holds 10 patents and has published more than 40 technical papers during his career. Dr. Chen has pioneered numerous initiatives to improve control of paper machines, reducing costs and enhancing quality. His recent paper on “VAP and new indices for quantifying sheet quality and trouble shooting” won the 2009 Jasper Mardon Award.

Dr. Chen has served in a number of offices within TAPPI, including PaperCon Steering Committee, PaperCon Track Manager, PCE&I Division Technical Program Chair, PC Division Vice Chair and PC Division Chair. He has developed a plan for the Process Control Division focusing on member involvement, contributions from the Common Interest Groups and networking with local chapters and student sections.

Dr. Chen and the other new TAPPI Fellows will be honored at the TAPPI Fellows Luncheon, Sunday, May 1, 2011, at the Northern Kentucky Convention Center in conjunction with the 2011 PaperCon meeting in Covington, Ky. USA. www.papercon.org

ABB’s customized control system showcases its power in high-end projects

ABB solves the problem of off-machine coater automation control, and delivers large-scale paper projects to Sun Paper and Huatai. Each papermaker obtained tailor-made, world-leading technology and equipment, including drive control systems and high-efficiency frequency conversion motors, which not only ensure the smooth and efficient operation of the production lines, but also realize energy savings and emission reduction.

In January this year, ABB completed the commissioning of a PMC800 multi-drive control system in a high-end coated paper project at Huatai Paper. Installed on the mill’s PM8, a machine with an annual production of 700,000 tons, the system met Huatai’s design requirements – it solves the problem of off-machine coating automation control, ensures the smooth and highly efficient operation of the production line, and realizes energy savings and emission reduction.

There are only two off-machine coaters of the same type in China, and each is equipped with ABB drive systems. Commissioned in 2004 and 2005 respectively, each is operating well.

Lin Shuming, head of ABB Pulp and Paper North Asia, said: “It indicates that, by integrating unique innovative technologies, ABB’s customized service model successfully passed the test of China’s high-end paper projects. ”

Optimal utilization of advanced technology

During a recent interview, Chen Linfeng, Sales Director of ABB Pulp & Paper China, said that ABB tailored the drive control system PMC800 installed on Huatai’s PM8 according to customer requirements and specific application needs. The drive system on Huatai’s PM8 and coating machine is by far one of the most complicated drive systems used today in the paper industry. The system includes 223 drive sections, 241 AC frequency conversion motors and 10 AC800M controllers ,as well as additional control equipment. It provides AC drive and control for specific parts of the production line, including the paper machine, rewinder, off-machine coater, super calendar and winder.

In China, along with Huatai’s PM8, there are two other production lines with large off-machine coaters. These lines are located at the APP Dagang and Sun Paper.

Production lines of this type are commissioned at the average rate of one every three years. So far, there are several dozen such production lines in the world. The difficulty lies in the control of the off-machine coater, particularly the flying splice control. While the off-machine coater operates at a designated speed, this control method is applied so that online roll-changing can proceed without shutdowns.

Meeting this challenge requires drive equipment that has control precision down to a millisecond level (1-10 ms), along with extensive cooperation and experience between the drive supplier and equipment supplier. Because ABB meet these key requirements, it executes most similar drives projects worldwide.

At Huatai, there are numerous tension control points on the production line. When the speed on the production line varies, it is very difficult to precisely control the tension. The maximum speed of PM8’s coater is 2100 meter/min, which is the extreme speed of the machine and motor. But ABB’s leading drive control technology ensures the production line will operate smoothly and continuously even under such high speeds. This prevents the waste of items such as paper and paint that occur when the coater shuts down, and it also saves the additional labor, water and electricity needed to clean the coater..

To minimize energy consumption, ABB installed customized motors with optimization design on various parts of Huatai’s production line, including the winder, rewinder, super calendar and coater. This kind of motor is much smaller and lighter than standard motors. Its design is optimized according to a piece of equipment’s specific load requirements, so that control and efficiency are optimized. But the overload multiples are high enough to prevent high energy-consumption “light load drives”.

The current installed power of paper machines in China’s paper industry is dramatically higher than it was in the past. This renders the 400V motor, which was previously prevalent, unable to meet new industrial demands. As a result, ABB promotes its 690V grade low voltage motor – the ABB M3BP is the most high-efficiency AC motor in the industry. It is the first batch of motors to obtain China’s authentication of energy-saving product, with an efficiency level of IE2. So far, these new motors have been used in new projects at mills that include the APP Dagang mill, Lee Man Paper, and Huatai Paper.

“It has higher voltage than the 400V motor, so there is less heat loss due to smaller current, contributing to energy-saving,” said Linfeng. The efficiency of ABB’s standard motor is 3.8% higher than that of a normal motor. On Huatai’s PM8 production line with total installed power estimated to be 390,000 kW, this motor can annually save nearly 5 million yuan in electricity costs and almost 3700 tons of coal, a very outstanding amount.

Problem-solving with the world’s best combined service resources

In terms of technology, PM8 is the most complex paper machine in China - or even the world. So ABB selected its best global service team to ensure the project’s smooth implementation. During project execution, ABB Finland sent its principal engineers to meticulously oversee the software and equipment design work, key technology, project progress, etc. They worked with a Chinese team consisting of highly-skilled engineers who are experts in different aspects of the automation. These Chinese specialists could fully utilize local service and equipment manufacturing systems to provide Huatai with the most efficient and high-quality service possible.

Said Linfeng: “Engineers from ABB Finland and China cooperated by contributing their strengths and advantages, which overcame many technical difficulties, accomplished the project meeting its schedule, quality and quantity requirements, and achieved customer satisfaction.” In the past, projects at APP Dagang were usually accomplished by ABB’s European engineers. Now a Chinese local service team dominates the PM8 project.

Linfeng added: “Currently, the most challenging and state of the art paper equipment and projects in the world can be seen in China. The transition from participation roles to leadership roles indicates that ABB China’s local team is gradually growing up. Such localized customized service leads to the formation of long-term strategic cooperation and partnerships between ABB and its China customers. ABB has many customers similar to Huatai, such as, Sun Paper, Lee Man Paper, APP, HengAn, Nine Dragons Paper and Shan Ying Paper. ABB finds the best cooperation points with these customers, and establishes long-term partnerships. HengAn Paper has 15 paper machines, and ABB provided drive control systems and integrated automation control systems for 14 of them. The automation and electrification equipment of 16 paper machines and 3 pulp mills of Lee Man Paper all come from ABB. This is due to the tailor-made service, which provides a very cost-competitive plan.”

Shuming said: “The paper industry is a high energy consumption industry. ABB’s automation technology could significantly help customers improve energy efficiency, and realize green environmental production and sustainable development. Shandong Huatai Corporation is a world-leading paper enterprise. The long-lasting cooperation between ABB and Huatai demonstrates the mutual trust between the two partners, raising excellent cooperation model and energy-saving example for the industry.”

ABB’s System 800xA receives KEMA certification for electrical integration

Controller interface for integrating intelligent electronic devices and other power system components passes rigorous KEMA conformance tests for global IEC 61850 standard

ABB announced today that its System 800xA Extended Automation controller has received KEMA certification for its IEC 61850 electrical integration interface. IEC 61850 is the global communication standard for Power Distribution and Substation Automation. System 800xA’s unique ability to integrate wide variety of intelligent electronic devices provides a single platform for process and electrical systems, resulting in significant operational and energy efficiency benefits.

Founded in 1927, KEMA is a global provider of business and technical consulting, operational support, measurement and inspection, testing and certification for the energy and utility industry. KEMA’s Protocol Competence and Test Center is the leading certification organization for IEC protocols, and is the first independent test organization authorized by UCA (Utility Communications Architecture) International Users Group to perform the official IEC 61850 conformance tests and issue certificates.

This certification assures that System 800xA’s AC 800M controller is in full compliance with the global IEC 61850 standard for electrical devices. ABB has been delivering integrated process and power automation systems for many years, and has been active in the development IEC 61850, which ensures global consistency and interoperability of industrial electrical system components.

The IEC 61850 standard, along with other emerging technologies, has lowered the investment barrier for customers to integrate the process and power devices on their plant floors. The demand for integrated process and power automation is growing in traditional markets that are heavy energy users, such as Oil and Gas, Power Generation, Pulp and Paper, Minerals and Metals industries.

By integrating power and process systems on the common 800xA platform, customers optimize the design and performance of their electrical and automation systems and see additional benefits in reduced maintenance, engineering and overall lifecycle costs. According to ARC, typical savings can result in a 20% reduction in CAPEX (capital expenditures) and OPEX (operating expenditures) by integrating these two, usually separate, automation infrastructures.

ABB’s groundbreaking extended automation System 800xA has improved industrial productivity, safety, and operational profitability for customers in virtually every industry and every region, from process industries such as oil and gas, petrochemicals, pulp and paper, cement, and mining to traditional electric and water utilities to alternative energy production such as solar, waste-to-energy and bioethanol. For more information, please visit http://www.abb.com/controlsystems.