Ian Melin-Jones

AxFlow Finland acquires TM-Palvelu OY

AxFlow Oy in Helsinki Finland, part of the AxFlow Group has announced its acquisition of TM-Palvelu Oy, a well established pump service and piping contractor in Finland.

The take-over which was formalised in May 31, 2011, is a major development for AxFlow Oy as it provides the company with a substantial in-house competence in pump maintenance and after sales services.

![]() TM-Palvelu has been established in 1988 in Kotka, one of the main port-cities in Southern Finland. From this base, the company has developed its strong foothold in the service of power plants and liquid terminals. The other key segments include the chemical and pulp & paper industries. Under the stewardship of founder Pentti Anttila, TM-Palvelu has built up a fine team of skilled service technicians, most of them certified to work in the oil & gas and energy plants.

TM-Palvelu has been established in 1988 in Kotka, one of the main port-cities in Southern Finland. From this base, the company has developed its strong foothold in the service of power plants and liquid terminals. The other key segments include the chemical and pulp & paper industries. Under the stewardship of founder Pentti Anttila, TM-Palvelu has built up a fine team of skilled service technicians, most of them certified to work in the oil & gas and energy plants.

Announcing the acquisition, AxFlow Managing Director Harri Lindroos said: “Service is a major growth area for AxFlow Finland. By bringing TM-Palvelu into AxFlow we strengthen our service capabilities and gain the additional engineering resources that will allow us to expand in, for us new, segments such as the liquid terminals. The combination of the resources and competence of TM-Palvelu and AxFlow will bring considerable benefits for both companies’ existing customers and prospects in a form of a wide product portfolio, professional pump maintenance and after sales services.”

ROXCEL takes over Brigl & Bergmeister and Papirnica Vevče.

The Vienna-based multinational paper trading company ROXCEL Group has today signed an agreement to purchase the paper manufacturer Brigl & Bergmeister and Vevce from the Prinzhorn Group, taking over complete ownership.

Brigl & Bergmeister runs two production facilities in Niklasdorf/Austria and Vevče/Slovenia which produce an aggregate of 165.000 tons of paper per year with 500 employees. Brigl & Bergmeister is the world market leader and specialist manufacturer for label paper with an export share of 95%.

With aggregate sales of EUR 729 Mio./USD 1.033 Mio in 2010, the ROXCEL Group is one of the world’s largest paper and paper board trading companies. ROXCEL is based in Vienna and operates through a global network of sales offices in more than 100 countries. With the acquisition of Brigl & Bergmeister, ROXCEL is entering the field of paper manufacturing for the first time in its history. The production arm will operate separately from Roxcel’s trading division.

With highly qualified, motivated employees and a strong Brigl & Bergmeister and Papirnica Vevče management team, Roxcel aims to further strengthen its pre-existing excellent business relationships in the print and packaging industry through innovative and ecologically sustainable products and to further improve the supply chain.

The transaction is subject to merger control approval from the Monopolies and Mergers Commission. All parties concerned have agreed to treat the purchase price as confidential.

Rengo to Resume Operations at Marusan Paper

Rengo Co., Ltd. (Head Office: Kita-ku, Osaka; President & CEO: Kiyoshi Otsubo) announces the resumption of operations by Marusan Paper Mfg. Co., Ltd. (Head Office: Minamisoma-shi, Fukushima Prefecture), a Rengo subsidiary. Marusan Paper facilities were damaged by the Great East Japan Earthquake, and the company is located 25 kilometers from the Fukushima No. 1 Nuclear Power Plant operated by Tokyo Electric Power Company. A decision was made to suspend operations until the end of June, but following discussions with officials from the local governments of Fukushima Prefecture and Minamisoma-shi, Rengo decided to resume operations as detailed below.

Resumption of Operations by Marusan Paper

Marusan Paper produces containerboard and specialty papers using three paper machines, but operations will be resumed in stages in accordance with the following schedule.

| Machine | Product | Resumption of operations |

| No. 2 paper machine |

Specialty paper |

June 20 |

| No. 7 paper machine | Containerboard (corrugating medium) | July 1 |

| No. 6 paper machine | Containerboard (linerboard) | July 10 |

Careful testing of the radiation levels has been conducted since March 11, and levels are substantially below the regulatory standards. Therefore, there is no problem with conducting operations at the plant, but plant entrances will be covered with sheets of Cellgaia, a product developed by Rengo that contains zeolite. Likewise water used in paper making processes will be processed by passing it through water tanks that contain bags packed with zeolite to eliminate any radiation.

Rengo Commences Construction Work at its Shin-Sendai Plant

Rengo Commences Construction Work at its Shin-Sendai Plant, Aiming for the Earliest Possible Reconstruction and Revitalization After the Great East Japan Earthquake.

Rengo Co., Ltd. (Head Office: Kita-ku, Osaka; President & CEO: Kiyoshi Otsubo) announces that it is constructing the Shin-Sendai Plant (Taiwa-cho, Kurokawa-gun, Miyagi Prefecture) as a reconstruction and revitalization of the Sendai Plant (Miyagino-ku, Sendai-shi, Miyagi Prefecture) that suffered catastrophic damage in the Great East Japan Earthquake and Tsunami of March 11.

A ceremony was held on June 17 in order to pray for the safety of the construction, which is scheduled to be completed in March 2012.

The construction of this new plant will ensure employment for workers from the Sendai Plant, and is also being carried out in an earnest manner together with Rengo’s desire to serve as a leader in the restoration, reconstruction and revitalization of the areas in the Tohoku region that were affected by the disaster, beginning with Miyagi Prefecture. It is also expected that accelerating our efforts in revitalizing the corrugated board industry—a packaging material that has close ties with the regional economy as an essential item for transporting objects—will promote the revival of the local economy.

As an appropriate facility for manufacturing fully recyclable and environmentally friendly corrugated board, the new plant aims to be an ideal plant for the 21st century, with ample consideration given to environmental impact, seen in its installation of solar power generation systems. An additional goal is to complete the plant at an early stage so it can serve as a central base in the Tohoku Region, as well as a symbol of reconstruction and revitalization after the disaster.

Shin-Sendai Plant Outline

| Name | Shin-Sendai Plant, Rengo Co., Ltd. |

| Location |

6-3-2 Matsusakadaira, Taiwa-cho, Kurokawa-gun, |

| Total site area | Approximately 73,500m2 |

| Building site area | Approximately 23,800m2 |

| Products | Corrugated board/boxes |

| Total investment | Approximately 10 billion yen |

| Scheduled date of completion | March 2012 |

| Plant concept | This plant aims to be an environmentally friendly corrugated board plant under the concept of “Less Weight, Less Carbon” and as a continuation of the Fukushima-Yabuki Plant that was opened last year. Using the experience of the recent earthquake, this plant also aims to become strong at withstanding such disasters. |

New quality control system and service contract for paper mill in Italy

The paper manufacturer Cartiere del Polesine commissioned Voith Paper Automation with the delivery of a new quality control system (QCS) for the BM 4 at the Cavanella Po plant in Italy. The OnQ Profilmatic basis weight CD profile control with the associated OnQ ModuleJet actuator system that are currently installed will be expanded to include the OnQ Profilmatic moisture CD profile control for controlling the nozzle moisturizer installed by the customer. This will therefore ensure the required quality for the basis weight and moisture CD profiles of the machine. Two Voith LSC scanners, 5.60 m and 6.50 m wide, are also included in the delivery. They will have four sensors in total. In addition, the automation system will be expanded to include OnQ GradeControl MD controls for basis weight and moisture. The new QCS should be installed by end of December 2011.

On the BM 3 in the same plant, stable basis weight CD profiles and short setting times (until achieving the guaranteed quality values after stoppages, grade changes or breaks) are also to be accomplished. In the future, the OnQ ModuleTap at the headbox will ensure this. The automatic control system is especially suitable for retrofitting existing headboxes from various manufacturers on which there is no dilution water system.

In addition, Cartiere del Polesine has chosen to conclude a service contract with Voith Paper Automation for both machines. Within the framework of the "remote diagnostics" service module, the package allows a remote diagnostic service of the automation systems used, if the customer so desires. A Voith Paper Automation service employee logs into the system of Cartiere del Polesine via an online connection and in this way can check the current status and eliminate malfunctions or carry out optimizations, if required.

The service module also includes 24/7 telephone support by the Voith service team. This guarantees very short reaction times and allows Cartiere del Polesine to get competent advice and support any time it is necessary. The service contract will come into effect in July 2011.

Back in 2007, Voith Paper Automation had equipped the BM 4 with its OnQ Profilmatic moisture CD profile control and the associated OnQ ModuleJet actuator system. This follow-up order is now the best proof that Cartiere del Polesine considers Voith Paper Automation to be a reliable partner. The automation upgrade has been planned in close collaboration with both teams and precisely adjusted to the needs and the available budget.

Körber is seeking an investor for Paper Systems

Within the context of its long-term corporate strategy to boost profitable growth, the Körber Group is planning to reposition itself. In order to sharpen its focus on fast-growing future markets, the Körber Executive Board has decided to sell off companies which are no longer part of the core business. For this reason Körber will be selling the companies E.C.H. Will, Pemco and Kugler-Womako, which are part of the Körber PaperLink Group, to a suitable investor. The Supervisory Board was informed about these plans yesterday. With the changes to the portfolio that are currently being sought, the Körber Group will be establishing the preconditions necessary to enable it to concentrate on its profitable core business, while at the same time expanding into new markets.

The three companies, which work closely together as Paper Systems, collectively have around 440 employees. Sales in 2010 amounted to some €100 million. All three have strong market positions with their technologies, and are amongst the leading companies in their respective fields of business. They have performed very successfully in the aftermath of the economic crisis.

A new owner is being sought for Paper Systems which is capable of continuing this positive performance in the long term. There is no specific time horizon for the divestment. While Körber is keen to complete the sale quickly, what is more important is finding the best possible investor for the companies.

The Körber PaperLink Division is set to remain part of the Körber Group. It will concentrate on its competencies in the fields of tissue, hygiene, mailing solutions and production logistic, and will further strengthen and expand these interests.

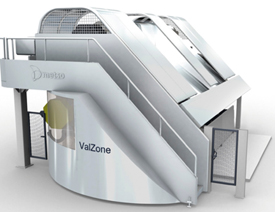

First ValZone metal belt calender for fine paper starts up at Sun Paper Group mill in China.

A Metso-supplied ValZone metal belt calender was started up on the PM 23 fine paper machine of Yanzhou Huamao Paper Industry Co. Ltd., member of Sun Paper Group, in Yanzhou city, Shandong Province, China at the end of April. Earlier the line was operated with a soft calender. The Metso-supplied paper machine has a wire width of 7.85 m and a design speed of 1,600 m/min, and it produces approximately 350,000 tonnes of uncoated fine papers annually.

With the metal belt calender, the line is able to produce top quality printing paper grades with superior feel and visual appearance. The ValZone metal belt calender allows raw material optimization, for instance by allowing an increase in the filler content of the sheet. Also, as a result of increased bulk, the same printing qualities can be reached with a lower grammage.

With the metal belt calender, the line is able to produce top quality printing paper grades with superior feel and visual appearance. The ValZone metal belt calender allows raw material optimization, for instance by allowing an increase in the filler content of the sheet. Also, as a result of increased bulk, the same printing qualities can be reached with a lower grammage.

The delivery is a repeat order of the ValZone technology as Sun Paper Group’s coated board line PM 22 also is equipped with metal belt calendering. The ValZone metal belt calender of PM 23 is the first installation for fine paper grades.

“This start-up is a milestone that brings the metal belt calendering technology into a whole new area of application. It is now for the first time used for printing papers and for the first time in a wide and fast paper machine thus demonstrating that the metal belt calendering technology has a lot of potential with regard to future development,” says Timo Valkama, Senior Paper Technology Manager, Metso’s Paper business line.

Yanzhou Huamao Paper Industry Co. Ltd. belongs to Sun Paper Group, which is one of the foremost paper and board producers in China. Altogether the group runs 22 paper machines mostly producing printing and writing grades with a combined capacity well exceeding 2,200,000 t/y. Sun Paper Group employs more than 7,000 persons.

M-real increases woodfree uncoated paper prices by 5-8% in August

M-real Office Papers will implement a 5-8% price increase for all its woodfree uncoated and recycled paper products across Europe in August. The increase will be done due to increasing costs of key raw materials such as pulp, starch and other chemicals as well as energy.

Despite the price of paper increasing over the last year, the margins for papermakers are still historically low and are insufficient to absorb the rising production costs.

M-real Office Paper’s Marcel Bigler, Senior Vice President, Sales, Marketing and Supply Chain says: “We must put up our prices so we can continue to deliver quality, innovative paper products. Trying to absorb the escalating costs of our key raw materials and energy is no longer an option.”

Thurso Mill Looks to the Future

The installation of four 110-ton boilers on site at the Thurso pulp mill this week not only marks a crucial step in converting the mill to a full-time specialized dissolving pulp producer, it also marks the beginning of some other notable changes for the Quebec facility.

Construction on a brand new 25-megawatt cogeneration plant will begin this summer. Capturing excess heat and steam from the process of making dissolving pulp, the cogeneration plant will convert these energy sources into power for both the mill and the province of Quebec. Initial plans see Fortress exporting 18.8 megawatts of energy to the provincial power grids over a 15-year term with the remaining energy used to power the Thurso mill and its operations.

But energy isn’t the only thing that this new facility could produce. Thurso plant manager Marco Veilleux told Le Droit last week that the additions to the mill could also lead to the inclusion of a biorefinery – a facility that integrates biomass conversion to produce numerous byproducts.

“Reflection on exactly what we want to do is coming,” he told the French newspaper. “Our process is one that will extract an enormous amount of sugars from our materials and there are lots of products that can be developed with these sugars.”

Indeed, there are more than one hundred products that can be created as a result of biorefineries Luc Bouthillier, a professor in wood and forestry sciences at Laval University, told Le Droit. Plastics, pharmaceuticals, lubricants, industrial vinegars, alcohols and adhesives are only some of the options.

For now, though, the Thurso mill will concentrate on its current changes – another of which includes the planting of 5000 poplars to create a “visual barrier” around the mill and coul

Mondi hosts Green Event at WWT Wetland Centre in Barnes, UK.

Mondi Uncoated Fine Paper UK invites key sustainability managers to the Green Event, which will cover a variety of topics including green procurement, current climate issues, and active environmental projects.

Mondi Uncoated Fine Paper UK is holding the Green Event at the WWT Wetland Centre in Barnes, London, UK, on the 29th September 2011. Guest speakers include representatives from WWF, FSC®, Action Sustainability, World Resources International, Two sides Campaign, Mondi’s Sustainable Development team as well as Dr. James Pryke, a specialist on ecological networks. With changing dynamics in the market place and a greater emphasis on sustainability, Mondi wishes to use its position as one of the leading pulp and paper producers to address environmental issues of importance for both consumers and industry – today and in the future.

The event is free to attend but places are limited and offered on a first come first served basis. All attendees will be entered into a prize draw that will take place at the Green Event. The 1st prize is an eco-holiday. To reserve a place at Mondi’s Green Event, please register at www.mondigroup.com/GreenEventUK

Green Event guests will also have an opportunity to explore Mondi’s recycled digital printing brand, NAUTILUS®. The range consists of three 100% recycled papers, NAUTILUS® SuperWhite (with CO2 neutral option), NAUTILUS® Classic and NAUTILUS® Universal, and the recently launched NAUTILUS® ReFresh TRIOTEC made with unique TRIOTEC sandwich technology, which combines outer layers made from TCF (Totally Chlorine Free) virgin fibre with an inner layer made from 30% recycled fibre.

For more information about Mondi’s recycled paper portfolio, please visit: www.mondigroup.com/nautilus