Ianadmin

Getting ready at Beihai Mill

Stora Enso has two paper mills in China, as well as core factories, production and distributing units through the packaging company Inpac. The Beihai consumer board mill project is the first time the company has started building a mill on an empty field in China.

Stora Enso’s large-scale mill construction project of a consumer board mill in Beihai, Guangxi region, China, is getting closer to completion. The board machine is expected to be operational in the second quarter, and the project is proceeding according to plan.

The idea of establishing a complete production chain in Guangxi, from raw material to end product, came in 2006. Already, Stora Enso had been establishing sustainable eucalyptus plantations in Guangxi since 2002. Then in 2012, we announced the plan to build a world-class integrated consumer board mill in China, to provide excellent service with cost-competitive, locally produced high quality liquid packaging boards on a regional basis for global key customers.

Today, the Beihai Mill is well underway.

More than a machine

A project like this is not only about building a mill, although that in itself is a massive operation with thousands of employees and contractors on-site. It is also about recruiting the most capable work force in China, ensuring training and knowledge-sharing between Beihai Mill and Stora Enso’s Nordic mills, mapping the markets in-depth, planning sales, strengthening customer relations, and preparing for the best logistics routes and partners for deliveries. Naturally, it is important that all the sales and support functions are set when the consumer board machine goes operational.

Jari Latvanen, Executive Vice President, Division Consumer Board stresses the significance of the project: “The Beihai operations will add considerable value to our business in Asia. We see great opportunities for growth and building on our relationships with key customers in high quality end-uses.”

An important part in the project has also been to make Stora Enso better known in the surrounding communities and to cooperate with local authorities, universities, organisations and villagers to find long-term sustainable solutions for development.

During 2015, the progress in the mill construction was tremendous. It is even more impressive considering the high level of work safety that Stora Enso has been able to instill. In October 2015, the project could celebrate 10 million working hours without Lost Time Accidents, contractors included.

When ready, this state-of-the-art mill will have the capacity of 450 000 tonnes consumer board per year.

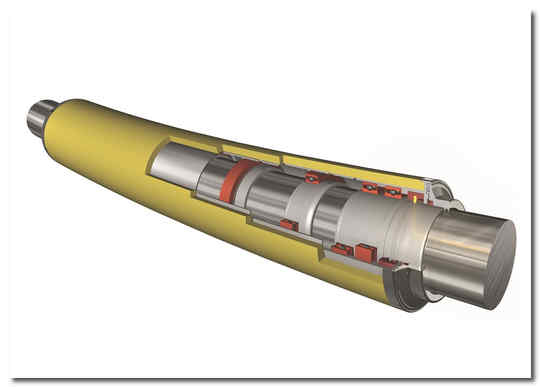

Innovative spreader roll technology from Voith: EvoStretch and SolarStretch

With the EvoStretch spreader roll, Voith has launched a new model at the start of the year that offers significantly longer service intervals than standard spreader rolls. The newly developed EvoStretch high-performance bearings feature one or two ceramic balls as well as the usual steel balls, giving each bearing a special self-repairing effect. The ceramic balls remove contaminants, smooth the contact surfaces and thus have an integrated polishing function. This ’self-healing effect’, proven in close cooperation with a well-known ball bearing manufacturer, clearly slows bearing wear and substantially reduces servicing costs.

The StretchUp Service from Voith is the roll service tailored to spreader rolls. As part of the StretchUp Service, it is now possible to upgrade spreader rolls of all manufacturers to use the EvoStretch bearings. Handling the roll service through Voith’s central service center in Laakirchen, Austria ensures short transport paths and delivery times and thus also saves costs.

Voith has now also successfully developed a further spreader roll component to increase service life: The market leader in high-performance roll covers made from polyurethane now also offers SolarStretch polyurethane sleeves for spreader rolls. SolarStretch features abrasion resistance that is twice as effective as standard rubber sleeves and can also be supplied in a variety of surface designs.

Increased abrasion resistance significantly extends service intervals and thus ensures continuous availability of the spreader rolls.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith industrial Services.

Suzano Papel e Celulose contracts with Voith to deliver two tissue paper machines

![]() Suzano Papel e Celulose has contracted with Voith to deliver two tissue machines. The machines will be installed at the company's Imperatriz and Mucuri locations. The machine located in Imperatriz is scheduled for start-up in June 2017, whereas the one located in Mucuri is expected to go on-line in September 2017.

Suzano Papel e Celulose has contracted with Voith to deliver two tissue machines. The machines will be installed at the company's Imperatriz and Mucuri locations. The machine located in Imperatriz is scheduled for start-up in June 2017, whereas the one located in Mucuri is expected to go on-line in September 2017.

Voith will be responsible for supplying the complete tissue lines, which will be equipped with NipcoFlex T shoe presses and the EcoChange system to allow a reliable reel spool change. Within the Process Line Package Voith provides the machines and also the supply of all the auxiliary equipment and services. Once completed each machine will have a manufacturing capacity of nearly 220 metric tons of paper daily, at a speed of 2,000 meters per minute.

"The customer's choice of Voith for this project is extremely important, since it underscores both companies' long-term partnership. There is currently a strategic expansion at Suzano. This is the company's first project in the tissue segment,” said Flávio Silva, President for Voith Paper South America.

Suzano Papel e Celulose is a forestry-based company and one of the largest producers of pulp and paper in Latin America. Its annual production capacity amounts to 4.7 million metric tons of paper and pulp.

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

Major investment in Mörrum

On 16 February, the Board of Directors of Södra decided to invest SEK 1 billion in the pulp mill at Mörrum. The investment is the second stage of a long-term initiative at Södra Cell Mörrum, and will increase the mill's capacity by 45,000 tonnes.

"This is great news for us here at the mill, because our competitiveness and opportunities will increase. Södra's decision to invest in Mörrum is also important for the region," says Stefan Sandberg, Site Manager at Södra Cell Mörrum.

This particular investment includes a new evaporator, and a modernisation of the brown stock washing system in the dissolving pulp line, where pulp for textile uses is produced. A new evaporator will make it possible to increase the production rate, as well as deliveries of energy products, such as electricity, district heating and biofuels. The new investment will increase production capacity by 45,000 tonnes, bringing the total production of paper and dissolving pulp to 470,000 tonnes.

"The investment will allow us to meet customer demands for both paper and dissolving pulp. Our facility at Mörrum produces high-grade pulp with unique properties. We will now be able to offer higher volumes of these sought-after products to the market. In addition, dissolving pulp and paper pulp based on a renewable source are highly interesting from a climate perspective. More and more people are beginning to see the significance of finding materials that facilitate the transition toward a fossil-free society," says Stefan Sandberg.

The project will commence in spring 2016 and is scheduled for completion by November 2017.

For comments:

Stefan Sandberg, Site Manager at Södra Cell Mörrum,

+46 (0)70-638 78 78

Archroma enforces further its newly patented OBA technology

Archroma, a global leader in color and specialty chemicals, today announced that it has entered into a license agreement with Igcar, a Spain-based group producing optical brighteners for the paper, textile, detergent and coatings industry. The agreement provides Igcar with access to Archroma’s patented “improved optical brightening compositions” technology (patent family WO 2009/118247). This patent has been granted in many countries, and in Europe was confirmed after appeal.

- Archroma enters into a license agreement with Igcar for its newly patented OBA technology

- “Cease and desist” orders sent to suppliers using the technology without Archroma’s permission

The Optical Brightening Agent (OBA) technology developed by Archroma combines magnesium salts with optical brighteners. Papers treated with the patented process show enhanced brightness and whiteness levels, offering consumers a more pleasurable writing and printing experience. The patent covers mixed salts of most of the common paper optical brighteners with magnesium cations.

The Optical Brightening Agent (OBA) technology developed by Archroma combines magnesium salts with optical brighteners. Papers treated with the patented process show enhanced brightness and whiteness levels, offering consumers a more pleasurable writing and printing experience. The patent covers mixed salts of most of the common paper optical brighteners with magnesium cations.

Archroma follows standard business practice in defending and respecting patents and has recently issued “cease and desist” orders to several OBA suppliers whose products have been shown by independent analysis to infringe its proprietary technology.

Valerie Diele-Braun, President Paper Solutions at Archroma, said: “Archroma strives to offer innovation to our customers and partners. The license agreements announced today recognize the value that our innovations add to paper to benefit paper makers and end-users whilst protecting our property rights.”

Cyclus is poster child for Jacknife and Arjowiggins graphic collaboration

Arjowiggins Graphic, the leading manufacturer of recycled papers, and Antalis UK, a distributor of the Cyclus range, have launched a new creative campaign to showcase the quality of Cyclus paper as a poster application. The campaign centres on a creative collaboration with Jacknife studios, the company behind iconic gig and tour posters for bands including Blur, Queens of the Stone Age and the Foo Fighters.

Jacknife founder and lead designer, Chris Hopewell, has produced a bespoke, limited edition striking poster inspired by the forest and designed to showcase the quality of Arjowiggins Graphic leading 100% recycled range, Cyclus. The poster, known as ‘The Guardian’, will be hand silk screen printed by Jacknife on CyclusOffset 300gsm 100% recycled in a limited edition.

Chris Hopewell says: “To capture the qualities of Cyclus I chose a figurative design, featuring a non-aggressive guardian at the entrance to a forest. Her look is both ancient and modern. She is young but wise and holds the future in her hands.”

As part of the campaign, the limited edition prints of The Guardian will be distributed to designers, who, along with the broader design community, will also be invited to enter a poster design competition by designing a poster of their choice and posting this on instagram or twitter using #cycluspaper to be automatically entered. The winning poster, judged by Chris Hopewell, will be hand silk screen printed by Jacknife, framed and awarded at the Antalis Review at The Village Underground in Shoreditch on 29th September 2016.

Commenting on the campaign, Angela De Vorchik, Operational Marketing Manager, Arjowiggins Graphic UK says, “This Cyclus campaign is one of our most ambitious yet. We want to creatively inspire the design community to consider using recycled paper to add something unique and environmentally sustainable to their designs. We are very proud to work with Jacknife who are the perfect partner to showcase how Cyclus can be used in printing and to inspire other designers.”

Mike Bennett, Marketing Manager, Antalis UK says, “We are proud to be stockists of Cyclus. The superb quality allows designers to have their work represented in the highest quality finish without compromising their environmental credentials.”

About Arjowiggins Graphic

Arjowiggins Graphic is a leader in the development of innovative environmental paper solutions, offering consistently high quality coated and uncoated recycled papers. The branch is part of Arjowiggins, the world's leading manufacturer of creative high-tech materials and papers. With over 4,000 employees and 20 paper mills around the world, Arjowiggins generates sales of around €1 billion. Arjowiggins is the manufacturing arm of Sequana

About Cyclus

Cyclus is a highly sustainable, 100% recycled paper with FSC® Recycled certification*. Made without optical brightening agents (OBAs), it has an authentic natural appearance, yet offers the printing performance and texture of a modern virgin fibre paper. Cyclus is available in uncoated (CyclusOffset), coated (CyclusPrint), inkjet (Cyclus Jet Premium) and envelope (CyclusEnvelope) varieties, all in a uniquely subtle natural shade.

*FSC® Recycled Certified fibres for sheets, available on request for reels

About Antalis

Antalis is one of the leading distributors of communication support materials in the UK and Ireland. Their market leading range of over 13,000 products includes papers, envelopes and consumables, as well as packaging, promotional and visual communication products. Antalis has 16 logistic centres across the UK and Ireland.

Antalis is the leading paper, packaging and visual communications merchant in Europe. As number 2 worldwide with a turnover of 2.585€ billion in 2014, the Group employs 5,585 people serving over 120,000 clients, companies and printers, in 44 countries via their 118 distribution centres. Antalis carries out 14,000 deliveries each day in the world and distributes 1.8 million tonnes of paper per year on a global level. Antalis is the distribution branch of Sequana.

Antalis and Arjowiggins are fully owned subsidiaries of Sequana

About Jacknife:

Jacknife first started producing hand screenprinted gig posters back in 2006 when founding member Chris Hopewell visited Flatstock at SXSW in Austin, Texas. He was so impressed by the work he saw there that he went straight home and bought an old French screenprinting deck. At that point Chris was making music videos so he had a whole bunch of contacts in the industry.

Over the last nine years Jacknife have produced gig and tour posters for hundreds of bands including Queens of the Stone Age - Wilko Johnson and Roger Daltrey - Beirut - Midlake - the Horrors - Eagles of Death Metal – Black Rebel Motorcycle Club - Blur - Spinnerette - Brody Dalle – to name but a few.

Founding Chris Hopwell ran a production company Collision Films for ten years producing and directing over a hundred music videos. He’s now independently directing commercials, music promos and feature films.

Chris has worked with all the major record labels as well as the coolest indies and has been lucky enough to work with some of the most outstanding acts of the last decade, including The Killers, Radiohead. Franz Ferdinand, The Knife, Scissor Sisters, Graham Coxon and The Offspring. In 2003 he won MTV’s Moon Man award for best art direction in Radiohead’s “There, there” a video which he also directed/ It also picked up Video of the Year at the NME awards that same year and about 30 Silver Pencils.

www.jacknifeprints.com

www.chrishopewell.com

ABB to power the world’s most energy efficient pulp mill

ABB to power the world’s most energy efficient pulp mill, generating more than double the power it consumes

The first mill to operate fully free from fossil fuels will increase the share of renewable energy in Finland by more than two percent

ABB will supply the complete power and process electrical systems for Metsä Group’s new bioproduct mill in Äänekoski in central Finland, opening in 2017. The mill will produce 1.3 million tonnes of pulp per year and bioproducts such as tall oil, turpentine, lignin products, bioelectricity and bark-based solid fuel.

ABB will supply the complete power and process electrical systems for Metsä Group’s new bioproduct mill in Äänekoski in central Finland, opening in 2017. The mill will produce 1.3 million tonnes of pulp per year and bioproducts such as tall oil, turpentine, lignin products, bioelectricity and bark-based solid fuel.

ABB’s pioneering technology solutions will support the mill to maximize its bioenergy production and thus, increase the share of renewable energy in Finland by more than two percent. Using over 1,000 of the most advanced energy efficient motors and state-of-the-art power systems the mill will produce 2.4 times more electricity than it consumes. The mill is designed to produce 1.8 terawatt hours of electricity annually, representing 2.5 percent of the electricity produced in Finland today. The orders are worth over $30 million, the majority has been booked in the last half of 2015.

“We have long experience of good cooperation with ABB. Their wide product portfolio, project expertise and high degree of domestic content affected most our decision”, said Timo Merikallio, project director of Metsä Group’s bioproduct mill.

“We are extremely happy that we can participate in the largest investment in history of the Finnish forest sector with our expertise and products,” said Tauno Heinola, Managing Director ABB Finland. “Our products will be part of ensuring the mills’ high availability, reliability and efficient production, as well as their energy efficiency, fully in line with our company`s Next Level strategy.”

ABB (http://www.abb.com) is a leading global technology company in power and automation that enables utility, industry, and transport & infrastructure customers to improve their performance while lowering environ-mental impact. The ABB Group of companies operates in roughly 100 countries and employs about 135,000 people.

Valmet to supply a paper machine wet end rebuild for Sappi's Kirkniemi mill in Finland

Valmet will supply a paper machine wet end rebuild for the Kirkniemi mill of Sappi Finland Operations Oy in Finland. The start-up of the rebuilt machine is scheduled for the fourth quarter of 2016.

The order is included in Valmet's first quarter 2016 orders received. The value of the order is not disclosed. A project of this type and scope is typically valued at approximately EUR 10-15 million.

"We have worked with Valmet for a long time, and the cooperation has been very good. Valmet is familiar with our paper machine and they know its potential. These are important factors when choosing a supplier. We wanted to have a reliable partner with good technical solutions," says Martti Savelainen, Mill Manager from Sappi.

"This new project is the third major rebuild for Sappi (Alfeld PM 2and Gratkorn PM 11) in just a few years. Our personnel is very familiar with the Kirkniemi machine, and our knowhow on the process and technical solutions are optimal for printing grades. By combining our experience and expertise, we were able to come up with a solution that met the customer's targets well, and we are pleased that Sappi chose Valmet for this rebuild project," says Petri Paukkunen, Vice President, Paper Mills Sales and Marketing, Valmet.

Information about the customer Sappi

Sappi is a global company focused on providing dissolving wood pulp, paper pulp and paper-based solutions to its direct and indirect customer base across more than 100 countries. Sappi produces approximately 5.7 million tons per year of paper, 2.4 million tons per year of paper pulp and 1.3 million tons per year of dissolving wood pulp.

Kirkniemi Mill has been a front runner in developing light-weight publication papers for demanding end-uses. Today, the mill's three paper machines produce coated papers for heat set web offset printing to customers around the world.

For further information, please contact:

Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills, Valmet, tel. +358 40 744 8182

Pekka Turtinen, Senior Sales Manager, Sales and Marketing, Paper Mills, Valmet, +358 40 770 7649

Toscotec S.p.A. attracts an investment by Synergo SGR to accelerate its growth

![]() Sinergia II, a closed-end fund managed by Synergo SGR (“Synergo”), has acquired a minority stake in Toscotec S.p.A. (“Toscotec” or the “Group”); the Mennucci family will remain as majority shareholder.

Sinergia II, a closed-end fund managed by Synergo SGR (“Synergo”), has acquired a minority stake in Toscotec S.p.A. (“Toscotec” or the “Group”); the Mennucci family will remain as majority shareholder.

Toscotec is a world leader in the design and production of turnkey plants and machines, as well as a first class supplier for components and services dedicated to the global paper and tissue industries. With innovative technological process solutions and a wide products portfolio the Group has gained, through the years, a significant position in the worldwide market.

Synergo aims to support Toscotec further growth, both organically and through selective strategic add- on acquisitions.

The Group, based in Lucca, Italy, has doubled the EBITDA since 2011, and recorded over €100 million in total revenues in 2015, out of which approximately 90% generated abroad.

Alessandro Mennucci, shareholder and CEO, with an experience of more than 20 years in the industry, will continue to lead the Group. Mr. Mennucci commented: “As of today, the Group has been able to build a strong brand in terms of quality and reliability, and has become one of the leading companies in the global reference market. With this new “synergy” we will have the possibility to further enhance our organization and strengthen our business activity worldwide. We want to continue to develop high technology products and to export the Italian excellence, providing first class services to our customers”.

Paolo Zapparoli, Synergo CEO, further explained: “It is a real pleasure to partner with Toscotec and its shareholders; the undisputed technological capabilities that the Group has developed over the years offer the opportunity to further extend its leadership in its reference industry. We look forward to working closely with Alessandro Mennucci and his management team to fulfil Toscotec’s growth ambition”.

Toscotec was advised by Ethica Corporate Finance (financial advisor), Mazzoni, Regoli, Cariello ePagni (legal advisor), and Studio Lazzarini.

Synergo was advised by Lombardi Molinari Segni (legal advisor), PwC (financial due diligence), Poyry (business and market due diligence), and Ciro Cornelli, name partner of Cornelli Gabelli e Associati (tax advisor).

About Toscotec

Toscotec is a turnkey supplier to the global paper and tissue industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects, and individual machineries. Headquartered in Lucca, the nerve center of the Italian paper district, with offices in China and North America, the Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities. Key to the Group’s success is the machineries’ innovation and energy saving, and the partnership with customers. Toscotec currently employs approx. 180 people.

Additional information is available at www.toscotec.com

About Synergo SGR

Synergo SGR is a private equity firm. Fully owned by its Senior Partners, Synergo specializes in partnering with ambitious entrepreneurs and managers in order to increase the value of their companies by providing financial resources and managerial guidance.

Additional information is available at www.synergosgr.com

Stora Enso’s Annual Report 2015 published

Stora Enso’s Annual Report 2015 is published today as PDF documents. Stora Enso’s Annual Report is comprised of four separate publications: the Progress Book 2015, the Sustainability Report 2015, the Financial Report 2015, and the Corporate Governance Report 2015.

Stora Enso’s Annual Report 2015 is published today as PDF documents. Stora Enso’s Annual Report is comprised of four separate publications: the Progress Book 2015, the Sustainability Report 2015, the Financial Report 2015, and the Corporate Governance Report 2015.

The Progress Book explains Stora Enso’s strategy, how we create value, and how our transformation is progressing. The publication is available in English, Finnish and Swedish. The Sustainability Report covers Stora Enso’s sustainability performance, following the Global Reporting Initiative G4 framework. The report is available in English.

The Financial Report consists of Stora Enso in capital markets, a summary of our sustainability performance, and the audited Report of the Board of Directors and financial statements. The Corporate Governance Report covers Stora Enso’s corporate governance policy, practices, and actions in 2015. The Financial Report and the Corporate Governance Report are available in English.

Printed publications will be published during the week commencing Monday 7 March 2016. The Progress Book 2015 will be distributed to shareholders registered with Euroclear Finland and Euroclear Sweden who have requested a copy. Printed copies of the Progress Book 2015 and the Financial Report 2015 can be ordered at storaenso.com/order or by sending an e-mail to This email address is being protected from spambots. You need JavaScript enabled to view it.. The Sustainability Report 2015 and the Corporate Governance Report 2015 are available as a PDF.

Stora Enso has today also published the following separate PDF documents:

- The official Financial Statements in Finnish

- English translation of the Parent Company Financial Statements for 2015

- Finnish translation of the Corporate Governance Report 2015

All of these publications and documents can be downloaded at the group’s website at storaenso.com/annualreport

For further information, please contact:

Ulrika Lilja, EVP, Communications, tel. +46 72 221 9228

Hanne Karrinaho, Head of Financial Communication, tel. +358 2046 21446

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Our aim is to replace non-renewable materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 26 000 people in more than 35 countries, and our sales in 2015 were EUR 10.0 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market. storaenso.com

Attachments:

Sustainability_Report_2015.pdf

Progress_Book_2015_ENG.pdf

Financial_Report_2015.pdf

Stora_Enso_Oyj_Parent_Company_financial_statements_2015.pdf

Corporate_Governance_Report_2015.pdf