Ianadmin

Clearwater Paper Comments on U.S. District Court Decision

Ruling Allows Delivery of TAD Paper Machine to Clearwater Paper by July 2012, Facilitating Completion of Shelby Tissue Facility on Schedule

SPOKANE, Wash. --- Clearwater Paper Corporation (NYSE:CLW) has commented on the ruling in the United States District Court for the District of South Carolina in favor of Metso Paper USA and Clearwater Paper in connection with a lawsuit filed by First Quality Tissue SE, LLCthat sought to enjoin Metso Paper from delivering a Through-Air-Dried, or TAD, paper machine to Clearwater Paper.

"Clearwater Paper is very pleased with the court's decision to deny the request for injunctive relief and dismiss the amended complaint, and we look forward to completion of our Shelby TAD paper machine facility," said Gordon Jones, chairman and chief executive officer. "We expect that the final components of our TAD paper machine will be delivered by Metso Paper by July 2012, pursuant to our contract with them, and that our Shelby TAD paper machine facility will be completed and begin operations prior to the end of 2012."

In 2010, Clearwater Paper contracted with Metso Paper to construct a TAD paper machine for its tissue manufacturing and converting facility under construction at Shelby, North Carolina. Clearwater Paper's contract with Metso Paper calls for an expected delivery of the TAD paper machine by July 2012. In August 2011, First Quality filed a lawsuit against Metso Paper seeking to enjoin Metso Paper from delivering the TAD paper machine toClearwater Paper based on the terms of an agreement between Metso Paper and First Quality. Clearwater Paper intervened in the litigation inNovember 2011 to ensure representation of its interests.

Source: Clearwater Paper Corporation

Stockholm conference draws hundreds of paper physicists and paper chemists

For the first time, the International Paper Physics Conference and the International Paper and Coating Chemistry Symposium were held at the same time, in the same location and with a coordinated programme. Paper Conferences 2012 in Stockholm was a resounding success, attracting more than 400 participants from 24 different countries, and exceeding all expectations of the organisers, Innventia and the Royal Institute of Technology. By the time the final speaker left the podium on Thursday afternoon, a total of 138 presentations, together with several poster presentations, had been given during four days of parallel sessions at Stockholm’s Clarion Hotel Sign.

For the first time, the International Paper Physics Conference and the International Paper and Coating Chemistry Symposium were held at the same time, in the same location and with a coordinated programme. Paper Conferences 2012 in Stockholm was a resounding success, attracting more than 400 participants from 24 different countries, and exceeding all expectations of the organisers, Innventia and the Royal Institute of Technology. By the time the final speaker left the podium on Thursday afternoon, a total of 138 presentations, together with several poster presentations, had been given during four days of parallel sessions at Stockholm’s Clarion Hotel Sign.

“A joint event has meant greater exposure,” explains Marco Lucisano, chairman of the organising committee. “We were able to attract more researchers than if we had held the conferences separately. It has also meant greater exposure for the participants, who have had access to more talks and other participants. We’re particularly pleased to note that nearly 40 percent of the participants were industry representatives. This shows that the content of the conferences is relevant in terms of meeting both current and future industrial challenges.”

Prizes were awarded for the best poster presentations at the conference dinner, held at Winterviken on 13 June. The paper physics award went to Paul-Philipp Post, Christian Berger, Klaus Villforth, Heinz-Joachim Shaffrath and Samuel Schabel for the poster ”Optical measurement of deformation of paper under tensile load”, while the paper chemistry award was presented to Florian Loyal, Melanie Gattermayer and Markus Biesalski, for the poster ”Mussel-inspired polymers for papermaking and functionalization”. Franz Schmied received the prestigious Best Presentation Award for his talk “A model approach to understand the fiber – fiber bond”, as voted for by participants at the International Paper Physics Conference 2011 in Graz.

Buckeye Technologies completes sale of cotton linter pulp production facility in Brazil

Buckeye Technologies Inc. has announced that it has completed the sale of its Brazilian subsidiary Buckeye Americana Ltda. to Vicunha Participacoes S.A. Net cash proceeds from the sale were $6.4 million. The Company ceased production of cotton cellulose pulp at the Americana, Brazil facility in December 2011, but had continued to operate its waste water treatment facility for the shared industrial site.

Buckeye, a leading manufacturer and marketer of specialty fibers and nonwoven materials, is headquartered in Memphis, Tennessee, USA. The Company currently operates facilities in the United States, Germany and Canada. Its products are sold worldwide to makers of consumer and industrial goods.

Source: Buckeye Technologies Inc.

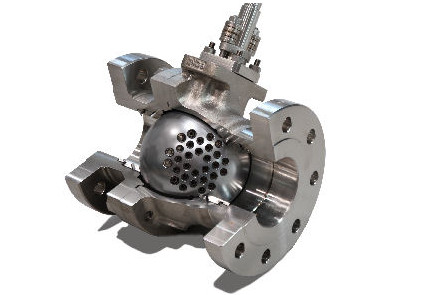

Metso's new Neles Q2-Trim™ eliminates noise before it is born

Metso's new Neles Q2-Trim ™ reduces noise up to 30 decibels compared to a typical control valve helping process industry customers to improve personnel and plant safety while simultaneously increasing efficiency and reliability..

For more than 30 years Metso's patented Q-trim technology has been the industry benchmark for rotary noise attenuation solutions in challenging applications. Now Metso adds a new level of performance by introducing new Neles Q2-Trim which solves aerodynamic noise problems and reduces noise up to 30 decibels compared to a typical control valve.

Metso's frontrunning Q2-Trim technology is combination of various techniques resulting multiple benefits for customers. By eliminating the damage that high noise can cause to process plants, employees and surroundings Q2-Trim ensures safe working environmental for personnel and stabile process control and longer uninterrupted plant runtime .

By reducing noise and related vibration to acceptable levels Q-Trim technology also protects process equipment thus lowering the operating costs and minimizing the need for spare parts for valves and other accessories.

Combining Q-Trim technology with quarter-turn valves results in emission levels that meet all relevant industry standards. Compact size and selection of mounting positions means less pipeline support and easier piping layout design.

New Neles Q2-Trim is an addition to the existing Q-Trim technology and is available for pressure classes ASME 150 - 600 in sizes 2" - 16" and PN 10 - PN 100 in sizes DN 050 - DN 400 in standard ball valve offering. The standard trim material is stainless steel, Q-Trims made of special alloys and larger sizes are available on request. Q2-Trim has several key application in various fields in Power, Oil & Gas, Petrochemical, Industrial gas and Chemical industry.

Alfa Laval wins SEK 120 million energy efficiency order in South Korea

Alfa Laval – a world leader in heat transfer, centrifugal separation and fluid handling – has received an order to supply of Alfa Laval Packinox heat exchangers from a refinery in South Korea. The order value is about SEK 120 million and delivery is scheduled for 2013.

The Alfa Laval Packinox heat exchangers will be used in catalytic processing sections in the production of mixed Xylenes used for synthetic nylons and PET bottles, among other things.

“The order confirms Alfa Laval's strong local presence in South Korea and long working relation with Korean EPC contractors”, says Lars Renström, President and CEO of the Alfa Laval Group.

Did you know… that South Korea is now the fourth largest market for Alfa Laval, behind the US, China and Nordic?

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Sonoco Announces a Surcharge for Wood Reels

Sonoco will implement a surcharge of 8.6 percent for its nailed wood reels, effective July 1, 2012. The surcharge is necessary to offset the steady increase in lumber costs experienced over the past two years.

"We have chosen to use a surcharge rather than changing our base price because we feel lumber costs should soften later this year," said Greg Powell, general manager, Sonoco Reels. "Our plan will be to adjust the surcharge to reflect any future decline in lumber pricing. At the same time, should the cost for lumber continue to increase, our surcharge would be adjusted accordingly."

Sonoco Reels is the most comprehensive provider of reels produced from nailed wood, plywood, poly-fibers, molded plastic and steel materials. Reels produced by Sonoco are used by the wire and cable industry to serve the power transmission and distribution; telecommunications; commercial and industrial building; oil and gas; mining and marine industries.

For more information about Sonoco's complete line of reels or to learn more about current pricing, please visit the Company's website or contact Sonoco Reels at +800/633-3962.

SOURCE Sonoco

Putting forests at the heart of a new, greener economy (Rio+20)

New FAO report profiles how sustainable forestry can help meet development goals

The world's forests have a major role to play in the transition to a new, greener economy, a theme being discussed at the Rio+20 Conference. But to spark that shift, governments must enact programs and policies aimed at both unlocking the potential of forests and ensuring that they are sustainably managed, FAO said today.

The world's forests have a major role to play in the transition to a new, greener economy, a theme being discussed at the Rio+20 Conference. But to spark that shift, governments must enact programs and policies aimed at both unlocking the potential of forests and ensuring that they are sustainably managed, FAO said today.

In a new report, The State of the World's Forests 2012 (SOFO 2012), the UN Food and Agriculture Organization makes the case that better and more sustainable use of forestry resources can make a significant contribution to meeting many of the core challenges being discussed in Rio, including reducing poverty and hunger, minimizing the impacts of climate change, and creating alternative and more sustainable sources of bio-products and bio-energy for human use.

The report will be presented today during an event at the Rio+20 Conference organized by FAO and its partners, Brazilian Pulp and Paper Association (Bracelpa) and the International Council of Forest and Paper Associations (ICFPA).

"Forests and trees on farms are a direct source of food, energy, and cash income for more than a billion of the world's poorest people," said FAO Assistant Director-General for Forestry Eduardo Rojas-Briales. "At the same time, forests trap carbon and mitigate climate change, maintain water and soil health, and prevent desertification. The sustainable management of forests offers multiple benefits -- with the right programs and policies, the sector can lead the way towards more sustainable, greener economies."

"Brazil has successful examples of forest plantation management, and its good practices can be disseminated to other developing countries in order to promote the green economy and strengthen the synergies between sustainable development and climate change mitigation. The Rio+20 discussions must be the starting point to strengthen the balance of the triple bottom line. Brazil's pulp and paper industry is prepared to promote innovation in biotechnology and sequestration of forest carbon that can support a sustainable expansion of triple bottom line activities. This means social inclusion and protection of the environment", added Elizabeth de Carvalhaes, Bracelpa's executive president.

"The global forest products industry is at the forefront of forest conservation efforts," said Donna Harman, President of ICFPA. "Through sustainable forest management practices, our industry not only produces a sustained annual yield of timber, but also ensures its abundance for future generations. The global forest products industry also contributes to livelihoods and human well-being by employing millions of people around the world and by producing products that provide shelter and increase literacy. The emerging bio-economy can only increase the important role of this industry."

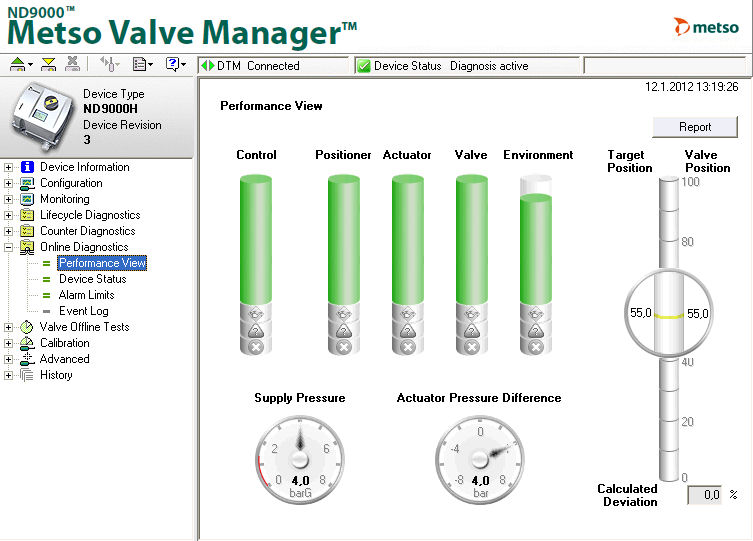

Metso's 3rd generation control valve diagnostics offer enhanced maintenance efficiency and process performance

New Metso Valve Manager™, representing 3rd generation diagnostics, is taking predictive control valve maintenance to a new level, which makes the available information more user friendly and more easily understandable thus enabling several benefits for the customers: Enhanced maintenance efficiency, improved process performance and significant cost savings.

Metso's new Valve Manager represents state-of-the art, 3rd generation valve diagnostics which is capable of processing the collected diagnostics information to visualize the condition of the valve in question with five different indices: Control performance, Valve condition, Actuator condition, Positioner condition and condition of the operating environment.

With processed and visualized diagnostics information the maintenance managers and engineers and process operators are capable of making educated decisions concerning the control valve maintenance without deep valve know-how. Unexpected shutdowns can be avoided and the control valve performance can be maintained at optimum level by continuously monitoring the condition of the installed base at the plant or mill and by taking the necessary preventive actions based on the available diagnostics information. Also, with the help of the diagnostics, the available maintenance resources can be more efficiently allocated during shutdowns.

When so called preventive or schedule based maintenance strategy is followed, many valves are often needlessly maintained during shutdowns. By focusing the maintenance actions on the valves really needing maintenance, significant maintenance cost savings can be achieved through reduced spare part purchases and reduced need for maintenance resources.

Metso's new Valve Manager is available for the ND9000 series intelligent valve controllers. The ND9000 series intelligent valve controllers include several in build sensors and they are measuring various internal parameters. Based on this data and on the wide installed base and extensive service experience, Metso has developed mathematical algorithms to calculate the indices in the Performance view (presented in figure 1.).

Figure 1. Performance view

Control performance is the most important index out of the five. It shows how well the whole control valve assembly is performing its task to control the flow in the pipeline.

Valve condition index presents the status of the valve based on its use history and current measured values. Based on the index value the user can also estimate whether the valve will shortly be in a need of maintenance or not.

Actuator condition index presents the status of the actuator based on its use history and current measured values. Based on the index value the user can also estimate whether the actuator will shortly be in a need of maintenance or not.

Positioner condition index presents the status of the positioner based on its use history and current measured values and in addition also on several self-diagnostics parameters. Based on the index value the user can also estimate whether the positioner will shortly be in a need of maintenance or not.

Environment conditions index takes into account the conditions of the assembly (e.g. supply pressure value and its steadiness) and also selected aspects of valve assembly configuration.

Future development areas

The 3rd generation diagnostics are already available for control valves. Same level of information can't yet be received from on-off or from ESD valve performance but Metso is developing its valve solutions further to bring these features available for the on-off and ESD valves as well. The technology benchmark devices on the on-off side, such as Metso's SwitchGuardTM intelligent on-off valve controller, already include diagnostics features that are especially designed for on-off applications.

The industry standard for on-off valve control is presently more or less using solenoid valves to control the on-off movement. One of the downsides with the solenoids is clearly that those can't provide any diagnostics data on the on-off valve performance. Thus it can already be seen with ESD valves, which are the most critical type of on-off valves,that in new green field projects smart partial stroke testing (PST) devices are being implemented.

The state-of-the-art smart PST devices, such as Metso's ValvGuardTM, are used to conduct different tests for the ESD valves, both online and offline, providing diagnostics information on the ESD valve condition. Next step would be then to have the smart PST devices analyze the data further and provide similar indices that are presently already available for control valves.

For other on-off applications, besides the ESD, Metso has brought integrated solenoid and limit switch combinations to the market. An example of such a device is Metso's Axiom on-off valve controller, which can also provide basic diagnostics by giving fault alerts of possible changes in the on-off valve condition. Some customers have already identified the need for diagnostics on the process critical on-off valves and the integrated devices can be seen as a first step towards this direction.

Buckeye's Florida plant temporarily closed due to Dryer Drum failure

Buckeye Technologies Inc. has announced that on Sunday, June 17, Buckeye’s Florida wood cellulose fibers facility near Perry, Florida, experienced a significant failure of a steam drum on the number 2 paper machine causing damage to multiple drums and structural damage to the paper machine building and structure. Fortunately, there were no injuries to any personnel working in the area. Following the incident, which occurred about 5:20 p.m. EDT, the plant was shut down in an orderly manner. A team at the plant, including contractor resources and structural engineers, immediately began an investigation to determine the root cause of the drum failure. While it is too early to know the extent or timing to return the plant to normal operations, Buckeye management will have more details on the incident later in the week and will provide updates on plans for resuming production.

Buckeye resources are working with all stakeholders including customers, suppliers and employees to manage and minimize the impact of this outage to the supply chain and to operations.

Buckeye Chief Executive Officer John Crowe stated, “Buckeye can and will repair the damage to the number 2 machine and the building. The safety of people is our highest priority, and we are thankful there were no injuries in this significant incident.”

Source: Buckeye Technologies Inc.

International Paper Named Among 100 Best Places to Work

International Paper has announced that Computerworld, the leading source of technology news and information for IT influencers worldwide, ranked International Paper No. 45 on its 2012 Top 100 Best Places to Work in IT.

International Paper was recognized as one of the Top 100 organizations that challenge its IT staff while providing great benefits and compensation. By achieving 45th place this year, it continues IP's upward trend in the rankings, moving up from 59th in 2011 and 90th in 2010. Honorees and full results from the 19th annual Best Places to Work in IT survey will be included in a special edition of Computerworld that will be issued today.

"This is a great accomplishment for our entire IT team," said John Balboni, senior vice president, Chief Information Officer. "To be recognized as one of the Best Places to Work in IT is a reflection of total commitment, full engagement, great execution and outstanding teamwork around the globe."

International Paper's IT organization employs more than 1,400 IT professionals throughout its global operations. The group is responsible for designing, implementing, upgrading and sustaining the information infrastructure and systems that support 70,000 employees and their operations in more than 24 countries worldwide.

"The organizations on this year's Best Places to Work in IT list consistently seek out and hire the most talented IT people, offer them competitive pay and provide great benefits," said Scot Finnie, editor in chief of Computerworld. "Many of these organizations have spent years building top-notch IT workplaces, and we applaud the amazing work they've done to sustain dynamic environments where IT professionals can work with the latest technologies and play a key role in business-critical projects."

SOURCE International Paper