Ianadmin

Kotkamills’ Consumer Board products soon available across Europe

Kotkamills has formed its European sales network for their upcoming folding boxboard and barrier board products. With 13 sales representatives in over 30 countries, Kotkamills can now offer personal service through local presence all over Europe.

The newly formed sales network consists of 13 sales representatives covering over 30 countries. A local sales network is at the core of Kotkamills’ strategy, as its new consumer board machine is to start production later this summer in Kotka, Finland.

The network allows Kotkamills to be present where the customers are and to provide a local service.

“We have carefully chosen our sales representatives for our main market, where we are entering with our new FBB and barrier boards,” says Pirjo Eteläinen, Director of Kotkamills Consumer Boards.

According to Eteläinen, the key is to offer excellent local service to all customers, especially those who demand a quick and reliable service.

“It is crucial that our sales agents understand our product as well as the needs of our customers. We need to have proficient representatives to be able to communicate our new product range and to serve our customers in the best ways possible. We believe we have succeeded in building the right team.”

Many of the sales representatives are already familiar with Kotkamills’ paper customers. In the UK and Ireland markets, for example, Kotkamills Consumer Boards has now teamed up with Crossleys, with whom Kotkamills has cooperated since 2011.

“We are delighted to have been appointed as the UK and Ireland sales representative for the new Kotkamills Consumer Board products. Their unique technology and local service are definitely greeted with anticipation in the market,” says Jonathan Blundell, Sales Manager at Crossleys.

Kotkamills is investing over 150 million euros to convert its printing paper machine into consumer boards’ production. The new machine, starting production in the end of June, is a first of its kind. It will bring to the market board with dispersion barrier coating applied online with board production. This brings a fully recyclable, renewable and repulpable alternative to PE coated board.

Further information:

Pirjo Eteläinen, Director, Consumer Boards

tel. +358 5 210 1204

This email address is being protected from spambots. You need JavaScript enabled to view it.

About Kotkamills

Kotkamills is a responsible partner that delivers renewable products and performance to its customers’ processes via product innovations created from wood, a renewable raw material. Our key brands include Absorbex® and Imprex®, both innovative laminating paper products for the laminate, plywood and construction industries. Moreover, Kotkamills offers ecological, technically sound and visually attractive wood products for demanding joinery and construction. In summer 2016, Kotkamills will start-up a new cartonboard machine designed to produce folding boxboard and food service boards for consumer markets, including the capability to add barriers on-machine. All Consumer Boards material solutions will be fully recyclable and repulpable.

Kotkamills has two production sites in Finland, located in Kotka and Imatra, and a subsidiary L.P. Pacific Films for Imprex® production in Malaysia. The majority shareholder of Kotkamills is MB Funds, a Finnish private equity firm.

www.kotkamills.com

Tieto to support Ahlstrom’s IT transformation

Tieto and Ahlstrom into agreement for faster and agile response to Ahlstrom's business needs.

![]() The leading Nordic software and services company Tieto and global fiber-based materials company Ahlstrom have agreed to extend their long business relation and are now deepening the partnership in the area of order fulfillment services. With the agreement, Ahlstrom aims for improved and more effective end-to-end service management.

The leading Nordic software and services company Tieto and global fiber-based materials company Ahlstrom have agreed to extend their long business relation and are now deepening the partnership in the area of order fulfillment services. With the agreement, Ahlstrom aims for improved and more effective end-to-end service management.

Tieto will take the end-to-end responsibility for Ahlstrom’s order fulfillment services including the manufacturing execution system CarelMill and order-to-cash ERP system OrderPlan. Six employees in Finland, the UK, the USA and South Korea will transfer to Tieto on 1stof June 2016 with the same terms of employment as currently.

“Tieto and Ahlstrom have worked together more than 20 years. Ahlstrom has been transforming its IT function during the last two years. This agreement with Tieto enhances our partnership and further develops our capability to support the business. The co-operation will secure these key competences also in the future”, says Kristiina Lammila, CIO at Ahlstrom.

“We aim to become customers’ first choice for business renewal and are very proud of Ahlstrom’s continuous trust towards us in their own transformation. Our aim is to deepen our position as business transformation partner to companies in process industry”, says Henrik Reims, head of Forest business at Tieto.

For more information please contact:

Henrik Reims, VP, Tieto Forest, tel +358 40 515 5719, email This email address is being protected from spambots. You need JavaScript enabled to view it.

Kristiina Lammila, CIO, Ahlstrom Corporation, tel +358 40 801 9794, email This email address is being protected from spambots. You need JavaScript enabled to view it.

Tieto aims to capture the significant opportunities of the data-driven world and turn them into lifelong value for people, business and society. We aim to be customers’ first choice for business renewal by combining our software and services capabilities with a strong drive for co-innovation and ecosystems. www.tieto.com

Ahlstrom provides innovative fiber-based materials with a function in everyday life. We are committed to growing and creating stakeholder value by proving the best performing sustainable fiber-based materials. Our products are used in everyday applications such as filters, medical fabrics, life science and diagnostics, wallcovers, tapes, and food and beverage packaging. In 2015, Ahlstrom's net sales amounted to EUR 1.1 billion. Our 3,300 employees serve customers in 22 countries. Ahlstrom's share is quoted on the Nasdaq Helsinki. More information is available at www.ahlstrom.com

Kemira shortlisted in the EU Sustainable Energy Awards

Kemira's site in Helsingborg, Sweden has been shortlisted in the EU Sustainable Energy Awards 2016 for industrial symbiosis that facilitates sharing recovered energy from industrial processes.

Kemira's site in Helsingborg, Sweden has been shortlisted in the EU Sustainable Energy Awards 2016 for industrial symbiosis that facilitates sharing recovered energy from industrial processes.

Kemira's site in Helsingborg operates under the name of Industry Park of Sweden (IPOS). The business idea of IPOS is industrial symbiosis, which means that all businesses based in the industry park cooperate in order to achieve resource efficiency, reduce costs and to minimize their environmental impact. The site currently hosts around 20 different companies within chemical and food industry, logistics and service. All companies within the park collaborate around energy, material, utilities, logistics, infrastructure and services.

An important part of the industrial symbiosis is sharing of the recovered energy from Kemira's own processes. Today, 600 GWh of energy is recovered every year to replace the consumption of primary fuels not only for Kemira but also for the companies within IPOS and Helsingborg City. This recovered energy is the base load of the district heating network in Helsingborg, accounting for 1/3 of the total yearly heat demand.

As Kemira's recovered energy is produced by exothermal reactions and by heat recovery from product flows it does not generate any CO2 emissions. If the corresponding volume of energy were to be produced by for example natural gas, yearly emissions would be 120 000 tons CO2 per year.

"Our aim has been to create added value and to reduce costs and environmental impact by innovative cooperation", says Lennart Albertsson , Director, Pulp & Paper, Kemira Helsingborg.

The EU Sustainable Energy Awards recognize outstanding innovation in energy efficiency and renewables. Around 200 submissions for the 2016 Awards have been evaluated, and the nominees have been chosen from a shortlist of the year's most successful projects for clean, secure and efficient energy in three categories: Consumers, Businesses and Public sector. Three winners among nine nominees will be unveiled on 14 June as part of the 2016 EU Sustainable Energy Week (EUSEW) in Brussels.

For more information, please contact

Kemira Oyj

Lennart Albertsson, Director, Pulp & Paper, Helsingborg

Tel. +46 4217 1467

Tero Huovinen, SVP, Communications & Corporate Responsibility

Tel. +358 10 862 1980

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2015, Kemira had annual revenue of EUR 2.4 billion and around 4,700 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd.

www.kemira.com

International Paper to Acquire Weyerhaeuser's Pulp Business for $2.2 Billion

![]() International Paper (NYSE: IP) announced that it has entered into a definitive agreement to purchase Weyerhaeuser's pulp business. Under terms of the agreement, IP will acquire five pulp mills and two converting facilities that produce fluff pulp, softwood pulp, and specialty pulp for a number of consumer applications including diapers, other hygiene products, tissue, and textiles.

International Paper (NYSE: IP) announced that it has entered into a definitive agreement to purchase Weyerhaeuser's pulp business. Under terms of the agreement, IP will acquire five pulp mills and two converting facilities that produce fluff pulp, softwood pulp, and specialty pulp for a number of consumer applications including diapers, other hygiene products, tissue, and textiles.

- Compelling Transaction Will Strengthen IP's Position in Global Fluff Pulp Market

- Acquisition Offers Significant Synergies, Superior R&D Capabilities and Valuable Patent Portfolio

Because the transaction is a purchase of assets, International Paper expects to realize a tax benefit with an estimated net present value of approximately $300 million. Including this benefit, the net price is approximately $1.9 billion. International Paper forecasts annual synergies of approximately $175 million by the end of 2018, which will require the need for one-time costs of approximately $85 million.

"Weyerhaeuser's pulp business has an outstanding customer base served from low-cost, well-run assets that complement our existing system and offers significant synergy opportunities," said International Paper Chairman and CEO Mark Sutton. "This transaction will position us as the premier global supplier of fluff pulp and will enhance our ability to generate additional free cash flow. We look forward to working with the talented employees of Weyerhaeuser as we integrate our businesses and create an even stronger company."

Weyerhaeuser's pulp business has approximately 1900 employees throughout the U.S. (Mississippi, Georgia, North Carolina), Canada and Poland. The combined business will provide the company flexibility to manage a wide portfolio of products to meet customer needs.

The acquisition is expected to close in the 4th quarter of 2016, subject to certain closing conditions, primarily the receipt of regulatory approval.

International Paper (NYSE: IP) is a global leader in packaging and paper with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include industrial and consumer packaging along with uncoated papers and pulp. Headquartered in Memphis, Tenn., the company employs approximately 55,000 people and is strategically located in more than 24 countries serving customers worldwide. International Paper net sales for 2015 were $22 billion. For more information about International Paper, its products and stewardship efforts, visit www.internationalpaper.com

SOURCE International Paper

Minerals Technologies Signs 25th Commercial Agreement for Fulfill® High-Filler Technology

Agreement with Prestigious Paper Company in China Will Lower Papermaking Costs by Reducing Fiber Consumption

Minerals Technologies Inc., (NYSE: MTX) have just announced that it has entered into a commercial agreement with another leading paper company in China to provide Fulfill® E-325 higher filler technology, which allows papermakers to produce quality paper at lower cost by replacing higher-cost fiber with precipitated calcium carbonate (PCC).

"Our FulFill® portfolio of high-filler products continues to gain acceptance by papermakers around the world, and we are extremely pleased that this prominent papermaker in China, who wishes to remain unnamed for competitive reasons, is adopting the cost-saving technology," said Joseph C. Muscari, chairman and chief executive officer.

"Our FulFill® portfolio of high-filler products continues to gain acceptance by papermakers around the world, and we are extremely pleased that this prominent papermaker in China, who wishes to remain unnamed for competitive reasons, is adopting the cost-saving technology," said Joseph C. Muscari, chairman and chief executive officer.

Minerals Technologies now has 25 agreements with paper mills that have adopted the FulFill® technology introduced in late 2010. The company now has 10 agreements with paper companies in Asia; eight in North America; six in Europe; and one in South America. The Fulfill® E-325 series allows papermakers to increase PCC loading levels by three to five points, replacing higher cost pulp and increasing PCC usage between 20 and 30 percent.

"The commercial validation of our Fulfill® high-filler portfolio of products by major papermakers worldwide confirms the continued acceptance of the Fulfill® technology," said W. Rand Mendez, senior vice president & managing director, Paper PCC. "In addition to the 25 commercial agreements we now have, MTI is also actively engaged with 19 additional paper mills that are interested in FulFill®."

PCC is a specialty pigment for filling and coating high-quality paper. By substituting PCC for more expensive wood fiber, papermakers are able to produce brighter, higher quality paper at lower cost. Minerals Technologies originated the satellite concept for making and delivering PCC on-site at paper mills, and the concept was a major factor in revolutionizing North American papermaking from an acid to an alkaline-based technology. Minerals Technologies constructed its first PCC satellite plant in 1986. Today, the company has 62 satellite plants in operation or under construction around the world and continues to lead the industry with consistent quality and technical innovation.

New York-based Minerals Technologies Inc. is a resource and technology based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral based and synthetic mineral products and related systems and services. MTI serves the paper, foundry, steel, construction, environmental, energy, polymer and consumer products industries. The company reported sales of $1.798 billion in 2015.

For further information about Minerals Technologies Inc. look on the internet at http://www.mineralstech.com/

ANDRITZ successfully starts up tissue machine with steel Yankee for St. Croix Tissue, USA

International technology Group ANDRITZ has successfully completed the start-up of the first of two supplied PrimeLineTM W8 tissue machines with steel Yankees at the St. Croix Tissue mill in Maine, USA.

The machine has a design speed of 2,000 m/min and a width of 5.6 m. The Yankee is manufactured entirely of steel and has a diameter of 18 ft. It enables efficient drying at minimized energy costs and a safe operation.

Preparations are underway for start-up of the second ANDRITZ tissue machine supplied to St. Croix Tissue, which is scheduled for end of July 2016. Both machines have an aggregate capacity of 126,000 t/y for the production of hygienic papers and napkin tissues.

This successful start-up again confirms ANDRITZ PULP & PAPER’s position as one of the global market leaders for supply of complete tissue production lines, key components, and services.

What Does It Take to Move Pulpwood from Western Russia to Scandinavia by Water?

As many of you know, Forest2Market recently started operating in Europe and western Russia. We have named the new product the Baltic Rim/Russia Timber Price Index, which basically covers Scandinavia, the Baltic States, Poland and western Russia. On a recent trip to western Russia, I visited with some of the new customers, as well as potential customers of the benchmark service, and of course learned some very interesting things about the regional market.

The last week of February, I toured Karelia Oblast. Our home base was Petrozavodsk, which is the capital city of the Republic of Karelia, Russia—an area that stretches along the western shore of Lake Onega for some 27 kilometers. Petrozavodsk is very pleasant town with a population of about 250,000, and our hotel was situated right on Lake Onega. As a point of reference, Lake Onega is a large lake of US Great Lake scale; it is only diminutive to its neighbor lake to the west called Lake Lagoda.

Everyone in this business knows that a substantial amount of wood fiber moves from western Russia to Finland via truck and/or a combination of truck and rail. I was eager to talk about this trade with our new and prospective customers, and was hopeful to understand these supply chains a bit better.

Then on an early afternoon walk one day, I encountered a log vessel firmly entrenched in the ice of Lake Onega. This vessel was at port and not stranded—or at least not stranded at sea.

Luckily, the gentleman I was meeting the next day was a large leaseholder of Russian timber, and I aimed to ask him about the vessel. Even more fortuitously, during our meeting I learned that the vessel was actually one that he used to move low-grade pulpwood to customers in Sweden, which is some 1600 km away.

This particular leaseholder has a port loading facility on the east side of Lake Onega where wood is trucked from up to 250 km away and loaded on the aforementioned log vessel for the journey across Lake Onega. The vessel then passes through a series of canals and channels to Lake Lagoda, through yet another series of canals and channels past Saint Petersburg port before hitting the Baltic Sea, where it sails unimpeded before finally reaching a port in southeastern Sweden.

This whole experience—the visit to Russia and the involvement of starting the Baltic Rim/Russia Timber Price Index has really opened my eyes to the extent to which the industry goes, and can go, to transport wood long distances, as well as the effect that exchange rates have on these wood flows. The US dollar to Ruble exchange rate at the time of my visit was about 80 to 1. The last time I visited Russia—about 10 years ago, it was roughly 16 to 1.

Obviously, at this exchange rate and with the Russian economy stumbling, there is great incentive to export anything of any value. As the world gets smaller and governments and economies grow larger (and fail on larger scales), we will continue to see these wild fluctuations in exchange rates. These vast swings will open up market opportunities that are simply unimaginable now.

Finding those opportunities will be a challenge for all of us in the forest products industry moving forward, which is one of the reasons Forest2Market started the Baltic Rim Index as a complement to our North American and Latin American Indexes. It will provide clear and transparent market data to our global customers regardless of the market conditions, currency fluctuations or political climate.

source. forest2market.com

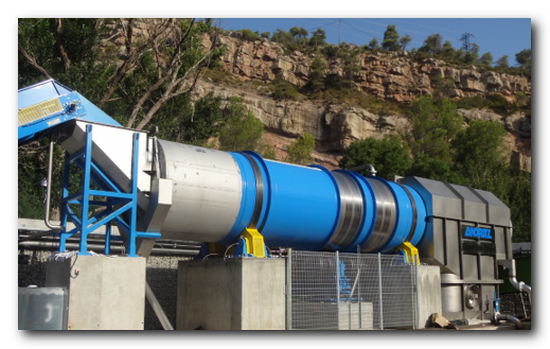

Successful start-up of ANDRITZ FibreFlow drum pulper at ISMA 2000

International technology Group ANDRITZ successfully started up a FibreFlow drum pulper, type FFD225, for the Spanish tissue manufacturer ISMA 2000 S.L.

ANDRITZ FibreFlow drum pulper FFD225 at ISMA 2000 S.L., Spain Photo Andritz

The new drum pulper processes various recycled fiber materials and is designed for a feed capacity of 120 t/d. It has replaced an existing conventional pulper in order to raise the pulp quality for production of premium tissue products. The scope of supply also included engineering services as well as installation supervision, start-up, and commissioning support.

ISMA 2000 produces its environmentally-friendly tissue papers - sold under the name Ismax – from 100% recycled paper, ranging from mixed and sorted office waste and colored ledger to various card and paper board grades as well as packaging and laminated paper. For these raw materials, the reject content to be removed by the pulper ranges from two to 20 percent. The ANDRITZ FibreFlow drum FFD can flexibly handle this wide range of fiber sources at lowest energy consumption and maximum yield.

With the ANDRITZ FibreFlow drum pulper technology, a variety of cheaper waste paper raw material composites can be used, without compromising the performance of pulping and paper production. The new design of the FibreFlow drum pulper type FFD225 enables a reduction of the installed power for the pulping process as well as paper producers to use raw material mixtures from UBC (used beverage cartons) and polyethene-coated papers to OCC (old corrugated containers) and office waste grades.

Stora Enso inaugurates next generation Varkaus Mill in Finland

Finnish Minister of Agriculture and the Environment, Kimmo Tiilikainen, today joined Stora Enso at the official inauguration of a containerboard machine and a wooden building element production line at the Varkaus Mill.

Stora Enso has successfully converted a fine paper machine at Varkaus Mill to produce virgin-fibre-based containerboard. Stora Enso invested EUR 110 million in the conversion work, which took place in 2015. Kraftliner production began in October 2015 and full production is expected in early 2017. The capacity of the Varkaus Mill will be about 390 000 tonnes of light-weight kraftliner per year.

Moreover, Stora Enso has built a new production line in Varkaus Mill that will make wooden building elements, laminated veneer lumber (LVL). The investment of EUR 43 million will further enhance Stora Enso’s position as a global provider of high quality engineered wooden elements. The production is scheduled to begin in June 2016, and the estimated yearly capacity will be around 100 000m3.

“Both investments in Varkaus are part of Stora Enso’s transformation into a customer-focused renewable materials company,” says Karl-Henrik Sundström, CEO of Stora Enso. “By converting the fine paper mill into a kraftliner mill we are responding to the increasing global market need for renewable packaging, while the new LVL production line will meet the growing need for sustainable wood products for construction and industrial applications.”

The renewed mill directly employs some 400 people and the estimated total employment impact for the Varkaus region is 1 600 FTEs. The investments in Varkaus will increase the demand for softwood raw material by about 1.3 million cubic metres.

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Our aim is to replace fossil based materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 26 000 people in more than 35 countries, and our sales in 2015 were EUR 10.0 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market. storaenso.com

Paper manufacturer signs up for Siemens total approach to complex turnkey project

Siemens installs new drives and software at Stora Enso Langerbrugge

Ghent paper manufacturer Stora Enso Langerbrugge is relying on Siemens expertise and solutions to replace the drives and machine control system for one of its paper machines. Siemens will carry out the installation later this year in June.

Stora Enso attaches great importance to recycling material and developing and using renewable energy. So the Ghent company chooses biomass as a source of energy for its production processes, and what’s more continuously invests in its machinery in search of more sustainable solutions. That is why Siemens has now been engaged to provide one of the paper machines with new drives and to replace the existing machine control system.

Stora Enso attaches great importance to recycling material and developing and using renewable energy. So the Ghent company chooses biomass as a source of energy for its production processes, and what’s more continuously invests in its machinery in search of more sustainable solutions. That is why Siemens has now been engaged to provide one of the paper machines with new drives and to replace the existing machine control system.

Chris De Hollander, Managing Director of Stora Enso Langerbrugge:

“We are opting for Siemens expertise because they provided a great deal of positive input in the project to create the most efficient solution that was within our budget. Siemens came to the table with a small but efficient team that took decisions rapidly during the negotiations and provided support where needed.”

Complex turnkey project

“We are proud that Stora Enso has chosen Siemens to bring this project to a successful conclusion”, says Christian Hacken, execution manager of Siemens’ Fiber Industry department. “It’s a complex order in which a lot is involved. Firstly a very specific new machine guideline must be implemented as regards integrated safety for people and machinery (EN1034). Secondly the upgraded machine, which will now run on our SIMATIC PCS 7 software, will also have to be able to communicate with existing ABB protocols of other devices in the company, including AF100-bus.”

Stora Enso produces no less than 555,000 tonnes of recycled newsprint and magazine paper annually with the help of two paper machines. When a paper machine is brought to a halt, every second counts. So besides the complexity of the system, the short time span in which everything must be completed is of crucial importance. “This is a complex turnkey project”, says Tommy Wagemans, business segment manager of the Fiber Industry department. “To minimize downtime we have to be able, in the space of just one week, to deliver and install the necessary components and then get the paper machine up and running again. Considering the size of the system, this is a challenging order.”