Ianadmin

International Paper To Release Third Quarter 2012 Earnings

International Paper (NYSE: IP) will release third quarter 2012 earnings on Thursday, October 25, before the opening of the New York Stock Exchange. The company will host a webcast to discuss earnings and current market conditions at 9 a.m. EDT (8 a.m. CDT) that day.

All interested parties are invited to listen to the webcast via the company's Internet site at http://www.internationalpaper.com by clicking on the Investors tab and going to the Webcasts and Presentations page. A replay of the webcast will also be on the Web site beginning approximately two hours after the call.

Parties who wish to participate in the webcast via teleconference may dial +1 (706) 679-8242 or, within the U.S. only, (877) 316-2541, and ask to be connected to the International Paper Third Quarter Earnings Call. The conference ID number is 35786152. Participants should call in no later than 8:45 a.m. EDT (7:45 a.m. CDT). An audio-only replay will be available for four weeks following the call. To access the replay, dial +1 404-537-3406 or, within the U.S. only, (855) 859-2056, and when prompted for the conference ID, enter 35786152.

SOURCE

The transfer of Ahlstrom's wipes business in Brazil to Suominen postponed

Ahlstrom, a global high performance materials company, announced that the transfer of its wipes business in Brazil to Suominen Corporation will be postponed.

The transfer has been subject to receiving all necessary Brazilian regulatory permits for the operations in addition to competition clearances, which have been received. Ahlstrom had previously anticipated that the transfer would take place in the third quarter of 2012.

Due to the delay in receiving all necessary permits, Ahlstrom and Suominen have now concluded that the transfer cannot be done in the planned time schedule. The parties are negotiating the prerequisites, including financing, for completing the transaction. Ahlstrom and Suominen are together looking into opportunities to move the wipes business in Brazil to Suominen through alternative interim solutions within the scope of the current permits. The aim is to transfer the operations in Brazil to Suominen as soon as possible.

The Home and Personal business area, excluding the Brazilian part of the operation, was transferred on October 31, 2011 to Suominen Corporation.

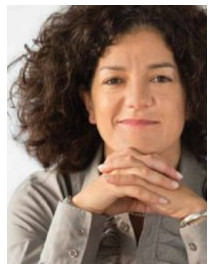

Sonia Bertetto is the new PMT Tissue Sales Manager

Sonia Bertetto has been appointed to the position of Tissue Sales Manager at PMT Italia with the task of consolidating PMT’s Tissue Business in its traditional geographic areas and expanding it worldwide, reporting to PMT Sales Director.

Sonia Bertetto has been appointed to the position of Tissue Sales Manager at PMT Italia with the task of consolidating PMT’s Tissue Business in its traditional geographic areas and expanding it worldwide, reporting to PMT Sales Director.

Sonia Bertetto earned a degree in IT Engineering at Politecnico di Torino and a master’s degree in Paper Making at EFPG in Grenoble (F).

Sonia started her career in the Paper Industry with PMT Italia in 2001. Since then she run several projects worldwide as a Project Manager, for different paper grades and tissue, gaining a vast and deep experience from engineering to contractual skills as well as from subcontracting to field services management.

Sonia already benefits from the trust of many PMT’s customers and PMT Italia’s Top Management believes she will boost the Company’s position in the Tissue market thanks to her wide skills and her broad experience.

Verso Paper Corp. Awards First Verso Forest Certification Grant

Verso Paper Corp. (NYSE:VRS) has announced that Sustainable Resources Institute (SRI) Inc. will be the first recipient of a Verso Forest Certification Grant. The two-year grant will enable SRI to target the owners of small, private non-industrial properties (2,400 acres or less) in Michigan and help them achieve certification at an affordable cost. Third-party certification to credible forest management standards advances responsible management practices that keep U.S. forests vibrant and healthy. SRI's first-year goal to certify an additional 15,000 acres has the potential to add up to 35,000 tons of certified fiber in the marketplace. "We launched the Verso Forest Certification Grant program to increase certified fiber and certified acreage on lands near Verso's three paper mills," said Verso Senior Vice President of Manufacturing and Energy Lyle Fellows. "SRI's grant proposal demonstrated not only a solid plan to help us advance this goal, but also strong partnerships with the Michigan Master Logger Certification program, the Michigan Association of Timbermen and others that provide a strong foundation for success." "The start-up funds provided by the Verso Forest Certification Grant will help us reach out to landowners who already have responsible forest management plans and offer them a more accessible path to affordable certification," said SRI Executive Director Don Peterson. "We're anxious to get underway and are committed to seeking additional funding from other sources to make sure we're able to continue the terrific certification opportunities that Verso's initial two-year funding provides." Anyone interested in learning more about the Verso Forest Certification Grant Program or in obtaining a grant application may contact:

Greg Barrows (This email address is being protected from spambots. You need JavaScript enabled to view it.)

Verso Paper Corp. Bucksport Mill

P.O. Box 1200

2 River Road

Bucksport, ME 04417

Source:

South Korea and Japan will become large importers of pellets and energy chips.

Both Japan and South Korea intend to reduce the consumption of fossil fuels and increasingly rely on renewable energy in the future. As a consequence, both countries will increase their importation of wood pellets and energy chips from other countries in Asia and from North America in the coming years, reports the Wood Resource Quarterly.

Both Japan and South Korea intend to reduce the consumption of fossil fuels and increasingly rely on renewable energy in the future. As a consequence, both countries will increase their importation of wood pellets and energy chips from other countries in Asia and from North America in the coming years, reports the Wood Resource Quarterly.

Asia will consume more wood pellets and energy wood chips in the future. The governments in Japan and South Korea have announced definite plans to increase their usage of green and low carbon energy alternatives. South Korea is taking steps to reduce its dependence on imported fossil fuels and instead invest in domestic renewable- energy technology, including wind, solar, hydropower and biomass. The long-term plan is to increase the renewable energy share from less than four percent in 2011 to 6.1 percent in 2020, and then to 11.5 percent in 2030. As part of this effort the government has initiated a program, which has included building eight new pellet plants, as well as exploring opportunities to import large volumes of pellets in the future. The goal is to consume five million tons of pellets by 2020, a huge increase from the less than a few hundred thousand tons used in 2011.

South Korea has access to wood residues from the domestic sawmilling industry, which could be used for the manufacturing of pellets. This domestic supply, however, will not be sufficient, so South Korea will need to increase pellet imports in order to meet the ambitious 6.1% goal only eight years from now. The government estimates that by 2020, 75-80 percent of pellets consumed in the country will need to be imported. Some of the major energy companies in South Korea have reportedly been exploring the opportunities to import pellets from Australia, Vietnam, Indonesia, the Philippines, Canada and the US.

Japan is another Asian country expected to increase importation of energy chips and wood pellets, due in part to the nuclear power plant accident in Fukushima last year. Following the disaster, the Japanese government decided to close down all nuclear plants, at least temporarily. Even if a few plants eventually reopen, nuclear energy will never again be as important for energy production as it once was.

In the future, Japan will increasingly rely on renewable energy sources, with biomass likely to be one important supply source. Up until this year, Japan has imported only very limited volumes of wood pellet, primarily from Canada, but it is likely that import volumes of both pellets and energy chips will increase in the coming years.

Deal reached, Port Hawkesbury workers head back to work

Only one day after the intended buyer of a closed pulp and paper mill in Nova Scotia announced the deal was off, a new financial agreement with the provincial government and utilities regulator has put the sale of the mill back on track.

Pacific West Commercial Corp.’s Ron Stern announced on Saturday, Sept. 22, that an agreement had been reached which would allow the sale of the shuttered mill to proceed.

“I am very pleased – for the employees of the mill, members of the community, and the mill's many suppliers and customers – to be able to announce that the issues that yesterday prevented the mill from restarting have been overcome.

“Starting next week, we intend to call all employees back to work,” Stern said.

Pacific West plans to take ownership Sept. 28, and for production to begin in the first few days of October. Stern says the mill is now taking orders.

“I really want Nova Scotians to know how hard their government leaders - both provincially and municipally - have worked to ensure there is a future for this world class mill and its people," said Stern.

Nova Scotia premier Darrell Dexter said the new arrangement will significantly increase the annual share of profits paid by Pacific West to the province and it will ensure a significant amount of the tax savings generated by Pacific West in other provinces will be shared with Nova Scotia.

In addition to that, as a result of the Canada Revenue Agency ruling earlier this month, the province will receive millions in additional revenue.

source: Pulp & Paper Canada

Sophisticated innovations support green energy production in pulp mills

Historically, the standard of living has followed the consumption of fossil fuels. Concern over the environment, global warming, and the predicted shortages in fuel reserves are gradually shifting the focus to energy saving, developing new processes and the search for new fuels. Metso acknowledged the challenge in its annual report in 2009: “The greenhouse effect necessitates significant changes in energy use and production. Technology development is one of the key solutions to these challenges.”

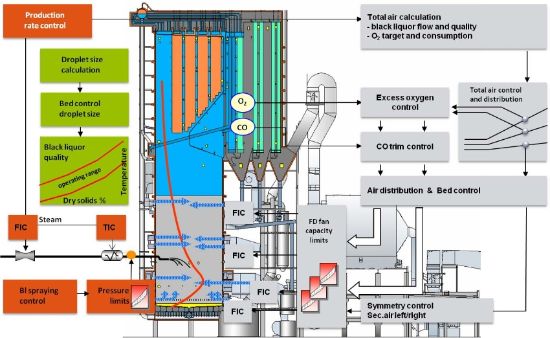

Automation is often overlooked, but it is a great potential performance booster when the process has to be pushed to the limit. In addition, the more challenging fuels and mixtures of them, modern combustion technology, and the continuous monitoring of the environmental impacts of the new, state-of-the-art plants call for advanced measurement and control applications.

R&D shows the way to energy savings

Fuel chemistry together with burning process know-how is the specialty of the Process Chemistry Center at Åbo Akademi University, where Professor Mikko Hupa is in charge of a team of over 50 international scientists. Cooperation with the university complements Metso’s knowledge and experience. For example, the rapid development of the furnace flow modeling technique known as Computational Fluid Dynamics (CFD) has become a crucial tool in the design of new furnaces. It is partly due to advanced CDF that Metso has been able to develop the huge, recovery boilers, with black liquor capacity of over 7000 tds/d, which fully comply with the tightest environmental regulations. Metso has also made use of the groundbreaking detailed descriptions of the black liquor droplet combustion process in its development of boiler operation control systems and advanced automation solutions. Accurate control is essential when pushing the performance of these complex units to the limit.

Professor Mikko Hupa, Process Chemistry Center at Åbo Akademi University

The Metso Recovery Boiler Optimizer has been used successfully for recovery boiler burning and sootblowing controls in several applications. It carefully controls the black liquor flow to the furnace, maintains a stable spraying pattern and adjusts the liquor droplet size according to quality variations. Air distribution controls guarantee the supply of the necessary combustion air for the burning process. Maintaining the optimum combustion conditions in the boiler furnace practically eliminates SO2 and TRS emissions.

click on the picture to enlarge

The Intelligent sootblowing controls enhance the availability of the recovery boiler by cleaning the heat transfer surfaces only when and where needed. This results in sootblowing steam savings and increased thermal efficiency. Typical energy savings include an approximate 5% increase in burning capacity, a 5% increase in steam production, and extending the uninterrupted operating period beyond one year.

“It is impossible to maintain the optimum combustion conditions in the furnace continuously using manual controls. Also, systems based on what is called adaptive control will often face difficulties in the practical solutions of the process industry,” states Professor Hupa.

Renewable fuels as profitable business

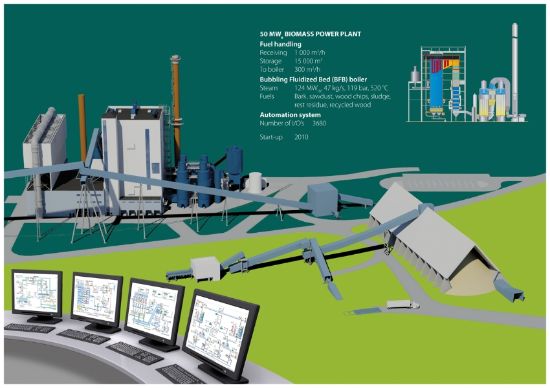

The search for new potential fuels is ongoing, and it is becoming more and more important to understand the whole value chain from feedstock to end product. Biomass like agro residue, wood waste, and other waste materials require fuel handling and preprocessing before the proper conversion process can be applied.

click on the picture to enlarge

Maintaining a high and stable combustion temperature in the furnace simultaneously with a moderate boiler equipment corrosion/erosion rate is challenging because of the extensive quality variation of some bio fuels. In addition, recycled wood often contains variable amounts of zinc and lead, which lead to superheater corrosion in the boiler.

Fluidized bed boilers like CYMIC and HYBEXprovide a state-of-the-art and environmentally suitable solution for the demanding new bio fuels. As with the recovery boilers, the operation of these plants benefits from sophisticated automation. The Combustion Management Solution calculates the heat value of the fuel mixture used continuously. The fuel power computed from the fuel heat value and fuel flow is used as the basis for combustion air calculation and fuel feed control. The fuel flow disturbance control compensates variations in fuel quality and flow by modulating the fuel feed to the furnace. The air-to-fuel ratio control allows for the correct air fuel mixture for the complete oxidization of the fuel at the desired excess oxygen level. At the same time, steam production is monitored and the necessary adjustments are carried out in the feed water flow and fuel feed. The furnace temperature is maintained between acceptable limits to prevent melting of the fluidized bed and the formation of thermal NOx. SO2 emissions can be controlled by means of the limestone feed to the furnace and by the combustion temperature control.

The plant’s thermal efficiency is continuously monitored and reported to the operators for immediate actions. The performance follow-up is beneficial especially during process disturbances and in load change situations. Several installations of the Combustion Management Solution have proven that a stable steaming rate from the boiler can be achieved regardless of quality variations in the feedstock.

Professor Hupa reflects: “Deeper understanding and a reliable prediction of the behavior of several fuels burned together is one of the future development targets.”

Environmental solutions manage plant performance

Power plants have to comply with environmental requirements in order to receive an operating permit. Running old inefficient equipment means plants face the threat of closure. Deviations have to be reported to the authorities and the necessary actions have to be initiated immediately. The consequences can be fatal if disturbances remain unnoticed.

The emission monitoring and reporting solutions are built on the Metso DNA Information system platform to comply with the LCP Directive and the plant’s environmental permit. The process operators have online access to the emission measurements and the condition of the automated measurement systems. Alarm reporting complements the process information for fast and efficient management in disturbance situations. In addition, the accumulated information can be used for operation improvement and the development of new processes.

Large Combustion Plants (LCP) emissions can be effectively managed by dedicated monitoring application

The system compares the accumulated averages of the measured data with the previous two-day averages and the permitted limits. The forecasts for the coming two days are calculated based on the present operating parameters and the collected process data. The analyzer display monitors the current status, last maintenance, and calibration of the equipment so that the quality assurance of AMS according to EN 14181- standard can be realized.

Daily, monthly, and annual reports can be used for self-assessment of the mill’s emissions and in reports to the authorities. A summary display collects the real-time and cumulative emission measurements and their averages in an easy-to-use information window. The data and related forecasts are compared with the operational permits. The summary display provides an effective tool for evaluating the environmental performance of the mill because it contains complementary information of the process and equipment status. This knowledge can also be utilized in communications with the authorities.

Total emission reporting with corresponding trends complies with regulations applied on LCP

Metso DNA Eco Diary is an efficient environmental data analysis and knowledge distribution tool for all relevant users. It contains the process measurements and the event-based manual entries regarding the disturbance, production loss, and shift operation. The operators’ descriptions in the diary of the time and place of the disturbances build up experience. They also list the actions taken and the consequences of the incident. Recommendations on how the situation could be prevented in the future complement the analysis.

Kari Kerkelä, automation manager at UPM Kaukas Mill, summarizes the benefits that can be achieved with the environmental automation solutions: “With Metso’s applications, we can prove that we comply with the requirements of the new environmental permit. We are continuously aware of the plant emissions and can react to potential problems in time.”

Sustainability is achievable

Our welfare continues to be based on the use of fossil fuels. The coal consumption in 2010 was 10% higher than the average during the 2000s, and the total electricity consumption increased by 7.6% during 2010. Yet Professor Hupa is optimistic about the future: “It is possible to get rid of fossil fuels in the long run. Sustainable energy is achievable, but lots of innovative engineering supported by genuine scientific research is needed to reach the goal.”

More information:

Jukka Puhakka, Manager, Pulp & Paper Applications

jukka.puhakka(at)metso.com

Metso to relocate and rebuild paper machine for Chinese Shandong Chenming Paper

Metso will supply Chenming Jilin, part of Shandong Chenming Paper Holdings Ltd., with the relocation and rebuild of a paper machine for the company’s new mill site in Jilin Province, China. The value of the order will not be disclosed. A typical market value of this type of a relocation and rebuild project ranges from EUR 10 to 20 million.

“The main target of the project is to increase production by improving the efficiency of the paper making line and by increasing the drying capacity of the paper machine,” says Metso’s Sales Manager Jukka Vuorela.

A paper machine of Chenming Jilin will be relocated within Jilin City from the current mill site to the company’s new mill site. Metso will supervise the dismantling and packing of the paper machine line and supervise the installation and start-up of the relocated equipment. Metso’s delivery will also include a rebuild of the relocated PM 12. The start-up of the relocated and rebuilt machine is scheduled for the second half of 2013.

The order is included in Metso’s Pulp, Paper and Power third quarter 2012 orders received.

Technical information

The paper machine to be relocated is the 6.95-m-wide (wire) PM 12 paper machine. The modernization will include forming and drying section modifications and a press section rebuild with a new SymBelt shoe press. Originally the PM 12 produces coated wood-containing LWC (light weight coated) paper grades and after the rebuild the target is to also produce other new paper grades.

Chenming Jilin is part of Shandong Chenming Paper Holdings Limited, one of the biggest paper producers in China. In 2010, the company’s paper production capacity was over 4 million tonnes, turnover over EUR 2 billion and the number of employees approx. 17,000.

Cost review will lead to redundancies at Södra

This measure will affect all Swedish business areas, and staff at all levels. Trade union negotiations will commence with immediate effect. These redundancies are part of the group's initiative to reduce its overall costs.

"Södra operates in an international market. Just like other companies, Södra is affected by the prevailing economic situation and trading conditions. The outlook for our main markets remains uncertain. To be able to face up to international competition, we have to undertake measures to reduce our costs," said Gunilla Saltin, Acting CEO at Södra.

Mondi partners with Tieto and Metso

Mondi partners with Tieto and Metso in largest single one time advance process control project in the pulp and paper industry.

Mondi has partnered with Tieto and Metso to to increase the efficiency and profitability of the pulp and paper production at Mondi’s Syktyvkar Mill in Russia. Tieto and Metso provide the mill advanced control and optimization systems for the fiber lines. By improving the overall operation of the fiber line Mondi will improve the yield, chemical consumption and production capacity of the three lines, leading to significant reduction in operating costs and improving productivity.

The advance control and optimization system for Syktyvkar includes the following process areas: three continuous digesters, three brownstock washing lines, two oxygen delignification lines, and two bleach plants. The Tieto part, Tieto Integrated Paper Solution TIPS, applications include budgeting, order entry, production, process and quality management integrated into mill-level reporting.

The flexible optimization options from Metso for each application are Continuous digester, Washing optimizer, Oxygen delignification optimizer and Bleaching optimizer. Coordinating these various applications maximizes the overall benefit for Mondi for fiber line optimization. These applications join the almost four hundred Pulping and Recovery Advance Control Applications Metso has installed globally.

The Mondi Group is an integrated packaging and business paper manufacturer with production operations in 28 countries and around 23,400 employees. Tieto is the leading IT service company in Northern Europe providing IT and product engineering services with about 18,000 employees.