Ianadmin

How Brexit will impact your paper or wood products business

The decision of the United Kingdom to leave the European Union at some point in the next two years (seemingly sooner, rather than later) sent shock waves around the global economy on Friday and across the weekend.

Given the shock and panic it engendered, it seems the exit of Britain from the European Union was unexpected, or at least considered unlikely. In a two horse race, its peculiar this result was so unexpected, but there’s nothing like financial markets for behaving like high-strung thoroughbreds startled by the merest bite from a horse-fly.

As global business comes to terms with the implications of Britain’s impending exit from the European Union, it is important to keep the situation in perspective. The world keeps on turning.

For businesses in the paper and wood products industry, IndustryEdge considers the following to be the key issues:

Currency crunch has just begun

The currency and exchange rate implications of the British referendum outcome were immediate and severe.

For the immediate future the focus will be on market stability. Almost all major capital markets lost value when the results of the vote were announced. Some of this was realignment after markets were primed the wrong way in the lead up to the vote.

The upside of the falling value of the British Pound (GBP), particularly against the US Dollar (USD), is that it also dragged down the Australian Dollar (AUD) and the New Zealand Dollar (NZD), as well as the Euro. All of these currencies declined to a far lesser extent than the GBP. To what extent this may assist or hinder Australasian exporters and importers is unclear. The length of time the local currencies are suppressed will be the critical factor. If a stronger USD is a component in the medium term, further turmoil can be expected as the US elections draw near, especially given the disparity between Trump and Clinton.

We offer the cautionary note that the fracturing of global financial markets on the back of the seemingly unimaginable Brexit may merely be a precursor to the dysfunction that will arise in November should the USA’s most unimaginable election result transpire.

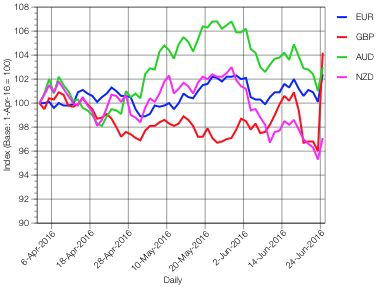

As the chart below shows, the last month has seen turbulence for relevant currencies, with speculation about the outcome of the British referendum providing some of the uncertainty over that period.

USD v Selected Currencies: 1 Apr '16 - 24 Jun '16

The USD had, until Friday, tracked pretty much sideways for the AUD and the Euro, despite the turbulence, since the beginning of April. It was a different story for the NZD and the GBP, which had appreciated strongly against the US Dollar.

All of that changed on 24th June, with the AUD, the Euro and NZD losing approximately 2% of their value as a result of the Brexit decision. For the GBP, the result was a single day 8.5% loss of value against the USD, as the chart's red line shows.

In Australia, as a result, an interest rate cut became more likely, according to surveyed economists. The RBA meets on 5th July and our view, if anyone is interested, is they are unlikely to see events unfold sufficiently to warrant an urgent rate cut.

Balance of trade creates concern only at specific product level

The UK, and also to a large extent Europe, are not significant destinations for wood products or pulp and paper products from Australia and New Zealand. The balance of trade between the two regions show there is a greater propensity for Australia and New Zealand to import from the UK and Europe. However, compared with the volume and values being traded between Australasia and Asia, any changes in the European trade are not going to be significant in the overall balance of trade.

At a product-by-product level, this is less the case, with some key grades, especially of printing and communication papers, being extensively imported from Europe. Some of these are hotly contested, where the market operates on wafer thin margins and in a context of global over-supply. For some, there is a component of domestic manufacturing, for other products, it is an entirely import trade.

It is notable that wood processing and pulp and paper manufacturing equipment continues to be imported from Europe. Brexit is unlikely to impact that element of the trade.

The balance of trade with Europe in total, including the UK, for both Australia and New Zealand, will be the subject of detailed features in the July editions of Pulp & Paper Edge (Edition 132) and Wood Market Edge (Edition 35).

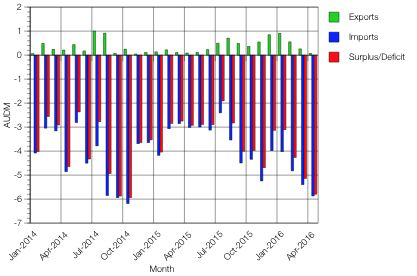

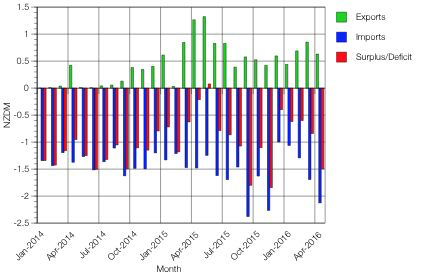

To provide a snapshot of trade with Britain, the charts below provide the balance of trade in paper and paper products between first, Australia and the United Kingdom, and the second, between New Zealand and the United Kingdom.

Australia's Balance of Trade in Paper & Paper Products with UK: Jan '14 - Apr '16 (AUDM)

Source: ABS

NZ's Balance of Trade in Paper & Paper Products with UK: Jan '14 - Apr '16 (AUDM)

Source: Statistics NZ

What the charts convey is that both Australia and New Zealand have a small trade interface with the United Kingdom. In both cases, the red bars show that by value, Australasia imports more than it exports to Britain.

However, there isn't much in it. For instance, in April 2016, Australia's trade deficit with the UK for paper and paperboard was AUD5.8M, with imports accounting for just 2.8% of the total value of paper and paperboard imports for the month. In New Zealand, the deficit was NZD1.5M, in what is an observably far less stable two-way trade with the UK.

At least when it comes to trade with the UK, there is little about which to be immediately concerned.

In closing, we can do no better than paraphrase Rudyard Kipling’s ‘If’:

“If you can keep your head when all about you are losing theirs… Yours is the Earth and everything that's in it…”

Demand and consumption fundamentals did not change last week. Supply patterns, on the other hand, may change and could do so dramatically in Europe. It is less likely there will be significant trade impacts in Australia and New Zealand, but there will, as outlined above, be some distractions, if not disruptions.

For detailed product level analysis, further information or discussion about the support IndustryEdge can provide your business, contact us at This email address is being protected from spambots. You need JavaScript enabled to view it., call us on +61 3 5229 2470, or go to www.industryedge.com.au.

Valmet selected to replace automation system at Papeterie du Bourray in France

Arjowiggins' Papeteries du Bourray graphic papers mill in France has ordered a Valmet DNA distributed control system (DCS) for PM1 to replace an earlier control system that is reaching end-of-life. The new Valmet DNA system will replace an old system from another supplier.

The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed. Typically the order value of this kind of automation system deliveries is below EUR one million.

The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed. Typically the order value of this kind of automation system deliveries is below EUR one million.

"Our Valmet DNA is based on more than 30 years of developing distributed control systems ranging from micro-sized systems to mill- and plant-wide systems that support global organizations. In this project we are replacing an old distributed control system from another supplier. The limited space in the mill's cross connection room meant that a major requirement for the mill was our ability to install the new system in the existing cabinets. Meeting both the ergonomic and performance expectations of the mill were keys to winning the replacement," says Boris Hosteins, Valmet Sales Manager in Bordeaux.

Technical details of the delivery

Valmet's delivery includes engineering, installation supervision, training and commissioning. The start-up of the new system scheduled for September 2016.

Valmet DNAis a single automation system for all applications - process, machine, drive and quality controls. It can also cover information management functions along with mechanical and field device condition monitoring. Guaranteed compatibility between different generation Valmet products helps to future-proof investments and maximizes the effectiveness of existing equipment.

About the customer Papeterie du Bourray

Arjowiggins manufactures a range of high quality natural white 100% recycled papers at the Papeteries du Bourray Mill in Le Mans, France. Printing paper production at the site started in 1951 and the present capacity is 80,000 tons per year.

BillerudKorsnäs reports serious fraud to Swedish police

BillerudKorsnäs has during June 2016 been exposed to serious external fraud of an advanced nature. The company has, despite rigorous control mechanisms, been deceived to make payments on the basis of false invoices. The situation was quickly identified by the BillerudKorsnäs finance function and the extent of the fraud could therefore be limited through recovery of major parts of the payments. After these measures, the maximal damage is about SEK 25 million.

The fraud has been reported to the Swedish police who is currently investigating the case. BillerudKorsnäs has initiated an internal investigation to assess if, and if so where, there has been lack of compliance with internal routines. Until the internal investigation is finalized, BillerudKorsnäs has taken measures to prevent similar situations to occur.

The fraud has been reported to the Swedish police who is currently investigating the case. BillerudKorsnäs has initiated an internal investigation to assess if, and if so where, there has been lack of compliance with internal routines. Until the internal investigation is finalized, BillerudKorsnäs has taken measures to prevent similar situations to occur.

“We treat this situation seriously. This type of fraud becomes more and more advanced and difficult to detect. This is a signal to us and to the rest of the business community about the importance of increased alertness”, comments Per Lindberg, President and CEO, BillerudKorsnäs AB.

BillerudKorsnäs has reported the claim to the insurance company and an insurance case has been initiated.

For further information, please contact:

Susanne Lithander, CFO, +46 (0)8 553 335 00

Henrik Essén, SVP Communication and Sustainability, +46 (0)8 553 335 00

The information is such that BillerudKorsnäs Aktiebolag (publ) is obligated to publish under the Swedish Securities Market Act. Submitted for publication at 11.10 CET, June 23rd 2016.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4 200 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

SCA to close tissue production plant in Spain

SCA will close its tissue production plant in Sant Joan de Mediona, Spain. The decision is aligned with the company’s strategy to optimize its geographic production footprint in order to drive cost and capital efficiency and further increase value creation in Tissue. SCA remains fully committed to the Spanish market, which is the Group’s sixth largest market based on sales in 2015.

SCA will close its tissue production plant in Sant Joan de Mediona, Spain. The decision is aligned with the company’s strategy to optimize its geographic production footprint in order to drive cost and capital efficiency and further increase value creation in Tissue. SCA remains fully committed to the Spanish market, which is the Group’s sixth largest market based on sales in 2015.

The production plant has an annual capacity of 45,000 tons. Production will be discontinued in July 2016.

The restructuring costs for the closure of the production plant are expected to amount to approximately SEK 230m and will be recognized as an item affecting comparability in the second quarter of 2016. Of the restructuring costs, approximately SEK 140m is expected to be recognized as an impairment loss.

For additional information please contact:

Johan Karlsson, Vice President Investor Relations, 46 8 788 51 30

Karl Stoltz, Media Relations Manager, 46 8 788 51 55

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo, Vinda and Zewa. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2015 amounted to approximately SEK 115bn (EUR 12.3bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

European paper industry announces new Director General, Sylvain Lhôte

CEPI (Confederation of European Paper Industries) hereby announces the appointment of Sylvain Lhôte as its new Director General. As of 5 September 2016, Sylvain Lhôte will take over from the current Acting Director General, Jori Ringman. Mr Lhôte is currently Vice-president Governmental Affairs in Europe for Alcoa, the leading aluminium and light metals engineering group.

“We are very pleased to welcome Sylvain Lhôte on board and are sure his leadership and expertise will help CEPI reach ever higher levels of excellence. We are thankful to both Marco Mensink for his work during his mandate and Jori Ringman, who ensured the smooth functioning of the organisation until the new Director General was found”, said Peter Oswald, CEPI Chairman.

“We are very pleased to welcome Sylvain Lhôte on board and are sure his leadership and expertise will help CEPI reach ever higher levels of excellence. We are thankful to both Marco Mensink for his work during his mandate and Jori Ringman, who ensured the smooth functioning of the organisation until the new Director General was found”, said Peter Oswald, CEPI Chairman.

Prior to joining Alcoa, Sylvain directed EU and sustainability affairs for the Borealis Group, in the base chemicals and plastics industry and led a global CSR programme for the company in the EMEA region. He previously chaired the Fleishman-Hillard Public Affairs practice in Europe and headed its environment department, advising major trade associations and industries in the field of sustainability policies and public affairs strategies. Sylvain began his career in parliamentary cabinets at the European Parliament and the French National Assembly.

French national, Sylvain studied political sciences, international law and business administration at Strasbourg and Paris-Sorbonne Universities and post-graduated cum laude in European Administration at the College of Europe in Bruges.

CEPI aisbl - The Confederation of European Paper Industries

The Confederation of European Paper Industries (CEPI) is a Brussels-based non-profit organisation regrouping the European pulp and paper industry and championing the industry’s achievements and the benefits of its products. Through its 18 member countries (17 EU members plus Norway) CEPI represents some 505 pulp, paper and board producing companies across Europe, ranging from small and medium sized companies to multi-nationals, and 920 paper mills. Together they represent 23% of world production.

WWF´s Check your Paper now supports Chinese pulp and paper producers and buyers

WWF launches the Chinese version of WWF´s global online tool “Check your Paper”, designed to support the China Sustainable Paper Alliance (CSPA) in engaging strategic market players on responsible paper products procurement and sales. The launch coincides with the RISI Asian Forest Products Summit and a panel discussion by the CSPA on the “Challenges and Opportunities for Increasing Responsible Fiber Use in Asia”.

On the direct request of the WWF-led China Sustainable Paper Alliance, parts of the online platform “checkyourpaper.panda.org” were translated into Chinese. “Check Your Paper and especially the private Self- Check section have been successful in the US and Europe in helping suppliers demonstrate to buyers sustainability and discuss improvements,” said Emmanuelle Neyroumande, WWF´s Global Manager Pulp and Paper . “We believe that this initiative will be very much welcomed by customers and traders of Chinese pulp and paper products all over the world. It will give importers the ability to work closely and in confidence with their Chinese suppliers.”

The Chinese Sustainable Paper Alliance (CSPA) aims to promote the development of responsibly sourced paper products in China, together with leading producers and buyers of paper products. It was founded in 2015 by WWF and the Chinese Forestry Industry Association. In a training organised by the Alliance on 20 June in Shanghai, around 70 persons from over 35 companies were supported on responsible procurement issues linked to pulp and paper and on how to eliminate and avoid illegal and controversial sources in their supply chains. How to use WWF´s online tool Check your Paper was also part of the training.

Designed for all the main pulp and paper categories, Check your Paper offers a non-public Self-Check but also allows to publish brands publicly. The basis for Check your Paper is a simple but scientifically robust method in evaluating a paper product’s footprint, developed by WWF together with scientists, paper buyers, producers and NGOs. It reduces complexity in evaluating the forest, water and climate performance of individual paper brands.

“Check Your Paper not only helps pulp & paper suppliers to proactively evaluate forest, climate and water performance of their products, but also provides buyers with a database to choose more environmental friendly paper products. We hope more Chinese companies can use this tool to increase the transparency of their supply chain and benefit from what they have done”, said Wenbin Huang, Forest Manager of WWF China.

Founding members of the China Sustainable Paper Alliance include 11 domestic and international companies covering the whole supply chain of China's pulp and paper industry: China Paper, China's biggest state-run paper company, Sun Paper, the country's largest private paper company; the global producers Kimberly-Clark, International Paper, UPM, SIG Combibloc, Stora-Enso and Fibria, as well as buyers such as HP, Fuji Xerox and IKEA.

The pulp and paper industry in China has an enormous opportunity to positively influence global forests. Over the course of the last decade China tripled its paper production and in 2008 became the world's biggest paper producer, increasing the importance of responsible procurement. Given the lack of domestic supply of fibre, China has become the world’s biggest importer of pulp, including from WWF Priority Places.

Based on the online platform Check Your Paper WWF will issue the WWF Environmental Paper Awards 2016 in November 2016. Proactive use of WWF´s Online Self-Check is part of the Award criteria. Details on the Award can be found on wwf.panda.org/environmentalpaperaward2016

Mitsubishi HiTec Paper receives PEFC™ certification and renewed FSC® certification

As a responsible manufacturer of speciality papers, Mitsubishi HiTec Paper has now been certified with the PEFC™ Chain-of-Custody for the first time, whilst at the same time the existing FSC® Chain-of-Custody certification has been successfully renewed.

The conscious use of resources and the sustainable production of premium speciality papers is a special concern for Mitsubishi HiTec Paper. As a result of this, in addition to ISO 9001 (quality management), the two plants in Bielefeld and Flensburg are both ISO 14001 (environmental management) and ISO 50001 (energy management) certified. Now both sites have also been certified with the PEFC™ Chain-of-Custody.

The conscious use of resources and the sustainable production of premium speciality papers is a special concern for Mitsubishi HiTec Paper. As a result of this, in addition to ISO 9001 (quality management), the two plants in Bielefeld and Flensburg are both ISO 14001 (environmental management) and ISO 50001 (energy management) certified. Now both sites have also been certified with the PEFC™ Chain-of-Custody.

PEFC™ is the largest institution for ensuring sustainable forest management by an independent certification system. Timber and timber products with the PEFC™ seal are known to originate from ecologically, economically and socially sustainable forestry.

At the same time, Mitsubishi HiTec Paper has successfully renewed the FSC® Chain-of-Custody certification for both sites. "We do not only place high demands on the quality of our speciality papers, but also on their sustainable production and the protection of our environment," says Dr. Dieter Becker, Director New Business Development & Corporate Social Responsibility at Mitsubishi HiTec Paper. "Both PEFC™ and FSC® are important components of our CSR and environmental policy".

Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's leading manufacturers of speciality paper. The roughly 700 employees at Mitsubishi HiTec Paper Europe produce high-quality direct thermal, digital imaging, carbonless, label and barrier papers at two tradition-rich locations in Bielefeld and Flensburg.

Each factory stands out for own base paper production, state-of-the-art production machinery and innovative coating technologies. Through its dense global sales network, Mitsubishi HiTec Paper Europe supplies a full range of speciality papers featuring a modular system for every application and printing technology – and is a highly capable partner whenever customized coated paper solutions are required.

The District Court dismissed Metsähallitus’ claim concerning roundwood purchases in Finland in 1997–2005

In its ruling issued on the 22nd June 2016, the Helsinki District Court dismissed Metsähallitus’ claim for damages against Stora Enso Oyj, Metsäliitto Cooperative and UPM-Kymmene Oyj. The claim was based on the competition infringement found by the Finnish Market Court in its decision on 3 December 2009.

According to Metsähallitus’ claim, the companies had caused damage to Metsähallitus through the competition infringement found by the Market Court in its decision on 3 December 2009. According to Metsähallitus, the companies had purchased roundwood from Metsähallitus below market prices during 1997–2005.

According to Metsähallitus’ claim, the companies had caused damage to Metsähallitus through the competition infringement found by the Market Court in its decision on 3 December 2009. According to Metsähallitus, the companies had purchased roundwood from Metsähallitus below market prices during 1997–2005.

Originally in 2011, Metsähallitus was claiming compensation for damage in a capital amount of EUR 282.5 million. The claim was reduced during the legal proceedings to EUR 159.4 million, of which approximately EUR 87.2 million were based on roundwood transactions between Metsähallitus and Stora Enso.

Stora Enso considers the ruling by the District Court to be correct, and denies that Metsähallitus suffered any damages.

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Our aim is to replace fossil based materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 26 000 people in more than 35 countries, and our sales in 2015 were EUR 10.0 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market. www.storaenso.com

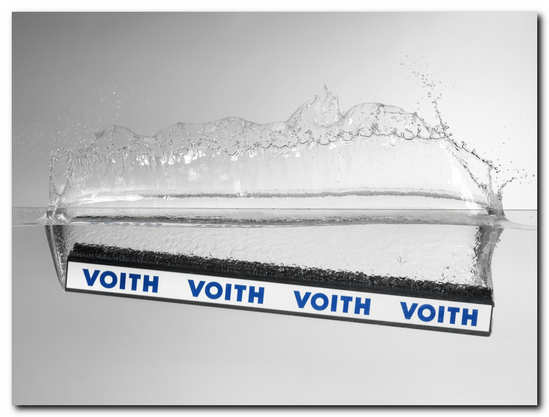

Smart Seal Wear Monitoring system from Voith reduces machine downtimes and improves efficiency

Voith has developed a ‘Seal Wear Monitoring’ system which will make sealing strip replacement easier to plan in future. Used for the first time at Swiss company Model, it helps minimize unscheduled downtimes due to roll failure or sealing strip wear or defects. The technology is one of Voith’s innovations from its Papermaking 4.0 range and enables paper producers to also take a significant step towards ‘smart factory’ conversion.

Marc Erkelenz explains how the smart monitoring of the sealing strip works: “Our product automatically informs the client by email when a defined wear level has been reached and also predicts the residual service life.” Erkelenz is responsible for developing new products for roll service at Voith and has lead the Seal Wear Monitoring project.

The system installed in the pick-up roll continuously monitors the sealing strip wear and predicts a replacement date based on the data obtained. Following a second wear indication conducted subsequently for validation purposes, the system automatically adjusts this date if necessary. Fully automatically, and with sufficient notice, the monitoring system then emails this information to all relevant parties such as the paper manufacturer, maintenance provider or customer service at the respective Voith roll service center. The risk of a roll failure is thus minimized, and the roll change can be done during scheduled downtimes or safely postponed. This was the scenario at Model, a family-run company in Switzerland, where the first signal from Voith's Seal Wear Monitoring system was received in May 2016 along with a predicted date for a roll change.

Jochen Honold, Product Manager for mechanical roll service at Voith, sums up the benefits for the customer: “This global innovation guarantees scheduling that is based on facts and therefore reduces the risk of an unexpected roll failure, which in turn avoids unnecessary costs. The customer has enough time to plan the shutdown and ensure that sufficient personnel are available to change the roll. In addition, a time window can already be booked for the roll service in a Voith Paper roll service center. This allows spare parts to be ordered in advance and the roll gets back to the customer much sooner.”

Voith’s intelligent wear monitoring system with fact-based scheduling of any necessary replacement represents a completely new procedure for planning preventive roll changes. Until now, changes have almost always been done on the basis of empirical values which do not, however, take account of the actual condition of the rolls. The main reason for this is that following installation of the wear parts it is not possible to check their condition at all, or only with a great deal of effort. This is why the decision-making procedure has been based on historical data and process or roll irregularities. The result is that in many cases, a roll is replaced even though the sealing strip system could have been used for longer. Thanks to the real-time data transmitted by the Voith Seal Wear Monitoring system, paper producers and maintenance providers can now decide on the timing of a replacement based on factual evidence. In practice, this allows the possible wear potential to be exhausted and therefore provides the option of extending service life with minimal risk of breakdown. Swiss papermaker Model is expecting the best case scenario to be a doubling of service life.

But even if the sealing strip wears sooner than expected, having real-time data now ensures that such events can be identified and predicted, allowing the operator to rectify them in good time. Seal Wear Monitoring therefore helps in any case to minimize the risk of a failure of the suction roll and consequently, a costly production downtime. Because the replacement is planned, Model can also produce a long-term schedule for its servicing activities and order all necessary spare parts at exactly the right time.

Moreover, the patented system is compatible with Voith’s HydroSeal sealing strips which can reduce the lubrication water consumption of the suction roll by up to 87%. The system can be readily installed in all suction roll types regardless of age and manufacturer.

Model produces packaging solutions from solid and corrugated board at 12 sites in Europe, including the home of the PM 3, the Niedergösgen production facility in the canton of Solothurn. The PM 3, on which the innovative system was installed, produces 215,000 metric tons per annum corrugated baseboard with basis weights of 120 to 170 g/m2 from recovered paper on a working width of 5,200 mm.

The Seal Wear Monitoring system is a product from Voith’s Papermaking 4.0 range, which allows paper machine efficiency to be increased through visualization, stabilization and optimization. The focus is on a modular concept that can be tailored individually to the needs of each customer and is independent of any existing process control system and the age of the machine.

About Voith Paper

Voith Paper is a Group Division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

Valmet to supply a demonstration scale plant for next generation dissolving pulp cooking to Sappi in South Africa

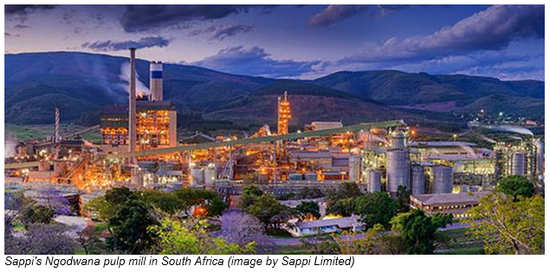

Valmet will supply a dissolving pulp cooking demonstration plant to Sappi in South Africa to explore and optimize the extraction of biorenewable chemicals. The plant will be close to industrial size and is located at Sappi's Ngodwana mill. The demonstration plant will make it possible to study the next generation dissolving cooking process and test new ideas in mill scale. Start-up of the new plant is scheduled for the beginning of 2017.

The order is included in Valmet's second quarter 2016 orders received. The value of the order will not be disclosed.

In this project Sappi and Valmet will together take the next step in dissolving pulping and explore new revenue possibilities in the dissolving pulp production. These new revenues include possibilities to extract bio-based materials from the cooking plant pre-hydrolysate stream such as sugars and lignin to beneficiate to higher value bio-chemicals.

"This investment in new technology continues to support Sappi's strategic direction of seeking new bio-based opportunities and at the same time will generate a platform with associated benefits for further increased volumes and quality of dissolving wood pulp," noted Andrea Rossi, Sappi's Group Head Technology.

"We are very pleased that Sappi has selected Valmet as the supplier of the Ngodwana mill dissolving cooking demo plant. Our common target is to create the next generation dissolving pulp cooking concept which has the potential to be a game changer for our industry the coming years. The main features with the new concept are higher dissolving pulp quality, lower operating cost and a new optimized hydrolysate revenue stream. This project is in line with our R&D targets to provide advanced technologies and promote the use of renewable material. This will also further strengthen our market leadership position within dissolving pulp technology," says Lars Sjödin, Director at Valmet's Fiber Processing business.

Information about the customer Sappi

Sappi Specialised Cellulose is a division of Sappi Limited and sells dissolving wood pulp (specialised cellulose) to converters for a wide range of consumer products, but in particular for the manufacture of viscose staple fiber (VSF) for clothing and textiles. They are the world's largest manufacturer of dissolving wood pulp (from two mills in Southern Africa and the Cloquet Mill in North America) and export almost all of the production from their mills.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.