Ianadmin

Toscotec achieves a new record for Steel Yankee width in rebuilding project at ST Tissue.

Toscotec has been chosen to supply ST Tissue in Franklin, Virginia, with the widest Steel Yankee ever to be manufactured. ST Tissue F-5 machine will be converted to produce bathroom tissue and kitchen towel.

The market leader in Steel Yankee Technology, Toscotec will rebuild the dry-end section and redesign the F-5 machine to convert it to dry crepe tissue.

The current paper machine configuration, consisting in a forming section, nip-press section, dryers section and Reel drum, will be converted to dry crepe tissue machine keeping the existing fourdrinier and redesigning the nip-press section to felt run arrangement which includes new Toscotec dry end equipment. Toscotec scope of supply includes TT SuctionPressRoll-SPR1045, an under machine broke pulper TT MachineBrokePulper-MBP75, and a TT SYD-12FT x 257” face width (6530 mm), the widest Steel Yankee Dryer ever manufactured.

The TT SYD-12FT, second generation rib design, fits the customer needs thanks to the high drying capacity performance and energy saving concept which includes Toscotec’s Patented Head Insulation.

All the existing drying drums will be removed, and a new Toscotec tail feeding system will be provided and installed between the Toscotec Steel Yankee and the existing pope reel.

Erection supervision, commissioning and start up will be performed by Toscotec Service Team. The PM5 conversion is part of a plan of investments that ST tissue has decided to implement with the aim to follow the market's demand.

About ST Paper & ST Tissue

Founded in 2007 by Sharad Tak and his son Sahil Tak, ST Paper & ST Tissue operate in Oconto Falls, WI and Isle of Wight, VA, respectively. In 2012 the Tak's purchased a portion of a shuttered paper mill in Isle of Wight, VA from International Paper and transformed it into a tissue mill by 2013. In the process, ST Tissue helped revitalized the surrounding communities by bringing back almost 90 direct jobs and hundreds more indirect jobs

Metsä Board to close down its wallpaper base machine in Kyro

Metsä Board, part of Metsä Group, announced on 4 August 2016 that it was planning to close down the wallpaper base machine (PM3) located at its Kyro mill in Hämeenkyrö, Finland, and to discontinue its loss-making wallpaper base production. In 2015, sales from Kyro’s paper business totalled EUR 50 million, and the operating result was EUR -5 million.

The statutory labour negotiations, which affected all of the 250 people working at the mill, have been completed. As a result, the Kyro mill wallpaper base machine PM3 will be closed down and the number of personnel at the mill will decrease by 94 people.

The statutory labour negotiations, which affected all of the 250 people working at the mill, have been completed. As a result, the Kyro mill wallpaper base machine PM3 will be closed down and the number of personnel at the mill will decrease by 94 people.

Metsä Board’s third quarter result is estimated to include non-recurring net costs of around EUR 9 million related to the closure. The closure is estimated to have a positive cash impact of around EUR 10 million, the majority of which consists of working capital released during the fourth quarter.

The folding boxboard machine with annual capacity of 190,000 tonnes will remain at the Kyro mill, producing premium packaging board for beauty and healthcare products and graphics end uses, among other things. In addition, Hämeenkyrön Voima’s biopower plant producing heat and electricity is located in the mill area.

Metsä Board is a leading European producer of folding boxboards and white linerboards made from fresh fibres. Its lightweight paperboards are developed as the perfect fit for consumer goods, retail-ready and food service packaging. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in northern forests.

The global sales network of Metsä Board supports customers worldwide, including brand owners, converters and merchants. In 2015, the company’s sales totalled EUR 2.0 billion, and it has approximately 2,600 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

A.Celli opens a facilityTurkey

The Lucchese Group is increasingly becoming a Global Partner!

A.Celli Group announces the opening of a new branch facility in Istanbul, Turkey.

The new offices, which have been operational since the beginning of September, are a further confirmation of the strong desire by the A.Celli companies to broaden their sales and customer service network in the world.

For the A.Celli Group, Turkey – a natural bridge between east and west – represents a market with great potential and that already counts many active customers. The new offices are a demonstration of the attention and commitment that the Lucca company shares with its partners, and will become a reference point for sales and post-sales relationships in the region of western Asia. The opening of the subsidiary in the city of the Bosporus is the result of the Group’s consistent growth and joins the A.Celli global network that already includes China and the United States.

The address of the Istanbul facility is:

A.Celli Turkey

Brandium Residence - R2 Blok K 9 D 90, 34750 Atasehir - Istanbul - Turkey

Phone: +90 533 2764570 – Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Kimberly Clark Products Malaysia, Kluang Johor Mill: an old winder from the 1980s comes back into fashion… with style!

Earlier this year, A.Celli Paper’s Customer Service team installed and successfully concluded the upgrade performed on a tissue winder (combining winder AC820) from the 1980s with the startup of the machine.

The intervention, which entailed updating the machine’s motorisation with a sectional drive transmission and the addition of a new axial unwinder, allowed the customer to immediately increment production at the same technical-operating conditions, substantially reducing energy consumption at the same time.

A.Celli Paper worked in close contact with the customer and the teamwork yielded optimal results. Indeed, the solutions applied were designed in advance, tested and then shared with the customer’s work team. The new configuration kept into consideration the convenience of the operations to be performed on the one hand, and the needs of KCC Products Malaysia on the other, in order to obtain the best results in terms of efficiency in the shortest possible installation times, turning a thirty-year plant into a superbly operating and productive system.

The customer was very appreciative of the project, acknowledging the high level of professionalism of A.Celli Paper’s Customer Service team and its ability to always find functional, practical and intelligent solutions through engineering/design analyses, and always keeping the strategic-industrial demands of the individual customers in mind.

A.Celli Paper is capable of offering prompt & effective consultancy in-line with any type of investment and production demand.

Valmet to supply paper machine modifications and a new winder to Laakirchen Papier in Austria

Valmet will supply paper machine modifications and a new winder toLaakirchen Papier AG in Austria. Laakirchen Papier will convert its paper machine 10 (PM 10) to produce lightweight containerboard. Currently PM 10 is producing publication paper. The start-up of the paper machine and the winder is scheduled for the autumn of 2017.

The order is included in Valmet's third quarter 2016 orders received. The value of the order will not be disclosed. The value of an order of this type is typically EUR 5-10 million.

"With this investment, the product range of Laakirchen Papier will be widened into a growing market sector. Valmet's technology and vast reference list of high speed containerboard winders convinced us," comment project manager Johann Stadlmayr and production manager Jan Reibert from Laakirchen Papier.

Valmet OptiWin Drum two-drum winder

Technical details about the delivery

Valmet's delivery includes a press section upgrade, relocation and modification of the existing reel and one OptiWin Drum two-drum winder. The winder is equipped with Dual Unwind, which is Valmet's new two-unwind system. This new feature makes it possible to change the parent roll in only one minute.

"Grade conversion projects often include a production change from two winders to one high capacity winder to increase mill's automation level. This also the case in Laakirchen PM10. A Valmet high capacity winder with two-unwind will do the demanding job," says Kenneth Åkerlund, Product Manager, Winders and Reels from Valmet.

The 7,500 mm wide (reel) PM 10 will produce containerboard products with a basis weight range of 70 g/m2 upwards. After the full extension, the annual production of PM 10 will reach 450,000 tonnes.

Information about the customer Laakirchen Papier AG

Laakirchen Papier AG is part of Heinzel Group, which is united under the Heinzel Holding umbrella. The group ranks among the largest producers of market pulp and magazine paper in Central and Eastern Europe. Laakirchen Papier produces SC paper, a high-gloss publication paper for magazines, catalogues and printed advertising material. The paper production amounts to an annual 550 000 tons, manufactured on two paper machines PM 10 and PM 11.

Valmet carried out the first maintenance shutdown of CMPC Guaíba's new pulp line in Brazil

Valmet was given an important role in the first maintenance shutdown of CMPC Guaíba's new pulp line in Brazil. The executed shutdown is one of the biggest shutdowns managed by Valmet. The facility's pulp line 2, also called G2, invested in planned maintenance in order to reach its annual capacity of 1.5 million tons/year of bleached eucalyptus pulp. The maintenance shutdown was carried out by Valmet and it took place between July 31 and August 10, 2016.

"We made careful planning with the customer for several months, and thanks to this work we were able to start the line again faster than planned. The geographical location of CMPC Guaíba's pulp mill demands special attention on safety and environmental issues as well as good cooperation with local community. In this respect, our role is not only to ensure that the equipment is running well, we also need to take care of the overall aspects which are part of the mill's operation", says Rogério Duarte, Valmet's Mill Sales Manager.

"Valmet contributed to the successful shutdown of G2 with its personnel's technical skills and organization, and its planning, safety and environmental state-of-the-art criteria. There is no doubt, Valmet and CMPC reinforced their partnership and I believe the company will be a strong candidate for future planned shutdowns," says Fernando Pereira, Maintenance Manager at CMPC.

Working towards a common goal

Valmet's expertise was the key for a well-planned shutdown. "We avoided rework during G2 maintenance as both Valmet and CMPC teams worked together focusing on the same goal," says Paulo Ormeneze, Valmet's Services Manager in South America.

Valmet was in charge of the overall maintenance of the core equipment delivered to this Southern Brazilian pulp mill including cooking, the fiber line, drying machines, causticizing, the evaporation plant and the recovery boiler. All maintenance activities were performed in line with Valmet's and CMPC's safety, quality and environmental criteria.

The first shutdown at CMPC Guaíba G2 was executed by Valmet's Service and Project Execution teams. Taking into account third-party companies and suppliers, Valmet managed altogether over 600 people at the site during 10 days.

Information about the customer CMPC and Guaíba mill

CMPC Celulose Riograndense Ltda is part of the Chilean group, CMPC Celulosa, one of the largest forestry-based companies in Latin America. Its mills in Chile and Brazil produce around 4 million tonnes of pulp per year.

Guaíba pulp mill in Rio Grande do Sul state in southern Brazil has two pulp production lines. The new line G2 was delivered by Valmet and was started up in May 2015.

Nordic Paper goes pink

Nordic Paper usually has a blue logo. But during October we will be pink!

The reason? Simply that we care!

We have decided to support the Cancer Foundation and their campaign agains breast cancer that is ongoing all over the world, every year - Pink Ribbon.

By selling a ton of sheeted Greasproof paper through an action where the buyer can place their bids, Nordic Paper is supporting the campaign Pink Ribbon.

The selling amount for this ton will go directly to Cancer Foundation and their Pink Ribbon Campaign.

Once a week we will update our social media with the company name that has offered the highest bid. The auction will start 1th of October and end the last of October.

The sheeted paper is of course a Natural Greaseproof paper and the only difference between the ordinary paper that we usually sell and this auctioned paper is that this ton is delivered in pink boxes. And of course the fact that the selling amount is donated to Cancer Foundation and Pink Ribbon.

This means that the buyer also contributes to the cancer research!

Pink Ribbon campaign is held every year and the purpose is to finance cancer research , but also to support breast cancer pations, survivors and their families all over the world. It´s an internationally operationg charity organization aimed to create a global community for these purposes.

Nordic Paper is an international company that manufactures both Greaseproof paper and Kraft Paper. We are among the biggest manufacturers in the wold and we want to be a part of the amazing work that colors, not only Sweden, but hopefullly most of the world pink during a mont due to a good cause. Therefore we really hope that a lot of people and companies around us becomes a part of this!

- The design of the pink boxes is specially developed by a Swedish designer, Maria K Back at Whiter Shade, for this campaign and we really hope that there will be a lot of buyers that place their bids since we are sending the selling amount directly to the Pink Ribbon , says Marie Stenquist, Corporate Communications/PR manager at Nordic Paper.

We have been producing paper in Scandinavia since the late 19th century and continue to make top-quality paper and pulp that suits our customers’ needs today. We are an independent manufacturer and our modern paper and pulp mills are the heart of our business. Living and working in the heart of Scandinavia, we are surrounded by nature, where the vast forests of inland Sweden and Norway provide the raw materials for the premium Natural Greaseproof and Kraft paper we produce.We are your global paper partner; today we supply customers in more than 80 countries. We deliver the paper you want with the specifications you need. We work with you to develop and manufacture exactly the right paper to help you do better business. We have mills in Bäckhammar, Säffle and Åmotfors in Sweden, as well as in Greåker in Norway. Our headquarter is located in Bäckhammar.

About Us

Nordic Paper is a leading producer of Greaseproof paper and Kraft Paper.We are located in Scandinavia and operates in Sweden and Norway. Our four paper mills and two pulp mills are all within 250 kilometers of one another.We have been manufacturing special paper for a range of applications since the late 19th century. Our expert knowledge of paper manufacturing has been passed down through generations.We use only renewable forestry resources in our manufacturing processes. Everything we do, we do with the greatest possible consideration for the environment, which is witnessed by the many certification processes we have satisfied.Our motto is that we always are near, natural and premium!For more information, please visit: www.nordic-paper.com

‘A Cellulose-Based Society’ generates three new research projects

The ‘Cellulose Fibre materials’, ‘Cellulose for the Future’ and ‘Paper mill for textile recycling in the circular economy framework’ research projects have recently been launched as a direct result of Innventia’s ‘A Cellulose-Based Society’ project. The preliminary studies from these projects will result in, among other things, proposals for our next research programme, which starts in January 2018.

Back in spring, Innventia launched its third Global Outlook Report ‘A Cellulose-Based Society’, which surveyed people’s attitudes to materials that we all use in our everyday lives and described trends and driving forces that are pushing us towards a more sustainable future. The three projects are the results of the needs inventory and research campaign that were organised within the framework of ‘A Cellulose-Based Society’.

The three projects in brief:

Elisabeth Sjöholm, project manager, what is ‘Cellulose Fibre materials (CelFi)’ about?

Elisabeth Sjöholm, project manager, what is ‘Cellulose Fibre materials (CelFi)’ about?

It focuses on scaling up All-cellulose composites (ACC) – a hot-pressed, high-density cellulose material. An increased understanding of the properties of ACC material and the scope for upscaling also provides us with important knowledge for continued development of other types of hot-pressed cellulose-based materials, such as hybrid laminate consisting of a core containing cellulose and a metal skin. Potential applications include modern materials for buildings and cities.

Katarina Ohlsson, project manager, what is ‘Cellulose for the Future (CelFu)’ about?

Katarina Ohlsson, project manager, what is ‘Cellulose for the Future (CelFu)’ about?

One of the challenges of research into cellulose is that the amount of new materials is often limited. This project will facilitate, in various ways, the creation of technology and a knowledge platform for research and upscaling for separation of fibres and wood components within the 1-10 kg range. The focus will also be on establishing cooperation and partnerships with academic research groups.

Tatjana Karpenja, project manager, what is ‘Paper mill for textile recycling in the circular economy framework (Circular Fibres)’ about?

Tatjana Karpenja, project manager, what is ‘Paper mill for textile recycling in the circular economy framework (Circular Fibres)’ about?

The project is evaluating the techno-economic and sustainability performance of a new concept for paper production. The work focuses on new paper materials where a significant proportion of the fibre raw material consists of low-grade fibres from textile recycling plants. During pilot testing at Innventia, we previously proved that it is technically possible to manufacture paper with attractive material properties from just such raw materials. Based on the framework for a circular economy, this involves so-called ‘cascade recycling’ of fibres from the textile industry to the paper industry. You can experience the new paper in the cover of the ‘A Cellulose-Based Society’ report, which is Innventia’s demonstrator of potential applications for this exciting new material.

Sonoco Announces Price Increase for Paperboard Tubes and Cores

Sonoco (NYSE:SON) have just announced it will raise the price for all paperboard tubes and cores by 6 percent to 10 percent, effective with shipments in the United States and Canada, beginning October 24, 2016.

“This price increase, our first in more than a year, is necessary due to the recent increase in costs for uncoated recycled paperboard, our primary raw material, combined with price escalations in energy, labor and other input costs,” said James Harrell, vice president for Sonoco’s North America Tubes and Cores Division.

“This price increase, our first in more than a year, is necessary due to the recent increase in costs for uncoated recycled paperboard, our primary raw material, combined with price escalations in energy, labor and other input costs,” said James Harrell, vice president for Sonoco’s North America Tubes and Cores Division.

Sonoco is the largest producer of paper-based tubes and cores in North America, which are used to serve the paper, textile, plastic film, and tape and specialty industries. For more information about Sonoco’s complete line of paperboard tubes and cores or to learn more about current pricing, please visit the Company’s website (www.sonoco.com) or contact the Company at +800-377-2692.

About Sonoco

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging and display and packaging supply chain services. With annualized net sales of approximately $5.0 billion, the Company has 21,000 employees working in more than 300 facilities in 34 countries, serving many of the world’s best known brands in some 85 nations. For more information on the Company, visit our website at www.sonoco.com.

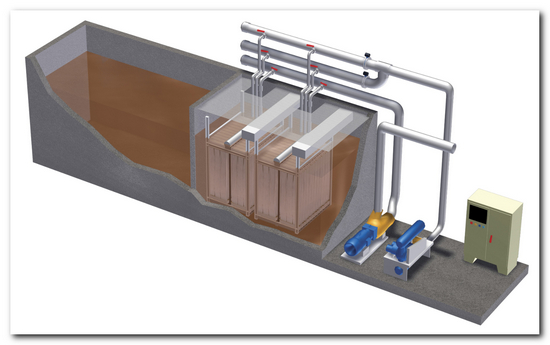

Arizona Paper Mill Reuses 300,000 Gallons of Water Daily with GE Technology

Doubletree Paper Mills in Gila Bend, Arizona, is saving 300,000 gallons of water daily by using GE’s (NYSE: GE) advanced water reuse technology. With GE’s ZeeWeed* membrane bioreactor (MBR) technology, the paper mill has doubled its paper production capacity without impacting the limited treatment capacity of the city’s existing municipal wastewater treatment plant.

- Doubletree Paper Mills in Gila Bend Has Doubled Its Paper Production with the Installation of GE Membrane Bioreactor (MBR) Technology

- First MBR Wastewater Reuse Project for a Paper Mill in the United States

- By Reusing Process Water, Doubletree Paper Mills Doubled Production without Impacting City’s Wastewater Treatment Plant

Over the past year, Doubletree Paper Mills has been treating and reusing its process water, reducing water consumption and preserving the limited capacity of the city’s wastewater treatment plant for its residents. Gila Bend is a small desert town with limited wastewater treatment infrastructure. Prior to the installation of GE’s ZeeWeed MBR technology, the paper mill was unable to increase its paper manufacturing capacity due to the limitations of the existing city water treatment plant.

“With the installation of GE’s MBR water treatment technology, Doubletree Paper Mills was able to reuse enough water to double paper production without burdening the city’s public wastewater plant. By reusing process wastewater for production, we are being environmentally and fiscally responsible members of the community,” said Samir Kanuga, vice president of finance, Doubletree Paper Mills. “GE’s MBR system works flawlessly every day. It requires minimal maintenance, and we have peace of mind knowing it is monitored by GE 24 hours a day, seven days a week, 365 days a year.”

“The paper and tissue manufacturing process requires large quantities of water and produces an abundance of wastewater. Being in the desert southwest, Doubletree Paper Mills is a model for environmental stewardship. Doubletree is using GE technology in a production-critical process that is enabling the mill to double capacity without burdening the city’s wastewater treatment plant. That’s sustainability in practice,” said Kevin Cassidy, global leader, engineered systems—water and process technologies for GE Power.

Situated approximately 70 miles southwest of Phoenix, Doubletree Paper Mills is GE’s first MBR wastewater reuse project for a paper mill in the United States. Doubletree Paper is a privately owned mill producing high-quality paper and tissue products for retailers in the southwest.

About Doubletree Paper Mills

Further to our commitment to obtaining the most responsibly sourced raw materials, Royal Paper Converting opened its own paper mill in 2007. Located in Gila Bend, Arizona, with the capability of sourcing 100 percent of its products, the state-of-the-art facility features more than 100,000 square feet, over 40 employees and equipment that produces both virgin and 100 percent recycled paper. Doubletree Paper Mills provide the paper for a comprehensive range of items (bath tissue, kitchen towels, napkins, facial tissues and more) for commercial and retail private label and in-house brands.

About GE

GE (NYSE: GE) is the world’s Digital Industrial Company, transforming industry with software-defined machines and solutions that are connected, responsive and predictive. GE is organized around a global exchange of knowledge, the "GE Store," through which each business shares and accesses the same technology, markets, structure and intellect. Each invention further fuels innovation and application across our industrial sectors. With people, services, technology and scale, GE delivers better outcomes for customers by speaking the language of industry. www.ge.com

About GE Power

GE Power is a world leader in power generation with deep domain expertise to help customers deliver electricity from a wide spectrum of fuel sources. We are transforming the electricity industry with the digital power plant, the world’s largest and most efficient gas turbine, full balance of plant, upgrade and service solutions as well as our data-leveraging software. Our innovative technologies and digital offerings help make power more affordable, reliable, accessible and sustainable.