Ian Melin-Jones

Stora Enso plans restructuring of packaging operations

Stora Enso’s Packaging Business Area plans to increase its cost competitiveness and respond to market demand by restructuring its core and coreboard operations in Finland, Germany, the United Kingdom and the USA, and streamlining corrugated packaging production in Finland.

“In core and coreboard markets the main customer is the board and paper industry. Decreased demand for paper mill cores in mature markets has made the market situation tighter, and in the current financial situation the outlook is uncertain. Corrugated packaging markets are very local and closely related to national economies. In Finland demand is still clearly below pre-crisis levels, and there are no signs of sustained recovery. The planned restructuring and streamlining measures, including some development investments, will enable us to better meet customer and market expectations and ensure our competitiveness by being more cost efficient and streamlining our operations,” says Mats Nordlander, EVP, Stora Enso Packaging Business Area.

The planned restructuring measures would reduce approximately 80 employees in corrugated packaging operations in Finland, and approximately 70 employees in core and coreboard operations mainly in Germany, Finland, the United Kingdom and the USA. In addition, the plans include possible temporary lay-offs at corrugated packaging operations in Finland. Stora Enso’s Packaging Business Area plans to reduce annual costs by approximately EUR 6 million, starting during the first quarter of 2012, with all planned actions to be completed by the end of the third quarter of 2012. Stora Enso will record a restructuring provision and an inventory write-down of approximately EUR 4 million in the Industrial Packaging segment in the fourth quarter of 2011 results.

All decisions will be made after the local co-determination negotiations have been concluded. Stora Enso would make every effort in co-operation with local communities to help the affected personnel find new employment opportunities, and all job openings in other Stora Enso units would be available to those affected.

SCA establishes a joint venture in Australasia with Pacific Equity Partners

SCA has decided to form a joint venture partnership for its existing operations in Australasia with the Australian company Pacific Equity Partners (PEP). SCA and PEP Fund IV will each hold 50% of the company.

Working with local partners and in joint ventures in selected markets is a strategy that works well for SCA. This deal in Australasia enables a more efficient financing as well as it increases the speed of development of the operations.

SCA’s operations in Australia, New Zealand and Fiji employ about 1,500 people. In 2010, this business had net sales of SEK 4,400m, with some 70% related to tissue and some 30% related to personal care products. In the region, SCA manufactures and markets a number of leading brands including TENA, Tork, Sorbent, Purex, Libra, Treasures, Deeko and Handee Ultra.

The transaction involves a deconsolidation of the business, which will be financially reported as a joint venture according to the equity-share method.

In connection with the refinancing of the business and the divestment of 50% of the equity, SCA will receive SEK 3,200m. Also, there will be a SEK 700m write-down of the tangible book value, which will impact the result in Q4 2011.

“This deal strengthens our operations in Australia and New Zealand, and it secures our access to local competence and the local capital market. This enables a faster development of the operations”, says Jan Johansson, President and CEO of SCA.

The deal will be subject to approval from relevant authorities. Closing is expected to happen within two to three months.

Wolfgang Büchele has been appointed Kemira Oyj's President and CEO

Harri Kerminen will retire on April 1, 2012 after successfully leading the company through a major strategic change into a water chemistry company and turning the company around to a profitable path. This last assignment completes his 26 years of successful career at Kemira.

Wolfgang Büchele (PhD, Chemistry) has been appointed Kemira Oyj's President and CEO as of April 1, 2012. He has been a member of Kemira's Board of Directors since 2009.

"Kemira's Board of Directors started the CEO succession process this summer due to Harri Kerminen's anticipated retirement in 2013. The process was faster than expected and therefore we agreed with Harri Kerminen that he will retire earlier than planned. As a member of Kemira's pension fund he has the right for this", says Pekka Paasikivi, the Chairman of the Board.

Wolfgang Büchele will bring to Kemira extensive and broad industrial knowledge combined with international experience and network, especially in the fast developing Asian markets. He has spent most of his career, from 1993 until 2007 in BASF's Fine Chemicals organization in Europe, China and United States. Since 2009 he has been member of the Board and CEO of BorsodChem Zrt. in Hungary. He and his family will move to Finland.

Metso strengthens service with new partner in Czech Republic

Metso has entered into a partnership agreement with ZANAP, a service provider for the pulp and paper industry based in Frýdek-Mistek, Czech Republic. The agreement strengthens Metso’s position as a leading service and technology provider in Europe. ZANAP provides maintenance, repair and retrofit services for the pulp and paper industry in Central Europe and will thus complement Metso’s existing service capability in the area.

ZANAP has extensive experience of working with Metso. As an authorized service partner, ZANAP’s trained and competent team of service experts will work exclusively for Metso in the pulp, paper and fiberboard industry.

“Our objective is to enhance customer satisfaction by offering customers access to a knowledgeable and well-trained service team capable of meeting their requirements for the knowledge and skills necessary for boosting their overall operational availability, says Robert Mohr, head of Metso’s Paper and Fiber Technology, Central Europe North Region.

Metso to supply Arkhangelsk Pulp and Paper mill in Novodinsk, Russia

The order will increase the mill's energy independence to a large extent

Metso has signed a contract with Arkhangelsk Pulp and Paper Mill to deliver a biomass-fired BFB (bubbling fluidized bed) power boiler including main auxiliary equipment for boiler and site advisory services. This new boiler replaces one of the client's existing power boilers and further increases mill's energy independence and cut present electricity costs.

Bark and sludge will be used as fuel in the new boiler which has a capacity of 60MWth. By replacing old coal boilers with new biomass boiler the Arkhangelsk mill will obtain an additional amount of own steam and electricity and Arkhangelsk Pulp and Paper mill expect a fast return of investment by reducing electricity costs to more than 216 million rubles a year.

"We are very excited about this project, in which we help our customer to use their mill residuals to produce energy in an efficient and environmentally friendly way," says Kari Remes, General Manager Sales Capital Sales, Metso.

Start-up of the new biomass boiler is scheduled for the first quarter of 2014. The value of the order is not disclosed, and the order is included in the Energy and Environmental Technology's Q4 orders received.

Arkhangelsk Pulp and Paper Mill celebrated their 70th anniversary 2010 and is one of the leading wood chemical enterprises of Russia and Europe. They specialize in manufacturing paperboard and market pulp, fiberboard, paper and paper stationery products. According to the results of 2010 they had net sales of 15 989 153 thousands rubles equivalent of approximately 320 million €.

Procon V3 Dosing output control system from Alltech

PROCON V3 DOSING OUTPUT CONTROL SYSTEM REDUCES CHEMICAL CONSUMPTION

Wherever chemicals are to be dosed in a periodical cycle, PROCON V3 is the proper control system. A typical application is the phosphate elimination process in water or waste water treatment. Even without online P-charge measurement, the consumption of chemicals can be reduced significantly.

PROCON V3 has been developed for the optimized control of dosing pumps through an external analogue signal or through trend guiding.

Core of the PROCON V3 is its easy-to-use touch screen display with clearly-arranged symbols and keys. Five set point values can be adjusted for weekdays (Monday to Friday), Saturday and Sunday to allow for maximum flexibility.

When operated via external analogue signals (optional), the device will automatically fall back to the adjusted trend curve if the signal fails (signal < 2 mA). If the signal is higher than 2 mA, the output will change according to the analogue input value. As an option, the output can be controlled by means of two external analogue signals (4-20 mA).

Sonoco Recycling to Manage Recycling Services for Onslow County

Sonoco Recycling, Inc., a wholly owned subsidiary of Sonoco (NYSE: SON) and one of the largest packaging recyclers in North America, has announced that it has been awarded a 10-year contract to operate the Onslow County, N.C., materials recovery facility (MRF). The Company plans to invest $1 million in facility upgrades.

"We are very excited to work with the County," said Jim Brown, vice president, Sonoco Recycling. "Residents of Coastal North Carolina will now have access to expanded, single-stream, or commingled, recycling, increasing the types of materials they are able to recycle.

"We also plan to build an education center at the County's MRF, developing recycling education efforts in and around Onslow County through partnerships with local schools and public education programs at the facility."

A recycling leader with locations and expertise worldwide, Sonoco Recycling annually collects more than 3 million tons of old corrugated containers, various grades of paper, metals and plastics. In addition, the Company has experts who provide secure, reliable and innovative recycling solutions to residential and commercial customers.

Currently, Sonoco Recycling operates six MRFs and serves more than 125 communities in which curbside-collected residential and commercial materials are processed. The Company also provides recycling programs which identify waste reduction opportunities that reduce operating expenses for many of the largest consumer product companies in the U.S.

SOURCE: Sonoco Recycling, Inc.

Metso to supply tissue line to CMPC Tissue, Chile

Metso will supply a complete tissue production line to CMPC Tissue S.A. of Santiago, Chile. The tissue line will be installed at CMPC’s Talagante mill in Chile. The line will be started up during 2013. The value of the order will not be disclosed. This kind of production line is typically valued at EUR 20-30 million, depending on the scope of the delivery and the production output.

Metso’s delivery will comprise a complete tissue production line with stock preparation equipment and a tissue machine including a headbox, a Yankee cylinder, a hood, a dust management system and a reel. The production line will be optimized to enhance final product quality and save energy.

The delivery will also contain an extensive automation package including a process automation system for machine, process and drive controls as well as a quality control system.

The new production line will produce high-quality facial, toilet and towel grades. The raw material for the new line will be virgin and DIP pulp.

The main part of the order is included in Paper and Fiber Technology’s third quarter 2011 orders received and the automation package in Energy and Environmental Technology’s third quarter 2011 orders received.

CMPC Tissue S.A. is part of the larger pulp and paper group Empresas CMPC, and is a leading tissue products supplier in Latin America with industrial operations in 8 countries of that region.

Metso receives large service contract from Arcelor Mittal

Metso and Arcelor Mittal Tubarão, located in Espirito Santo State, Brazil, have signed a service contract covering approximately 2,000 automatic and safety valves. The contract also includes intelligent tools for preventive and predictive maintenance and maintenance planning activities. It expands the existing contract and is one of the largest for Metso’s valve operations in South America.

Arcelor Mittal Tubarão is a world leader in the semi-finished steel market, accounting for 12% of global slab sales. It is also one of the largest companies in Brazil.

With Metso’s intelligent tools, the steel plant staff is able to monitor and analyze valve condition while the process is running. Conventional methods require stopping the process and removing or dismantling the valves for closer inspection.

“Constant awareness of overall valve condition prevents unexpected breakdowns, which can result in stopping the process completely, which is extremely costly. The customer can plan the maintenance schedule in advance, so any disruption to the process is kept to a minimum. In addition, the staff can focus maintenance activities on those valves needing it most,’’ explains Tercelino Leite, Service Manager, Automation business line, Metso.

As Metso’s strategy is to offer knowledge-based services close to its customers, the company is continuously growing its global service network. Currently Metso operates 31 service centers globally for valve maintenance. Investing in service capabilities is demonstrated in the large service contracts Metso has won from large global companies such as Arcelor Mittal and Petrobras.

Arcelor Mittal is the world's leading integrated steel and mining company, with operations in more than 60 countries. In 2010, Arcelor Mittal had revenues of USD 78 billion and crude steel production of 90.6 million tons, representing approximately 8% of world steel output.

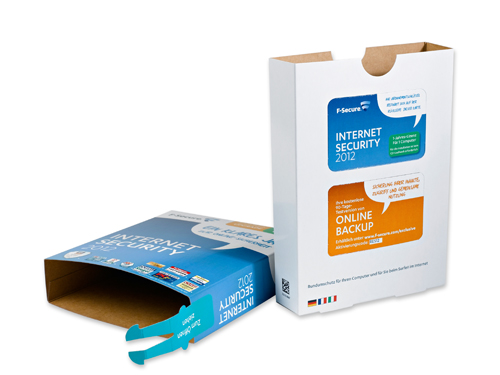

Scanstar award to Pyroll and F-Secure

The winners of the Scanstar 2011 packaging competition were announced on November 3rd in Sandefjord, Norway. The digital carton plant SOLVER palvelut Oy, part of the Finnish company Pyroll, was awarded a Scanstar for its packaging solution for F-Secure Corporation, a global IT security and antivirus provider.

The package in question is a digitally printed carton for IT software. Each package is an individual. The package contains an integrated license card and in the logistic process, the cartons are identified individually by 2D codes printed on the package surface. The carton offers a completely new packaging solution, it is eco-friendly and easy to use. As F-Secure’s products are delivered all over the world, the cartons are printed in numerous language versions and also in trade channel editions. Assembly is fast and easy, and no extra stickers are needed. Delivery volumes are adjusted to demand, and there are no stocks. The cartons are fully recyclable.

According to the Scanstar jury, this package “solves in an ingenious way the wrapping of a security product which was previously covered in plastic. The solution is as smart as it is simple, protects effectively and is easy to open. The amount of materials and energy used in the process is also lower than in the past.”

The awarded package was launched this autumn. It forms a good basis for further product development and future applications.

The Scanstar competition is arranged by the Scandinavian Packaging Association. This year the Norwegian association Den Norske Emballasjeforening was responsible for the arrangements. For Nordic manufacturers, Scanstar is the only way to participate in the global WorldStar packaging competition. In recent years, Pyroll has received three WorldStar awards.