Displaying items by tag: Toscotec

Toscotec to supply two new tissue machines to Chinese producer Liuzhou Liangmianzhen Paper Product Co.,Ltd

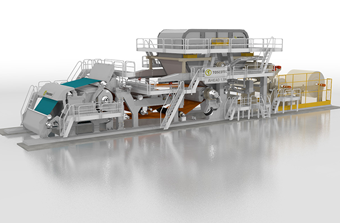

Liuzhou Liangmianzhen Paper Product Co., Ltd. has placed an order with Toscotec for #2 MODULO-PLUS ES tissue lines, which will be installed at its production site in Liuzhou, Guangxi.

Originally established in 1941 as a group of private soap enterprises, the LMZ Group was listed on the Shanghai Stock Exchange in 2004. It currently operates in 5 different areas: cosmetics, paper, fine chemicals, medicine and real estate.

The two TMs are based on Toscotec ES concept. Especially interesting for Asian market, the Energy Saving solution is capable to guarantee, according to the configuration, a substantial reduction in energy consumption during the tissue drying process. The two MODULO-PLUS are designed for a design speed of 1500 m/min and will produce 65 tons/day of high-quality toilet and facial tissue from pre dried virgin pulp and Slush pulp produced by LMZ.

The order includes the two crescent former machines, each equipped with a TT SYD-15FT (4572mm) and a double press configuration, a Milltech Steam Heated Hood, Toscotec stock preparation high efficiency equipment and the electrical and control systems. A TT WIND-M Tissue Slitter Rewinder, spare parts for the entire plant and a full service package complete the scope of supply.

Start-up is scheduled for the second half of 2015.

ECOFIBRAS STARTED UP TM#5 IN ARANGUREN, SPAIN, AFTER MAJOR REBUILDING

The Spanish Company ECOFIBRAS ARANGUREN SL, tissue manufacturing facility of the CEL group, has successfully completed and started up in cooperation with Toscotec the major rebuild of the tissue machine TM#5 in Aranguren – Zalla Bizkaia – after a major rebuilding.

Formerly KC Aranguren plant, Ecofibras initiated a new phase as an independent company in 2012. TM#5 rebuild project was part of the new development plan designed to increase company’s production capacity and improve product’s quality with the aim to supply current parent reels market, both in virgin and in deinked pulp reels.

The project’s scope was to rebuild into a crescent former the existing machine TM#5, originally equipped with a suction breast former and sloped wire configuration, in order to produce lower tissue grades, improve the machine speed as well as the runnability and maintenance.

Toscotec supplied to Ecofibras a stock preparation upgrading, a fully hydraulic step diffuser headbox TT Headbox-SLT and the replacement of the wet-end section into Crescent Former. Erection supervision, start-up assistance and training services completed Toscotec’s scope of supply.

The new configuration, besides reaching energy savings and a high product quality targets, allowed TM#5 machine to increase the operating speed from 1370 mpm up to 1500 mpm, with the possibility of reaching a speed of 1800 mpm once dry end section will be upgraded.

Due to the perfect integration of the mill and Toscotec teams, the rebuild has been carried out in a very short time and the target was reached both in terms of timing and performances.

Once more, with this new installation, Toscotec has demonstrated its capability and great experience in managing complex technological machine upgrading and rebuilding worldwide in a short delivery and installation time.

TOSCOTEC TO SUPPLY THREE NEW AHEAD-1.5M ES TISSUE MACHINES TO VINDA GROUP, CHINA.

![]() Vinda Group, producer and branded provider of household paper and personal care & hygiene products in China, has placed an order with the Italian manufacturer Toscotec for the supply of three new tissue lines at its two mills in Deyang, Sichuan and Laiwu, Shandong, which are scheduled to come on stream in the last quarter of 2015.

Vinda Group, producer and branded provider of household paper and personal care & hygiene products in China, has placed an order with the Italian manufacturer Toscotec for the supply of three new tissue lines at its two mills in Deyang, Sichuan and Laiwu, Shandong, which are scheduled to come on stream in the last quarter of 2015.

Vinda Group has stepped up its expansion plan. In line with the strong partnership established with Toscotec, it decided to place these new orders with the Italian manufacturer, based on Toscotec’s technological advantage, which delivers top product quality and considerably reduces the mill's energy costs. As a result, the Group will add an annual production capacity of 60,000 tons in Shandong and 30,000 tons in Sichuan.

The new Toscotec lines are AHEAD-1.5M ES crescent former tissue machines, designed for the production of high quality tissue products, with significant energy savings both with usage of gas and with steam. The speed is 1600 mpm, with a trim width of 3400 mm. Furthermore, the scope of supply also includes Toscotec’s Drying Optimization for Energy Saving solution TT DOES, a tailor-made drying package including also Milltech hood, which delivers higher drying efficiency and output, as well as key energy savings. Toscotec’s short approach flow TT SAF contributes to such savings, with an overall efficiency increase in the approach system.

Complete engineering and erection supervision, commissioning & start up assistance and training services are also part of the supply.

These orders continue along the line of a strong, successful, long-term partnership between Toscotec Group and Vinda Group, which begun in 2011. Vinda Paper (Shandong) Co. Ltd. already houses two Toscotec tissue machines, PM1 & PM2, which came on stream in the second half of 2013.

Established in 1985, Vinda Group has grown from a small private company into a leading manufacturer and branded provider of quality household paper and personal care & hygiene products in the PRC. Vinda is today, with major shares from Swedish group SCA, the third largest hygiene paper manufacturer in the PRC, with excellent performance in customer loyalty and satisfaction. With 9 manufacturing plants strategically located in different parts of the country, it serves the entire PRC, Hong Kong and Macau and exports to Australia, Singapore, Vietnam, Cambodia, Africa.

TOSCOTEC to rebuild PM4 Tissue Machine at Van Houtum - The Netherlands

Toscotec has been awarded a contract to deliver a dry end rebuilding of the Van Houtum B.V. PM 4 tissue machine in Swalmen, The Netherlands. The start-up of the rebuilt machine is scheduled for the third quarter of 2015.

Van Houtum is an independent producer of hygienic paper products and innovative washroom solutions for 80 years and is a leader in the area of Corporate Social Responsibility (CSR). This family-owned company operates one mill in Swalmen, located in the south of the Netherlands, where it can produce approximately 45,000 tonnes/yr of tissue from recovered paper on two machines. A separate location nearby houses nine converting lines: three rewinders produce toilet and industrial products and six lines produce interfold and multifold products. The firm has some 200 employees and generates annual sales of around €65m. Under the brand name of “Satino Black”, environmental labelled as FSC recycled and European Ecolabel as well as Cradle to Cradle-certified, the Company offers a wide range of products that includes toilet paper and paper hand towels.

In line with this green and dared philosophy, the Company has decided to choose Toscotec for its dry end rebuild on the PM4. The purpose of the rebuilding is to implement machine efficiency, reliability and safety in operations.

In line with this green and dared philosophy, the Company has decided to choose Toscotec for its dry end rebuild on the PM4. The purpose of the rebuilding is to implement machine efficiency, reliability and safety in operations.

Toscotec 's delivery includes a new reel TT Reel-P that will replace completely the existing old one. The supply is completed also by new tail threading system, sheet stabilizers and shaft puller with expandable shafts. The project will be handled on a turnkey basis, including dismantling of the existing equipment, installation of the new machinery, start-up assistance and training services.

The new machine parts will be designed for an operative speed up to 1800 mpm with a paper width of 2600 mm.

Toscotec is a major paper and tissue machinery supplier that operates worldwide, focused on process solutions that cover the whole plant area from stock preparation up to winders. This new project consolidates the well know Company capabilities to provide, not only a wide range of new machinery but also complex rebuild projects based on turnkey concept.

Toscotec to supply a new ahead tissue line to JSC Syassky Pulp & Paper Mill in Russia

Syassky Pulp and Paper Mill, based in St. Petersburg, Russia has signed a contract with the Italian manufacturer Toscotec for the supply of a new tissue line at its mill in Syasstroy, in the Leningrad region of Russia.

Syassky Pulp and Paper Mill, based in St. Petersburg, Russia has signed a contract with the Italian manufacturer Toscotec for the supply of a new tissue line at its mill in Syasstroy, in the Leningrad region of Russia.

The new Toscotec AHEAD tissue machine, designed for production of high quality tissue products, will replace the existing PM3 after its dismantling and will come on stream in first half of 2016.

In line with a huge investment process put in progress in the last years and to better expand its growing market in terms of quantity and quality, Syassky Pulp and Paper Mill has decided to invest in the new PM3 line adopting Toscotec’s state of the art latest technology with the aim of improving products offer and reduce the mill's energy costs.

The scope of supply of the new PM3 includes AHEAD-1.5M crescent former tissue machine with a single layer headbox, single press configuration with suction pressure roll TT SPR1045, a 12 FT diameter Steel Yankee Dryer TT SYD-12FT and a reel section TT Reel-P.

The delivery will also include the approach flow system, stock preparation plant, gas heated hood and steam & condensate system from Toscotec associate Milltech, as well as electrification & control system. Engineering and services (erection supervision, commissioning & start up assistance, training) complete the package. Machine speed will be up to 1400 mpm with a trim width of 4200 mm, for a daily production of 125 tons both from dry and slush pulps.

This new order from the Russian Company to Toscotec confirms the successful cooperation between the two companies begun in 2009. The Syasstroy’s site already houses a AHEAD-1.5M tissue machine supplied by the Italian manufacturer in 2012 to replace the existing PM2 as well as two rewinders TT WIND-H (for PM2 and PM3 lines) that came on stream in 2010 and 2012 respectively.

Syassky Pulp and Paper Mill is actually one of the most modern enterprises of the north west Russian region and the only integrated tissue producer in this area having in line pulp mill, tissue production (PM2, PM3 and PM5) and converting & packaging facilities. Founded in 1928 with the unique aim to cover the needs of the domestic market, the Company has been reorganized as joint stock company with the result to be able to satisfy the growing demand for domestic but also for AFH export markets.

Celupaper S.A. to invest in third tissue machine at Nicaragua mill in Argentina.

Celupaper S.A., part of Grupo Vual, South American leading regional player producing pulp and tissue, has signed a contract with Toscotec for a new PM3 tissue machine and a rebuilding of the existing PM2 at Papelera Nicaragua in Argentina.

Vual is an Argentinian group, owned by the Speranza family, specialized in the manufacturing and trading of tissue paper products, including napkins, towels and toilet paper, as well as the production of virgin pulp.

Today the group has three manufacturing plants (Jose Juan Yapur, Celupaper and Papelera Nicaragua), one pulp manufacturing plant (Celulosa Alto Vale) and distribution centers located in Santa Fe, Córdoba, Bahia Blanca and Buenos Aires employing more than 700 people.

With these new projects Grupo Vual will reach an annual total tissue production of 75,000 tons.

Based on an intensive energy-saving concept, PM3’s delivery includes the approach flow system featuring ultimate Toscotec technology TT SAF®, a MODULO tissue machine with single-layer headbox, single press configuration and Toscotec steel Yankee dryer TT SYD-2500MM. The supply will also comprise an electrification and controls package, Milltech gas heated hood and steam & condensate system.

Erection supervision, start-up assistance and training services complete Toscotec’s scope of supply.

The new line will enable the optimization of the production cycle, both in terms of flexibility and energy costs, and a production of 50 tons a day of different grades of high-quality tissue. Start-up is foreseen for 2nd half of 2015.

The PM2 rebuild has been designed to reconfigure the existing Fourdrinier machine. The new TT SuctionPressRoll-SPR820 and the steel yankee dryer TT SYD-2500MM, will be installed within the 1st Q 2015. The installation will allow to increase the production speed as well as to guarantee a considerable energy savings and improve paper quality.

Chinese Vinda Ltd. boosts its capacity with several repeated orders to Toscotec S.p.A.

In the last two years, the close partnership between the Hong Kong based giant tissue producer Vinda International Holdings Ltd's and the Italian leader tissue machinery Supplier Toscotec S.p.A., has delivered exceptional results: over 20 new TMs have been started up with a variety of models and drying configurations. This allowed the Vinda Group to double its production capacity reaching over 900,000 tpy tissue production.

Established in 1985, Vinda Group has grown from a small private company into a leading manufacturer and branded provider of quality household paper products in the PRC and Hong Kong. Vinda is today, with major shares from Swedish based group SCA, the third largest hygiene paper manufacturer in the PRC, with excellent performance in customer loyalty and satisfaction. With 9 manufacturing plants strategically located in different parts of the country, it serves the entire PRC, Hong Kong and Macau and exports to Australia, Singapore, Vietnam, Cambodia, Africa.

The first orders placed by the Chinese producer in year 2012 featured Toscotec’s Modulo Plus ES, with 12 ft TT SYD, a compact, modular and cost-effective machine concept with superior energy saving features. The most recent orders were for Toscotec’s advanced, high-performance tissue machines, the Ahead 2.0 ES, with 18 ft SYD.

The first orders placed by the Chinese producer in year 2012 featured Toscotec’s Modulo Plus ES, with 12 ft TT SYD, a compact, modular and cost-effective machine concept with superior energy saving features. The most recent orders were for Toscotec’s advanced, high-performance tissue machines, the Ahead 2.0 ES, with 18 ft SYD.

The key to this continuous success is represented by the great advantages in energy savings granted by Toscotec’s state of the art technology and its “TT DOES” solution, the Drying Optimization for Energy Saving.

TT DOES relies here, like in most of the orders secured to the Italian Supplier in China, exclusively on steam, the cost-effective energy source in the region, and delivers the lowest possible energy consumption.

Through the wide application and fine tuning of this solution over the years, Toscotec has now achieved the lowest consumption figures of the tissue industry, matched with the highest machine performance and runnability.

The increase in drying capacity translates directly into an increase in production output in the mill with an important side effect to reduce carbon footprint emissions.

In China since 2003, in a few years Toscotec has established itself as a leading tissue machine supplier catering to top Chinese producers. This is also the result of the recent investment effort and major steps taken by the Lucca manufacturer in establishing a new organization in China, Toscotec Paper Machine (Shanghai) Co., Ltd.

Started up in 2012, the Shanghai-based affiliate operates as Toscotec’s Sales & Customer Care Center for the entire Asian market.

L.C. Paper started up PM2 rebuild by Toscotec in Besalu, Spain

Besalu, Catalunya (Spain) - At the beginning of October 2014 the Spanish Company L.C. Paper 1881 has started up PM2 in Besalu, (Catalunya – Spain) after a major dry-end rebuild with Toscotec and its associate Milltech.

The rebuild project target was mainly to reduce PM2 energy costs and improve paper machine efficiency as well as increase the production at higher tissue grades thanks to the application of TT DOES (Drying Optimization for Energy Saving) package.

LC Paper was formed in 1881 on the back of the Industrial Revolution and is now well regarded for its production of niche tissue products contained with two tissue machines (PM2 and PM3) annually producing 65,000 tonnes of tissue for the AfH market. The main focus of the mill is toward energy saving aspects and for this reason since many years the Company has been focused on cogeneration applications.

LC Paper was formed in 1881 on the back of the Industrial Revolution and is now well regarded for its production of niche tissue products contained with two tissue machines (PM2 and PM3) annually producing 65,000 tonnes of tissue for the AfH market. The main focus of the mill is toward energy saving aspects and for this reason since many years the Company has been focused on cogeneration applications.

Already in 1993, LC Paper introduced in the mill a cogeneration plant. It was the first plant with a diesel engine of 6.5 MW in Spain that was expanded in 1999 with a second 6 MW engine.

In 2009 LC Paper launched PM3 with a patented process that takes gas from the cogeneration plant to dry the paper by the means of an innovative hood provided already by Milltech. In 2011 the first diesel engine was sold and in 2012 LC paper installed a new gas engine. 6 MW of this energy have been used for feeding the new hood by Milltech on PM2 with a further decrease of energy consumption.

The combined scope of supply Toscotec/Milltech featured a new double presses configuration with a rebuild of the felt run, a new TT SYD-15FT with doctoring system and a Duo-system Yankee hood, SMART eMT type from Milltech. The wet end hood is burner feeding type while the dry end hood could be fed either by cogeneration gases or by conventional burner.

The combined scope of supply Toscotec/Milltech featured a new double presses configuration with a rebuild of the felt run, a new TT SYD-15FT with doctoring system and a Duo-system Yankee hood, SMART eMT type from Milltech. The wet end hood is burner feeding type while the dry end hood could be fed either by cogeneration gases or by conventional burner.

So the exhaust gases coming from a gas engine are used to generate two stages of steam (high and low pressure) through steam generators in addition to the heat recovery to pre-heat the make-up and combustion air for the hood.

Maximum drying production with a machine trim width at reel of 3050 mm will be 130 tpd. With this new intervention the PM2 thermal consumption will be lowered to 1,350 kWh/t.

The rebuild project has been successful thanks to the close collaboration between the L.C. Paper staff and Toscotec and Milltech teams which were able once more to introduce innovative solutions to the tissue production process in accordance with LC Paper business philosophy.

YFY boosts its capacity in Taiwan with a new Toscotec tissue line

The Italian leading paper machinery manufacturer Toscotec will supply a complete tissue production line to the Taiwanese based Company Yuen Foong Yu (YFY).The tissue line will be installed in Ching-Shui mill located in Qingshui District, a coastal suburb an district in western Taichung City, Taiwan, Republic of China. The line will start up in the last quarter of 2015.

In April last year the Taiwan's largest paper and board producer announced to be poised to invest NT$8 billion ($268 million) in building several tissue paper machines at its mills in China and Taiwan over the next three years. This new investment is part of this big expansion plan into the tissue segment.

Founded in 1924, the company mainly dealt at the beginning in fertilizers, sugar, and grain. Yuen Foong Yu Paper Mfg. Co., Ltd was officially established on February 21, 1950. Yuen Foong Yu Paper produces reading and writing, industrial, and home use paper. It is characterized by a fully integrated production chain covering upstream (forestry, pulp), midstream (paper manufacturing) and downstream (printing, packaging, and design) operations, which yield beneficial synergy effects. Yuen Foong Yu Paper currently operates in the tissue business in China , with three mills ( Yangzhou-Jangsu, Kunshan-Suzhou Jangsu, Beijing-Mafang) with a total annual capacity of approx. 150,000 tpy, and in Taiwan with two mills (ChingShui and Yangmei) with a total annual capacity of approx. 74.000 tpy. In Taiwan the company has around 25% of the domestic market and it is looking at expanding its market share to 35% in three years' time

Founded in 1924, the company mainly dealt at the beginning in fertilizers, sugar, and grain. Yuen Foong Yu Paper Mfg. Co., Ltd was officially established on February 21, 1950. Yuen Foong Yu Paper produces reading and writing, industrial, and home use paper. It is characterized by a fully integrated production chain covering upstream (forestry, pulp), midstream (paper manufacturing) and downstream (printing, packaging, and design) operations, which yield beneficial synergy effects. Yuen Foong Yu Paper currently operates in the tissue business in China , with three mills ( Yangzhou-Jangsu, Kunshan-Suzhou Jangsu, Beijing-Mafang) with a total annual capacity of approx. 150,000 tpy, and in Taiwan with two mills (ChingShui and Yangmei) with a total annual capacity of approx. 74.000 tpy. In Taiwan the company has around 25% of the domestic market and it is looking at expanding its market share to 35% in three years' time

The delivery, based on an intensive energy-saving concept, includes the stock preparation plant with the approach flow featuring ultimate Toscotec technology TT SAF®, water system, an AHEAD-1.5M tissue machine with double-layer headbox, jumbo suction press TT SuctionPressRoll-SPR1425 and Toscotec steel Yankee dryer TT SYD-18FT. The supply will also comprise the electrification and controls package, tissue machine auxiliaries like the steam heated hood, steam & condensate system, dust removal system provided by Toscotec’s associate Milltech.

With a width of 3,60 m and a design speed of 1700 mpm, the new production line will produce 120 tons per day of high-quality facial, toilet and towel grade from 13,5 g/m2 to 23 g/m2 basis weight.

Toscotec is today one of the market leaders for tissue machines with numerous installations worldwide.

Toscotec is today one of the market leaders for tissue machines with numerous installations worldwide.

With this latest order the company continues on its further expansion in the Asian market where operates also thru its affiliate Toscotec Shanghai ( PRC).

The optimal features of the machine design with a large diameter SYD and a big SPR combined with a steam heated hood, experienced already by several installations and repeated orders supported with high level regional service by Toscotec, are the unique characteristics of this new project that made the difference in the decisional process of the Taiwanese Company in choosing the final Supplier.

Petrocart starts up the new Toscotec Tissue Line in Piatra Neamt

At the end of April, the Rumanian tissue producer Petrocart, has successfully started up their new Toscotec complete tissue production line installed in Piatra Neamt, headquarter of the company since 1908.

Based on a turn-key concept and an average production of 75 tons per day, the new line includes the stock preparation plant for virgin and recycled fibers, a MODULO-PLUS tissue machine with single-layer headbox, double press configuration and TT SYD-12FT, the tissue machine auxiliary plants including a Milltech hood and steam & condensate system . A three unwind stands tissue slitter rewinder TT WIND-M completes Toscotec scope of supply.

According to Petrocart green philosophy, the project was mainly focused on reduced energy consumption, usage of waste paper, recovery and re-usage of the water in the manufacturing process.

The project has been managed on the turn-key basis by Toscotec providing also the whole engineering services, erection supervision, start-up and training.