Ian Melin-Jones

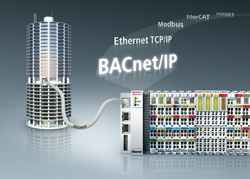

Beckhoff Building Automation: Software solution for Ethernet-based building standard

Beckhoff integrates BACnet/IP as a pure software solution into its TwinCAT automation suite. The BACnet/IP Server and Client are executable on all Beckhoff Industrial PCs and Embedded PCs. This means that every Beckhoff Embedded PC becomes a BACnet controller with the software extension. Since the I/O level (Bus Terminals or EtherCAT Terminals) can be added directly to the modular Embedded PCs, Beckhoff’s comprehensive range of Bus Terminals with over 400 different signal types is also available for BACnet applications. In a modular system, for example, information can be queried via temperature measurement or an occupancy sensor and sent via the appropriate data output to the heating or lighting controller.

The BACnet solution for TwinCAT supports all services of a BBC device (BACnet Building Controller). The BACnet objects are created in the TwinCAT System Manager and can be parameterised and linked there. Data from an I/O terminal or from the TwinCAT program can be connected directly to a BACnet object via a cyclic interface. An acyclic interface is used for reading and writing the “properties” of a BACnet object, so that these can be accessed from the PLC program during runtime. With the aid of TwinCAT, a network can be scanned for BACnet devices and objects or “properties” can be accessed.

The market introduction of the BACnet/IP solution is expected to be in late 2010.

Please send readers' questions regarding “BACnet/IP” to: Beckhoff Automation GmbH, Eiserstraße 5, 33415 Verl, Germany Phone: +49 (0) 5246 963-0, Fax: +49 (0) 5246 963-198 e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it., Internet: www.beckhoff.de

Building Automation: reducing control cabinet and assembly costs

The HD Bus Terminals are available in various versions, such as 16-channel terminals for digital inputs or outputs, 8-channel terminals for digital inputs or outputs with 2-wire connection, or “multi-tasking” combination terminals with eight digital inputs and eight digital outputs, offering the user a high degree of flexibility.

There is a broad range of applications for HD Bus Terminals in building automation: for example, 8-way buttons with integrated LEDs, for indicating the switching statuses, can be wired completely to a single 12 mm Bus Terminal. Eight thermal drives can be controlled completely by a single 12 mm output terminal using the 2-wire technique. On the input side, eight window or door contacts can be connected to one HD Bus Terminal using the 2-wire technique. With the compact I/O modules, the user saves valuable installation space in the control cabinet and the cost per channel is lowered significantly. A further advantage is the simplification of system assembly. Despite the high packing density, the convenient layout of the connection points is retained.

www.beckhoff.com/HD-Busterminal

Please send readers' questions regarding “Building HD Terminals” to: Beckhoff Automation GmbH, Eiserstraße 5, 33415 Verl, Germany Phone: +49 (0) 5246 963-0, Fax: +49 (0) 5246 963-198 e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it., Internet: www.beckhoff.de

Frost & Sullivan Recognizes Castolin Eutectic for High Quality Services

The 2010 Frost & Sullivan European Repair and Maintenance Welding Consumables Customer Service Leadership Award is presented to Castolin Eutectic. With end users becoming more aware of their welding requirements and also demanding a higher standard of service, Castolin Eutectic has raced ahead of competitors by providing improved services and paying more attention to critical issues like technical assistance, training courses, subcontracting facilities, etc.

The repair and maintenance welding consumables market has been one of the least affected markets during recession, mainly because end users prefer repair and maintenance to investing in asset replacement or newer technologies. Demand for repair and maintenance welding consumables is mainly from the heavy machinery user sectors, including power generating plants and the oil and gas extraction industries. Furthermore, the increasing prices of raw materials, competition from low-cost, low-quality Asian goods and the availability of alternative processes such as mechanical fasteners and adhesives offer challenges to the welding consumables market.

"Castolin Eutectic provides a wide array of alloy consumables, specifically for repair and maintenance in numerous end-user industries like heavy machinery, cement, automotive, power and offshore," says Frost & Sullivan Research Analyst Archana Chauhan. "All these quality services are selected to respond to the needs of the customers effectively, thereby demonstrating Castolin Eutectic's experience and insight into the diverse requirements of the customers."

The repair and maintenance welding industry needs an arsenal of diverse alloyed consumables for different repair and maintenance applications for which traditional welding products are not designed. Castolin Eutectic's proprietary alloys have helped it maintain a very strong historical relationship with the cement, oil & gas, waste and recycling, glass industry, pulp and paper and other industries. For the end users to achieve highest productivity gains through its special products, processes and services, Castolin Eutectic believes in providing them with technical know-how and training about how different alloy choices could best reduce their production downtime.

The company's international team of experts conduct production site surveys to identify "weak links" and thus can show clients the potential cost savings to be made by using Castolin Eutectic's specialised alloyed consumables. Its service processes are highly interdependent and hence, help to increase customer satisfaction and loyalty because the overall service experience is more effectively coordinated.

Significantly, while its competitors sell through distributors, who also stock consumables of other companies, Castolin Eutectic alloys are primarily sold direct through its own associated companies who can identify new repair subcontract opportunities. Such services are also responsible to develop application-specific procedures, processes and products to provide necessary customer technical support.

In addition, since the company has its own operations in several regions of Europe like the United Kingdom, France, Germany, Spain, Benelux, Scandinavia, Switzerland, Austria, Poland, the Czech Republic, Russia, Ukraine and Turkey, it can provide a rapid response service to customers.

"Although the overhead expenses of maintaining service is higher than distributor based supply chains, it is the company ethic to provide sufficient technical support to all its customers personally, which is more successful in the former case," says Chauhan. "The company has set appropriate standards for the timeliness of response for all forms of customer contact including phone calls, e-communications and grievance redressal cells."

Castolin Eutectic's success lies in its innate focus on customer satisfaction in its development and commercial activities. Besides studying client needs and providing innovative solutions and services, the company also monitors the outcome of its services. The company identifies individual customer needs at the first point of contact by an appropriate technical expert. When additional services appear to be likely, the company discusses with the customer the next step and indicates the probable overall time required to satisfy the needs successfully.

The Castolin Eutectic service organises workshops regularly, wherein the dedicated team of technical experts with full access to its unrivalled applications data base provides welding services to the end users. Its customers can now also subcontract all the welding operations to the CastoLab® Services teams in the absence of welders. In this way, the customers can have their work done safely by qualified technicians and remain satisfied, especially if insufficient welding skills or equipment exist in-house.

Furthermore, detailed brochures and initial technical visits by its technical experts are provided free of charge. Though the customers have to pay for any ensuing subcontracting services, it is still very cost effective compared with hiring welding experts at their plants to do the repair and maintenance work. The combination of innovative, application specific products and service with high value to customers make Castolin Eutectic the worthy recipient of the 2010 European Frost & Sullivan Award for Customer Service Leadership in the repair and maintenance welding consumables market.

Each year, Frost & Sullivan presents this award to a company that has demonstrated excellence in the timeliness of offering a novel service. The award recognizes efforts towards innovation, quality and cost effectiveness as well as the impact on customer satisfaction.

Frost & Sullivan Best Practices Awards recognize companies in a variety of regional and global markets for demonstrating outstanding achievement and superior performance in areas such as leadership, technological innovation, customer service, and strategic product development. Industry analysts compare market participants and measure performance through in-depth interviews, analysis, and extensive secondary research in order to identify best practices in the industry.

About Castolin Eutectic

With more than 2000 people worldwide, Castolin Eutectic is the leading company in fighting wear and providing specialist coating, repair & joining solutions in harsh operating conditions. We provide products with application know-how to customers and are increasingly moving to becoming a service based business. More than 100 years of experience in welding, brazing and thermal spraying technologies stands for professional and innovative solutions. Castolin Eutectic is your partner with industrial expertise in surface protection, repair and joining solutions. To find out more about us, please visit www.castolin.com or www.eutectic.com.

About Frost & Sullivan

Frost & Sullivan, the Growth Partnership Company, enables clients to accelerate growth and achieve best-in-class positions in growth, innovation and leadership. The company's Growth Partnership Service provides the CEO and the CEO's Growth Team with disciplined research and best-practice models to drive the generation, evaluation, and implementation of powerful growth strategies. Frost & Sullivan leverages over 45 years of experience in partnering with Global 1000 companies, emerging businesses and the investment community from 40 offices on six continents. To join our Growth Partnership, please visit http://www.awards.frost.com.

|

Catherine Brassell |

|

|

Best Practices |

|

|

Frost & Sullivan |

|

|

Tel: +44.207.915.7867 |

|

|

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. |

Georgia-Pacific Reaches Agreement to Purchase Alabama River and Alabama Pine Pulp Mills

Parsons & Whittemore and Georgia-Pacific have reached a definitive agreement for subsidiaries of Georgia-Pacific to purchase Parsons & Whittemore's Alabama River and Alabama Pine pulp mills in Perdue Hill, Ala. Terms of the deal were not disclosed.

Parsons & Whittemore and Georgia-Pacific have reached a definitive agreement for subsidiaries of Georgia-Pacific to purchase Parsons & Whittemore's Alabama River and Alabama Pine pulp mills in Perdue Hill, Ala. Terms of the deal were not disclosed.

This acquisition includes the assets of the pulp mills, Alabama River Woodlands, the tall oil plant, the biodiesel plant, the chip mills at Elba and Jacksons Gap, Ala., and a pulpwood yard at Demopolis, Ala. All employees of these operations will be offered employment with Georgia-Pacific. The sale is expected to close in the third quarter of this year. Both companies are committed to working toward a seamless transition of the business for suppliers and customers.

"With the help of literally thousands of people over the past 35 years, we have built a world-class business, with pulp mills that rank among the highest in quality, productivity, safety and environmental responsibility," said George Landegger, Parsons & Whittemore chairman and CEO. "Sincere thanks goes out to our employees for their diligent and dedicated efforts, and to all those in the local communities, such as landowners, wood suppliers and public officials, who had faith in us and who have assisted us greatly.

Landegger added, "I am proud of the relationships that we have developed in the Monroe County area and will continue to be active in local economic and social development. The sale to Georgia-Pacific represents a very good fit within the industry, and the pulp mills can look forward with confidence to a secure and successful future."

"Georgia-Pacific is committed to strategic growth of our businesses, both organically as well as through acquisition and innovation," said Jim Hannan, Georgia-Pacific CEO and president. "The employees and assets of Alabama River and Alabama Pine will be fully integrated into our GP Cellulose business unit. We believe this investment will add long-term value to our company, our cellulose business and the communities where we operate."

"We are excited to integrate the talented employees and high quality assets of Alabama River and Alabama Pine into our GP Cellulose business," said Pat Boushka, GP Cellulose president. "We look forward to serving the existing customers of these businesses and the completion next year of the current fluff conversion project so that we can continue to grow with our global fluff customers."

GP Cellulose is a non-integrated supplier of market and fluff pulp to global markets, with state-of-the-art pulp mills in Brunswick, Ga., and New Augusta, Miss. Commercial offices are located in Atlanta; Hong Kong; Montevideo, Uruguay; Shanghai, China; and Zug, Switzerland. GP Cellulose's Brunswick and Leaf River mills produce an array of pulp grades, which are delivered to every region of the world for a wide variety of end uses and converting technologies.

BMO Capital Markets acted as financial advisor to Parsons & Whittemore in the transaction.

Parsons & Whittemore, a privately held company based in Rye Brook, N.Y., was founded in 1853 and acquired by Karl F. Landegger in 1944. Throughout its history, the company has been recognized as a leading turnkey engineer/builder of pulp and paper mills, having completed some 60 projects in 28 countries. Alabama River Pulp is one of the largest pulp mills in North America and a leading global supplier of hardwood and softwood pulp.

Headquartered at Atlanta, Georgia-Pacific is one of the world's leading manufacturers and marketers of building products, tissue, packaging, paper, cellulose and related chemicals. The company employs more than 40,000 people at approximately 300 locations in North America, South America and Europe. Georgia-Pacific creates long-term value by using resources efficiently to provide innovative products and solutions that meet the needs of customers and society, while operating in a manner that is environmentally and socially responsible and economically sound. For more information, visit www.gp.com.

SOURCE Georgia-Pacific

Carl Marks Advisory Group Advises Gould Paper Corporation in the Majority Sale to Japan Pulp and Paper Corporation

Gould Paper Corporation Inc., a leading paper merchant headquartered in New York, has completed a majority sale to Japan Pulp and Paper Corp. (JPP), a Tokyo-based distributor of paper and paper-related products. Terms of the transaction were not disclosed. The investment banking group at Carl Marks Advisory Group LLC (CMAG) acted as financial advisor to Gould Paper.

JPP, established in 1845, is a USD 5 billion major paper trader and distributor and is listed publicly on the TSE stock exchange.

Founded in 1924, Gould Paper Corporation Inc. distributes business and printing papers. The company serves commercial printing, office papers, packaging, publishing, catalog and direct mail, paper traders and the closeout specials markets. It has operations in the United States; Canada; the United Kingdom; Paris; Helsinki, Finland; Moscow; Kiev, Ukraine; Auckland, New Zealand; Hong Kong; Shanghai; and Manila, Philippines. Additional information is available on www.gouldpaper.com

About Carl Marks Advisory Group LLC and Carl Marks Securities LLC

Carl Marks Advisory Group LLC, with offices in New York, Vienna, Va., Bedminster, N.J., and Charlotte, N.C., provides a wide array of investment banking and financial, operational and real estate advisory services to the middle market, including mergers and acquisitions advice, sourcing of capital, financial restructuring plans, strategic business assessments, improvement plans and interim management.

Carl Marks Securities LLC, based in New York, assists its clients in executing private placements of debt and equity. The firm is a member of FINRA and SIPC. Additional information about Carl Marks Advisory Group LLC and Carl Marks Securities LLC is available at www.carlmarks.com.

SOURCE Carl Marks Advisory Group LLC

Liquefied Natural Gas Market Worldwide Report Now Available on ReportsandReports

Natural gas accounts for 20% of the world's marketed energy, with more than 120 quadrillion Btu of natural gas consumed globally. It is a critical fuel in the generation of electric power and heat. Furthermore, it is used in industry as an energy source and/or feedstock for manufacturing fertilizer, pulp and paper, metals, chemicals, textiles, plastics and pharmaceuticals, among others.

Nearly 120 quadrillion Btu of natural gas is consumed globally. Some gas-producing countries, such as those in the Middle East and Africa, are able to satisfy all of their natural gas demand through domestic supply. Others, such as Japan and South Korea, are almost entirely reliant on natural gas imports to fuel power plants, industrial processes and provide heat. Still others, including those in Europe and North America, are able to partially meet natural gas demand with domestic supply while supplementing the rest with imports.

Over a quarter of global natural gas demand is fulfilled by imported natural gas. Countries in Europe and Eurasia are by far the leading importers of natural gas and import about 450 billion cubic meters of the fuel, or about 40% of the region's natural gas requirements, annually. This region is followed in natural gas imports by the Asia Pacific and North America regions. Together the three regions account for 95% of global natural gas imports.

Because of its low density and high volume, natural gas is costly and inefficient to store and transport over long distances in its gaseous state. Moreover, crossing international borders via pipeline amplifies commercial and investment risks and complexities. Pipeline construction and maintenance costs, along with technical challenges, escalate with distance. Further, when the pipeline must traverse countries which are not involved as gas producers or consumers, concessions may be difficult and costly to obtain.

Liquefied natural gas (LNG) is natural gas which has been converted to liquid form for ease of storage or transport. Liquefying natural gas allows access to natural gas from regions with vast production potential to end markets too distant to be connected by pipeline. The global market for LNG accounts for nearly 10% of total annual worldwide natural gas consumption. Pipeline gas continues to account for the majority of global natural gas trade. However, nearly 30% of natural gas trade is now provided by LNG.

Despite the global economic recession in 2008 and 2009, global demand for LNG increased by nearly 22% in volume terms from 2005 to 2009. North American imports are expected to more than double from 16 Bcm in 2009 to 40 Bcm in 2013. Over the past five years, significant investments in the LNG supply chain have been made around the world and global liquefaction capacity has increased by 40%.

LNG has assumed an increasingly significant role in the energy security of several nations around the world. LNG markets are expected to show robust growth over the next several years, driven largely by supply push. Driven by relatively low prices and a global economic recovery, LNG demand is expected to catch up with supply-chain capacity by 2014. LNG markets will likely experience renewed investments in supply-chain infrastructure in the years beyond 2015.

While the US currently accounts for less than 6% of global LNG imports, US domestic natural gas demand and supply dynamics have dramatically influenced global LNG investments over the past few years. Given the concurrent and rapid increases in US unconventional gas production capacity and LNG regasification and storage capacity, the US is likely to continue to re-shape global LNG trading in years to come.

Liquefied Natural Gas Market Worldwide includes a broad review of the global market for liquefied natural gas. Key technologies leveraged within the LNG supply chain, including liquefaction, shipping and regasification technologies are discussed. An overview of the LNG market structure, mechanisms and key participants is provided. Additionally, recent investments in LNG liquefaction capacity, shipping capacity, and regasification capacity across regions and major participating nations are discussed.

The report provides historic and forecast global energy demand 2005 to 2015 and energy demand drivers and trends are reviewed. Further, world energy supply sources 2005 to 2015 are discussed and the linkage between domestic natural gas production, import dependence and LNG trading are outlined. Finally, historic and forecast international LNG trade volumes and values are presented for the period 2005-2015.

Report Methodology

The information in Liquefied Natural Gas Market Worldwide is based on primary and secondary research. Primary research entailed gathering information from firms and individuals involved in LNG project development, marketing, distribution and sales of LNG and natural gas, utilities, analysts and consultants to the energy industry to obtain insight into the technologies and market factors shaping the industry. Secondary research entailed data gathering from relevant sources, including government and industry publications, company literature and corporate annual reports.

What You'll Get in This Report

Liquefied Natural Gas Market Worldwide contains important insights and projections regarding the future of this market around the world. The report provides both the comprehensive analysis and data. Subscribers will benefit from extensive data, presented in easy-to-read and practical charts, tables and graphs.

Liquefied Natural Gas Market Worldwide includes a broad review of the global market for liquefied natural gas. Key technologies leveraged within the LNG supply chain, including liquefaction, shipping and regasification technologies are discussed. An overview of the LNG market structure, mechanisms and key participants is provided. Additionally, recent investments in LNG liquefaction capacity, shipping capacity, and regasification capacity across regions and major participating nations are discussed.

The report provides historic and forecast global energy demand 2005 to 2015 and energy demand drivers and trends are reviewed. Further, world energy supply sources 2005 to 2015 are discussed and the linkage between domestic natural gas production, import dependence and LNG trading are outlined. Finally, historic and forecast international LNG trade volumes and values are presented for the period 2005-2015.

How You'll Benefit from This Report

If your company is already doing business in the market for liquefied natural gas, or is considering entering the marketplace, you will find this report invaluable. It provides a comprehensive package of information and insight not offered in any other single source. You will gain a thorough understanding of the current global market for liquefied natural gas, as well as projected markets and trends through 2015.

This report will help:

- Marketing managers understand the market forces shaping the

market for liquefied natural gas and identify market opportunities.

- Research and development professionals stay on top of competitor

initiatives and explore demand for LNG.

- Business development executives understand the dynamics of the

market and identify possible partnerships.

- Information and research center librarians provide market

researchers, product managers, and other colleagues with the vital

information they need to do their jobs more effectively.

Browse all Chemicals Market Research Reports ( http://www.chemical-market-reports.com/)

Browse all SBI Market Research Reports (

http://www.reportsandreports.com/Publishers/sbi/)

Browse all Latest Market Research Reports (

http://www.reportsandreports.com/LatestReport.aspx)

Related Reports

Production and Market of Gum Rosin in China ( http://www.reportsandreports.com/market-reports/production-and-market-of-gum- rosin-in-china/)

Research Report on Chinese Nitric Acid Industry, 2010-2011 (http://www.reportsandreports.com/market-reports/research-report-on-chinese-n itric-acid-industry-2010-2011/)

The Future of Low Density Polyethylene (LDPE), Market Forecasts and Growth Trends to 2020 - Packaging Applications Driving Demand Globally (http://www.reportsandreports.com/market-reports/the-future-of-low-density-po lyethylene-ldpe-market-forecasts-a/)

(Due to the length of these URLs, it may be necessary to copy and paste the hyperlinks into your Internet browser's URL address field. Remove the space if one exists.)

About Us

ReportsandReports comprises an online library of 10,000 reports, in-depth market research studies of over 5000 micro markets, and 25 industry specific websites. Our client list boasts almost all well-known publishers of such reports across the globe. We as a third-party reseller of market research reports employ a number of marketing tools, such as press releases, email-marketing and effective search-engine optimization techniques to drive revenues for our clients. We also provide 24/7 online and offline support service to our customers.

Contact:

Ms. Sunita

7557 Rambler road,

Suite 727, Dallas, TX 75231

Tel: +1-888-989-8004

http://www.reportsandreports.com/

http://reportsnreports.wordpress.com/

Brazil stocks down as China flashes slowdown signs

Brazilian stocks fell Tuesday, struggling in their first session in June after China, Brazil's biggest trading partner, posted signs of a slowdown in its economy.

Brazil's Bovespa fell 1.9% to 61.840.99, wiping out its 1.8% rise on Monday. The index tracking the largest Latin American equity market finished May with a 6.6% decline -- its steepest since October 2008.

Stock in pulp and paper producer Fibria Celulose also fell, by 4.5%.

A rise in the U.S. dollar against the euro helped pushed most dollar-denominated commodity prices lower, hurting Brazil's resource-rich market. Safe-haven buying into the greenback was supported by data showing a pullback in manufacturing activity in China.

Investment Bank Acquiring Fraser Papers

Fraser Papers Inc. announced that its subsidiary, Fraser N.H. LLC, has reached an agreement to sell substantially all of its assets to an investment fund managed by MerchantBanc, LLC, Manchester, NH.

The paper mill, located in Gorham, N.H., operates three paper machines. The mill produced 80,000 tons of uncoated freesheet papers and 37,000 tons of towel products last year.

The transaction is expected to close in late July and is subject to approval of the Ontario Superior Court of Justice and the United States Bankruptcy Court for the District of Delaware.

Fraser Papers remains under creditor protection pursuant to the provisions of the companies’ Creditors Arrangement Act, with its stay of proceedings having been extended by the court to July 9, 2010.

AbitibiBowater completes sale of for mills, in B.C., Que., N.B.

AbitibiBowater has completed the sale of three idle paper mills located in eastern Canada to a wholly owned affiliate of American Iron & Metal Company Inc. for $8.7 million and the sale of a paper mill and other assets located in British Columbia to an affiliate of Conifex Inc. for $33.9 million.

The three paper mills sold to American Iron & Metal, together with certain related assets and the property on which these paper mills are located, are located in Beaupré, Que., Donnacona, Que., and Dalhousie, N.B. As part of the sale, AIM has also agreed to acquire a fourth idle paper mill (Fort William), located in Thunder Bay, Ont. In addition, AbitibiBowater will be paid 40% of the net proceeds from any subsequent sale of paper machines from these mills.

The assets sold to Conifex, all located in Mackenzie, B.C., include a paper mill, two sawmills, including planer mills, as well as timberland operations with a forestry license providing an annual allowable cut of approximately 932,500 cubic meters.

AbitibiBowater has streamlined its asset portfolio to focus on top-performing facilities by closing or idling 3.4 million tonnes of paper capacity, moving from an overall production capacity of 10.4 million tonnes to 7 million tons since 2007. During this period, the company has also sold aggregate assets and land for total proceeds of over $980 million.

AbitibiBowater is currently under creditor protection in Canada and the U.S.

Suzano launches a forestry partnership program in the state of Piauí

Suzano Pulp and Paper is launching today the Forestry Partnership Program (Programa de Parceria Florestal – PPF) in the state of Piauí. The objective of the program is to enable rural landowners to participate in the pulp production chain through eucalyptus plantations by providing them with special financing lines. The Company thus hopes to create new opportunities for the region, strengthening its sustainable management model that takes into account the development of business and the communities where it operates.

One of the key goals is to develop forestry activities through incentives and initiatives to encourage the planting of eucalyptus trees on the property of local independent producers. The Program will primarily focus on the participation of small- and medium-size producers, making them responsible for part of the supply of Suzano’s industrial units, thus contributing with income generation and creation of direct and indirect jobs.

The Forestry Partnership Program is part of the investments in Suzano’s new growth cycle, which will allow the Company to achieve, within the next decade, an additional production capacity of 4.3 million tons of pulp per year, reaching a maximum production capacity of 7.2 million tons. To reach that capacity, the company has announced two new pulp mills in the states of Maranhão and Piauí, which should start-up in 2013 and 2014 respectively, and a third location yet to be defined, in addition to the project to increase production at the Mucuri Unit located in the south of the state of Bahia.

By including the rural landowners in its supply chain as wood suppliers, Suzano is stimulating forestry activities, enabling the most diverse types of alternative farming and assisting with the conservation of legal reserves and permanent preservation areas, contributing towards environmental balance and sustainable wood production.

Currently Suzano has partnered with more than 1000 landowners located in the states of São Paulo, Espírito Santo and Bahia. The objective of the Forestry Partnership Program is to make participants within the program account for approximately 30% of the total wood supply. Therefore, we estimate that 200 contracts will be signed annually, throughout Brazil, covering all types of producers.

By 2015, Suzano will invest approximately R$ 8 billion in the implementation of these new mills in Maranhão and Piauí and in the creation of its forestry base in these states (R$ 4 billion in each state), which will accelerate the growth and development in the regions within the scope of these developments.

So that these investments are made in a sustainable manner, Suzano has carried out active work with communities, through several communication channels to answer questions and receive suggestions, in addition to promoting meetings with organizations, community leaders and government representatives to discuss local development. Suzano has also had meetings with community associations to discuss specific programs and actions and, thus, consolidate the relationship with people that live in the community, as well as organizations in the municipalities.

Suzano and partners are not the only ones involved in the Program; financing institutions such as Banco do Brasil and Banco do Nordeste are also participating. The process to include farmers in Suzano’s Forestry Partnership Program is initiated whenever any candidate shows interest in developing forestry activities, with a major social, economic and environmental benefit, along with their traditional agricultural activities. Suzano will then send one of its technicians to the farmer’s property for the first technical visit, who will verify the potential and suitability of the area for forestry production.

The Suzano Forestry Partnership Program is divided into two categories —Renda Verde and Invest Verde (Green Income and Green Invest)—according to the social, environmental and land profile of the participants and the region of the country. The Program establishes the maximum area of property that can be allocated for eucalyptus plantations for each category and also the percentage of wood that Suzano agrees to purchase .

Renda Verde (Green Income)

This type of program in Piauí is intended for producers and landowners whose plot is up to 680 ha; maximum; 340 ha can be planted during the contract period.

Suzano guarantees to purchase at least 95% of the wood produced by Green Income partners. Suzano will assist farmers by providing forestry, agricultural and environmental incentive packages, support during the certification process and seedlings for planting and replanting.

Invest Verde (Invest Green)

This type will serve farmers and rural landowners as well as investors in Piauí, with 340 to 2,800 ha of land; up to 50% of the property may be allocated to forestry activities.

In this category, Suzano guarantees it will purchase at least 50% of the wood produced through a specific contract, as well as provide assistance, forestry incentive packages and seedling supply for planting and replanting.

| PPF | 2010 | 2011 | 2012 | 2013 | Project |

| Planted Area (ha) | 3,000 | 8,000 | 8,000 | 8,000 | 50,000 |

| Number of Partners | at least 20 | 60 | 60 | 60 | at least 400 |

About Suzano Pulp and Paper

As a forestry base company and one of the leading vertically integrated producers of eucalyptus pulp and paper in Latin America, Suzano Pulp and Paper is part of the Suzano Group. The Group has been investing in the pulp and paper sector for the past 86 years, with global presence in approximately 80 countries. The company has adopted a management model that takes into account the three main dimensions of sustainability: business, society and environment. Suzano currently has five mills: Suzano, Rio Verde and Embu, in the interior of the state of São Paulo, Mucuri in the state of Bahia and 50% stake in Conpacel in São Paulo, also located in the state of São Paulo.

For further information

|

GWA Comunicação Integrada 11 3030-3000 Letícia Volponi – This email address is being protected from spambots. You need JavaScript enabled to view it. Vanessa Fontes – This email address is being protected from spambots. You need JavaScript enabled to view it. |

Beckhoff’s PC-based control technology for building automation primarily utilises the global standard Ethernet TCP/IP for communication from the management to the field level. In addition to further Ethernet-based communication protocols, such as Modbus TCP, PROFINET and EtherCAT, the integration of BACnet/IP adds another standard for networking different systems, thus extending the areas of application for this open control technology.

Beckhoff’s PC-based control technology for building automation primarily utilises the global standard Ethernet TCP/IP for communication from the management to the field level. In addition to further Ethernet-based communication protocols, such as Modbus TCP, PROFINET and EtherCAT, the integration of BACnet/IP adds another standard for networking different systems, thus extending the areas of application for this open control technology.