Ian Melin-Jones

Mondi presents Color Copy at the Premier Paper Gro up “Do it in Style Event”

The scale of the Premier operation and having the chance to talk directly to the paper supplier, about their respective products and initiatives, were both of great interest to many customers. There was a focus on digital printing at IPEX and this event enabled us to showcase Premier’s extensive portfolio of digital papers in which Mondi’s Color Copy is a key product.”

STORA ENSO: Packaging for a very special occasion

Without a doubt, the most memorable event in Sweden this year will be the wedding day of Crown Princess Victoria on 19 June. Rörstrand, the porcelain brand of Sweden, launched a series of bowls, mugs and other serving dishes for the occasion, packed in cartons made from Stora Enso Performa White board.

Kartongbolaget in Helsingborg, Sweden, is the producer of premium folding cartons that has been entrusted by many leading brands to supply packaging of their Official Wedding Series products. "High quality and flexible deliveries of small batches were the benefits that Rörstrand was looking for from us," says Magnus Extergren, Marketing and Sales Manager of Kartongbolaget. Stora Enso's Performa White board was selected as the material due to its good print result and reliable performance in converting

and finishing processes. "We made the first mock-ups within 24 hours, using Performa White board from our own stock. The project grew to cover a whole series of package sizes and different constructions. All of our employees are proud to work for this unique project."

"The house board"

Kartongbolaget has got a reputation among brand owners of being a very flexible and service-oriented package printer. The company specializes in small batches and premium folding cartons for all kinds of prestige brands. "Like a restaurant's house wine, Performa White is our house board which we offer as the number one option to our customers," says MD Joakim Johansson. "With Performa White, the quality is always the same. We are also very happy with the service provided by the customer service centre in Fors."

"When it comes to service, it helps a great deal that Kartongbolaget always orders the board in full trucks," says Tomas Rosenskold, Sales Manager at Stora Enso Carton Board. "They are also really good at what they do, by which I mean the niche production of exclusive style cartons, so it's absolutely great to have our Performa White chosen as their house board."

More special effects, please!

"We see that the difference between premium segment and low-price volume products is growing. At the high end, everybody wants to have more and more special effects, such as embossing and hot foiling. Thanks to our versatile customer base covering pharma, food, cosmetics, toys, etc., we have been able to refine our skills and can now offer all necessary converting and finishing treatments in-house," says Joakim Johansson. "The company is building its future through carefully targeted investments and development of its service concept."

The cartons for the Rörstrand wedding series have been printed in six colours, featuring the official portrait of the Crown Princess and her fiancé, Daniel Westling. Matt water-based varnishing and high-gloss UV varnishing have been used to create a tactile surface with eye-catching graphics. The Performa White range covers all necessary basis weights for the different package sizes. The customer also appreciates the stiff and bulky board structure.

A direct link to image:

http://bmt.storaenso.com/storaensolink.jsp?imageid=100615CB_01

For further information:

www.storaenso.com/productnews

www.storaenso.com/consumerboard

www.storaenso.com

Tomas Rosensköld, Sales Manager, Tel. +46 411 13 300

Sanna Heiskanen, Marketing Services Manager, Consumer Board, Tel.

+358 20 46 23 440

Metso to supply a web inspection system to M-real Kyro Board Mill in Finland

Metso will supply a web inspection system to M-real Kyro Board Mill located in Kyröskoski, Finland. The board machine 1 produces coated folded boxboard with an annual capacity of 160,000 tons. The new system will be put into use in late August.

The web inspection system detects defects in the board web with machine vision. A two LED light beams and one camera beam located in front of the reeler measur ing the body and surface defects and second camera and LED light beam in the coating with low angle reflection measuring coating defects.

Thanks to the new web inspection system, M-real Kyro will be able to monitor its quality better than before. A similar system is already being used on the winder.

“An order for a second web inspection system is proof of the system’s technological excellence as well as of the customer’s trust in Metso’s support during its entire life cycle,” says Sales Manager Juha Mykkänen of Metso.

Metso acquired the Viconsys machine vision business in April 2010 to complement its product and service offering. The delivery to M-real Kyro is the first web inspection system supplied by Metso.

M-real, Europe’s leading board supplier and a major paper producer, provides its customers with high-quality board and paper for consumer packaging and to meet the needs of communications and advertising. The company’s global sales network serves brand owners, carton printers, publishers, printing houses, merchants, and office suppliers. The company’s sales in 2009 were EUR 2.4 billion and it has some 4,900 employees.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

For further information, please contact: Sales Manager Juha Mykkänen, Metso, Automation business line, tel. +358 40 543 4704, This email address is being protected from spambots. You need JavaScript enabled to view it.

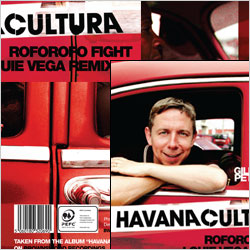

First Record Label to Use PEFC on Its Sleeve

A new 12" album hits the shops next month – Brownswood Recordings' Havana Cultura Remixed presented by internationally renowned DJ Gilles Peterson.

A new 12" album hits the shops next month – Brownswood Recordings' Havana Cultura Remixed presented by internationally renowned DJ Gilles Peterson.

What makes this album unique is that it is the first to print the record sleeve on Programme for the Endorsement of Forest Certification schemes (PEFC) certified paper and will also use the logo to prove it.

The album packaging was produced by London-based project management company, Clear Sound & Vision Ltd (CSV). The company was formed in 1997 and since then has worked predominantly within the music and film industries; managing and providing solutions for manufacturing of CDs, CD ROMs, DVDs, vinyl pressings and associated print, packaging and design. In recent years CSV has seen their client base extend both in and outside of the entertainment business. CSV works regularly with leading blue chip clients including Sony Music, EMI, Warner Music, O2 and Barclays.

As a major part of CSV's business is the provision of bespoke packaging solutions, the company has always been keen to demonstrate its strong commitment to using environmentally friendly products. In order to be able to provide its customers with assurances of responsibly sourced packaging materials, earlier this year the company recently achieved dual PEFC/Forest Stewardship Council (FSC) Chain of Custody certification. Chain of custody certification is the process by which wood-based products can be traced back to responsibly managed forests.

Commenting on its latest project, CSV's Clive Robins said "We take our commitment to responsible packaging very seriously and gained PEFC and FSC Chain of Custody certification to provide assurances to our customers. We are proud to demonstrate our support for responsible forest management by including both the PEFC and FSC logos on our packaging. We believe that these accreditations are valuable to both our business and our customers and it is something we actively promote to our clients."

Welcoming CSV's decision, PEFC UK Chairman, Peter Latham said, "We are delighted that Clear Sound and Vision has chosen this highly visible means of demonstrating their participation in the PEFC programme. With over 600 companies now having a licence to use the PEFC logo, it is beginning to appear on more and more consumer-facing printed products. However, this is the first time a company has used the logo this way and it presents an excellent opportunity to increase awareness of the PEFC logo to discerning consumers."

Viscose Specialities from Kelheim enhance paper properties – Kelheim Fibres presents test results at Zellcheming

Kelheim Fibres GmbH, leading producer of viscose speciality fibres, will showcase their new products at this year’s Zellcheming for the first time.

In addition to the well-known brands Danufil®, Galaxy® and Viloft® nonwoven Kelheim presents an impressive number of speciality fibres which are specifically designed to meet the needs of the paper making industry.

Through the incorporation of Kelheim’s speciality fibres, paper properties can be adjusted according to the individual requirements of the end product. Tear strength and tear resistance, porosity, retention, dewatering or bulk are all properties which can be influenced in this manner.

Beyond this, these viscose specialities can also generate additional functionality in the end product. By the incorporation of each of the fibres Verdi, Bramante, Dante or Bellini, for example, a significantly increased level of absorbency can be achieved. In speciality papers or filters, the viscose fibre DeepDye delivers a high dye absorption capacity and is therefore ideally suited for the incorporation in filters for the decolouration of the waste water from dye houses.

Poseidon is a fibre with ion exchange properties – integrated in papers or wet laid fabrics, it too serves its purpose mainly in filters: when used in tea or coffee bags, it can be used to soften drinking water, for example. By loading the fibres with metal ions such as silver or copper, it is possible to deliver an antimicrobial effect for medical applications.

The advantage of all these fibre specialities: they are manufactured from wood pulp - the same basic raw material used in the paper industry – and can therefore be easily incorporated in the papermaking process.

Kelheim Fibres has been a regular supplier to manufacturers of speciality papers for many years. Kelheim offers short cut fibres with a linear density 0.75dtex to 9dtex in cut lengths from 4mm to12mm and is therefore able to fulfil the needs of a wide range of customers and production processes. Fibres with engineered cross sections offering different functionalities as well as dry short cut fibre for the airlaid industry complete Kelheim’s range of products.

With their own in-house technical centre for paper development, Kelheim Fibres is able to intensively test these products during development and present the results as part of the product launch. In addition to this, close cooperation with the professionals of the Institute for Paper, Pulp and Fibre Technology (part of the Graz University of Technology), allowed the positive influence of viscose fibres on paper properties to be independently tested and proven.

A detailed report of the results of this research will be presented to the public by Dr. Ingo Bernt, a member of Kelheim’s R&D team, at this year’s ZELLCHEMING general meeting.

At the same time, a team from Kelheim Fibres is looking forward to your visit to our stand at ZELLCHEMING expo – visit us in Hall 2, Stand 207!

New Neles ValvGuard VG9000 increases safety cost-efficiently

Metso announce the launch of the HART version of its Neles ValvGuard VG9000 safety valve controller. Neles ValvGuard VG9000 is a ‘new generation’ safety-valve controller and automatic partial-stroke testing (PST) device for both emergency shutdown (ESD) and emergency venting valves (ESV). It combines new features and capabilities with all the benefits of the first-generation Neles ValvGuard VG800 taking automatic partial-stroke testing to a completely new level. TÜV Rheinland has certified VG9000 as compliant with IEC61508, up to SIL3.

Metso announce the launch of the HART version of its Neles ValvGuard VG9000 safety valve controller. Neles ValvGuard VG9000 is a ‘new generation’ safety-valve controller and automatic partial-stroke testing (PST) device for both emergency shutdown (ESD) and emergency venting valves (ESV). It combines new features and capabilities with all the benefits of the first-generation Neles ValvGuard VG800 taking automatic partial-stroke testing to a completely new level. TÜV Rheinland has certified VG9000 as compliant with IEC61508, up to SIL3.

Highly cost-efficient

Plant safety targets can be reached more economically with the Neles ValvGuard VG9000 than with traditional solutions. Its extensive safety-valve-testing capabilities include partial-stroke testing (PST), internal pneumatics testing and emergency trip testing. Safety-valve condition can be constantly monitored using the diagnostics data gained from the tests the controller performs. In addition, the VG9000 is able to collect valve diagnostics during trip situations.

There is no need to mount extra instrumentation and parallel limit-switches, because the VG9000 has market-leading pneumatics capacity and optional internal limit switches. The reduced number of safety-related components also increases plant safety while simultaneously creating cost savings. The VG9000, now available in both HART and FOUNDATION Fieldbus versions, can be used with both single- and double-acting actuators. The new HART version supports also both safety AO’s and DO’s.

Enables alarm management and predictive maintenance

The Neles ValvGuard VG9000 provides real-time alarm management at no extra cost. The availability of safety valves is maximized because emergency valve-related on-line diagnostics are integrated into device functionality.

The diagnostics information collected by VG9000 is presented in an easily understandable form via a graphical FDT/DTM interface, such as Neles FieldCare™. The usability of VG9000’s interface is also taken to a new level when compared to first-generation partial-stroke testing devices. Because the diagnostics information enables predictive maintenance, potential valve failures can be detected and corrected before they can have any impact on the process or plant safety.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

For further information, please contact: Juha Kivelä, Product manager,

This email address is being protected from spambots. You need JavaScript enabled to view it.

Great results with group-wide emission reporting for pulp production

The forest industry company Oy Metsä-Botnia Ab was the first in the world to implement a uniform group-level flue gas emission monitoring and reporting solution for pulp production. Metso provided the monitoring and reporting solution for the company’s Botnia pulp mill group, based on the metsoDNAinformation system platform.

Metso’s emission monitoring and reporting applications are widely used in other large combustion plants and Botnia Group’s reporting system is based on these practices, and on mill-specific environmental permits and EU directives and standards. The set-up was specially tailored for pulp production. The applications can either be an integrated part of Metso´s own metsoDNA CR automation platform or a stand-alone solution.

Each Botnia mill has its own data collection server, where emission data is collected and processed. Mill servers are connected to the main server at the Äänekoski mill in Finland. This arrangement enables any Botnia mill to review and compare their operation with the results of another mill via a web-based browser display.

The experience so far shows that the set-up makes it possible to respond quickly to any problems the mill might have and to benchmark operations against other Botnia mills. The solution enables uniform monitoring and reporting online, as well as short- and long-term emission reporting within the Botnia Group and to the authorities. Furthermore, it even enables proactive emission management and forecasting.

Energy efficiency is also considered crucial and therefore Botnia is planning to connect the monitoring of the current mill-specific measurement systems to the same common portal. This would offer the same advantages for group-wide energy efficiency monitoring and reporting.

For further information, please contact: Tiina Stenvik, Product Manager, Automation business line,

tel. +358 20 483 8013

Metso received confirmation of redemption price of shares in Tamfelt Corp.

Metso gained the title to all the shares in Tamfelt on May 4, 2010 when it lodged the security approved by the Arbitral Tribunal for the payment of the redemption price and the interest accruing thereon.

The Arbitral Tribunal appointed by the Redemption Committee of the Central Chamber of Commerce of Finland has today with its arbitral award confirmed that the redemption price of the shares in Tamfelt Corp. (currently, Metso Fabrics Inc.) is EUR 7.17 per share.

The total number of Tamfelt’s shares to be redeemed is 600,937 shares, that is, approximately 2 percent of the shares in Tamfelt. Metso will pay the redemption price and the interest accrued thereon to the minority shareholders of Tamfelt within one month after the arbitral award has become legally binding, which is estimated to take place in the second half of August 2010.

The arbitral award becomes legally binding after 60 days of its registration with the Finnish Trade Register, assuming that no appeal is filed against it.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

Further information for investors, please contact:

Johanna Henttonen, Vice President, Investor Relations, Metso Corporation, tel. +358 20 484 3253

Ahlstrom announces price increases on its wiping fabrics worldwide

Ahlstrom, a global leader in the development and manufacture of high performance nonwovens and specialty papers, announces price increases on its wiping fabrics as a consequence of the continuous rise of raw material costs.

The price increase will affect all products worldwide and will be effective as of July 1st, 2010. The increase range will vary depending on the nature of the products, on the regions and on the invoicing currencies.

The detailed actions will be discussed with customers through the appropriate business teams.

Ahlstrom offers a broad range of fabrics designed for consumer and industrial wipes applications. These products are manufactured by Ahlstrom's Home and Personal business area in several production sites across Europe, North America and South America.

For further information, please contact:

Jean-Marie Becker

Executive Vice President, Home and Personal

Tel. +33 4 7645 3515, This email address is being protected from spambots. You need JavaScript enabled to view it.

Timo Hiekkaranta

Vice President Sales & Marketing, Home and Personal

Tel. +39 0331 83601, This email address is being protected from spambots. You need JavaScript enabled to view it.

Seppo Parvi

CFO

Tel. +358 10 888 4768, This email address is being protected from spambots. You need JavaScript enabled to view it.

What do YOU Choose?

Sappi introduces a whole new world of choice in environmentally-sound paper packaging solutions

In a world filled with choices, what do YOU choose? This is the question Sappi is asking businesses and consumers as the leading global paper group introduces a whole new world of choice in innovative, custom-designed and environmentally-sound paper packaging solutions.

While sustainability is high on most organisational agendas, implementation often lags behind intent, especially as far as packaging is concerned. And this applies not only to the agricultural and manufacturing sectors but, more specifically, to the retail sector. The lack of environmentally-sound, sustainably-produced and biodegradable packaging choices is simply not meeting changing consumer demand or business targets.

"Many brand owners and retailers are coming under pressure from consumers to respond positively to sustainability and environmental issues,” says Albert Lubbe, Sappi Kraft MD, “and this is particularly evident in the area of packaging.”

“So Sappi is partnering with them right from the R&D stage to custom develop food-grade and other paper packaging solutions that meet the specific needs of both the business and its customers. New innovations in paper technology and packaging design are enabling us and our packaging industry partners to offer solutions that have the properties most needed in this sector, including strength, attractiveness, durability, and resistance, while also facilitating our sustainability objectives. ”

This is just one of the many sound reasons for making the switch to paper packaging, and forward-thinking brand owners and retailers that have partnered with Sappi to make the change in all of their outlets, are leading the way.

But, of course, not all paper is created equal. Consumers looking for food-safe, convenient and environmentally-sound paper packaging choices want to know that the paper they choose has a solid, reliable pedigree.

“One of the greatest benefits of paper is that it’s a sustainable resource,” says Lubbe, “and at Sappi, all of our tree plantations are accredited by the international Forestry Stewardship Council (FSC). Independent auditing procedures also mean that it is possible trace our virgin fibre from source to end product, something that is becoming increasingly important not only to consumers, but to shareholders and other stakeholders as well.”

Sappi only uses fibre sourced from either Sappi-owned or partner-owned tree farms, and not from old-growth or indigenous forests. And innovations in manufacturing technology pioneered by the group mean that many Sappi papers contain a high percentage of either sugar cane fibre, which is manufacturing waste from the sugar industry, or recycled paper.

“We’re also deeply committed to efficient energy and water usage,” says Lubbe, “and our papers are produced using up to 50% renewable energy, a percentage we hope to increase in the future.”

At the end user interface, consumers choosing packaging made from Sappi paper can be assured that it is not only an environmentally-sound choice to make, but a convenient one. Packaging solutions like grocery bags and take-away boxes are developed with the precise end use in mind, and are frequently more reliable than alternatives.

“From a usage point of view, our retail partners and Sappi have interrogated consumer needs very carefully, and have responded with solutions that are safe, strong and durable,” says Lubbe.

“From an environmental point of view, Sappi packaging papers are not only reusable and recyclable, but offer a host of other features and benefits. Most importantly, they’re biodegradable, and don’t leave toxic residue in either the soil or the water when they do degrade. Together with the non-toxic inks used in the printing process, brand owners can be assured of a truly planet-friendly solution.”

All Sappi papers are produced locally, using labour drawn from local communities, and the services of small and medium enterprises situated in the areas around plantations and production facilities. The group also has a best-practice training programme and, through its corporate social investment programme, is investing in the socio-economic development of the communities in which its workers live.

“So when you choose paper by Sappi, you’re not just making a convenient choice, you’re making a progressive, environmentally-sound and socially-conscious choice too,” concludes Albert Lubbe.

“In short, paper is the choice of the future. And paper by Sappi is the paper to choose.”

For further information on Sappi, please visit www.sappi.com, and for more information about "I choose paper", visit www.ichoosepaper.com. Follow “i choose paper” and chat about it on both Facebook and Twitter.

Contact details

André Oberholzer

Group Head Corporate Affairs

Sappi Limited

Tel +27 (011) 407 8438

Fax +27 (011) 403 8236

e-Mail This email address is being protected from spambots. You need JavaScript enabled to view it.