Ianadmin

PMP to supply (2) Intelli-Tissue® 1200 EcoEc tissue machines for Hebei Jinboshi Group Co., Ltd, China

On 22nd January 2016, PMP (Paper Machinery Producer) – a global provider of tissue, paper & board technology, signed a contract with Heibei Jinboshi Group CO., LTD. For the delivery of (2) Intelli-Tissue® 1200 EcoEc lines.

The (2) Intelli-Tissue® 1200 EcoEc will be characterized with 3650mm reel trim, operating speed of 1200 m/min, daily capacity 75 t/d and a basis weight 12.5-25 gsm each. This project will be based on a PMP Integrated Tissue Mill concept, which means 2 machines (left-hand and right-hand) in the same building, a shared control room as well as a warehouse. The same model of right and left hand machines layout in one building is the most compact solution and the two machines can share a common spare parts base. As a result, both space and costs are saved as well as number of personnel required to run the installations. At the same time high production flexibility plays a significant role in achieving top installations effectiveness.

The PMP’s scope of supply will cover the single layer Intelli-Jet V® hydraulic Headbox, 4-roll Intelli-Former®, compact Intelli-Press®, 12ft Steel Intelli-YD™, Intelli-HoodTM and Intelli-Reel®. In addition, PMP will provide mechanical drives, electrical drives, lubrication system, Steam & Condensate system and the PLC. The PMP team will also provide erection supervision and technological start-up.

The new project will be implemented based on the Optimum Cost Solution philosophy by executing the tissue machine fully designed in Europe (PMPoland & PMPower), manufacturing of the key components such as a hydraulic headbox and a steel Yankee in Europe, and the remaining manufacturing, as well as tissue machine pre-assembly and tests completed at the PMP Center of Excellence: PMP IB, Changzhou (China). This combination allows to lower a cost of investment for the customer, while maintaining the premium quality of the equipment supplied. The start-up is scheduled for the end of 2016 (1st machine) and the middle of 2017 (2nd machine).

With the excellent performance of operating reference and continuous new orders, PMP Intelli-Tissue® EcoEc Technology has been recognized worldwide to be a high-quality, high-efficient and ultra low-consumption solution for tissuemakers. This type of product was designed to suit Chinese Market in perfect way being totally in line with guidance of Chinese Government reflected in 12th 5 year plan.

Year by year, PMP increases its presence in China through implementation of projects for both tissue & paper customers. Only in the last decade in Mainland China, PMP provided 13 CF tissue machines and 20 capital paper machine rebuilds including core technological units such as Intelli-Jet V® Headboxes, Intelli-Nip® Shoe Presses, Intelli-Sizer™ Size Presses, etc. Combination of a state-of-art technology and rich experience of PMP and convenient local service from PMP IB results in smart integration of assets & competences. This way PMP Intelli-Tissue® 1200 EcoEc tissue solutions bring excellent support for its users daily.

About Hebei Jinboshi Group:

Hebei Jinboshi Group Co., Ltd is a professional tissue-making enterprise, located in Baoding, Hebei Province (established in July 2000). Jinboshi Group produces high-quality toilet paper, facial paper, napkin and wetnaps under brand “Golden doctor”, “Qinqin jiaren” and was awarded as “famous brand enterprise of Hebei Province”. Company keeps providing high-level products and service to customers with high efficiency. Ambicious goals and implementation of the best solutions available on the market heat a dynamic growth.

About PMP:

PMP – a global provider of tissue, paper & board technology, has been supporting the pulp and paper industry for over 160 years, executing projects on 6 continents, in 29 countries. Company owns 6 facilities in 4 countries (Poland, USA, China and Italy). PMP is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching new logo & visual identity. learn more: www.pmpgroup.com

Improved tail threading process at the Sappi Somerset mill (PM2) in Skowhegan, Maine

EV Group Oy (EVG) contributed to an improved tail threading process at the Sappi Somerset mill’s paper machine 2 (PM2) in Skowhegan, Maine. Bottlenecks in the PM2 tail threading process have been efficiently eliminated by installing a system for the transfer of the tail into the ropes in the single felted area of the machine. The delivery included the Gap, Stop, Cut and Transfer blow Technology, supported by a tail threading vacuum zone being drilled to one dryer cylinder on site. The rope pulleys were also relocated, adjusted to the new technology being installed.

EV Group Oy (EVG) contributed to an improved tail threading process at the Sappi Somerset mill’s paper machine 2 (PM2) in Skowhegan, Maine. Bottlenecks in the PM2 tail threading process have been efficiently eliminated by installing a system for the transfer of the tail into the ropes in the single felted area of the machine. The delivery included the Gap, Stop, Cut and Transfer blow Technology, supported by a tail threading vacuum zone being drilled to one dryer cylinder on site. The rope pulleys were also relocated, adjusted to the new technology being installed.

Additionally, the dryer section improvement supporting edge nozzles was installed in the press section to prevent harmful sheet edge flutter after the suction transfer roll.

The total delivery of the rebuild was supported by EVG Engineers, who supervised both the installation and start-up. After the PM2 improvements, tail threading into the ropes became more efficient and reduced the overall time needed for threading. The original project targets for threading were clearly achieved!

Valmet's new calendering technology introduced at Stora Enso's Ingerois Board Mill

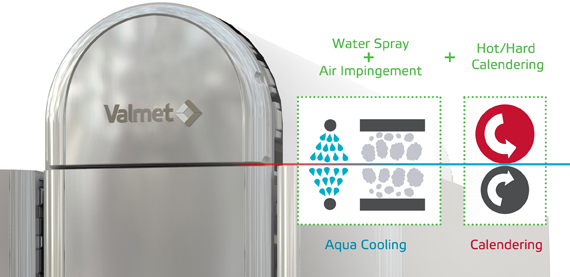

Valmet's new aqua cooling calendering technology has been taken into use first time at customer site at Stora Enso Ingerois Board Mill in Finland. Stora Enso decided to modernize the precalender of its board machine BM 4 to improve the quality of the produced board and lighten the board - i.e. increase its bulk - without compromising its properties. BM 4 produces folding boxboard for the consumer packaging industry.

The new aqua cooling technology has now been successfully used in production for a few months. The technology has made it possible to lower the basis weight of the end product at BM 4 while maintaining the functional and visual properties of the board.

"The new aqua cooling technology enables developing and optimizing the machine's operating method to achieve bulk saving potential. This brings significant energy and raw material savings throughout the value chain of the product," says Taisto Nevalainen, Mill Director of Stora Enso's Ingerois Board Mill.

"Cooperation with Stora Enso was excellent from the very first contact to the start-up and the whole process was exceptionally fast. Using the new aqua cooling equipment in practice has confirmed the earlier results from our pilot machine. Installation of the equipment itself went well, and thanks to its compact structure, the equipment fits in perfectly despite the narrow space available," says Mika Viljanmaa, development manager from Valmet's Paper Mills Business Unit.

A result of focused R&D work

Valmet focuses in its research and development work on three areas: 1) ensuring advanced and competitive technologies and services, 2) enhancing raw material, water and energy efficiency, and 3) promoting renewable materials. The now introduced aqua cooling technology focuses especially on improving the material and energy efficiency in paper and board making process.

The idea of aqua cooling is that the paper web is cooled down by evaporating moisture from the web. The effect can be enhanced by adding a small amount of water on the web surface before cooling. The cooler the web is before it reaches the calender, the more quality improvement and raw material savings can be obtained.

Aqua cooling calendering: www.valmet.com/aquacooling

Information about the customer Stora Enso

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Stora Enso's aim is to replace non-renewable materials by innovating and developing new products and services based on wood and other renewable materials. Stora Enso employs some 27 000 people in more than 35 countries, and the sales in 2014 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki and Stockholm.

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

For further information, please contact:

Mika Viljanmaa, Development Manager, Paper Mills Business Unit, Valmet, tel. +358 40 846 7078 / This email address is being protected from spambots. You need JavaScript enabled to view it.

Catalyst Paper Reports Fatality at its Crofton Mill

Catalyst Paper (TSX: CYT) regrets to report the occurrence of a fatal incident involving an employee at its Crofton mill. The incident resulted from an industrial vehicle roll-over which occurred yesterday evening at the mill.

Catalyst Paper (TSX: CYT) regrets to report the occurrence of a fatal incident involving an employee at its Crofton mill. The incident resulted from an industrial vehicle roll-over which occurred yesterday evening at the mill.

The Coroner, RCMP and WorkSafeBC have been contacted and an investigation is underway.

"We are saddened by this tragic incident," says Joe Nemeth, President and Chief Executive Officer. "We are doing everything possible to support the investigation. We extend our deepest sympathies to the family of the deceased."

WorkSafeBC will lead the investigation, fully supported by mill personnel.

About Catalyst Paper

Catalyst Paper manufactures diverse printing papers such as coated freesheet, C1S, coated and uncoated groundwood, newsprint, directory, as well as market pulp. Customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada, and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.

SOURCE Catalyst Paper Corporation

For further information:

Investor Contact: Frank De Costanzo, Senior Vice President & Chief Financial Officer, (604) 247-4014, This email address is being protected from spambots. You need JavaScript enabled to view it.; Media Contact: Eduarda Hodgins, Director, Organization Development & Communications, (604) 247-4369, This email address is being protected from spambots. You need JavaScript enabled to view it.

This information is being distributed to you by / Cette information vous est transmise par : Catalyst Paper Corporation

2nd PMP Intelli-Tissue® EcoEc tissue machine smothly launched in Hebei Xuesong Paper, China

Exactly a year ago (January 2015), Hebei Xuesong Paper Co., Ltd signed a contract with PMP (Paper Machinery Producer) for the delivery of 2nd Intelli-Tissue® EcoEc machine. That was a natural consequence of a successful start-up of the 1st machine six months before.

Efficient cooperation between two companies started from TM#1 project in 2013. First Intelli-Tissue® 1200 EcoEc was brought on stream in April 2014 and thanks to excellent cooperation between Hebei Xuesong Paper and PMP, just 5 days after start-up, the maximum production capacity and tissue quality guarantees were achieved. TM#1 is characterized by an ultra-low level of steam consumption (1.6-1.8 t/t) – the best in the industry in this level of technological solution. Optimized paramaters help to significantly minimize production costs and increase sales margins.

On January 16th this year, PMP successfully started up 2nd Intelli-Tissue® 1200 EcoEc at Hebei Xuesong mill. TM#2 (twin sister line to TM#1) is characterized by reel trim of 2850 mm, design speed of 1200 m/min and daily capacity 60 t/d (basis weight 12.5-20 gsm). After TM#2 installation, Hebei Xuesong Paper have two machines (right and left hand) in the same building based on an Integrated Tissue Mill concept. We are proud to announce that paper at reel appeared 3 hours after supplying the stock, at the same time paper reached saleable parameters on the 2nd jumbo roll.

TM#2 is a twin-sister machine of TM#1 and is also based on philosophy of Optimum Cost Solution including tissue machine fully designed in Europe, manufacturing of the key components such as a Intelli-Jet V® hydraulic headbox and a Intelli-YD™ steel Yankee in Europe, and the remaining manufacturing, tissue machine pre-assembly and tests completed at the Center of Excellence of PMP Group: PMP IB (Changzhou) Machinery & Technology, Changzhou (China). This combination has ensured to lower the cost investment for the customer, while maintaining excellent quality of the equipment supplied. PMP has provided a stock approach system, Intelli-Tissue® 1200 EcoEc machine, mechanical drives, electrical drives, a lubrication system, a steam & condensate system and PLC. The PMP team has also been responsible for an erection supervision and technological start-up.

The same model of right and left hand machines layout in one building is the most compact solution and the two machines can share a common spare parts base. As a result, both space and costs are saved as well as number of personnel required to run the installations. Finally, the valuable experience of PMP gained from TM#1 project has made TM#2 even more adapted to the customer’s requirements.

About Intelli-Tissue® EcoEc Technology:

PMP Intelli-Tissue® EcoEc Technology – is a response to market demands and requirements of newcomers in the tissue business, however it may also be applied successfully to changing the technological concept of the mill. EcoEc means an Ecological and Economical machine with ultra low media consumption and low investment and operating costs. Intelli-Tissue® EcoEc can replace outdated and slow tissue machines, bringing costs savings and additional profits from a ready-made product. Reductions are directly connected to the limitation of space needed in the mill, less personel required to run the line and significantly smaller replacement parts base. Additional profits come from higher quality of the final product (soft tissue – higher margins) and entering new, unexplored market niches. Also note that working with state-of-art technology – such as the Cresent Former – is more efficient and easier for the operation personel.

About Hebei Xuesong Paper:

Hebei Xuesong Paper - a famous tissue-making enterprise in Hebei Province, China - was founded in 1987 and produces high-quality tissue products under "Xuesong” brand.

PMP – a global provider of tissue, paper & board technology, has been supporting pulp and paper industry for over 160 years, executing projects on 6 continents, in 29 countries. Company owns 6 facilities in 4 countries (Poland, USA, China, Italy). PMP is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching new logo & visual identity. learn more: www.pmpgroup.com

Kotkamills awards Kemira with a start-up contract in a paper machine conversion project

Kemira has been awarded a start-up contract in the "Flying Eagle" project of Kotkamills mill in Kotka, Finland.

During the project, the current magazine paper machine (PM2) will be converted into a high performance food service board (FSB) machine. Kemira will supply the start-up with sizing, retention and drainage, board hygiene, and microbe control technologies. The start-up of the rebuilt machine is scheduled for June 2016, and the production capacity will be 400,000 t/a of high quality Nordic folding boxboard and recyclable barrier board for the food industry.

During the project, the current magazine paper machine (PM2) will be converted into a high performance food service board (FSB) machine. Kemira will supply the start-up with sizing, retention and drainage, board hygiene, and microbe control technologies. The start-up of the rebuilt machine is scheduled for June 2016, and the production capacity will be 400,000 t/a of high quality Nordic folding boxboard and recyclable barrier board for the food industry.

"Kemira is proud to have the opportunity to participate in the new Kotkamills board machine start-up", says Kimmo Strengell, Marketing Manager, Strength & Tissue Additives, Pulp & Paper EMEA. "With our expertise, service capability and broad portfolio of board making chemistries, we are able to support Kotkamills in reaching the desired quality and productivity targets of the new board grade."

Kemira microbe control programs ensure hygienic quality of the food service board. Hygienic quality control is critical for FSB machines: if the final board doesn't meet the expected hygienic quality standards, converters can reject the whole production. Optimal retention and drainage programs are a prerequisite for improved runnability, productivity and board quality. Kemira sizing technologies are applied to control liquid resistance and to improve the printability of the board.

By converting the paper machine to packaging boards, Kotkamills secures its position as a globally significant manufacturer of forest industry products. Kotkamills' bleached CTMP (Chemi-thermomechanical Pulping), high-quality Nordic folding boxboard and recyclable barrier board products are suitable for various types of end-use applications, such as frozen, chilled and dry food, beverages, cup-stock and plates, confectionery, pharma, and cosmetics. The Flying Eagle contract will further strengthen the long-lasting and strong partnership that utilizes core strengths of both parties.

For more information, please contact

Kemira Oyj

Kimmo Strengell, Marketing Manager, Strength & Tissue Additives, Pulp & Paper EMEA

Tel. +358 50 351 6993

Ari Pirneskoski, Director, Sales, Pulp & Paper, EMEA North

Tel. +358 500 668 204

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2014, Kemira had annual revenue of EUR 2.1 billion and around 4,250 employees. Kemira shares are listed on the NASDAQ OMX Helsinki Ltd.

Kotkamills pulp and paper operations consist of the new board machine BM2 (PM2) and Absorbex paper machines PM1 and PM7, as well as corresponding pulp lines: CTMP (Chemi-thermomechanical Pulping) for board, RCF (recycled fibre) and sawdust kraft for PM1 and PM7. Laminating paper capacity of the two machines is 200,000 t/a. In addition, Kotkamills Oy has a 200 000 m3/a sawmill and two impregnation machines, which utilize ca. 25,000 t/a of laminating paper in vertical integration.

www.kotkamills.com

Valmet to supply new high consistency bleaching system to Rottneros pulp mill in Sweden

Valmet will deliver a new high consistency bleaching system to Rottneros pulp mill in Sweden.

Valmet will deliver a new high consistency bleaching system to Rottneros pulp mill in Sweden.

This is the first step in a larger rebuild project, called Agenda 500, at the mill. The longtime goal is to increase both availability and the total production volume of Rottneros two pulp mills to reach a capacity of 500,000 ton per year.

Planned delivery time for the bleaching system is in July 2016.The order is included in Valmet's fourth quarter 2015 orders received. The value of the order will not be disclosed. Typically an order of this scale is valued at around euro 2-4 million.

"In our investment project we aim to increase capacity and lower our chemical consumption. We have had a long and good relation with Valmet over the years, which is one of the reasons for choosing them as supplier," says Nils Hauri, Production Manager at Rottneros mill.

"Valmet's bleaching system offers high availability with low operational cost, including energy and chemical consumption and maintenance costs. We are convinced that this bleaching system will live up to all expectations in this project," says Johan Eurenius, Sales Manager at Valmet.

Details about the delivery

Valmet's delivery includes machinery and erection, training, commissioning and start-up services. The new high consistency bleaching system consists of a chemical mixer and a bleaching tower, two washing stages with screw presses and mc pumps. This project aims to lower the peroxide consumption, increase capacity and keep maintenance costs to a minimum.

About the customer Rottneros

Rottneros produces market pulp and has an annual production capacity of just under 350,000 tonnes of pulp, produced at two mills in Sweden. In 2014 Rottneros employed around 250 people, the majority in Sweden and had sales amounting to approximately SEK 1.5 billion. Rottneros' shares have been listed on what is now Nasdaq Nordic, Stockholm since November 1987.

For further information, please contact:

Johan Eurenius, Sales Manager, Fiber Processing, Pulp and Energy Business Line, Valmet, tel. +46 70 592 55 29

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

ANDRITZ to supply two tissue machines with 20 feet steel Yankees to Guizhou Chitianhua, China

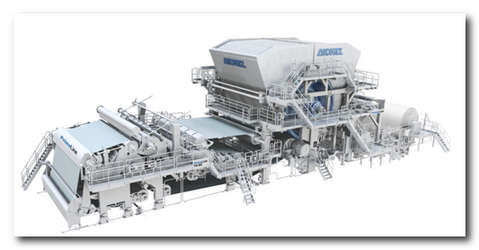

International technology Group ANDRITZ has received an order from Guizhou Chitianhua to supply two tissue machines (TM5, TM6) with steel Yankees for a mill in Chishui city, Guizhou Province, for the production of high-quality facial wipes, toilet paper, and handkerchief paper. The start-up of TM5 is scheduled for the end of 2016 and of TM6 for the beginning of 2017.

The new PrimeLineST tissue machines have a design speed of 2,000 meters per minute and a paper width of 5.6 meters. The machines of this type are currently unique on the market because they combine a high-performance Yankee with a steam-heated hood. Both Yankees for Guizhou Chitianhua are made entirely of steel, have a diameter of 20 feet, and hence are among the largest in the world. They enable a high drying capacity and achieve remarkable cost savings compared to systems operated with gas because of usage of steam.

Both Yankees will be manufactured at the ANDRITZ steel Yankee business center in Foshan, China, which offers customers in China state-of-the-art manufacturing, local field service, and quality management.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of almost 25,000 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, production equipment for biofuel (second generation), biomass torrefaction equipment, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

PMP (7) Tissue Machines in YFY’s fleet up & running – a strategic partnership is successfully continued

PMP (Paper Machinery Producer) has been supporting one of the leading Asian papermakers – Yuen Foong Yu Corporation for the last 20 years, executing projects both in the tissue and paper field.

At present, in the tissue area, YFY owns 7 PMP Intelli-Tissue® 1600 lines – all are installed in Mainland China: in Beijing, Yangzhou and Dingfung, reaching total capacity of 300 000 t/a. 1st CF Intelli-Tissue® machine (2.4 m wide) was launched in 2008 in Beijing, China. 2nd and 3rd (PM#5 & PM#6) 2.8 m wide CF Intelli-Tissue® were started-up in 2012 in Yangzhou, China. After successful start-ups in Beijing and Yangzhou mills, in spring 2015, PMP has been choosen again to support YFY’s development, this time adding (4) more tissue making lines.

YFY Corporation decided to continue partnership with PMP recognizing its strenghts, uniqueness and abilities to support long run strategy. PMP Optimum Cost Solutions, state-of-art technology, attractive return-on investment factor and extraordinary flexibility of PMP organization have met YFY team demanding requirements. Excellent communication between companies, which was recognized during the first project, had also a significant meaning.

At the end of March 2013, YFY officially announced a massive expansion plan which included investing over 260 mln US dollars in Taiwanese and Chinese plants. At the same time PMP has been awarded a project for (4) new complete CF Intelli-Tissue® 1600 machines.

To optimize the investment, YFY decided to follow the scenario from 2012 (PM#5 & PM#6 Yangzhou project) and clone the same concept for an Integrated Tissue Mill: two tissue machines with rewinders, with a common control room in the same building, as well as a warehouse and converting area.

The concept of the Integrated Tissue Mill was implemented both in Yangzhou mill (PM#7 & PM#8) and in Dingfung mill (TM#1 & TM#2) ensuring staff & space optimization, high production flexibility and a significant operation cost reduction.

On 3rd July 2014 (PM#7) and on 28th August 2014 (PM#8) in Yangzhou, China, 4th and 5th machine fully designed and produced by PMP started-up easily. Then, on 8th December 2015 (TM#1) and on 14th January 2016 (TM#2) in Dingfung, China, 6th and 7th machine were successfully brought on stream bringing all involved satisfaction & pride.

All recent (4) tissue machines are 2.8 (110 inch) reel trim CF type tissue machines with an operating speed of 1,600 mpm (5,250 fpm) and daily capacity of 80 tpd each. Machines are producing virgin fiber-based tissue in the basis weight range at the reel from 13 to 31.3 gsm (8-19.1 lbs/3000 ft2) for conversion into facial tissue, toilet rolls and kitchen towels. The project goals were premium quality of the final product and significant increase of capacity. In addition, it was important to minimize investment costs. That is why the Integrated Tissue Mill concept was chosen (two TMs under one roof).

This project is the next step of partnership strenghtening between YFY and PMP. Both teams are convinced that common understanding is a great base to stay agile and create a further pro-active development.

„We have decided to continue

co-operation with PMP

since they have good skill

and experience in tissue machines

manufacturing”

Mr. Ming Fa Tang, YFY Vice President Tissue

PMP is proud that YFY sees PMP as a strategic partner. Fruitful partnership, that has been developing over the years between those two companies, has resulted in extremely fast & efficient start-ups and overall, efficient cooperation based on win-win solutions. PMP is looking forward to future projects and is confident that the Intelli-Tissue® technology will help YFY to achieve their market goals and ambitions.

The cooperation between YFY and PMP teams brought common success and both companies look forward to potential projects in the nearest future.

About YFY:

Yuen Foong Yu – one of the leading Asian Corporations with a turnover of 1.8 billion US dollars, ranked in the top 5 among tissue producers in China, was founded in 1925. At present, YFY is active in three business areas: fine paper & board, packaging and consumer products. It owns 23 facilities in China, Taiwan and Vietnam. YFY’s activity within the tissue sector is focused on delivering value for consumers through Mayflower, Tender and Delight brands mainly in China and Taiwan. (learn more: www.yfy.com)

About PMP:

PMP – a global provider of tissue, paper & board technology, has been supporting pulp and paper industry for over 160 years, executing projects on 6 continents, in 29 countries. Company owns 6 facilities in 4 countries (Poland, USA, China, Italy). PMP is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching new logo & visual identity. (learn more: www.pmpgroup.com)

Two Lawsuits Filed by Halalt First Nation Against Catalyst

Catalyst Paper (TSX: CYT) has just announced that it has been served with two Notices of Civil Claim by the Halalt First Nation and its business partners. Catalyst denies the allegations contained in both claims and intends to vigorously defend itself.

Catalyst Paper (TSX: CYT) has just announced that it has been served with two Notices of Civil Claim by the Halalt First Nation and its business partners. Catalyst denies the allegations contained in both claims and intends to vigorously defend itself.

The first claim was filed by the Halalt and its members alleging Catalyst has illegally trespassed on, and caused damages to, the Halalt's asserted territories and fisheries resources through the operation of Catalyst's Crofton Mill since 1957. The Halalt is seeking an interim and permanent injunction restraining Catalyst from conducting its operations at the Crofton Mill that interfere with the Halalt's claimed riparian, water and land rights and are also seeking approximately $2 billion in damages.

The second claim was filed jointly by the Halalt, Sunvault Energy Inc. and Aboriginal Power Corp. alleging Catalyst disclosed certain confidential information pertaining to a proposed anaerobic digester facility in breach of a confidentiality agreement. The plaintiffs are seeking, among other things, approximately $100 million in damages from Catalyst in connection with the alleged breach of contract and a permanent injunction restraining Catalyst from constructing, owning or operating an anaerobic digester facility.

About Catalyst Paper

Catalyst Paper manufactures diverse printing papers such as coated freesheet, C1S, coated and uncoated groundwood, newsprint, directory, as well as market pulp. Customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada, and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.

SOURCE Catalyst Paper Corporation