Super User

Voith opens new OnPerformance.Lab (OPL) in São Paulo

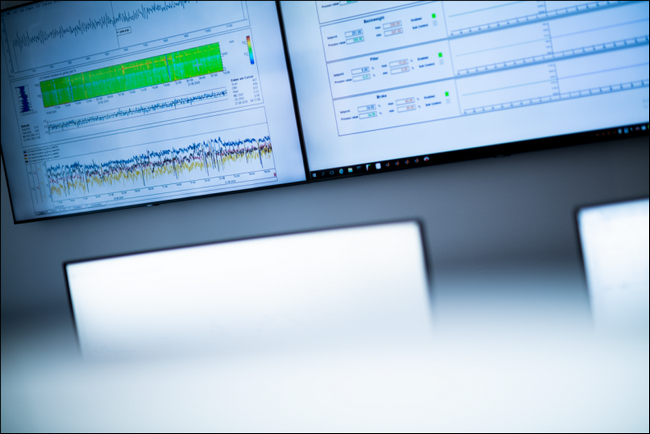

Voith announces the opening of a new OnPerformance.Lab (OPL) site in São Paulo, Brazil, South America. With this expansion, Voith strengthens its regional footprint and expands its service, optimization and consulting activities. The new OPL site is specifically designed to support paper manufacturers in automation, digitalization and achieving their sustainability goals.

Remote support represents an important part of Voith's service portfolio and complements existing on-site services offered by the leading full-line supplier. Customers can quickly and easily access the expertise of the experts and jointly find solutions to individual challenges. In this way, short-term problems can be solved efficiently, and long-term optimization projects can be carried out successfully. With the OPL, Voith takes a holistic and integrated approach that enables sustainable improvements.

"With the new location in São Paulo, we want to offer our customers even greater proximity and support," says Ivan Medeiros, Head of Digital and Automation at Voith Paper South America. "We want to help them use digitalization profitably and increase their resource efficiency to reliably achieve their goals."

The OPL in São Paulo is part of a global initiative by Voith to offer comprehensive know-how and expertise to its customers worldwide. Existing OPL locations can be found in Heidenheim, Germany; Kunshan, China; and Tokyo, Japan. The opening of additional regional offices is planned to further strengthen the regional footprint.

Interested customers can get in touch at any time to benefit from the wide range of digital solutions and service offerings. For more information on the Voith OnPerformance.Lab, visit https://voith.com/corp-en/onperformancelab/paper.html.

About Voith Paper

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Record commissioning: Voith and Sichuan Huaqiao Fenghuang Paper successfully start up highly efficient PM 6 packaging paper machine in only six months

On August 13, Sichuan Huaqiao Fenghuang Paper successfully started up its highly efficient XcelLine packaging paper machine at the Guanghan site. The leading full-line supplier Voith delivered the entire line. The project set a new record for the fastest start-up of such a paper machine. Only six months passed from installation to successful start-up – two months ahead of schedule. The commissioning of the BlueLine OCC stock preparation system and the XcelLine paper machine took just four and five weeks, respectively.

“Many thanks for the hard work and technical innovation of both teams! The very good performance of PM 6 is the excellent result of the continuous efforts and close cooperation of both teams,” says Yang Lichang, Project Manager Huaqiao Fenghuang in Sichuan. At the same time, the high performance reflects the outstanding efficiency of the Voith paper machines. The successful startup will further increase Huaqiao Fenghuang's production capacity and create a solid foundation for our future development.”

PM 6 has a width of 7.92 meters and a design speed of 1,400 meters per minute. It mainly produces high-quality packaging paper in the range of 90 to 170 gsm and has an annual production capacity of about 400,000 tons. The associated BlueLine OCC stock preparation line has an impressive capacity of 2,200 tons per day and is currently the largest OCC line in the Asian market.

Voith not only supplied the intelligent XcelLine paper machine and BlueLine OCC stock preparation line, but also leading control systems such as MCS, QCS, DCS, QMS and OnCare.Health. These advanced solutions enable full automation of the production process, ensuring stable product quality, a reliable process, and lower operating and maintenance costs. In addition, PM 6 uses Voith's latest industrial design, which combines the outstanding performance of the XcelLine paper machine with a high level of industrial aesthetics.

“The successful start-up of PM 6 exemplifies the strong technical competence and professional qualifications of both teams, and it also demonstrates the benefits of full-line delivery from Voith,” says Carlos Lin, Senior Vice President Order Processing and Operations at Voith Paper Asia-Pacific. “The full-line delivery reduces integration and coordination efforts for the customer, lowers operational risk and ensures product quality, all of which increase product competitiveness."

“Voith is committed to sustainable and environmentally friendly papermaking through innovative technologies that significantly reduce the consumption of fibers, energy and water,” confirms Kurt Yu, President at Voith Paper Asia-Pacific. "PM 6 symbolizes the shared passion and commitment of both teams to the paper industry. Voith's goal is to work with its customers to drive environmentally friendly development of the paper industry with reduced carbon emissions."

The excellent start-up performance is the result of the joint efforts of both teams. Voith's teams in China and Germany worked closely together to respond quickly to customer requirements. Early partial deliveries, shortening of installation and run-in phases, and other measures ensured that customer expectations were met in the best possible way. At the same time, the Sichuan Huaqiao Fenghuang Paper team demonstrated outstanding implementation strength and professional competence.

About Sichuan Huaqiao Fenghuang

Huaqiao Fenghuang Group is a diversified multinational enterprise with various industries. It is a large cross-border enterprise mainly engaged in six economic sectors: modern agriculture, industrial manufacturing, real estate, trade, finance, and international investment and trade activities. Sichuan Huaqiao Fenghuang Paper Co, Ltd. is a wholly-owned subsidiary of the Group and the largest coated paper manufacturer in Sichuan. Its main products are coated papers, high quality, light weight and environmentally friendly paperboard, corrugated base papers and other products. The production capacity is one million tons per year. Through continuous technical research and development, quality and service improvement, the company has become a supplier of high-quality, efficient and environmentally friendly packaging materials.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of €4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Valmet to supply key pulp and paper technologies to Naini Papers in India

Valmet will deliver key technologies, automation and services to Naini Papers’ cooking and fiberline rebuild and new specialty paper machine PM 3 at their mill in Kashipur, India. The delivery will increase the mill’s capacity and support meeting the market demand of specialty coated paper. The delivery is scheduled for the first quarter 2025.

The order was included in Valmet’s orders received of the second quarter 2023. The value of the order will not be disclosed, but a delivery of this size and scope is typically valued between EUR 40 and 60 million.

“We have been successfully collaborating with Valmet in many projects, including pulp mills, and decided to choose them again for this rebuild expanding our pulp production capacity. The additional pulp will be used in the upcoming PM 3. We see big potential for specialty coated paper in the Indian market and are eyeing the environment-friendly flexible packaging segment. The paper produced by the PM 3 can replace plastics in packages,” says Pawan Agarwal, Managing Director, Naini Papers Limited.

“We’re delighted that Naini Papers chose Valmet again as the supplier of their project. Our sustainable technologies, references, local presence and trust built through the projects and various pilot trials at the Valmet R&D center were the keys to win the order. India is a growing market for specialty grades and Naini Papers has taken the right step forward to be a leading player in this segment,” says Varun Jain, Director, India Region, Asia Pacific, Valmet.

Technical information about the delivery

The cooking and fiberline rebuild targets to increase the capacity from the current 300 bone dry tonnes per day (BD t/d) to 370 BD t/d. The delivery includes key process equipment, such as a SuperBatch digester, a TwinRoll Press, a bleach plant upgrade, and other auxiliary equipment. Basic engineering, detailed process engineering and site services are included. The automation package includes analyzers and measurements for the fiberline, such as Kappa number, brightness, residual chemical, white liquor to cooking and residual alkali, as well as pulp consistency. The spare parts package includes critical spares and consumables for the start-up of the equipment.

The specialty coated paper machine PM 3 is the first of its kind in India, with a design speed of 1200 m/min, producing mainly woodfree coated and uncoated grades with a basis weight range of 40–170 g/m2. The raw material used will be mainly hardwood pulp, with an option to mix bale softwood and precipitated calcium carbonate as filler. The paper machine delivery includes all key technologies from headbox to reel, air systems and winder, as well as Valmet Industrial Internet applications and spare part packages.

Information about Naini Papers Limited

Naini Papers Limited, founded in 1995, is one of the few premier paper manufacturing companies in India. Naini Papers offers high quality writing and printing papers with improved physical and optical properties. Naini Papers is a market leader in producing single layer cup stock for the manufacturing of paper cups and saturating kraft for the manufacturing of laminates.

About Valmet

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Sappi Saiccor signs long-term service agreement with ANDRITZ

Dissolving pulp producer Sappi Saiccor signed a three-year service contract with technology group ANDRITZ for two recovery boilers operating at the mill in Umkomaas, South Africa.

The two ANDRITZ boilers producing 230 tph of steam at 490°C and 86 bar have been operating since 2008 and 2021 respectively. The service agreement will help the Saiccor mill maintain safe and efficient operation while improving the reliability and availability of the boilers.

The scope includes operation support, engineering support, pre-shutdown services and annual shutdown services such as mechanical and process inspection, as well as an advisory service for boiler washing and boiler repair and replacement works.

The scope includes operation support, engineering support, pre-shutdown services and annual shutdown services such as mechanical and process inspection, as well as an advisory service for boiler washing and boiler repair and replacement works.

Saiccor mill, situated 50 km south of the port of Durban, produces elemental chlorine free (ECF) dissolving pulp (DP), mostly for the export market. It is one of the production facilities of Sappi group, a leading global provider of everyday materials made from wood fiber-based renewable resources.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Valmet to deliver an electrostatic precipitator to Shandong Huatai Paper in China

Valmet will deliver an electrostatic precipitator (ESP) for the recovery boiler in Shandong Huatai Paper’s 700,000 tonnes chemical pulp project in Shandong province, China. The delivery is scheduled for January 2025.

The order is included in Valmet’s orders received of the third quarter 2023. The value of the order will not be disclosed.

“Green is our mission, sustainability is our way. This is one more activity for Huatai to introduce Valmet's technology to implement the goal of low energy consumption, no pollution, and zero emissions. We look forward to Valmet's technology and services to further support our green manufacturing and circular economy,” says Houyue Ma, Vice General Manager of Recovery Boiler and Power Generation, Shandong Huatai Paper.

“We are very happy to continue our excellent cooperation with Huatai Group in this strategic investment. In addition to previous pulp, paper, and automation technology deliveries, we also have extensive services cooperation with the customer. The ESP project further develops our cooperation both in scope and depth. It is an important milestone for both companies and a good example of Valmet’s latest technology supporting customers to reach near-zero emissions through an environmentally friendly solution,” says Igor Panassol, Vice President, Pulp and Energy, China Area, Valmet.

Valmet will deliver an electrostatic precipitator for the recovery boiler in Shandong Huatai Paper’s 700,000 tonnes chemical pulp project in China.

Valmet will deliver an electrostatic precipitator for the recovery boiler in Shandong Huatai Paper’s 700,000 tonnes chemical pulp project in China.

Technical information about the delivery

Valmet’s delivery includes all mechanical parts of the ESP as well as electrification, instruments, and automation control equipment for the recovery boiler that has the capacity of 3,200 tonnes dry solids per day (TDS/D). The ESP will collect recovered alkali ash, and the guaranteed emission value is below 10 mg/Nm3.

About the customer Shandong Huatai Paper and Huatai Group

Shandong Huatai Paper Co., Ltd is part of the Huatai Group, a company listed on the Shanghai Stock Exchange. The Group is one of the global leaders in the paper and chemicals production sectors with a production of about three million tons of paper and board and two million tons of chemicals per year.

About Valmet

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Shawano Specialty Papers starts up Toscotec-supplied Steel Yankee Dryer in USA

Shawano Specialty Papers, a division of Little Rapids Corporation, started up a TT SYD Steel Yankee Dryer supplied by Toscotec at their paper mill in Shawano, Wisconsin, USA. It replaced an existing cast iron dryer on PM3.

Technological advantages

(From left to right): Michael Drage, President of Toscotec North America, and Michael Bogenschutz, Vice President and General Manager of Shawano Specialty Papers in front of PM3 at Shawano facility in Wisconsin, USA. The new TT SYD has significantly increased PM3’s production capacity and is ensuring higher operation safety. Compared with the replaced cast iron Yankee, it is delivering substantial energy savings, which reduce the overall operating costs of the tissue machine.

(From left to right): Michael Drage, President of Toscotec North America, and Michael Bogenschutz, Vice President and General Manager of Shawano Specialty Papers in front of PM3 at Shawano facility in Wisconsin, USA. The new TT SYD has significantly increased PM3’s production capacity and is ensuring higher operation safety. Compared with the replaced cast iron Yankee, it is delivering substantial energy savings, which reduce the overall operating costs of the tissue machine.

Indisputable market leadership

Toscotec holds a large majority of the global market share of Steel Yankee Dryers boasting more than 260 TT SYD sold worldwide. Since its first Steel Yankee started up in 2000, TT SYD has been installed in every corner of the globe. It is now present in more than 45 countries across 5 continents, with a stronghold in Europe where it holds close to 95% of the market share. With this successful start-up, it strengthens its position in the USA as undisputed Steel Yankee market leader.

Michael Bogenschutz, Vice President and General Manager of Shawano Specialty Papers, says “Toscotec provided excellent technical support throughout the entire project. Start-up of the new Yankee went smoothly, and the dryer is performing well. We are experiencing lower energy consumption and are seeing the potential for increased production efficiency.”

Michael Drage, President of Toscotec North America, Inc., says, “Our latest-generation design Steel Yankee delivers the highest possible drying efficiency in the tissue industry, which is of course a deal breaker for any tissue producer. We are happy to see that with this TT SYD Shawano Specialty Papers has gained a key competitive advantage to support their growth in North America.”

About Little Rapids Corporation

Founded by Charles Egan in 1947, it remains a family-owned business. The company’s core product lines serve the medical and beauty market segments, flexographic printing for a variety of packaging markets, and tissue, MG paper, and wet crepe paper for the specialty paper market. The company proudly employs over 450 people in its Green Bay and Shawano, Wisconsin locations.

ABB is first in world to deliver IE5 ultra-premium motor efficiency in explosive environments

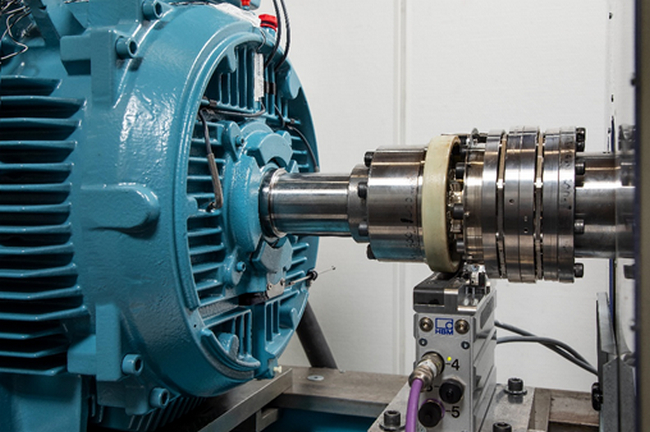

ABB has extended its award-winning IE5 SynRM (synchronous reluctance motor) series with a brand-new addition: the IE5 SynRM Increased Safety motor. In a world-first, customers operating in hazardous area industries can now ensure safety and boost their energy efficiency by deploying motors that offer up to 40 percent lower energy losses compared to commonly used IE3 motors.

- 40 percent lower energy losses in the most challenging of spaces: hazardous areas

- Cooler-running motor ensures a cost-efficient and competitive solution for increased reliability, lower maintenance needs and a longer life

The new version of the IE5 SynRM motor has been developed for use in potentially explosive atmospheres across a wide range of demanding variable speed industrial applications. It offers accurate control and high efficiency throughout the whole speed range, even at partial loads. This makes it the ideal upgrade choice for standard induction motors in pumps, fans and compressors for industries where explosive gas, vapor or dust might be present, such as oil and gas, chemicals, wood processing and flour milling.

In addition to energy savings, the new SynRM Increased Safety motors can help customers specify a more cost-effective installation. For example, in Zone 1, the cooler running design could allow the use of an increased safety motor where a flameproof motor with a special enclosure would be the traditional choice. While in Zone 2, the improved loadability of SynRM motors, that enables more power to be delivered from the same size as an induction motor, is important. This could enable a smaller, and therefore lower-cost, motor to fulfill the same duty.

Stefan Floeck, Division President IEC Low Voltage Motors, ABB, says: “We have achieved a significant world-first by bringing the benefits of IE5 ultra-premium efficiency to the hazardous area sector. Adopting best-in-class technology has made our IE5 SynRM motors a game-changer for operators in a wide range of industries. They see the capability to improve energy-efficiency as key to achieving their net zero ambitions while optimizing their business costs.”

A key benefit of IE5 SynRM Increased Safety motors is that they run cooler than standard designs. Bearing temperatures are reduced by up to 15°C and winding temperatures by up to 30°C. This provides increased reliability, prolongs the motor’s lifetime and reduces maintenance needs.

The SynRM design combines the performance advantages of permanent magnet technology, with the simplicity and service-friendliness of an induction platform. To ensure an environmentally friendly design, the motors don’t contain magnets or rare earth metals.

IE5 SynRM Increased Safety motors are available with output power of 5.5 to 315 kilowatt (kW) in frame sizes IEC 132-315.

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

Metsä Group’s Kemi mills are getting ready for the start-up of the investments

Metsä Group’s Kemi mills are getting ready for a maintenance and connection shutdown to prepare for the deployment of the largest ever investment of the forest industry in Finland – the new bioproduct mill and paperboard mill expansion in Kemi.

The shutdown will begin on Sunday, 10 September 2023, and the aim is to start up the mills on 20 September 2023.

During shutdown, odours may occur, and there may be temporary traffic congestion around the mill area, especially at the beginning of the week starting on 11 September. Odours may also occur before the shutdown due to preparations for the bioproduct mill's start-up.

The work carried out prior to start-up will ensure the mills come online smoothly and safely. During the shutdown, the existing pulp mill will be safely shut down, the paperboard mill’s new investments will be deployed, and the connections between the new bioproduct mill and the paperboard mill will be finalised.

The new Kemi bioproduct mill will annually produce some 1.5 million tonnes of softwood and hardwood pulp and many other bioproducts, including 2 terawatt-hours of renewable electricity. The mill features world-class production, environmental and energy efficiency, and despite the considerable increase in production capacity, the mill’s emissions are lower than the limits specified in the currently valid environmental permit for the existing Kemi pulp mill.

At the Kemi paperboard mill, renewal and bottleneck investments have been carried out to increase the annual production capacity of white top kraftliner by approximately 40,000 tonnes. The investments will reduce the mill’s water consumption by 40 per cent and energy use by 5 per cent per tonne of paperboard produced.

The investments are a major step towards Metsä Group’s 2030 sustainability targets and will support our customers’ sustainable business.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 7 billion, and we have around 9,500 employees in around 30 countries. We promote a culture of diversity, equality and inclusion. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by over 90,000 forest owners.

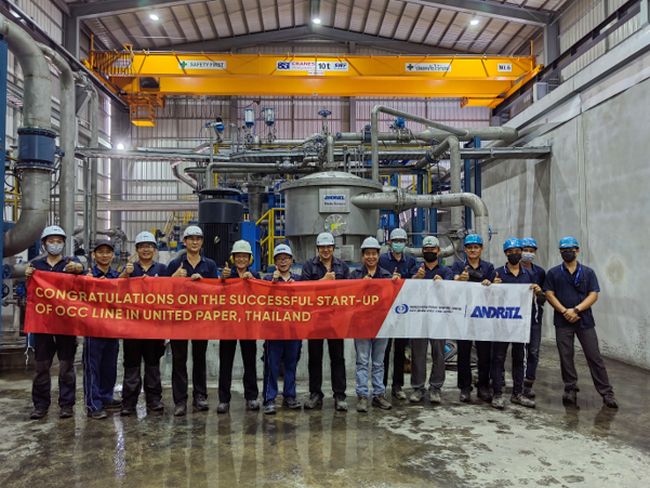

United Paper successfully starts up new, energy efficient ANDRITZ OCC line in Thailand

United Paper Public Company Limited has successfully started up an OCC (Old Corrugated Containers) line supplied by ANDRITZ at its mill in Prachinburi, Thailand. This is the second OCC line from ANDRITZ in operation at this mill.

The new line – complete from pulping to the storage tower – has a capacity of 550 bdmt/d and processes a mixture of AOCC and LOCC for the production of high-quality linerboard grades.

The LC pulping system, with FibreSolve FSR pulper and innovative Detrasher, ensures superior slushing of the raw material at minimum fiber loss, as well as highly efficient separation and removal of rejects. In combination with PrimeScreen X screen baskets, energy savings of up to 25% compared to conventional systems are achieved.

Successful start-up of the ANDRITZ OCC line at United Paper, Thailand. “Photo: ANDRITZ”.

Successful start-up of the ANDRITZ OCC line at United Paper, Thailand. “Photo: ANDRITZ”.

Mr. Wachara Chinsettawong, Managing Director, United Paper, says: “Together with the ANDRITZ fiber experts, execution of the entire project was smooth, fast and of highly professional. The two lines from ANDRITZ are equipped with separate drum and LC pulpers, which gives us more flexibility in the use of raw materials. We can’t wait to expand our business with our new premium grades.”

Thailand-based United Paper Public Company Limited was founded in 1994 and is an important producer of various kraft paper grades for liner board and corrugated medium.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

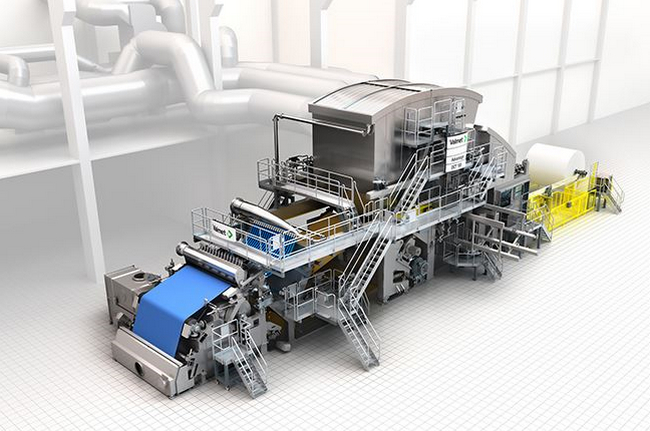

Valmet to deliver seventh tissue production line to Papel San Francisco in Mexico

Valmet will supply an Advantage DCT 100TS tissue production line to Papel San Francisco in Mexico. The new TM 10 machine will be installed at the company's mill in Mexicali and the start-up is planned for the second quarter 2025.

The order was included in Valmet's orders received of the second quarter 2023. The value of the order will not be disclosed.

Papel San Francisco currently has five Valmet lines in operation, started up between 2006 and 2020. TM 9 is currently under delivery and will start up in 2024. The upcoming delivery of TM 10 in 2025 will mark a milestone for Valmet as it features the 100th ViscoNip press that Valmet has delivered to customers globally over the years. The press has been recognized among tissue producers for its unique flexibility, uniformity, energy saving capability and high-quality tissue paper.

“To meet the increasing demand of tissue products we need to grow our capacity. The previously installed tissue lines from Valmet have served us well and allow us to run at maximum speed to get the output we need. Our operators are familiar with the machine concept, and it is easy to operate. Therefore, it was a natural choice to select an Advantage DCT line again,” says Dario Palma y Meza Espinoza, Operational Director, Papel San Francisco.

“It has been an exciting experience to participate in Papel San Francisco’s impressive growth journey as a supplier. They always pay attention to details and expect the best. We are convinced that we will have another successful project together,” says Jan Larsson, Director of Sales, Tissue Mills, North America, Valmet.

Technical information about the delivery

The new tissue machine will have a width of 2.8 m and a design speed of 2,200 m/min. It will add 30,000 tons of tissue paper per year to Papel San Francisco's current production of toilet tissue, kitchen towels and napkins.

Valmet's scope of delivery will comprise an Advantage DCT 100TS tissue machine. The machine will be equipped with an OptiFlo headbox and cast alloy Yankee cylinder. The machine will also feature the well proven Advantage tissue technology including a ViscoNip press, an AirCap hood and the WetDust dust system. Start-up and commissioning are included in the delivery.

About the customer Papel San Francisco

Papel San Francisco started up their first tissue machine in 1982. In the past 40 years the company has grown steadily and is today operating seven tissue machines with a yearly capacity of 210,000 tons of tissue products.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com