Ian Melin-Jones

ANDRITZ: new Executive Board responsibilities as of April 2011

- Franz Hofmann will retire as planned on March 31, 2011

- Wolfgang Semper becomes new member of the Executive Board

Franz Hofmann, who has been member of the Executive Board of ANDRITZ AG since 1999 and responsible for the METALS and the ENVIRONMENT & PROCESS business areas as well as for Automation on a Group-wide level, will retire as planned on March 31, 2011.

In this context, the ANDRITZ AG Supervisory Board took the following resolutions effective as of April 1, 2011:

- Wolfgang Semper will become new member of the Executive Board and will be responsible for the HYDRO business area (together with Friedrich Papst) and for Automation on a Group-wide level. Wolfgang Semper, aged 52, is a graduate of mechanical engineering and has successfully headed the ‛Large Hydro’ division of the HYDRO business area of ANDRITZ.

- Friedrich Papst, who is responsible for the HYDRO and the FEED & BIOFUEL business areas, will additionally assume responsibility for the METALS business area.

- Humbert Köfler, who is responsible for the Service & Units segment of the PULP & PAPER business area, will additionally assume responsibility for the ENVIRONMENT & PROCESS business area.

The responsibility areas of Wolfgang Leitner, President and Chief Executive Officer, and of Karl Hornhofer, member of the Executive Board, will remain unchanged.

The Swedish Legal, Financial and Administrative Services Agency selects ÅF for project consulting services in IT

The Legal, Financial and Administrative Services Agency has selected ÅF in the allocation of framework agreements for government agencies. The contract covers project consulting services in IT and spans two years, with the option of a subsequent two-year extension.

"As the Swedish Legal, Financial and Administrative Services Agencynegotiates on behalf of practically all government agencies, this is an important contract that will help to boost our growth even more in the public sector," says Johan Olsson, President of the Infrastructure Division.

ÅF primarily won the contract thanks to its experience of turnkey deliveries that encompass all parts of the tender. The contract is expected to form the basis of assignments for the seven selected consultancies worth a total of nearly SEK 400 million per year.

In project consulting services, ÅF takes principal responsibility for the result of a certain specified assignment. ÅF benefits from its large size and breadth in such services. The contract covers the areas of usability, management and control, operational development and strategy, system development and system management, information security, infrastructure and GIS.

Corporate Information

ÅF AB

For further information, please contact:

|

Johan Olsson, President, Infrastructure Division |

+46 (0)70-249 00 75 |

|

Viktor Svensson, Director, Corporate Information |

+46 (0)70-657 20 26 |

ÅF is a leaderintechnicalconsulting, with expertise founded on more than a century of experience. We offer highly qualified services and solutions for industrial processes, infrastructure projects and the development of products and IT systems. Today ÅF has more than 4,000 employees. Our base is inEurope, but our business and our clients are found all over the world.

Buckeye CEO to Participate in UBS Global Paper & Forest Products Conference

Buckeye Technologies Inc. (NYSE:BKI) has just announced that John B. Crowe, Chairman and Chief Executive Officer, will participate in the UBS Global Paper & Forest Products Conference in New York City on Wednesday, September 15, 2010, at 8:00 a.m. (ET).

A live audio webcast of Mr. Crowe's remarks and a copy of presentation materials will be accessible at www.ibb.ubs.com/Conferences or www.bkitech.com. To access the webcast, follow the Conference link to the UBS Global Paper & Forest Products Conference heading.

Buckeye, a leading manufacturer and marketer of specialty fibers and nonwoven materials, is headquartered in Memphis, Tennessee, USA. The Company currently operates facilities in the United States, Germany, Canada, and Brazil. Its products are sold worldwide to makers of consumer and industrial goods.

Certain matters discussed in this press release may constitute forward-looking statements within the meaning of the federal securities laws that involve risks and uncertainties, including but not limited to economic, competitive, governmental, and technological factors affecting the Company's operations, financing, markets, products, services and prices, and other factors.For further information on factors which could impact the Company and the statements contained herein, please refer to public filings with the Securities and Exchange Commission.

SOURCE: Buckeye Technologies Inc.

Buckeye Technologies Inc.

Steve Dean, 901-320-8352

Sr. Vice President and Chief Financial Officer

or

Daryn Abercrombie, 901-320-8908

Investor Relations

www.bkitech.com Buckeye Technologies among Top 20 Percent of Sustainable Businesses in Southeast

Buckeye Technologies Inc. (NYSE:BKI) today announced that it had been named in the top 20% of publicly held companies headquartered in the Southeast on their Corporate Sustainability policies and practices.

The first annual Southeastern Corporate Sustainability Rankings, announced in May of this year by GreenBusiness Works and its partners, rated 280 companies on their environmental, social and governance (ESG) factors and policies. These rankings were compiled by KLD Research & Analytics Inc., which was also instrumental in naming Newsweek's Green 500 ratings.

John Crowe, Chairman and CEO, expressed appreciation for this recognition. "In April of 2009, we published our inaugural Sustainability Report, emphasizing sustainable business practices throughout our operations worldwide and detailing our focus on reducing fossil fuels, water, solid waste, and air emissions. Our latest report will be released in early September and we are proud of the measurable progress we have so rapidly made. It is rewarding to receive the acknowledgement of our efforts by the top quintile placement in these rankings."

As a result of being ranked among the top 20 percent, Buckeye was also invited to attend the group's first C-Suite and Sustainability Breakfast session conducted August 24. This session, and those that will follow, provide an ongoing forum for senior executives to gain fresh insights and share ideas which will increase the pace of sustainable developments.

For more information about Buckeye Technologies and its sustainability efforts, and for a downloadable copy of the 2008 Sustainability Report, please visit our website at www.bkitech.com.

Buckeye, a leading manufacturer and marketer of specialty fibers and nonwoven materials, is headquartered in Memphis, Tennessee, USA. The Company currently operates facilities in the United States, Germany, Canada, and Brazil. Its products are sold worldwide to makers of consumer and industrial goods.

Certain matters discussed in this press release may constitute forward-looking statements within the meaning of the federal securities laws that involve risks and uncertainties, including but not limited to economic, competitive, governmental, and technological factors affecting the Company's operations, financing, markets, products, services and prices, and other factors.For further information on factors which could impact the Company and the statements contained herein, please refer to public filings with the Securities and Exchange Commission.

SOURCE: Buckeye Technologies Inc.

Buckeye Technologies Inc.

Steve Dean, 901-320-8352

Senior Vice President and Chief Financial Officer

or

Investor Relations:

Daryn Abercrombie, 901-320-8908

www.bkitech.com KapStone Paper and Packaging Corporation Gains Approval as Producer of Cellulosic Biofuel

KapStone Paper and Packaging Corporation (NYSE: KS) ("KapStone") announced that the Company was notified that its registration as a producer of cellulosic biofuel for the tax year 2009 has been approved. With this registration, KapStone may apply for a nonrefundable income tax credit of $1.01 per gallon of qualified cellulosic biofuel for the black liquor burned in early 2009 when the Company did not claim the alternative fuel mixture tax credit. KapStone estimates that a net $22 million benefit related to cellulosic biofuel will be reflected in the Company's third quarter 2010 income tax provision. There is no certainty the full benefit will be utilized to offset future taxes payable as it will be dependent on future taxable income.

About the Company

Headquartered in Northbrook, IL, KapStone Paper and Packaging Corporation is a leading North American producer of unbleached kraft paper products and linerboard. The Company is the parent company of KapStone Kraft Paper Corporation which includes paper mills in Roanoke Rapids, NC and North Charleston, SC, a lumber mill in Summerville, SC, and five chipping mills in South Carolina. The business employs approximately 1600 people.

Safe Harbor

This press release contains forward looking statements. These statements reflect management's current views and are subject to risks and uncertainties that could cause actual results to differ materially from those expressed or implied in these statements. Information on the risks and uncertainties is provided under Item 1A "Risk Factors" in the Company's Annual Report on Form 10-K for the year ended December 31, 2009, which is incorporated herein by reference, and elsewhere in reports that the Company files or furnishes with the SEC. These filings can be found on the Company's Web site at www.kapstonepaper.com. Forward looking statements included herein speak only as the date hereof and the Company disclaims any obligation to revise or update such statements to reflect events or circumstances after the date hereof or to reflect the occurrence of unanticipated events or circumstances.

SOURCE KapStone Paper and Packaging Corporation

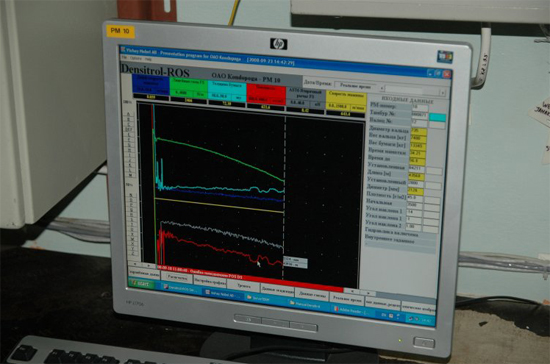

Vishay Nobel ROS reduces bottom waste

Several centimeters of paper left on a parent reel spool is a common sight in many paper mills. These left-on-spool or bottom waste losses, which cannot be wound because of tension control problems and crepe wrinkles during the initial phases of reel building, may add up to several percentage points of lost production. Many wrinkles and breaks in the winders and supercalenders are attributed to uneven density and web tension near the reel spool. Papermakers do what is natural by overbuilding a jumbo reel with extra paper which eventually ends up in the broke pit.

Vishay Nobel AB of Karlskoga, Sweden has come up with a solution to this chronic waste problem by introducing its Reel Optimization Control System (ROS) to the paper industry. Developed several years ago at mills in Sweden, the product is being commissioned on machines with older pneumatic reeling systems which are often imprecise and lack the feedback of actual reel building conditions and reel density.

Vishay Nobel converts the old pneumatic systems to hydraulic control systems so the primary and secondary arms are controlled and coordinated more precisely and repeatably for smoother operation, even sheet tension and more uniform reel building during the entire reeling cycle. In particular, the primary to secondary arm transfer is controlled so uneven sheet stresses are avoided. The primary arms, primary arm hooks, relief cylinders and secondary arms are equipped on the tending side and on the drive side with Vishay Nobel load cell sensors to measure nip pressure between the reel and the drum. The positioning of the hydraulic actuators is measured with transducers for precise feedback control. The entire reeling operation is supervised by operators through a video terminal interface.

Vishay Nobel’s customers report excellent results with much lower reel spool waste, higher production and other operating benefits. These typical results are confirmed by the following mills:

• Stora Enso Kvarnsveden, Sweden, which produces improved newsprint and magazine papers. Three ROS systems have solved the previous reel density control problems and have allowed the machines to produce jumbo reels with the right density profile without encountering winder runnability problems on the bottom sets with sheets containing up to 15% filler. The mill can now produce jumbo reels with a full complement of sets with a minimum of left-on-spool losses.

• OAO Kondopoga, Karelia, Russia. Five ROS systems have been installed on the mill’s newsprint machines. Bottom waste has been reduced significantly, adding to saleable production. On one machine production was increased by 7 tons/day. At the same time, reel snap-off breaks have been reduced or eliminated and the consistency of winding density and wound roll sheet area yield has been improved.

• Cartiere Burgo, Verzuolo, Italy. A new reel supplied by Comecart in Cuneo, Italy was supplied with a factory-installed ROS on the off-machine coater of PM8 line. The product is light-weight coated paper. With more uniform paper density at the reel spool, the losses reported by the supercalender operators have been cut dramatically - by over 70%. Since wrinkling in the supercalenders has been eliminated the throughput has been increased . The line operating efficiency is up 2 per cent and finished production has increased by about 10 tonnes per day.

The real-time progress of the reel density optimization controls is shown to the operators on a control room video monitor. The system also reports reel length and diameter so the operators can build the reel to the needed dimensions to suit the winders’ set production requirements.

An optical sensor (blue) measures reel bar rotation speed. A Vishay Nobel load cell sensor mounted behind it measures nip pressure applied by the secondary arms.

For more info please contact:

Ståle Hamnvik

Director, Nobel

Nobel Weighing Systems

Phone: +47 22 88 40 90

Mobile: +47 900 90 454

www.weighingsolutions.com

The employee group buyout effort for Pine Falls abandoned

The employee group considering the purchase of the shuttered Pine Falls newsprint mill has told the mill's owner, Tembec, that the deal is off. The group concluded it could not make a viable business case for the purchase.

According to the Winnipeg Free Press online edition on Aug. 24, Bruce Hansen, a consultant advising the buyout group, said the group was "quite astute in their approach" to the task and did its due diligence. It was just powerless to overcome the many barriers that have defeated so many other companies and would-be forestry industry investors in recent years.

"This is a difficult time for the former Tembec workers, their families and the buyout group who have worked so long to preserve the mill and the jobs that are critical to the town," said Manitoba Labour and Immigration Minister Jennifer Howard. "I commend the extensive efforts and diligence undertaken by the buyout group as it explored the financial viability of purchasing the mill from Tembec."

Metso to supply a cartonboard machine to Chinese Lee & Man

Metso will supply a coated cartonboard production line to Lee & Man Paper Manufacturing Co., Ltd to the company’s Hongmei mill in Guangdong province, China. The start-up of the new production line is scheduled for the end of 2011. The value of the order is not disclosed. A typical value of a board production line of this type is about EUR 70-90 million, depending on the scope of delivery and production output. The order is included in Paper and Fiber Technology’s Q3 orders received.

Metso’s delivery will include a complete white lined chipboard machine, from four-ply multi-Fourdrinier forming section to winder, with related air systems.

Lee & Man Paper and Metso have a long and prosperous co-operation, a good example of which are the Changshu and Hongmei kraftliner machines delivered earlier.

Lee & Man Paper Manufacturing Co., Ltd. is one of China's largest paper and pulp producers and it employs currently over 7,000 people. The company, founded in 1994, is listed in the Hong Kong Stock Exchange. In 2009, Lee & Man had a combined annual production capacity of close to 4.5 million tonnes of paper and 300,000 tonnes of pulp. In the financial year ending March 2010 the Group’s net sales amounted to about EUR 1.3 million.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

Further information for the press, please contact:

Kaarlo Hedman, Vice President, Sales, Paper business line, Metso

Tel. +358 40 585 9943

Further information for investors, please contact:

Johanna Henttonen, Vice President, Investor Relations, Metso Corporation, tel. +358 20 484 3253

International Paper Chairman & CEO to Speak at UBS Global Paper and Forest Products Conference

International Paper Chairman and Chief Executive Officer John V. Faraci will speak at the UBS Global Paper and Forest Products Conference in New York City on Tuesday, Sept. 14. The presentation is scheduled for 8:45 a.m. EDT, and will be followed by a question and answer session.

All interested parties are invited to listen to the webcast via the company's Internet site at www.internationalpaper.com by clicking on the Investors tab and going to the Webcasts and Presentations page. A replay of the webcast will also be on the Web site beginning approximately three hours after the presentation.

About International Paper

International Paper is a global paper and packaging company with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include uncoated papers and industrial and consumer packaging, complemented by xpedx, the company's North American distribution company. Headquartered in Memphis, Tenn., the company employs about 60,000 people in more than 20 countries and serves customers worldwide. 2009 net sales were more than $23 billion. For more information about International Paper, its products and stewardship efforts, visit internationalpaper.com.

SOURCE International Paper

Federal government pays $130 million to settle AbitibiBowater expropriation

The Government of Canada will pay AbitibiBowater $130 million in compensation for the expropriation of the company's assets in Newfoundland and Labrador, considering that amount fair market value for the newsprint mill, water and timber rights, power plants and hydro infrastructure. As part of the settlement, AbitibiBowater will withdraw its request for NAFTA arbitration on the issue. The payment will be made after AbitibiBowater completes its restructuring.

Premier Danny Williams of Newfoundland says his province, which took possession of the assets in March 2009, will not repay the federal government for the settlement. Williams is unrepentant concerning the hasty expropriation, according to a story by the Canadian Press appearing in the Winnipeg Free Press on Aug. 25. Williams also says he'd do nothing differently - except for the accidental seizure of the mill itself.

In a joint statement, the Department of Foreign Affairs and International Trade Canada said: "The Government of Canada has resolved this dispute for the benefit of Canada's long-term economic interests. In reaching this agreement, the Government of Canada is avoiding potentially long and costly legal proceedings."

"We believe this is an acceptable settlement for our company, stakeholders and creditors, given the set of circumstances faced by the company at this particular time as well as the inherent uncertainty of any judicial process," stated David J. Paterson, president and CEO. "We are now able to move forward and focus on finalizing our restructuring process and plans to emerge from creditor protection in the fall 2010."