Ianadmin

Pankaboard improves main features of its coated cartonboard grades

Pankaboard is reintroducing its main cartonboard grades PankaBrite and PankaWhite with clearly improved product features and performance. Over the past year the company has made substantial efforts and investments in order to bring forward the overall product quality of its major packaging grades. As a result of this determined work Pankaboard is now proudly presenting cartonboard grades, which are bulkier, stronger, optically whiter and which are remarkably improved in terms of sensoric properties. In its production Pankaboard combines sustainable forest management with high ecological and environmental values.

Throughout the entire range of PankaBrite (GC2) the thickness of the board has been increased by 30 microns. For PankaWhite (GC1) the increase has been 10 microns. This has improved the CD bending stiffness of PankaBrite by up to 3 %, bringing the stiffness ratio of the board closer to the optimum. This improvement will have a direct impact on ready-made packaging. It helps to protect the contents better than before. It also guarantees, that cartons will stay in better shape.

The increase in the product thickness has been achieved by optimising process conditions and improving the quality of the ground-wood pulp, which is used for the middle-layer of the boards.

Development in the quality of the ground-wood pulp has, in addition to the increased bulk level, also enabled remarkable quality improvements regarding the visual and surface characteristics of PankaBrite and PankaWhite. More consistent surface smoothness and appearance enables immaculate print reproduction in both offset and flexo printing.

Both products are now optically whiter than before. The shade of whiteness has been brought considerably towards blueish-white by optimising the surface coating.

Last but not the least, extensive work has also been carried out to improve the sensoric (odor and taint) properties of both products in order to better meet the requirements of today’s demanding brand-owners. Pankaboard can today guarantee a level of 1.5 units for its products in the Robinson scale for odor and taint. The products are therefore ever more suitable and reliable for use in a wider field of end-uses.

As a result of these, improvements both PankaBrite and PankaWhite are today completely refreshed products,now stronger, visually more appealing and . definitely . offering a far better printing result than in the past. Not to forget, the new, improved sensoric properties now offers a lot more new opportunities for the usage of the products.

The New products are available now. For further information and samples, please contact Pankaboard or the . sales agent for Pankaboard products in your market.

ANDRITZ Biax to supply another MESIM film stretching line to China

After successful start-up of the worldwide largest and fastest MESIM film stretching line for a customer in Europe at the beginning of this year, international technology Group ANDRITZ has received the order to supply another MESIM line. Chinese film manufacturer Zhejiang Nanyang Technology Co., Ltd., Taizhou, ordered a 5.1 m wide line for the production of various PET films in a range from 2-75 µ. Start-up is scheduled for the first quarter of 2014.

After successful start-up of the worldwide largest and fastest MESIM film stretching line for a customer in Europe at the beginning of this year, international technology Group ANDRITZ has received the order to supply another MESIM line. Chinese film manufacturer Zhejiang Nanyang Technology Co., Ltd., Taizhou, ordered a 5.1 m wide line for the production of various PET films in a range from 2-75 µ. Start-up is scheduled for the first quarter of 2014.

MESIM (Mechanical Simultaneous Stretching System) is a stretching technology patented by ANDRITZ Biax. The stretching variable process in both the longitudinal and transverse directions takes place simultaneously in only one step. The stretching area can be adjusted over a wide range while in operation to suit all kind of polymers (PET, PP, PA, PI, PEEK, COC, PC, and many others). The MESIM film products have outstanding optical and physical properties and are used for high-quality applications (for example, in the food packaging and entertainment industries).

Zhejiang Nanyang Technology manufactures smooth, rough, and metalized polypropylene films for various types of capacitors as well as PET films for different products.

Cascades inc. establishes a program for small shareholders to sell shares without comission

Run your print marking systems simply and efficiently using Trace-it!

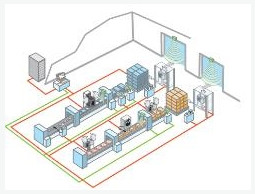

Would you like to run your various print marking systems – inkjet, labelling and thermal transfer – automatically and reliably? Trace-it! is the solution.

As a manufacturing company, you must meet specific printing requirements which are increasingly restrictive. The efficiency of your supply chain depends on this and so does the satisfaction of your customers. An oversight or the wrong code on a product means you have a dissatisfied customer on your hands and can result in significant extra costs – transportation, credit notes and more.

The challenges

You need to have accurate information, available in real time, for each of your products. You want a seamless connection between your print marking tools and production management system in order to minimize the risk of mistakes.

Trace-it! unifies all marking data (GS1) in a single database management system. This means you access data in real time, securely, from any terminal

linked up to the system.

Trace-it! employs client-server technology and is a one-stop shop for managing the different elements of your marking system – databases (containing data

on the items being produced, work orders, printers etc.), labelling software, print drivers, label formats, users and packing lines.

Unlike the majority of software on the market today, with Trace-it! there is no need to acquire numerous software licences for each user station. Trace-it! print server management saves you time and money. Having variable data sent to your marking systems automatically means that you improve the overall output rate of your packing lines.

Your key questions

• Can I set the system up so that the right information is available at the right place, to the right person?

• Will I be able provide guarantees to my customers regarding compliance with their marking requirements?

• How can I make my EDI messages reliable?

Your solution

Production labelling and data management – Trace-it!, an “all-in-one” Avery Dennison software solution!

Trace-it! has many built-in features which can be set and adjusted to meet the needs of your customers – the running and supervision of printing systems, the real-time generation and printing of print masks in accordance with the GS1-128 standard, batch number and use-before date administration, manual and automatic updating of Trace-it! data using your company’s data (ERP, CAPM etc.).

Avery Dennison Trace-it!

The multi-brand one-stop shop for managing your supply chain

The efficiency of your supply chain depends on the standards and accuracy of printed data, in particular that of barcode data.

The Trace-it! server delegates functions to the different client stations in accordance with your requirements. The application’s flexibility allows you to customize the man-machine interface to suit your needs. In addition, the interface provides information to operators on the progress of a given works order in real time, at several points along the line. Trace-it! can communicate with and run virtually any printing software available on the market (Nice Label, Code Soft, Jet Mark, Bar Tender etc.).

Trace-it! can run in client/server mode or connect directly to your production management system. In the latter case, when a works order is triggered by your existing system, Trace-it! receives a file and processes it automatically by combining the data contained in a work order, product data and line

configuration data.

In addition to your existing print management system, or as a separate printing solution, Trace-it! is an essential tool for your supply chain.

Your benefits at a glance

• You save time and eliminate the risk of data-entry mistakes

• Ethernet network architecture

• Supply chain data reliability

• One solution runs all of your printing systems

• Customizable features and multilingual options are standard

Metso to adjust its Finnish operations

Metso is to begin statutory employer-employee negotiations on personnel reductions and layoffs in several of its units serving the paper industry and in its paper production service business. Negotiations will cover approximately 4,100 employees at Metso’s Finnish units serving the paper industry. It is estimated that reductions will affect a maximum of around 630 employees, with around 150 positions likely to be outsourced.

“It’s very unfortunate that we are forced to resort to such drastic measures affecting our employees. They are essential to maintain our competitiveness and leading position in a rapidly changing business environment, however,” says Pasi Laine, President of Metso’s Pulp, Paper and Power business. “The negotiations that we are now initiating are aimed at finding solutions to this situation, together with our employees.”

Personnel reductions are necessary because of the need to adjust the manufacturing capacity of Metso’s paper business unit to the permanent structural changes that have impacted the business and weakened its competitiveness and profitability. The main factors here have been the ongoing reduction in in the demand for paper machinery, increasing demand for cheaper solutions, growing competition, and the downturn in demand for foundry products. The general climate of uncertainty in the global economy has also affected the paper industry’s appetite for new investments.

“The gains made by new communications technologies have weakened growth in the consumption of printing and writing paper. As a result, the market for new printing paper machines has slowed, while the demand for more economical medium-sized board machines has continued. This global change in demand means that we must adjust our capacity not only in Finland, but also abroad, including China. The medium-sized machine segment is also of interest to smaller suppliers, which makes competition here particularly tough. We have to be able to produce cheaper, quicker, and more flexible solutions to survive in this market,” says Laine.

The aim of the personnel reductions is to bring production capabilities in line with current and expected demand, and secure Metso’s global competitiveness over the longer term. A lighter operational cost structure and greater flexibility is essential. Outsourcing some operations will also improve Metso’s ability to adapt to changing workloads and focus on its core business.

“The paper industry will continue to be of great interest and importance to us as a business area, despite the slowdown in the printing paper machinery market. Board and tissue consumption is continuing to grow moderately, and Metso’s vast installed base will offer us opportunities to further develop our service business. A lighter cost structure will enable us to compete more effectively in the marketplace,” continues Pasi Laine.

Personnel reductions

The estimated need for reductions at Jyväskylä, Järvenpää, Tampere, Raisio, Juankoski, and Valkeakoski covers approximately 630 people in maximum, with around 150 positions likely to be outsourced. Negotiations will commence immediately and will affect all personnel groups. Reductions are expected to be implemented during the first half of 2013.

Temporary layoffs

The need for temporary layoffs will affect all personnel serving the paper industry at Metso’s locations in Jyväskylä, Järvenpää, Tampere, Raisio, Juankoski, and Valkeakoski, approximately 3,500 employees in all. Negotiations will commence immediately. The exact number of reductions will be determined on the basis of the 2013 production situation and order book.

Targeted savings

The target is to achieve savings of approximately EUR 30 million in annual operational costs as a result of the negotiations. It is estimated that the cost reductions will be implemented in full as of the third quarter of 2013.

Understanding the Traditional Knowledge and Resources of Indigenous People

With an estimated 1.6 billion people globally depending on forests for their livelihoods, including some 60 million indigenous people, the loss of forests would threaten  the way of life and the very livelihoods of communities that live and work directly in forests and forest landscapes.

the way of life and the very livelihoods of communities that live and work directly in forests and forest landscapes.

Equally important is the potential loss of their traditional forest-related knowledge and practices that have supported the livelihoods and cultures of local and indigenous communities for centuries, while sustaining and enhancing biological diversity in forests and associated agro-ecosystems.

To access and better understand this traditional knowlegde and to identify opportunities for forest certification to contribute to indigenous peoples communities, PEFC selected a project by Kadioan for support by the 2011 PEFC Collaboration Fund. Kadioan is a Philippines-based indigenous people’s organization tasked with promoting indigenous resource systems. The Malaysian Timber Certification Council provided additional support to the project.

The project recognized that indigenous communities have limited knowledge of forest certification yet that indigenous peoples are potentially interested in forest certification given the benefits that it provides them with, specifically in terms of rights recognition. This includes criteria concerning free, prior and informed consent, recognition of customary and traditional rights such as outlined in ILO 169 and the UN Declaration on the Rights of Indigenous Peoples, and the protection of sites with recognized historical, cultural or spiritual significance.

The project, which included indigenous communities in Malaysia, Thailand and the Philippines, also raised awareness of group certification as a mechanism best suited for their particular needs. “There is now certainly a better understanding of the linkages between forest certification and the sustainability of indigenous forest management systems, “ said Minnie Degawan from the International Alliance of Indigenous and Tribal People of the Tropical Forests (IAITPFT) and member of the PEFC International Board of Directors. “Equally important, it has strengthened collaboration, which is an important enabler for group certification, among indigenous communities, though more work is certainly needed.”

Going forward, KADIOAN intends to continue its activities – notably forums and training workshops – with indigenous communities to promote the value of certification to their livelihoods. KADIOAN will also work to link its activities to the Smallholder Group Certification project which may offer a mechanism for small indigenous forest dwellers to become certified.

Leading Publishers Partner with SFI in Responsible Forestry

Four leaders of the North American publishing industry announced they will partner with the North American-based PEFC member Sustainable Forestry Initiative® (SFI®) to help spur the growth of certification to preserve and protect forests.

Time Inc., the National Geographic Society, Macmillan, and Pearson will become Founding Partners of the SFI Forest Partners Program. The alliance was announced at the SFI annual conference in Milwaukee, attended by foresters, land owners, conservation groups, First Nations, industry and government agencies.

SFI Forest Partners allows market leaders to support certification, as well as landowners and manufacturers facilitate forest certification and the certified sourcing of forest products. Partners will work collectively with the SFI community to make certification more efficient and accessible by providing resources for activities such as shared consulting expertise, group certification or audit coordination.

"A decade ago, Time Inc. was one of the first companies to make a public commitment to use 80% certified fiber. Progress beyond that goal has been hampered by the limited availability of adequate supply," said Guy Gleysteen, Senior Vice President of Production at Time Inc. "SFI Forest Partners lets us have a direct impact on the growth of forest certification and the responsible sourcing of forest products."

By the end of 2014, SFI Forest Partners aims to certify five million acres (two million hectares) of forests to the SFI 2010-2014 Standard. By the end of 2017, the Forest Partners Program hopes to certify 10 million acres (four million hectares) of forest across the United States and Canada. It will also seek to certify more small and medium-sized mills to SFI certified sourcing or chain-of-custody certification.

"We believe strongly that we, as publishers, have a role to play in encouraging responsible forestry practices," said Hans Wegner, Chief Sustainability Officer for the National Geographic Society. "We know that humans are deforesting the globe, particularly in the tropical regions of the world, at a clip of approximately 2 percent a year, a trend that is completely unsustainable. We may well be the last generation with the opportunity to reverse that trend."

"Sustainability is a core mission for Macmillan," said CEO John Sargent. "By committing to the use of certified fiber sourced from well-managed North American forests we are ensuring responsible, environmentally-friendly forestry while also supporting the most efficient global use of recycled fiber. Third-party certification instills confidence that we are making informed choices that keep domestic forests healthy, rural communities strong, and preserves fragile forests in other areas of our world."

"Forest Certification is an increasingly important tool in the ongoing struggle to create a sustainable world. Trees absorb carbon. Well-managed forests help address deforestation, protect and enhance biodiversity, and underpin sustainable livelihoods," said Rich Glicini, Senior Vice President, Corporate Social Responsibility, Pearson. "Five years ago we made a commitment to climate neutrality for our directly-controlled operations. Helping to promote responsible forest management practices complements that commitment and continues to be a priority for Pearson companies."

"The SFI Forest Partners Program builds on an innovative pilot project in Maine that resulted in an additional 1.4 million acres/570,000 hectares certified to the SFI 2010-2014 Standard," said SFI President and CEO Kathy Abusow. "The Maine project also resulted in 100,000 acres of forest lands certified to the American Tree Farm Standard. We look forward to building on that initiative with these four founding members of the Forest Partners Program."

Chile and Brazil have began to supply Eucalyptus chips to Chinese pulp mills

Chile and Brazil have began to supply Eucalyptus chips to Chinese pulp mills; however Japan continues to be the major destination for Latin American wood chips, reports the Wood Resource Quarterly

In late 2011, Brazil and Chile sent the first chip vessels to pulp mills in China in over five years. In the past, Japan had been the major destination for Latin American Eucalyptus chips. With Japanese pulp mills paying considerably more than Chinese pulp mills for chips, it is likely that a majority of Eucalyptus chips from Latin America will continue to be shipped to Japan.

Seattle, USA. In 2007, China imported wood chips from only three countries: Vietnam, Indonesia and Australia, who together shipped 1.1 million tons throughout the year. With the fast expansion of the pulp industry in China, the country is rapidly growing its need for wood fiber. Domestic supplies have proven inadequate, so the list of supplying countries has expanded from three to eight over the past 12 months.

Two of the three chip-exporting countries in Latin America, Chile and Brazil, sent the first vessels with Eucalyptus chips since 2006 in the third quarter last year. The total volume exported from the two countries in 2011 was 100,000 tons, and during the first seven months this year, 76,000 tons have been shipped, a majority from Chile.

Wood chips from Latin America still accounted for only three percent of all hardwood chips imported to China in the 2Q/12, and these chips were among the costliest chips landing in the country, as reported in the Wood Resource Quarterly. So, although Chinese pulp mills will be in search of additional wood fiber in the coming years, it is not likely that either Chile or Brazil will be major competitors to countries in closer proximity to China, including Vietnam, Thailand, Indonesia and Australia.

Chile will most likely continue to ship a majority of its chips to Japan, where its chips are more competitively priced with other supplying countries. During the first six months of 2012, Chile was the largest supplier of hardwood chips to the Japanese pulpmills, followed closely by Australia. Chile’s market share in this market has gone from 17 percent five years ago to 27 percent in the first half of 2012. With chips from Chile being less costly than Australian chips delivered to Japan, there will continue to be opportunities for Chile to gain market share in the Japanese chip market in the coming year.

DuraPulp - the feel of paper with the strength of plastic

Södra's DuraPulp has attracted a lot of interest around the world and already won a number of awards for its winning combination of the feel of paper with the durability of plastic.

Södra's DuraPulp has attracted a lot of interest around the world and already won a number of awards for its winning combination of the feel of paper with the durability of plastic.

In late October, Södra will be exhibiting DuraPulp at the Scandinavian packaging fair, Scanpack.

DuraPulp is a composite material made up entirely of renewable and biodegradable components. This material has unique properties: it is durable, water repellent and heat sealable. Examples of end uses include interior and design products, a wide range of speciality papers and packaging solutions for special requirements.

There are many options, and depending on the manufacturing process, DuraPulp can be used to create unique solutions.

Södra will be exhibiting in Scanpack's Innovation Packaging section to pave the way for new partnerships. Visit us on stand H04:09 at the Scandinavian packaging fair, Scanpack, on 23-26 October.Kemira Capital Markets Day, "Fit for Growth" timeline set

Kemira held its Capital Markets Day (CMD) 2012 in London today.

Kemira retained its existing outlook for 2012. In 2012, Kemira expects revenue and operative EBIT to be approximately at the same level as in 2011. In the near term, uncertainty in Europe and a slowdown in global economic growth may affect the demand for our products in our customer industries. This guidance assumes current currency exchange rates and an oil price level of 115 $ per barrel.

Kemira's financial targets remain as communicated earlier. The company's medium term financial targets are:

- revenue growth in mature markets > 3% per year, and in emerging markets > 7% per year

- EBIT -% of revenue > 10%

- positive cash flow after investments and dividends

- gearing level < 60%.

The theme of the CMD was the "Fit for Growth" restructuring program, launched on July 26th, 2012. Wolfgang Büchele, President and CEO gave an update on the implementation of the program:

"The expected EUR 60 million cost saving impact of the program will occur as follows: EUR 10 million in 2012, EUR 50 million in 2013 and EUR 60 million in 2014. The ultimate goal of the program is to reach at least 10% EBIT margin in 2014. Redundancies will account for 50% of the expected savings, and the remaining 50% will be achieved through manufacturing network consolidation and leaner operations. Currently 14 manufacturing sites are under review as part of the ongoing manufacturing consolidation."

Wolfgang Büchele also gave an update on the ongoing work to sharpen Kemira's strategy. "Our main focus is on delivering our 'Fit for Growth' program, but we have also started to analyze how the company should look in 2020. The highest growth in our accessible markets is focused on Asia-Pacific and South America. Our oil and gas business is expected to grow strongly in all regions. One of Kemira's key strengths is the capability to tailor products and applications to customers' needs based on innovation and extensive manufacturing capability. We are also a leading global chemical supplier to the paper industry with long-term commitment. The strategy will be communicated, once approved, in connection with the Q1 results in 2013".

Jyrki Mäki-Kala, CFO, also gave further details on the "Fit for Growth" restructuring program: "The expected restructuring charges connected to the program amounts to EUR 85 million of which EUR 35 million will be cash cost and EUR 50 million being write-downs. EUR 55 million of the restructuring charges will be booked in the second half of 2012, and the balance in the first half of 2013. Our cost savings estimates for the different segments, based on the detailed action plan, are: Paper EUR 22 million, Municipal & Industrial EUR 22 million, Oil & Mining EUR 12 million and ChemSolutions EUR 4 million."

Other Kemira speakers at the Capital Markets Day included Petri Helsky, President, Paper segment, Hannu Virolainen, President, Municipal & Industrial segment, Randy Owens, President Oil & Mining segment, Frank Wegener, Managing Director of ChemSolutions, Joe Chan, Region head, APAC and Hilton Casas de Almeida, Region head, SA.