Ianadmin

TM Systems - Key Supplier in the world's biggest pulp mill project

TM Systems is a key supplier in the world’s largest pulp mill project in OKI Pulp & Paper in South Sumatra, Indonesia. TM Systems delivers a mill-wide HVAC system to this massive project.

TM Systems is a key supplier in the world’s largest pulp mill project in OKI Pulp & Paper in South Sumatra, Indonesia. TM Systems delivers a mill-wide HVAC system to this massive project.

OKI Pulp & Paper Mill is a part of the Asia Pulp & Paper (APP) group. In this project APP is committed to use BAT - the best available technology.

OKI Pulp Mill will produce approx. 2 million tons of pulp a year. The total investment is 2,8 billion USD.

The HVAC system delivered by TM Systems in this project covers almost 70 special rooms, all of them having exceptionally strong requirements regarding heating, cooling and humidity control.

The delivery is based on a standardized modular HVAC system concept by TM Systems and it has been delivered to Sumatra in over 150 containers.

During its 40 years of operation, TM Systems has made hundreds of EPC (engineering procurement contracting) deliveries all over the world. This project is one of the biggest in size.

TM Systems has made several deliveries to APP in Indonesia and in China throughout the years. For example, in 1998, TM Systems made a large delivery to APP Dagang, world’s biggest paper mill at the time and, later, to Ningbo, world’s largest board mill at the time. TM Systems proven ability and commitment to run large EPC projects successfully has made APP convinced that TM Systems is the best partner also in OKI, APP’s flagship project of all times.

One of the main focuses of TM Systems throughout the years has been R&D especially in energy and production efficiency. In 2015, TM Systems published a study proving that the air systems delivered by TM Systems in China have increased the energy efficiency of paper manufacturing by 9%.

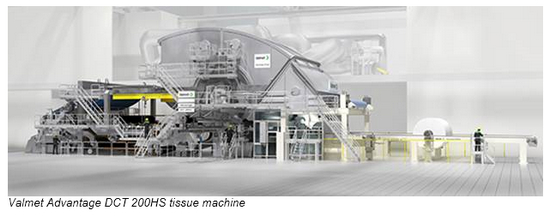

Valmet receives repeat order for two new tissue production lines from Lee & Man Paper Manufacturing in China

Valmet will supply two Advantage DCT tissue production lines and related automation systems to one of China's leading paper and pulp producers, Lee & Man Manufacturing Ltd. The new lines will be installed at Lee & Man's mill in Chongqing and start-up is planned to take place in late 2016.

The order is included in Valmet's first quarter 2016 orders received. The value of the order is not disclosed.

Continuation of good cooperation

The Valmet's Advantage DCT 200HS tissue lines to be delivered are designed for production of high quality tissue products. The new tissue lines will fulfill the high requirements for effective technology and sustainability set by Lee & Man. Previously the company has ordered three Advantage DCT 200HS tissue lines of which one started up at the Chongqing mill 2015 and two will start up this year.

"Our first installation in Chongqing is running very well and we are convinced that the Advantage DCT technology and the partnership with Valmet will support our market expansion in China," says Raymond Lee, Chairman of the Board, Lee & Man.

"It's an honor that Lee & Man have again decided to extend the cooperation which already includes three tissue machine deliveries to the Chongqing mill. As seen from the earlier installations, it is possible to reach significant drying energy savings and highest paper quality by our innovative combination of flexible pressing, casted Yankee and steam heated hood. With this combination we are able to bring concrete benefits to our customers and to take their performance forward,"says Svenerik Olsson, Director, Tissue Mills Business Unit, Valmet China.

Valmet's Advantage DCT concept is well established on the market and has proven to enable cost- and energy-efficient production of high quality tissue products.

Technical information about the delivery

The new tissue machines will have a width of 5.6 m and a design speed of 2,000 m/min. Each machine will produce 60.000 tons of toilet and facial tissue per year, using virgin wood pulp and bleached bamboo fiber as raw material.

Valmet's scope of delivery will comprise complete tissue production lines featuring stock preparation systems and Advantage DCT 200HS tissue machines. The machines will be equipped with OptiFlo headbox and cast alloy Yankee cylinders. The machines will also be featured with the well proven Advantage tissue technology including ViscoNip press, steam heated AirCap hood, WetDust dust system and a SoftReel P reel. Basic engineering, installation supervision, training, start-up and commissioning are also included

The delivery will also include Valmet's proven automation package including Valmet DNA machine and process control system (DCS) as well as Valmet IQ quality control system (QCS) and Valmet IQ Dilution Profiler. The automation package provides a single source solution, utilizing only one system to perform all the essential measurements and controls for tissue production.

About the customer Lee & Man Paper Manufacturing

Established in 1994, Lee & Man Paper Manufacturing Ltd has grown from a small company into a leading paper and pulp manufacturer. The company's 6,500 employees are located at the company's five production sites in China. The company had a capacity of 7 million tons of container board, duplex board and tissue paper as well as 180,000 tons of pulp in 2014.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

For further information, please contact:

Svenerik Olsson, Director, Tissue mills, China area, Valmet, Tel. +86 139 10171872

Krister Harnesk, Sales Manager, Tissue mills, Valmet, Tel. + 46 766 397543

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Brenntag expands specialty chemicals portfolio for the pulp & paper industry

Brenntag, the global market leader in chemical distribution, has signed an agreement with C-IP SA, Luxembourg, on the exclusive rights for the blending, sale and distribution of two innovative rheology modifiers. Both products, RheborTM Plus and Rhebor™ CB 6810, are exclusively distributed by Brenntag Holding GmbH worldwide, excluding North America and Mexico. Furthermore, Brenntag is taking over the blending of the products at its Duisburg site in Germany.

Brenntag, the global market leader in chemical distribution, has signed an agreement with C-IP SA, Luxembourg, on the exclusive rights for the blending, sale and distribution of two innovative rheology modifiers. Both products, RheborTM Plus and Rhebor™ CB 6810, are exclusively distributed by Brenntag Holding GmbH worldwide, excluding North America and Mexico. Furthermore, Brenntag is taking over the blending of the products at its Duisburg site in Germany.

Both RheborTM products are mainly utilized in the production of corrugated board and are newly developed, high-performance substances. Following the needs and requests of the industry and in order to comply with the REACH registration, the products are innovative alternatives for common products containing boron.

Uwe Schültke, COO Brenntag Europe, Middle East and Africa: “With this agreement, we are strengthening our specialty chemicals portfolio in the promising pulp & paper industry. In addition, we are increasing our successful blending business, and, finally, are expecting cross selling potential within our existing customer and product portfolio.”

About Brenntag:

Brenntag, the global market leader in chemical distribution, covers all major markets with its extensive product and service portfolio. Headquartered in Mülheim an der Ruhr, Germany, the company operates a global network with more than 490 locations in 72 countries. In 2014, the company, which has a global workforce of more than 13,500, generated sales of EUR 10.0 billion (USD 13.3 billion). Brenntag connects chemical manufacturers and chemical users. The company supports its customers and suppliers with tailor-made distribution solutions for industrial and specialty chemicals. With over 10,000 products and a world-class supplier base, Brenntag offers one-stop-shop solutions to around 170,000 customers. This includes specific application technology, an extensive technical support and value-added services such as just-in-time delivery, product mixing, formulation, repackaging, inventory management and drum return handling. Long-standing experience and local excellence in the individual countries characterize the global market leader for chemical distribution.

Thomas Langer, Diana Alester, René Weinberg

Brenntag AG

Corporate Finance & Investor Relations

Stinnes-Platz 1

45472 Mülheim an der Ruhr

Germany

Telephone: +49 (208) 7828-7653

Fax: +49 (208) 7828-7755

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

http://www.brenntag.com

Emerson introduces a new non-intrusive temperature solution that delivers accurate and repeatable process temperature measurement

EMERSON INTRODUCES A NEW NON-INTRUSIVE TEMPERATURE SOLUTION THAT DELIVERS ACCURATE AND REPEATABLE PROCESS TEMPERATURE MEASUREMENT WHILE SIMPLIFYING DESIGN, INSTALLATION AND MAINTENANCE

Rosemount™ X-well™ Technology is a complete point solution for accurately measuring process temperature without the need for a thermowell or process penetration

Emerson Process Management introduces Rosemount X-well Technology, a surface sensing temperature measurement solution that eliminates the need for thermowell process penetration when measuring process temperatures in pipe applications. This solution provides an accurate and repeatable internal process temperature measurement, while eliminating possible leak points and simplifying specification, installation and maintenance.

Emerson Process Management introduces Rosemount X-well Technology, a surface sensing temperature measurement solution that eliminates the need for thermowell process penetration when measuring process temperatures in pipe applications. This solution provides an accurate and repeatable internal process temperature measurement, while eliminating possible leak points and simplifying specification, installation and maintenance.

Rosemount X-well Technology is available in the Rosemount 648 Wireless Temperature Transmitter and Rosemount 0085 Pipe Clamp Sensor Assembly. These components work together to calculate process temperature via the transmitter’s thermal conductivity algorithm. Rosemount X‐well Technology works by measuring the pipe surface temperature and ambient temperature, and combining this information with an understanding of the thermal conductivity properties of the installation and process piping.

A major advantage of Rosemount X-well Technology is accurate process temperature measurement without requiring any intrusions or penetrations into the process, allowing for quicker and easier installation along with simplified long-term maintenance. Users do not have to design, size or maintain thermowells. Wake Frequency Calculations are eliminated, as well as time spent determining material compatibility, the right insertion length and the necessary profile.

With Rosemount X-well Technology, users can also add temperature measurement points without having to shut down a process. X-well Technology can be installed with a standard pipe clamp procedure and ordinary hand tools, and does not require a skilled contractor.

“Rosemount X-well Technology is the best of both worlds as it provides an accurate process temperature similar to a thermowell while maintaining the benefits of a non-intrusive surface measurement,” said Jason Rud, senior principal design engineer at Emerson Process Management. “Current surface temperature sensing technology only provides a surface measurement that can be easily influenced by ambient temperature, while Rosemount X‐well Technology corrects for external conditions to infer the process temperature.”

Applications that can benefit from Rosemount X-well Technology include pipelines, high velocity flows, slurries, heavy particulate fluids, wellheads, clean-in-place processes, high viscosity fluids and harsh processes in the oil & gas, chemical, refining, food and beverage, metals and mining and pulp and paper industries.

To learn more about the Rosemount X-well Technology, please visit www.EmersonProcess.com/Rosemount-Xwell.

About Emerson Process Management

Emerson Process Management (www.EmersonProcess.com), an Emerson business, is a leader in helping businesses automate their production, processing and distribution in the chemical, oil and gas, refining, pulp and paper, power, water and wastewater treatment, mining and metals, food and beverage, life sciences and other industries. The company combines superior products and technology with industry-specific engineering, consulting, project management and maintenance services. Its brands include Bettis™, DeltaV™, Fisher™, Micro Motion™, Ovation™ and Rosemount™.

About Emerson

Emerson (NYSE: EMR), based in St. Louis, Missouri (USA), is a global leader in bringing technology and engineering together to provide innovative solutions for customers in industrial, commercial, and consumer markets around the world. The company is comprised of five business segments: Process Management, Industrial Automation, Network Power, Climate Technologies, and Commercial & Residential Solutions. Sales in fiscal 2015 were $22.3 billion. For more information, visit www.Emerson.com.

Contact information

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.EmersonProcess.com/Rosemount-Xwell

Caption:

Rosemount X-well technology provides an accurate, repeatable process temperature measurement while eliminating possible leak points and simplifying specification, installation and maintenance.

Glatfelter announces 5% Price Adjustment for Its Food & Beverage Filtration Papers

Glatfelter, a global supplier of specialty papers and fiber-based engineered materials, have just announced a price increase of five percent for all beverage filtration papers, with immediate effect. The announcement comes as a result of higher raw material costs.

Glatfelter, a global supplier of specialty papers and fiber-based engineered materials, have just announced a price increase of five percent for all beverage filtration papers, with immediate effect. The announcement comes as a result of higher raw material costs.

Martin Rapp, President for Glatfelter’s Composite Fibers Business Unit said, “The cost particularly for long and natural specialty fibers used in the manufacturing of our filtration papers has continued to rise substantially in the last few months. The global demand for these specialty fibers has grown significantly due to a shift of consumer requirements in the beverage industry along with new technical applications driven by the trend for more sustainable products. The rise in demand is adversely coupled with the attractiveness to cultivate cash crops to the farmers.”

“We understand that this need for a price adjustment will be challenging for our customers, but the current market dynamics are no longer sustainable for the whole supply chain from farmer to end consumer. We have focused our efforts to mitigate this impact by driving down costs and improving efficiencies. Despite good progress, we have been unable to counterbalance all the rising input cost we are currently facing.”

Glatfelter is a global supplier of specialty papers and fiber-based engineered materials, offering innovation, world-class service and over a century and a half of technical expertise. Headquartered in York, PA, the company employs over 4,300 people and serves customers in over 100 countries. U.S. operations include facilities in Pennsylvania and Ohio. International operations include facilities in Canada, Germany, France, the United Kingdom and the Philippines, and sales and distribution offices in China and Russia. Glatfelter’s sales approximate $1.7 billion annually and its common stock is traded on the New York Stock Exchange under the ticker symbol GLT. Additional information may be found at www.glatfelter.com.

Gernsbach Facility

Gernsbach, Germany

Contacts:

CFBU

Martin Rapp

49 (7224) 66 331

This email address is being protected from spambots. You need JavaScript enabled to view it.

CFBU

Dr. Mattis Gosmann

49 (7224) 66 204

This email address is being protected from spambots. You need JavaScript enabled to view it.

ABB to increase efficiency and productivity at SCA’s expanded pulp mill

For the first time ever an integrated automation solution will manage end-to-end production in the pulp industry — from the woodyard to the baling line — from a single control room

ABB, the leading power and automation technology group, will provide integrated solutions using ABB’s market-leading automation platform System 800xA and custom-engineered software for pulp processes. The solution includes engineering for the control system and optimization of all processes at SCA Östrand's expanded pulp mill in Timrå, Sweden opening in June 2018, as well as the design of the control room.

Photo: SCA Östrand pulp mill

Traditionally, in a pulp mill, different operations such as woodyard, digester, recovery boiler etc., is controlled from separate control rooms. By integrating the management and control systems of the entire production process of the mill into a single control room the efficiency and productivity of all processes will be increased. The fully integrated control system will provide unparalleled connectivity and full plant overview of the whole process and all devices.

The control center where the control room will be situated, will be designed to apply the latest advances in ergonomics, design and layout to ensure the operator environment is attractive, efficient and conducive to cooperation between all employees at the mill, resulting in one of the best operator environments in the world. To this end, all operators will monitor and control the entire mill from eight Extended Operator Workplaces, fully integrated operator solutions that provide process control, access to the right information and unrivaled opportunities for personal intelligent ergonomics, in a single solution. To this end, all operators will monitor and control the entire mill from eight Extended Operator Workplaces, with a fully integrated control system that provide unparalleled connectivity and full plant overview of the whole process and all devices. The result is improved operations, engineering, control and maintenance through a collaborative environment.

This type of environment aims to create proactive control centers that will also attract a new generation of operators to the pulp and paper industry.

Photo: ABB Extended Operator Workplaces

The order also includes a simulator for testing the control of all processes in the mill before delivery, and for operator training and process optimization over time. To ensure that the commissioning of the entire plant is as smooth as possible, five simulators will be used at the same time before and during start up.

“By utilizing our systems as an integrated platform for the entire plant, we can contribute to SCA Östrand's goal of creating the world's most modern and efficient softwood kraft pulp mill.” said Roger Bailey, Managing Director of ABB’s Process Industries business.

About ABB

ABB (http://www.abb.com) is a leader in power and automation technologies that enable utility, industry, and transport and infrastructure customers to improve their performance while lowering environmental impact. The ABB Group of companies operates in roughly 100 countries and employs about 135,000 people.

About SCA Östrand:

SCA invests MSEK 7 800 in expanding the Östrand kraft pulp mill in Timrå, Sweden, into the world’s largest production line for bleached softwood kraft pulp. The expanded plant will have a capacity of 900 000 tons of softwood kraft pulp per annum and it will come on stream in June 2018.

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2015 amounted to approximately SEK 115bn (EUR 12.3bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit http://www.sca.com

EU must put cascading use of wood at the heart of circular economy and the bioenergy strategy – WWF and Mondi

Using wood more efficiently to meet projected demand for wood-based products in Europe should be at the heart of the European Commission’s bioenergy strategy and circular economy, according to a new report.

Using wood more efficiently to meet projected demand for wood-based products in Europe should be at the heart of the European Commission’s bioenergy strategy and circular economy, according to a new report.

The report, Mapping Study on Cascading Use of Wood Products[1], commissioned by WWF and global packaging and paper group Mondi, looks at how regulation either hinders or promotes what is known as ‘cascading use’ of wood – prioritising value adding non-fuel uses so wood is burned for energy only after it has been used, re-used and recycled as a material first wherever possible.

“Demand for wood-based materials and energy is projected to increase threefold worldwide between 2010 and 2050. We urgently need to innovate and make more products from fewer resources to help reduce pressure on our forests”, says Emmanuelle Neyroumande, Manager: Forest Product Consumption & Footprint at WWF International.

“Cascading use of wood is the smart way to use a natural resource – putting it to good use before it is reused, recycled and finally burnt for energy. Taking wood straight from the forest and burning it just doesn’t make sense if it can be used for other products first”, says Peter Oswald, CEO Mondi Europe and International.

The report's findings suggest the need for: a broadly accepted definition of cascading use among policymakers, researchers and industry; EU policy guidance that incentivises effective cascading use; as well as better integration and implementation of existing bio-energy and waste policies.

At a national level, the analysis found that countries such as Finland and Germany had practices that promote cascading wood use and recycling; and that while others like Spain had advanced policies in place, these were challenged by poor integration with other policies.

It also revealed that the need for cascading use was felt more acutely in countries with relative scarcity of wood resources, such as Germany, and more weakly in countries with a relative abundance, such as Poland. In Germany, where 50% of the wood resource (recycled or virgin) is used for bioenergy, increasing demand could only be satisfied by imports, more cascading use or the expansion of the forest area from which wood can be harvested.

We urge the European Commission to take the report’s recommendations into account for the sustainable bioenergy policy up to 2030 and as they take forward activities related to the circular economy. We believe the Commission needs to provide guidance to the Member States on how best to integrate cascading use of wood into relevant national policies.

The European Commission consultation on a sustainable post-2020 bioenergy strategy is now open until 10 May 2016.

###

Read Mapping Study on Cascading Use of Wood Products

WWF has published a position paper, which states that “Cascading use of biomass as well as combined heat and power production need to be incentivised where appropriate" (WWF 2012). Mondi has a similar position, aligned to the one of CEPI, which is to “Place the cascading use principle at the core of its climate and energy policy, with a view to ensure the most efficient use of the available biomass, in particular to contribute to the EU growth and jobs objectives”.

About the WWF Mondi Global Partnership

Mondi Group and WWF are working together in a three-year strategic partnership (2014 to 2016) that focuses on promoting environmental stewardship in the packaging and paper sectors.

The partnership enables shared learning and action to promote ecosystem, manufacturing and product stewardship.

Thorough its initiative, the partnership aims to demonstrate that environmental stewardship and responsible business practice can, and need to go hand in hand. It also hopes to catalyse widespread positive change in the global packaging and paper sector and beyond

For more on the partnership please visit: www.panda.org/mondipartnership

[1] The report is based on research from the nova-Institute and the Institute for European Environmental Policy (IEEP)

WWF

Emmanuelle Neyroumande

Manager: Forest Product Consumption & Footprint

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Mobile: +33 6 62 10 74 78

Mondi Group

Lora Rossler

Group Head of Communications

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel: +27 31 451 2111

International Paper Signs Agreement to Sell Asian Corrugated Packaging Business

International Paper (NYSE: IP) have just announced that it has entered into a definitive agreement to sell its corrugated packaging business in China and Southeast Asia to Xiamen Bridge Hexing Equity Investment Partnership Enterprise. International Paper's corrugated packaging business in Asia has 18 plants and a workforce of approximately 3,000 employees.

![]() Under terms of the transaction, International Paper will receive a total of approximately RMB 1 billion (approximately US$150 million at current exchange rate), subject to post-closing adjustments and other payments, including the buyer's assumption of the liability for loans of approximately US$50 million to be paid to International Paper within six months of closing of the sale.

Under terms of the transaction, International Paper will receive a total of approximately RMB 1 billion (approximately US$150 million at current exchange rate), subject to post-closing adjustments and other payments, including the buyer's assumption of the liability for loans of approximately US$50 million to be paid to International Paper within six months of closing of the sale.

The transaction is expected to be completed in the next few months, subject to satisfaction of closing conditions, including obtaining required governmental approvals.

SOURCE International Paper

Valmet to supply new white liquor plant to CMPC Celulosa S.A., Laja pulp mill in Chile

Valmet will deliver a new white liquor plant to CMPC Celulosa S.A.'s Laja pulp mill in Chile. The new white liquor plant will replace the existing one and will comply with new environmental permits coming into force in 2018. Furthermore it will give higher white liquor plant production rate and increase flexibility of the lime cycle management within CMPC Corporation. Start-up of the new plant is scheduled to be in February 2018.

Valmet will deliver a new white liquor plant to CMPC Celulosa S.A.'s Laja pulp mill in Chile. The new white liquor plant will replace the existing one and will comply with new environmental permits coming into force in 2018. Furthermore it will give higher white liquor plant production rate and increase flexibility of the lime cycle management within CMPC Corporation. Start-up of the new plant is scheduled to be in February 2018.

The order is included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. A new white liquor plant with this scope is usually valued between EUR 70-80 million.

"We have selected Valmet to supply this project due to the company's solid performance in carrying out different projects for us, while maintaining excellent environmental and safety standards during the construction phase. We trust that the new white liquor plant will not only improve Laja's environmental performance, but will also help to reduce our operational costs", says Neil Chablani, Director of Projects & Technology at CMPC Celulosa S.A.

"We have shown that our white liquor plant technology is competitive both from a capital as well as an operational point of view, and confirms our position as a leading technology supplier in South America region," says Carl Mikael Stål, Technical and Operational Manager at Valmet in Andes Region.

Technical information of the delivery

Valmet's delivery includes a white liquor plant with causticizing and lime kiln for efficient chemical recovery. The new white liquor plant will have a capacity of 5,500 m3 of white liquor per day and a lime kiln capacity of 450 tons per day. Valmet's reliable Recovery Analyzer is a key element for the process control of the white liquor plant. This implementation will be the first Recovery Analyzer reference for Valmet in the Andes region.

About the customer CMPC Celulosa S.A.

CMPC is a pulp and paper company, established in 1920, which produces solid wood products, pulp, paper, packaging products and tissue in Latin America, operating in 8 countries, selling to over 30 thousand clients in more than 45 countries. CMPC has around 16,800 employees around the world.

For further information, please contact:

Carl Mikael Stål, Technical and Operational Manager, Andes Region, Valmet tel. +56 9982 66 255.

Paulo Aguiar, Sales Manager, SA Fiber Process & WPH & Biotech BR, Valmet +55 41 3341 4663.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

UPM closes Madison Paper Industries and plans to sell related hydro power assets in the U.S.

UPM-Kymmene Inc. and Northern SC Paper Corp., a subsidiary of the New York Times Company, has just announced the dissolution of their partnership, Madison Paper Industries, in the USA. The partnership's paper business will end and paper production is expected to conclude by the end of May at the latest. Hydro power assets located at the mill site will be sold.

UPM-Kymmene Inc. and Northern SC Paper Corp., a subsidiary of the New York Times Company, has just announced the dissolution of their partnership, Madison Paper Industries, in the USA. The partnership's paper business will end and paper production is expected to conclude by the end of May at the latest. Hydro power assets located at the mill site will be sold.

With the closure of the mill, UPM will reduce production of a total of 195,000 tons of its supercalendered paper capacity.

The closure will impact approximately 214 employees located at the mill site. Some employees will remain beyond May to maintain buildings, operate the hydro generating facilities and support activities related to the closing. All employment related actions will be handled in accordance with federal and state statutory requirements.

"Despite everyone's best efforts, the difficult decision has been made to cease paper production at Madison. Demand for SC papers declined significantly in 2015 and the decline is expected to continue. The Madison mill is not cost-competitive and has lost a significant amount of sales in the recent past," says Ruud van den Berg, Senior Vice President of UPM Paper ENA.

For more information, please contact:

Ruud van den Berg, Senior Vice President, UPM Paper ENA, tel. +49 151 1215 8310

Russ Drechsel, President and CEO, Madison Paper Industries, tel. +1-207-696-1228

About Madison Paper Industries

Madison Paper Industries is a partnership of UPM and Northern SC Paper Corp., a subsidiary of the New York Times Company, producing approximately 195,000 tons of supercalendered paper on one paper machine. The mill employs more than 200 employees and is located in Maine, in the USA. The assets include 2 hydro power plants.

UPM Paper ENA (Europe & North America) is the world's leading producer of graphic papers, serving customers in Magazine Publishing & Advertising, Merchants, Home & Office, and Newspaper Publishing. A leader in sustainable and high performance papers, UPM Paper ENA's production is located in Finland, Germany, the United Kingdom, France, Austria, and the United States. With headquarters in Germany, UPM Paper ENA employs approximately 9,500 people. To learn more about UPM Paper ENA visit: www.upmpaper.com

UPM

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 19,600 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM - The Biofore Company - www.upm.com