Ian Melin-Jones

EBIT margin forecast for 2010 downgraded

The ongoing preparation of Hartmann's interim report for H1 2010 has given rise to a downgrade of the company's EBIT margin forecast for 2010 to approximately 7% against the previous forecast of approximately 10% (actual 2009: 5.7%). The downgrade is due, among other factors, to higher raw materials prices in H1 2010 and even sharper increases in raw materials prices in the first part of H2 2010. New initiatives have been launched with a view to increasing the company's EBIT margin in the long term.

Based on the ongoing preparation of the interim report for H1 2010, Brødrene Hartmann A/S has resolved to downgrade its forecast for the 2010 financial year. According to the preliminary figures, consolidated revenue for Q2 came to DKK 326 million (2009: DKK 310 million), and the company generated an operating loss of DKK 7 million (2009: DKK 12 million). The preliminary figures further show that Hartmann's consolidated revenue for H1 2010 came to DKK 706 million (2009: DKK 675 million) and that the company generated an operating profit of DKK 31 million (2009: DKK 24 million) and an EBIT margin of 4.3%.

The EBIT margin forecast is revised to approximately 7%, down from the previous forecast of approximately 10% (actual 2009: 5.7%). The revised EBIT margin corresponds to an expected operating profit for 2010 of approximately DKK 90-105 million against the previous forecast of an operating profit of approximately DKK 140 million (actual 2009: DKK 79 million).

The downgrade of the EBIT margin forecast and the operating profit forecast for 2010 is due to higher raw materials prices (paper, energy and other raw materials) in Europe in H1 2010 and even sharper increases in raw materials prices in the first part of H2 2010. This trend is most pronounced for recycled paper, one of the key raw materials in Hartmann's production. Furthermore, the prices of energy and other materials have increased moderately. The increase in raw materials prices alone is believed to be capable of reducing the company's EBIT margin for 2010 by approximately two percentage points.

Moreover, the previous forecast was based on expectations of significant organic growth in the North American operations. However, growth fell short of expectations, adversely affecting the guidance for 2010.

The cost level in H1 2010 was also adversely affected by a number of additional costs incurred in connection with the recruitment of a new management and the launch of a range of initiatives forming part of the strategy phase 2011-13, which aims to optimise Hartmann's processes and strengthen the company's EBIT margin in the long term.

The earnings downgrade for 2010 implies that several planned investment projects will be postponed in order to ensure cash inflows and retain focus on production for the remainder of the year.

In the long term, Hartmann aims for a significant improvement of its EBIT margin relative to the expected EBIT margin for 2010. Initiatives (in addition to the '10 in 10' initiatives) have already been launched with a view to improving efficiency in production and planning, etc., and the company is currently assessing how to compensate for the increase in raw materials prices.

The company's interim report for H1 2010, to be released on 25 August 2010, will include additional information on developments in Brødrene Hartmann A/S in H1 2010 and the background for revising the company's forecast for 2010.

Brødrene Hartmann A/S

Peter Arndrup Poulsen

CEO

Mobile: +45 51 51 40 69

Darmstadt University of Technology and Heidelberg Extend Joint Research Platform for Another Two Years

The Institute for Printing Presses and Printing Methods (IDD) at Darmstadt University of Technology and Heidelberger Druckmaschinen AG (Heidelberg) are extending their joint research platform till 2012. The two partners have been working on the "functional printing" development project since 2007. The main aim of the project is to develop new applications for the print media industry. This involves devising new surface-finishing technologies that enable print shops - and packaging printers in particular - to stand out from the crowd. "Functional" here means properties that enhance the print medium, such as new, decorative, visual, electrical, and electronic functional characteristics. The first three years of collaboration successfully culminated in predevelopment work for new decorative elements and simple display elements known as demonstrators. Examples include display elements based on electroluminescence or thermochrome inks that can be used for special effects on packaging and a display stand with light effects for use at the point of sale. "Our motivation is based on developing a feel for what the market of the future needs and investigating this using feasibility studies," explains Manfred Jurkewitz, Head of Research and Development at Heidelberg.

Research work is currently devoted to new applications for the print media industry. The first examples are promising and include innovative new effects with structural coating and special optical effects in 3D. "We are looking to develop further visual effects and applications that lie between the print applications of today and organic electronics applications of the future," says Professor Edgar Dörsam, Director of the IDD, describing the joint research.

Heidelberg is providing the relevant printing technology for the cooperation project - a Gallus RCS 330-HD rotary press. The press is tailored to development needs and has been configured accordingly. It has four printing stations and four printing processes - flexographic, screen, offset, and gravure. The printing units for the individual processes are separate modules that can be operated in every position of the printing stations. The sequence of processes is therefore freely configurable and can thus be adapted to numerous requirements for new applications. Space for further equipment such as dryers and special measuring technology is available between the individual printing stations. "The applications we're developing on this modular platform are then transferred to the Heidelberg sheetfed press sector to ensure our Speedmaster customers can also benefit from them," explains Dr. Martin Schmitt-Lewen, project manager at Heidelberg for the cooperation project with the IDD.

Applications outside the print media environment

Further applications are possible outside the print media sector. This applies in particular to the up-and-coming area of organic electronics. The fields for applications here are even wider and more varied. Examples include organic photovoltaics, OLED (organic light emitting diode) systems for displays and illumination, sensor technology, and applications relating to electrical/electronic circuits with transistors, for instance.

These topics are being covered by Heidelberg in a further research project that is also being conducted in partnership with the IDD and is backed by a large research association publicly funded by the German Federal Ministry of Education and Research (BMBF). Heidelberg's role, in collaboration with the IDD, is cross-functional, spanning various applications and including the development of (print) processes for thin layers. This is putting the development of "functional printing" on an even broader footing and may subsequently also open up new areas of application outside the print media world.

This activity, which aims at developing new processes for manufacturing organic electronics, is a key project in the "Organic Electronics Forum" cluster of excellence. This is a cooperation network of three DAX companies, eight large international enterprises, five SMEs, and eleven research institutes and institutions of higher education, including two elite universities. The objectives of the cluster of excellence are to create a world-beating research, development, and production site for organic electronics, one of the most attractive locations for current and future specialists, and the world's leading center of innovation for knowledge transfer and company startups. The 27 enterprises, institutions of higher education, and research institutes are working together on the research projects, which are receiving funding from the BMBF to the tune of EUR 40 million, in the future technology of organic electronics.

For further information, please contact:

Heidelberger Druckmaschinen AG

Corporate Public Relations

Hilde Weisser

Phone: +49 (0)6221 92 5066

Fax: +49 (0)6221 92 5069

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Mackenzie pulp mill open for business

Paper Excellence B.V. celebrated the official re-opening of the Mackenzie Pulp Mill in Mackenzie, B.C. on Aug. 17. More than 220 workers have been brought back to work to support the re-opening of the mill and an estimated 500 spin-off jobs will be created.

"I would like to thank Paper Excellence for their valuable investment in the community of Mackenzie, the Omineca region and the province of British Columbia," said B.C. Premier Gordon Campbell. "I also want to thank Minister Pat Bell, the McLeod Lake Indian Band, the entire community and all partners for working together to ensure working families in this region have an opportunity to build a future right here in Northern British Columbia."

Located in the Northern Interior Rocky Mountain Trench and strategically centered in the "fibre basket" of the B.C. interior, the Mackenzie Mill operates at a total capacity of over 235,000 tonnes per year. The unique characteristics of the fiber resources within the region make Mackenzie pulp one of the brightest, cleanest, and strongest pulps in the world.

"Our land is full of precious resources, so we are willing to endorse companies that have the expertise, commitment and willingness to work with us to manage our resources in an environmentally sound manner," says Chief Derek Orr of the McLeod Lake Indian Band. "I look forward to working with Mackenzie Pulp Mill and exploring other opportunities that will benefit the McLeod Lake Indian Band, local communities and the province."

The Mackenzie mill was built in 1972 and was significantly modernized in 1996 with the addition of short fiber softwood digesting production capabilities.

It had been shut down for two years prior to being purchased by Paper Excellence earlier this year.

Verso Paper Corp. Launches Mobile Version of Corporate Website

Verso Paper Corp. has announced the launch of its mobile website to provide easy access to Verso information for customers and the financial community.

The mobile version of www.versopaper.com features a simple and efficient user interface that provides quick access to Verso product specifications, contact information for the company's inside and outside sales representatives, and investor relations information.

"We strive to provide our customers with tools that make doing business with Verso simple. With the proliferation of smart phones and the increase in mobile browsing, I believe providing a mobile version of our corporate website is a step in the right direction," says Mike Weinhold, Senior Vice President of Sales and Marketing. "Future phases of this mobile site will include the ability for our customers to access their own order information and search for available inventory, enabling them to get the information they need to make decisions more quickly, even when they are on the go."

To access the mobile version of Verso's corporate website, just enter www.versopaper.com in your smart phone's browser.

About Verso

Based in Memphis, Tennessee, Verso Paper Corp. is a leading North American producer of coated papers, including coated groundwood and coated freesheet, and supercalendered and specialty products. Verso's paper products are used primarily in media and marketing applications, including magazines, catalogs and commercial printing applications such as high-end advertising brochures, annual reports and direct-mail advertising. Additional information about Verso is available on the company's website at www.versopaper.com.

Forward-Looking Statements

In this press release all statements that are not purely historical facts are forward-looking statements within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934. Forward-looking statements may be identified by the words "believe," "expect," "anticipate," "project," "plan," "estimate," "intend," and similar expressions. Forward-looking statements are based on currently available business, economic, financial and other information and reflect management's current beliefs, expectations and views with respect to future developments and their potential effects on Verso. Actual results could vary materially depending on risks and uncertainties that may affect Verso and its business. For a discussion of such risks and uncertainties, please refer to Verso's filings with the Securities and Exchange Commission. Verso assumes no obligation to update any forward-looking statement made in this press release to reflect subsequent events or circumstances or actual outcomes.

SOURCE: Verso Paper Corp.

Verso Paper Corp.

Mike Weinhold

Senior Vice President

Sales and Marketing

901-369-4128

This email address is being protected from spambots. You need JavaScript enabled to view it.

Nash starts “Oldest Pump Contest”

Gardner Denver Nash has started a contest to find the oldest Nash pump. The submitted product must be a Gardner Denver Nash manufactured liquid ring vacuum pump or compressor. This includes any previous company brands, including elmo and Siemens-Schuckert. Deadline will be November 01, 2010.

Like people, most liquid ring vacuum pumps retire after 30 or 40 years. They get tired or their skills become surpassed by the younger generation. The NASH Hytor #6 pump, however, worked for 82 years before being removed for repair! The NASH #6 pump worked on the pulp dryer machine, on a top felt Uhle box, at Simpson Tacoma Kraft Company. The plant was built in 1928 by the Union Bag Company, and the #6 was there from the start. During its 82 years, the #6 pump has seen the company change hands a number of times, but it kept on doing its job.

The NASH #6 pump worked on the pulp dryer machine, on a top felt Uhle box, at Simpson Tacoma Kraft Company. The plant was built in 1928 by the Union Bag Company, and the #6 was there from the start. During its 82 years, the #6 pump has seen the company change hands a number of times, but it kept on doing its job.

Retirement comes eventually of course, and the NASH #6 pump has gracefully given way to a NASH Vectra XL. The former could have kept on working with bearings replacement, but the Vectra will give the same reliability with more efficiency. Its long-time companions remain hard at work at the paper mill – including the pump on an identical Uhle box system.

Do you have an old Nash pump still running?

Nash is running a contest to see what other pumps have been working hard for many years. The person who submits the oldest pump will win a GPS NAVIGATOR! Your pump doesn’t have to be 82 years old like the one shown; it just has to be older than the other contest entries. For contest details, go to www.GDNash.com/oldestpump.aspx. Entry forms will be accepted until December 1, 2010.

Mayr-Melnhof Karton AG releases the half-year results 2010

The Mayr-Melnhof Group succeeded in benefiting from the temporary recovery that the economy demonstrated in the first half-year 2010. Capacities in both cartonboard production and folding carton manufacturing were utilized almost to the full. The distinct growth in volume was, however, accompanied by significant price increases in the procurement markets. Thus it was only possible to gradually pass on these price increases to our end customers. Thanks to the high level of productivity and cost-efficiency, the Group managed however to confirm its sustained earnings power in the first half of the 2010 business year.

There is no indication that any reversal of trend in the dynamic volume development will occur during the third quarter of the year. It will remain our priority to pass on in-creasing input costs to end consumers, as it is no longer possible to offset them by higher volumes given that capacity is already fully utilized.

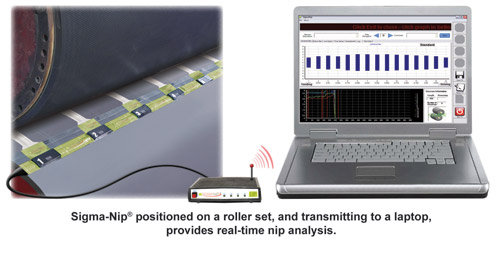

WITH SIGMA-NIP® Roll Alignment Diagnosis is Fast, Cost-Effective, and Accurate

Sigma-Nip®, is a technologically advanced electronic nip analysis system from Sensor Products Inc. that measures roller profiles and diagnoses roll alignment with unprecedented speed and cost-effectiveness. This sensor system, which records nip width, renders obsolete time-consuming and inexact tools such as carbon paper and embossed foils. When Sigma-Nip® is used, loading problems, skewing, and crown deficiencies are quickly exposed. It is more accurate, more durable, and has a more powerful software user interface than any of its predecessors. UPM, Metso Paper, Dupont Nonwovens, PGI Nordlys and Thai Paper are some of the leading companies around the world that have purchased Sigma-Nip®..

Sigma-Nip® consists of a chain of sensor elements and Windows-based software. The new sensors have been improved to withstand repeated high pressures and temperatures as well as routine exposure to grease and solvents. When placed between two contacting rollers, the sensors capture data and ultimately record and assimilate nip width readings on a laptop while it is being viewed. Adjustments to rollers are made in real time while the sensors are in the closed, (non-rotating) nip. Easy-to-interpret statistical data and graphical displays, which are being transmitted via wireless or through a USB port, update continuously as technicians perform their tests and adjustments.

Taking only minutes to deploy across the roller face by just one person, Sigma-Nip® is useful for ongoing maintenance, as well as during equipment setups and shutdowns. As a quality control tool, Sigma-Nip® facilitates evenly loaded roller sets that are much less likely to cause web breaks and costly down time. It improves web control and print quality by reducing uneven paper pulling, which can lead to sheet walking, wrinkles, jams and misregistration. By virtue of routine tests, Sigma-Nip® allows the user to greatly extend blanket life.

"Sigma-Nip® has come a long way from concept to being a reliable, easy-to-use nip profile measuring tool,” according to Mike Stoltz of Metso Paper. “Being able to save and review the entire real-time data from nip closing to nip opening is extremely useful, however, the ability to correlate accurate nip width data to roll deflection is an exceptional benefit."

Sigma-Nip –2

Sigma-Nip® is designed for maximum versatility. The system is portable and comes with its own carrying case. Depending on the number of sensors ordered, the same sensor chain can be used to measure different sized rolls. Nip widths from 0.15 in. (0.38 cm) to 9 in. (22.9 cm) can be measured, and pressures from 40 PSI (2.8 kg/cm2) to 3,000 PSI (211 kg/cm2) can be withstood, making Sigma-Nip® potentially usable throughout the machine. Large pulp and paper rolls, small converting rolls as well as calendar stacks are all potentially measurable by Sigma Nip. Face lengths of 35” – 443” (90 cm – 1,125cm) can be accommodated.

Minimal computer knowledge or training is needed since the system prompts users through the few steps needed for installation and set up. Software enhancements include a Comparison Mode, where up to three nip width readings can be viewed simultaneously, and an Alignment Tool, which instantly draws a line to indicate nip width variations.

, or to schedule a demonstration, contact Sensor Products Inc. at 1.800.755.2201 or 1-973-884-1755 (USA), e-mail This email address is being protected from spambots. You need JavaScript enabled to view it., or visit the website www.sensorprod.com/sigmanip.

About Sensor Products Inc. (USA)

Headquartered in New Jersey and established in 1990, Sensor Products Inc. is a world leader in the manufacture and distribution of tactile pressure sensing solutions. Their customized and off-the-shelf products are installed within all of the Fortune 500 industrial companies as well as thousands of smaller manufacturing firms. Their sensors are used in applications as diverse as tire testing to semiconductor manufacturing and from R&D labs to space missions. Additionally, Sensor Products provides in-house and on-site stress and pressure mapping analysis, as well as a variety of regional technical seminars.

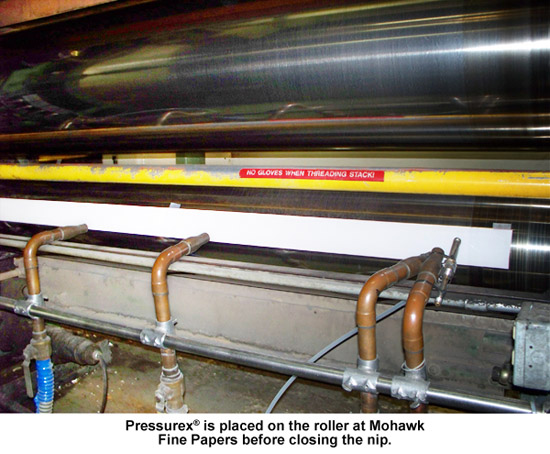

Mohawk Fine Papers uses Pressurex® Sensor Film To Extend Roll Life, Maximize Yields, and Improve Quality

During tough economic times it is tempting to reduce quality control to cut costs in maintaining rollers for papermaking, printing and converting. However Dolph Beyer, an engineer with Mohawk Fine Papers, asserts doing this is actually counterproductive. He has determined using Pressurex® pressure indicating sensor film as a quality control tool to aid in alignment and diagnose the condition of his rollers actually decreases costs and significantly improves product quality.

"By taking nip impressions with pressure indicating film every couple of weeks, we are able to extend roll life by a few months in many cases," says Mr. Beyer." By examining the roll nip impressions we can more accurately determine where we are in the life cycle of some of our rolls. This helps to pinpoint more accurately when rolls need to be changed and may indicate needed roll grind improvements or cover material changes to help extend roll run life cycles. Extended run cycles reduce the re-grind frequencies and therefore extend the cover life." This quality control measure not only lowers costs for the replacement of these covers, but also minimizes equipment downtime."

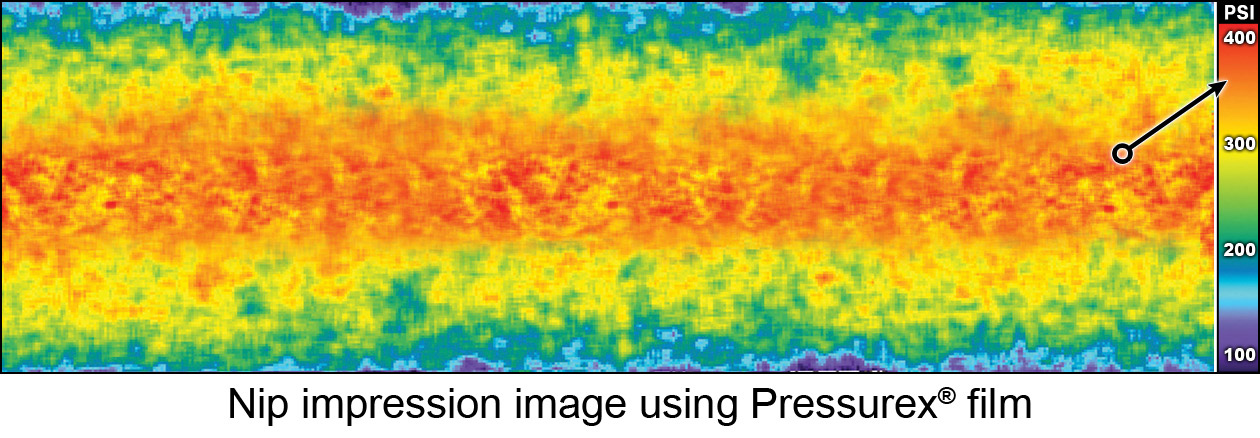

Pressurex® reveals pressure from 2 - 43,200 PSI (0.14 - 3,000 kg/cm2).

When placed between contacting rollers, the sensor film instantaneously and permanently changes color directly proportional to the actual pressure applied. Precise pressure magnitude is then easily determined by comparing color variation results to a color correlation chart (conceptually similar to interpreting Litmus paper). Variations in pressure that lead to defects in papermaking, converting and printing can be quickly and accurately detected and corrected -- improving yield, decreasing scrap, and increasing productivity.

By examining pressure variations in the nip, corrections in alignment and crown profiles can be made. The film is effective on virtually all roller  compositions and surfaces. A visual pressure mapping profile of an engraved pattern or drilled roll can be effortlessly produced that exposes minute surface defects and other imperfections.

compositions and surfaces. A visual pressure mapping profile of an engraved pattern or drilled roll can be effortlessly produced that exposes minute surface defects and other imperfections.

Pressure indicating sensor film is cited by Mr. Beyer as being especially helpful with calendar rolls, which are swim rolls that have mechanisms to allow the center of the rollers to exert a different level of pressure. "Similar to crown rolls, swim rolls need to be carefully monitored to ensure even and exacting pressure is being applied to achieve optimum nip conditions," says Mr. Beyer. "We use the film to create just the right nip and improve the roll shape and crown to deliver better sheet uniformity.

Mohawk Fine Papers uses Pressurex® to take static nip impressions on their press section and dynamic nip impressions on their calendars. Dynamic nip impressions are inspected for uniformity and static nip impressions for uniformity and nip pressure. Image results of Pressurex® are archived and used as a control to compare tools and processes.

Pressurex® is extremely thin (4 to 8 mils) and flexible, which allows it to conform to curved surfaces. It is ideal for invasive intolerant environments and tight spaces not accessible to conventional electronic transducers. While recommended for tests in non-operating conditions, the sensor film can be used at temperatures exceeding 200 Fº (93 Cº) for brief intervals.

For a free sample of Pressurex® in your desired range, contact Sensor Products Inc. at 1.973.884.1755 (USA), email This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.sensorprod.com/sample.

BASF to build dispersions plant in Huizhou to better serve growing markets in South China

BASF will invest in a dispersions plant in Daya Bay Petrochemical Industrial Park in Huizhou, China. With an annual capacity of 100,000 tons, the new plant will produce XSB dispersions for the paper industry and acrylic dispersions for industries such as coatings, construction, printing & packaging and adhesives . The facility will benefit from local availability of raw materials and proximity to key customers who serve Asia’s fastest-growing consumer markets. Production is scheduled to begin in the first quarter of 2012, subject to government approval. The investment is part of BASF’s growth strategy for Asia Pacific, which has the goal of doubling sales by 2020.

“This is an important step for BASF in Asia, following the establishment of our Paper Chemicals division in 2009. The investment strengthens BASF’s commitment to the paper and board industry, with South China offering one of the fastest-growing markets in the region. With this facility, we are well positioned to support our customers’ aspirations for growth and success in the South,” said EngSoo Chew, Senior Vice President, Paper Chemicals Asia Pacific.

“This is an important step for BASF in Asia, following the establishment of our Paper Chemicals division in 2009. The investment strengthens BASF’s commitment to the paper and board industry, with South China offering one of the fastest-growing markets in the region. With this facility, we are well positioned to support our customers’ aspirations for growth and success in the South,” said EngSoo Chew, Senior Vice President, Paper Chemicals Asia Pacific.

“With our upstream monomer integration in China, world-scale dispersion plants exceeding half a million tons in capacity and unique process for manufacturing low-VOC dispersions, we are well positioned to support our customers’ strong growth with a reliable supply of water-based acrylic dispersions in the region,” said Gops Pillay, Senior Vice President, Dispersions & Pigments Asia Pacific.

The investment reflects BASF’s focus on participating in the strong growth of markets in emerging Asia. The additional capacity will strengthen and complement its regional production network for XSB and acrylic dispersions, which currently includes plants in East China, Indonesia and India. XSB dispersions are used as coating binders for paper, while acrylic dispersions are used in paints and coatings, printing and packaging, construction materials and adhesives.

About BASF’s Dispersions and Pigments Division

BASF is the leading global supplier of raw materials for the coating and paint industry. The new division Dispersions & Pigments combines all BASF offerings towards this industry. The portfolio encompasses pigments, resins, dispersions and a broad range of additives like light stabilizers and photoinitiators. Further end-use industries include construction materials, adhesives, printing and packaging. Our portfolio is focused on environmentally friendly systems, such as low-VOC water-based coatings.

About BASF’s Paper Chemicals division

BASF’s Paper Chemicals division offers process chemicals to optimize costs and increase machine efficiency, functional chemicals to lend specific properties to paper and finishing chemicals to improve the appearance and performance characteristics of printed paper and board. With this comprehensive portfolio, BASF is the leading supplier of paper chemicals worldwide.

BASF established Paper Chemicals as a separate division when it acquired Ciba in April 2009. The ISO 9001:2000-certified Paper Chemicals division operates sites in Europe, Asia and the Americas. For more information, go to http://www.paper-chemicals.basf.com.

Commercial Printer Impressed with World's First Speedmaster CX 102

"Onward and upward - even against the flow" are the words that drive the corporate philosophy of Druckerei Kern, a print shop based in Bexbach in Germany. "We have always invested in the latest presses in order to offer our customers optimum products," says André Kern, Managing Director. The print shop has been utilizing the world's first Speedmaster CX 102 five-color press with coating unit since mid-May 2010. The Speedmaster CX 102 for industrial sheetfed offset printing was unveiled by Heidelberger Druckmaschinen AG (Heidelberg) at IPEX 2010 in Birmingham, U.K. "We have made the right choice. We were impressed by the Speedmaster CX 102 right from the outset and the complete investment package has enabled us to make great strides in our industrial production," adds Kern. The package consists of the Speedmaster CX 102, Speedmaster SM 52, and Prinect components for networking.

André Kern consulted a whole host of suppliers before making the investment. "Ultimately we felt we received the best advice from Heidelberg, and the company put together an attractive, comprehensive package." Prinect Prinance and Prinect Cockpit make the offerings and pressroom completely transparent.

The Speedmaster CX 102 has been successfully tried and tested, with Druckerei Kern reporting far shorter makeready times, only half the waste, stable production speeds, quiet, smooth sheet travel, and extremely high net speed. "We were amazed by the clear boost in quality for high grammages and coating jobs," adds Kern. The printers appreciate the press's excellent ergonomics and the fact that everything can be viewed quickly and easily on the large wallscreen of the Prinect Press Center. The process-oriented Intellistart operator guidance enables presses to be set up fast. The press, which is fully integrated into the Prinect workflow, inks up quickly and high speeds are now standard during the production run.

Family-owned Druckerei Kern, whose roots go back to the 19th century, is now in its fourth generation and has a workforce of 35 employees, generating sales of EUR 6 million in 2009. For the last ten years, the company has been based in Bexbach. The French branch in Saareguemines mainly produces large-format display stands, banners, and posters for sales promotion using laser technology. In Bexbach, the full-service print shop produces brochures, catalogs, and magazines using offset and digital printing in two-shift operation. The company specializes in personalized direct mailings and postpress operations, featuring a Flexomailer with a sheet reversal facility that it has developed itself and four Stahlfolder units.

Its production operations cater to manufacturers of branded goods and industrial customers, with a very wide range of run levels and grammages. It prints everything, from lightweight paper to 400 gsm cardboard - a further benefit of the new Speedmaster CX 102. "We are looking to be more actively involved in web-to-print in the future and apply our positive experience of transparent production to postpress with the Prinect Postpress Manager," says Kern, explaining his further plans.

The Speedmaster CX 102 from Heidelberg is the right press at the right time

Lying between the Speedmaster SM 102/CD 102 and the Speedmaster XL 105, the Speedmaster CX 102 from Heidelberg is the ideal press for every customer. As a new market segment in the 70 x 100 cm (27.56 x 39.37 in) format, the Speedmaster CX 102 comes just at the right time for large numbers of customers. The press offers an interesting alternative for many printers who are impressed with XL technology but do not have the quantity of jobs needed to make full use of such a productive press, particularly as it enables them to work with the same plate format. This is confirmed by the high level of interest shown in the Speedmaster CX 102 and the sales successes so far. Over 15 presses were sold by the end of IPEX 2010. The presentation of the Speedmaster CX 102 also attracted a great deal of interest at ExpoPrint in Brazil and at the Open House event for the West region in Germany. Almost 30 presses have now been sold, with buyers including commercial and packaging printers. One in three Speedmaster CX 102 units is equipped with Prinect Inpress Control, which significantly cuts waste and therefore makes a major contribution to ensuring eco-friendly production.

Demonstration opportunities extended for commercial and packaging printing

Customer demonstrations on a Speedmaster CX 102 six-color press with coating unit have been underway at the Print Media Center (PMC) in Wiesloch-Walldorf since May this year. The press is elevated by 500 mm (19.69 in), fitted with the CutStar sheeter and used for both conventional and UV production. The Speedmaster CX 102 is geared toward packaging printing and also demonstrates foil printing.

The demand for demonstrations is so great that Heidelberg will be putting an additional demonstration press into operation at the PMC in Heidelberg. This Speedmaster CX 102 five-color press with coating unit is aimed at commercial printers. It is equipped with Prinect Inpress Control and prints without alcohol, thereby enabling Heidelberg once again to demonstrate its commitment to eco-friendly production.