Ianadmin

Mondi teams up with TU Graz and Océ in search of the perfect paper

New laboratory in Graz, Austria, to research fibre swelling and its impact on paper characteristics

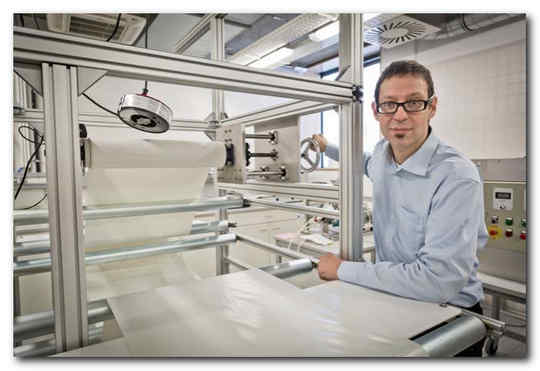

A project supported by Mondi, the new “Christian Doppler (CD) Laboratory for Fibre Swelling and Paper Performance” was officially opened 11 January 2016. The laboratory headed by Ulrich Hirn was set up in cooperation with the Graz University of Technology (TU Graz) and the industry partners Océ Holding B.V (Netherlands), a leading producer of digital printing machinery, especially in the field of high-speed inkjet printing and Mondi, the international packaging and paper Group.

photo c/o : TU GRAZ

The team of the CD Laboratory will investigate swelling and de-swelling processes during paper production, printing and converting. Ulrich Hirn explains that, “in modern high-speed inkjet printing presses the fibre swelling is crucial: less swelling means faster drying but fibre swelling also has a positive impact on paper stability. Based on our investigations we will develop simulation models of the different processes. We aim to find solutions to further improve the paper, the printing including inks and equipment as well as the converting in close collaboration with our industrial partners”.

At the opening ceremony, Harald Kainz, Rector of TU Graz, and sponsoring partner representatives Leo Arpa from Mondi and Michael Pohlt from Océ pointed out the positive elements of this collaboration of science and industry. They specifically highlighted the development of meaningful results for the industry, the creation of a powerful network of expertise for solving industrial and scientific questions, and the development of a talent pool of young technicians and scientists available for the industry.

We are Mondi. IN TOUCH EVERY DAY.

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are in central Europe, Russia, North America and South Africa. We offer over 100 packaging and paper products, customised into more than 100,000 different solutions for customers and end consumers. In 2014 Mondi had revenues of €6.4 billion and a return on capital employed of 17.2%.

The Mondi Group is fully integrated across the packaging and paper value chain – from managing forests and producing pulp, paper and compound plastics to developing effective and innovative industrial and consumer packaging solutions. Our innovative technologies and products can be found in a variety of applications including hygiene components, stand-up pouches, super-strong cement bags, clever retail boxes and office paper. Our key customers are in industries such as automotive; building and construction; chemicals; food and beverage; home and personal care; medical and pharmaceutical; packaging and paper converting; pet care; and office and professional printing.

Mondi has a dual-listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc under the ticker code MNDI.

For us, sustainable development makes good business sense. We don’t just talk about sustainability; we make it part of the way we work every day. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is a business unit of Mondi’s Europe & International Division. In 4 paper mills in Austria, Slovakia, and Russia Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

ANDRITZ to supply equipment for recycled fiber system to Sonoco-Alcore, Finland

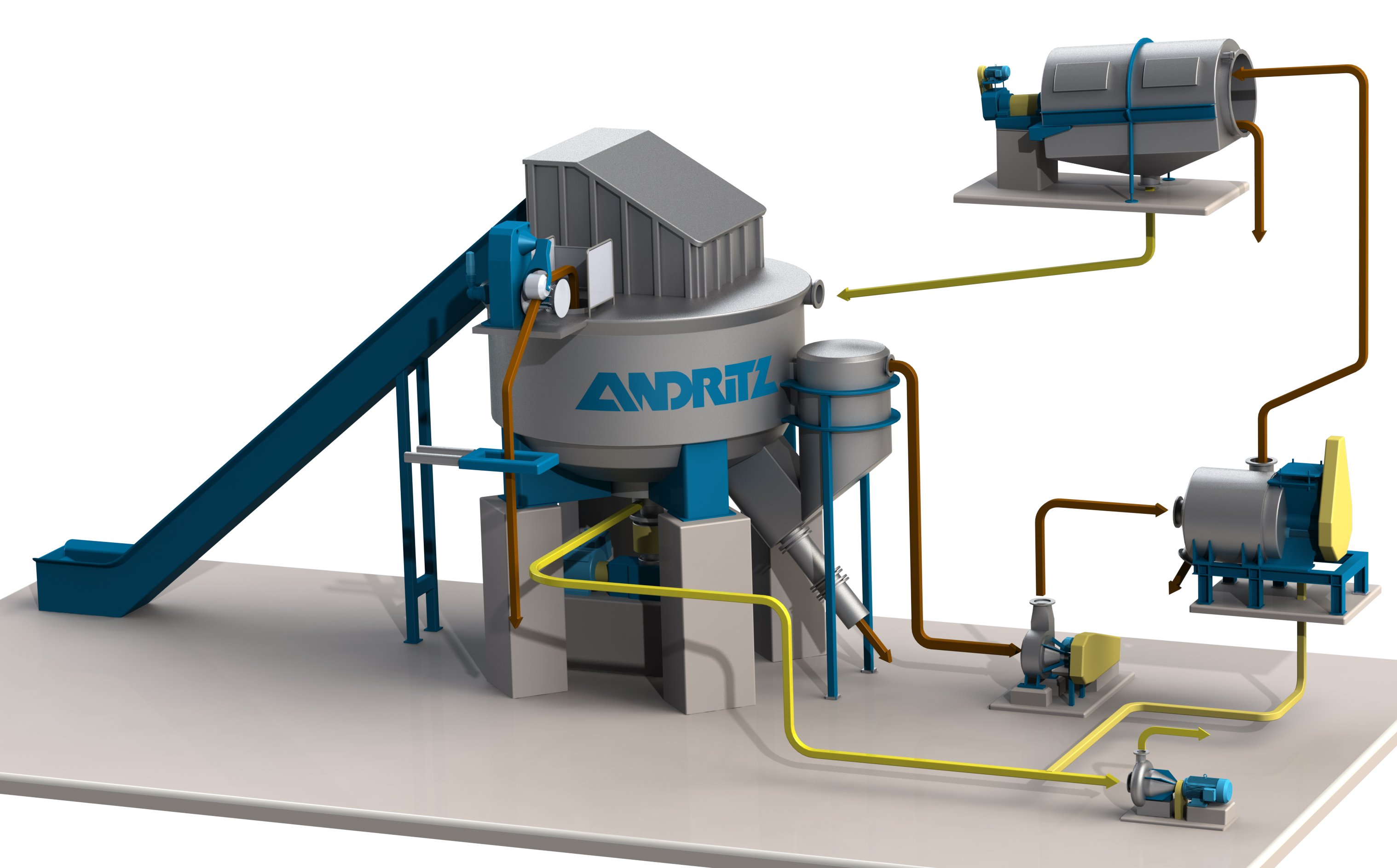

International technology Group ANDRITZ has received an order from Sonoco-Alcore, Finland, to supply pulping and de-trashing equipment for the OCC stock preparation line at the Karhula paper mill. Start-up is scheduled for the third quarter of 2016.

ANDRITZ is to supply equipment for a recycled fiber system to Sonoco-Alcore, Finland.

The order comprises supply of a new ANDRITZ FSR pulper rotor and a screen plate for the existing low-consistency pulper, a completely new de-trashing system including a trash trap, a de-trashing pump, a de-trasher FibreGuard, a new reject wash drum, field instruments, spare and wear parts, and a field service package.

After completion of the modification work by ANDRITZ, the production capacity of the pulping system will be increased significantly, while at the same time energy consumption will remain unchanged, fiber loss will be reduced, and pulping efficiency improved. This order once again confirms ANDRITZ’s wide technological experience with more than 60 pulping and de-trashing systems for packaging grades installed around the world.

For further information, please contact:

Michael Buchbauer

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.andritz.com

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, production equipment for biofuel (second generation), biomass torrefaction equipment, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

Kemira continues to invest in the growing market for bleaching chemicals after successful ramp-up of the new capacity in Oulu, Finland

In 2014, Kemira announced a substantial capital investment in its Oulu plant to capture the growth potential in the tight bleaching chemical market. The new hydrogen peroxide production process was successfully started during the third quarter in 2015 and the new volume has been sold out.

In 2014, Kemira announced a substantial capital investment in its Oulu plant to capture the growth potential in the tight bleaching chemical market. The new hydrogen peroxide production process was successfully started during the third quarter in 2015 and the new volume has been sold out.

Positive development in the fiber markets and the ongoing pulp mill capacity investments drive Kemira's investments in bleaching chemical capacity. Kemira has started a pre engineering study for additional capacity in the Nordics in order to invest in new production lines in Finland and debottleneck the existing units.

Kemira has several bleaching chemical production units in Europe; Äetsä, Joutseno and Oulu in Finland, Helsingborg in Sweden and Europoort in Netherlands.

For more information, please contact

Kemira

Antti Matula, Director, Marketing and Product Management

Pulp & Paper segment

Tel. +49 171 196 1641

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2014, Kemira's annual revenue was EUR 2.1 billion and we employed approximately 4,250 people. Kemira shares are listed on the NASDAQ OMX Helsinki Ltd.

www.kemira.com

Valmet to supply grade conversion rebuild for Kruger Packaging in Trois-Rivières, Québec, Canada

Valmet will modernize a paper machine (PM10) at the Kruger paper mill in Trois-Rivières (Québec), Canada. Currently producing newsprint, PM10 will be rebuilt using some of the most advanced containerboard manufacturing and automation technology to produce 360,000 metric tonnes (MT) per year of 100% recycled lightweight and high strength linerboard. The rebuilt production line will start up in 2017.

Valmet will modernize a paper machine (PM10) at the Kruger paper mill in Trois-Rivières (Québec), Canada. Currently producing newsprint, PM10 will be rebuilt using some of the most advanced containerboard manufacturing and automation technology to produce 360,000 metric tonnes (MT) per year of 100% recycled lightweight and high strength linerboard. The rebuilt production line will start up in 2017.

The order is included in Valmet's fourth quarter 2015 orders received. The value of the order is not disclosed. The value of paper machine rebuilds depends on the scope of the delivery. This kind of rebuild is typically valued around EUR 30 million.

"Kruger selected Valmet based on its innovative technology and track record of successful rebuilds, as well as their knowledge of North American recycled linerboard requirements," declared Project Manager, Christian Lemay of Kruger Packaging L.P.

Modernization project will generate significant growth opportunities

The solution for this ~8.4-meter-wide (wire) machine will be fully modernized from headbox to winder to produce linerboard with industry-leading high strength to basis weight properties, and with sheet formation and surface characteristics suitable for high-quality graphic printing for corrugated box plants.

In addition to the machinery improvements, the delivery will includeValmet DNA automation system with remote servicing capabilities for machine and process control as well as MD/CD controls. Valmet will deliver also Valmet IQ Dilution Profiler that contributes to improved sheet quality and minimized variability. To be delivered Valmet Pulp Analyzer will provide fast and precise online updates of key fiber and papermaking furnish properties.

"To be able to reach the targets, grade conversion modernizations require thorough expertise. Valmet is one of the few suppliers who can design, manage and deliver this kind of vast grade conversion projects. Additionally, Valmet's pilot plant played a substantial role since we could demonstrate the technologies to the customer in real life conditions," says Mike Gray, Valmet's Area Vice President in North America.

Information about the customer Kruger Packaging L.P.

Kruger Packaging L.P. is a Canadian manufacturer of containerboard and packaging products made from recycled fibers. The company currently operates one containerboard mill in Montreal (Québec), as well as two packaging plants in LaSalle (Québec) and Brampton (Ontario). Founded in 1904, its parent company, family-owned Kruger Inc., is also a major producer of publication papers, tissue products, renewable energy, cellulosic biomaterials, and wines and spirits. In addition, Kruger Inc. is a leading paper and paperboard recycler in North America.

Further information, please contact:

Mike Gray, Area Vice President, North America, Valmet, tel. +1 920 738 8542

Jari Siitonen, Sales Director, Paper mills, Valmet tel. +358 40 765 7406

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki

Sappi Europe strengthens Logistics Footprint in Europe with EUR 12.6 million Investment

As part of Sappi Europe’s successful newly developed ‘go to market’ strategy, the green light has been given for the building of a state of the art multi-purpose paper storage logistics facility of approx. 20,000 m2 close to Wesel, Germany. The rail-linked facility will hold more stock keeping units for German and Benelux customers in particular. The logistics services linked to this additional warehouse space will also be made available to other customers thanks to the operational support provided by long-standing partners.

As part of Sappi Europe’s successful newly developed ‘go to market’ strategy, the green light has been given for the building of a state of the art multi-purpose paper storage logistics facility of approx. 20,000 m2 close to Wesel, Germany. The rail-linked facility will hold more stock keeping units for German and Benelux customers in particular. The logistics services linked to this additional warehouse space will also be made available to other customers thanks to the operational support provided by long-standing partners.

This EUR 12.6 million investment supports Sappi Europe’s strategic focus on optimising logistics networks and reducing costs. The facility will be fully operation by the end of 2016.

Sappi has implemented a full train concept with a dedicated train between its Gratkorn Mill and the Wesel hub. Six trains per week carry paper and pulp between the sites. The strategic location of the hub facilitates the flow of goods across Europe, connecting overseas ports and Sappi’s railway distribution centres in Zeebrugge (Belgium) and close to Graz (Austria).

Hans-Juergen Peichler, Manager Logistics, Sappi Logistics Wesel GmbH has been closely involved in the initiative; “We have put a lot of emphasis on analysing both outbound and inbound logistics, working with our procurement and logistics teams to find synergies and to better utilise existing networks. The logistics services that we offer have been fine-tuned and are as multi-modal as possible. The Wesel facility supports this drive.”

BillerudKorsnäs strengthens competence in formable packaging

BillerudKorsnäs has strengthened its competence in formable packaging through a smaller investment in a 10 percent stake in the Danish packaging innovation company EcoXpac. The investment forms the foundation for collaboration and is part of BillerudKorsnäs commitment to innovation to solve the packaging challenges of the future.

BillerudKorsnäs has strengthened its competence in formable packaging through a smaller investment in a 10 percent stake in the Danish packaging innovation company EcoXpac. The investment forms the foundation for collaboration and is part of BillerudKorsnäs commitment to innovation to solve the packaging challenges of the future.

BillerudKorsnäs has in addition to a solid foundation in innovation, including the continuous development of our existing materials and solutions, also an ambition to take on a number of larger, more fundamental and long-term challenges in the packaging sector. This is done in order to find solutions and develop entirely new packaging concepts that can challenge plastic, glass and aluminium. One such concept is to produce a bottle completely made of paper. Through collaboration and by combining the knowledge and experience of BillerudKorsnäs and EcoXpac the aim is to achieve this.

"Innovation is a key factor in further strengthening our business in the long term but also a way for us to challenge conventional packaging for a sustainable future. Therefore it is natural for us to aim high in a number of well-chosen development projects and take on real challenges that can have a big and long term positive impact on our business and our contribution to a more sustainable world. Although the investment in EcoXpac is small in financial terms compared to the size of BillerudKorsnäs, it creates conditions for success for the innovation challenges we now take on." - says Magnus Wikström SVP Technology & Strategic Development at BillerudKorsnäs.

EcoXpac is a company specialising in advanced 3D-forming of fibre based structures. It was founded in 2005 and is based in Denmark.

"Our knowledge and experience in the area of moulded pulp and our entrepreneurial approach combined with the ability of BillerudKorsnäs to bring ideas and innovations to the market forms a strong base for our future cooperation. A base from which we aim to realize projects such as that to create a paper bottle"- says Jesper Servé the founder of EcoXpac.

For more information, please contact:

Henrik Essén, Senior Vice President Communication and Sustainability, +46 (0)8 553 335 00, This email address is being protected from spambots. You need JavaScript enabled to view it.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world leading provider of primary fiber based packaging materials and have customers in over 100 countries. The company has 8 production units in Sweden, Finland and the UK and about 4300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 21 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

EcoXpac is an innovative company specialized in designing, developing and implementing process solutions for moulded fibre. Since its establishment in 2005, the company follows a strategy striving to introduce fiber-based products into previously non utilized categories. EcoXpac already cooperates with a network of national research organizations, such as the Technical University of Denmark & Danish Technological Institute, to ensure innovation stems from a thoroughly analyzed basis. Learn more about EcoXpac: www.ecoxpac.dk or follow us on Twitter @EcoXpac.

Ari Saario appointed Director, Research & Development at Valmet

To strengthen Valmet's R&D operations Mr. Ari Saario (D.Sc. Tech.) has been appointed Director, R&D at Valmet as of January 18, 2016. He will report to Juha Lappalainen, Senior Vice President of Valmet's Strategy and Operational Development corporate function.

To strengthen Valmet's R&D operations Mr. Ari Saario (D.Sc. Tech.) has been appointed Director, R&D at Valmet as of January 18, 2016. He will report to Juha Lappalainen, Senior Vice President of Valmet's Strategy and Operational Development corporate function.

The aim of Valmet's research and technology development work is to ensure an advanced and competitive offering of technologies and services, enhance raw material and energy efficiency, and to promote the use of renewable raw materials. The R&D director position is new in the company, and Ari Saario will concentrate on ensuring an effective R&D process and commercialization of new innovations, right R&D project portfolio and a clear R&D road-map to secure Valmet's technological leadership also in the future.

"Valmet's strong R&D infrastructure is built around our 16 own R&D centers and pilot facilities. We have over 400 R&D professionals around the globe and around 1,800 protected inventions. As a result of our R&D work, we have continuously improved our products and services and brought new innovations to market. With this new position we aim to create an even more focused R&D process and portfolio, and accelerate the commercialization of new innovations," says Juha Lappalainen, Senior Vice President of Valmet's Strategy and Operational Development.

Ari Saario moves to this new position from Valmet's Pulp and Energy business line's R&D function. He has a strong background in technology and R&D from Oilon, Metso and Valmet. He has versatile experience of more than 10 years in research and technology development, R&D team leadership and R&D funding.

For further information, please contact:

Ari Saario, Director, Research & Development (as of Jan 18, 2016), Valmet, tel. +358 50 590 2046

Juha Lappalainen SVP, Strategy and Operational Development, Valmet, tel. +358 50 523 8708

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Vallvik Mill granted a new environmental permit

Rottneros' subsidiary Vallviks Bruk AB has on January 12th been granted permission by the Land and Environment Court in Östersund to produce the requested 255,000 tons of sulphate pulp. It is a comprehensive permit under the Swedish Environmental Code, which is associated with a number of conditions, which are broadly in line with the company's previously stated position.

Rottneros' subsidiary Vallviks Bruk AB has on January 12th been granted permission by the Land and Environment Court in Östersund to produce the requested 255,000 tons of sulphate pulp. It is a comprehensive permit under the Swedish Environmental Code, which is associated with a number of conditions, which are broadly in line with the company's previously stated position.

"The new permit will ensure that we can continue with our long-term industrial plan, Agenda 500 and increase the capacity of both our mills. The permit also ensures that we can continue to develop the company and our organization,” says Per Lundeen, CEO of Rottneros.

For further information, please contact:

Per Lundeen, CEO of Rottneros AB, +46 70 518 33 47

Rottneros is an independent producer of market pulp. The Group comprises the parent company Rottneros AB, listed on NASDAQ Stockholm, and its subsidiaries Rottneros Bruk AB and Vallviks Bruk AB with operations involving the production and sale of market pulp. The Group also includes the wood procurement company Rottneros Baltic SIA in Latvia. The Group has around 250 employees and had a turnover of approximately SEK 1.5 billion in the 2014 financial year.

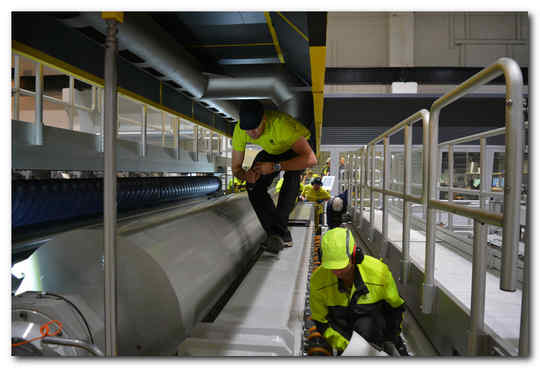

UPM celebrates inaugural opening of expanded Kymi pulp mill in Kuusankoski, Finland

UPM inaugurated its newly revamped Kymi pulp mill in Kuusankoski following a EUR 160 million investment in production expansion. Finland's Prime Minister Juha Sipilä officiated the proceedings by signing the charter together with UPM President and CEO Jussi Pesonen.

UPM invested in the Kymi pulp mill to strengthen its position in the growing end-use segments of the global pulp market. The investment marks a production capacity increase of 170,000 tonnes to 700,000 tonnes of bleached northern softwood and birch pulp annually.

Prime Minister Sipilä stated in his speech that the project is the fruit of a vast store of knowledge that has been accumulated at Kymi mill during the past decades. The investment supports the Finnish Government's target of establishing Finland as a pioneer in the bioeconomy, circular economy and clean-tech solutions by 2025.

"The year 2015 demonstrated that the forest industry continues to play an important role in Finland. Our exports were boosted especially by pulp and paper. Kymi's example is a clear signal of the ongoing strong growth of the forest industry and bioeconomy," stated Sipilä.

In his speech, Jussi Pesonen thanked the project team and all of the Kymi personnel, suppliers and partners for an excellent achievement.

"The construction of a competitive forest industry mill complex requires perseverance, and Kymi has maintained its competitiveness through operational efficiency and investments. In the past ten years, UPM has invested approximately EUR 550 million in the Kymi pulp mill and so far in the 21st century over EUR 900 million in total in the Kymi mill region," says Jussi Pesonen.

Looking to the future competitiveness of the Finnish forest industry, Pesonen emphasised the significant impact of the operating environment and the role of the government. The government must keep its promise not to increase costs for the industry through political decisions. The labour market furthermore needs to be able to negotiate local agreements in order to ensure operational efficiency and delivery reliability to customers in varying demand situations. In addition, Pesonen highlighted the importance of an efficient wood supply chain and measures to ensure a stable wood supply from private forest owners.

A top-notch project in many respects

The Kymi expansion project was completed safely and on schedule alongside ongoing pulp and paper production. The ramp-up of pulp production was faster than expected, enabling the mill to reach its targets. The entire Kymi pulp and paper mill integrate benefits from the improved energy efficiency and operational flexibility brought by the investment project.

The Kymi project was started in February 2014 and completed by the end of 2015. The new debarking plant started operation in June and the modernised softwood fibre line was commissioned in August along with new pulp drying machine, which was the largest single investment in the project. Other improvements made last summer include the expansion of the wood yard and the introduction of a new railway and wagon-loading system.

Today the Kymi integrated pulp and paper mill complex is even more energy-efficient and flexible than ever before. Its high energy efficiency and locally sourced wood reduce the carbon footprint of the mill's products, which already now is close to zero. Over 90% of the energy produced at the Kymi mill is bioenergy.

The investment also has a positive effect on local employment rates and businesses. The increasing use of wood in the mill integrate will generate wood harvest and transportation work for forest industry professionals and stumpage earnings for forest owners.

For further information, please contact:

Mr Markku Laaksonen, General Manager, UPM Kymi, tel. +358 400 754 649, This email address is being protected from spambots. You need JavaScript enabled to view it.

Kymi

UPM Kymi is an environmentally efficient mill integrate producing pulp, paper and energy. UPM Kymi employs about 650 people and is located in south-east Finland in Kuusankoski, Kouvola. Kymi produces bleached birch and softwood pulp as well as coated and uncoated fine paper.

UPM Pulp

UPM is one of the world's leading producers of northern softwood, birch and eucalyptus pulp supplying global customers in many end use segments such as tissue, specialty papers, board, and printing and writing papers through its own sales and technical service network close to the customers. UPM Pulp operates four modern pulp mills, three in Finland and one in Uruguay as well as eucalyptus plantations in Uruguay. UPM Pulp employs approximately 1,500 people. The annual pulp production capacity is 3.5 million tonnes. Pulp Business is part of the UPM Biorefining Business Area. To learn more, visit: www.upmpulp.com

UPM

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 20,000 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM - The Biofore Company - www.upm.com

Countrystyle wins Smurfit Kappa contract

Kent-based resource management and recycling specialist Countrystyle Recycling has been appointed by Smurfit Kappa, one of the world’s leading paper-based packaging solutions providers, to provide recycling services for various waste streams arising from their new machine at the Townsend Hook site in Snodland, Kent.

The contract, worth c. £6million, will run until April 2018. Countrystyle is providing resource management services for c. 30,000 tonnes of material per year arising from the new machine, including ragger rope, small and heavy rejects, fine rejects, plastics and sand. Countrystyle is also providing total waste management services for all non-processed waste streams at the Snodland site.

Countrystyle and Smurfit Kappa worked together closely in the lead up to this contract award on the design of specialist containers to optimise logistics and fit within the designated waste collection area into which the various waste streams arising from the mill are directed. Each waste stream is collected separately by Countrystyle’s own fleet and transported to various treatment and disposal sites including Countrystyle’s own state-of-the-art recycling facility in Ridham.

Malcolm Wright, Purchasing Manager at Smurfit Kappa, said, “We are pleased to be working with Countrystyle as we know that they are specialists in their field, using experience and innovation to tackle difficult waste streams such as ragger rope. We are confident that they will deliver our goal of 100% diversion from landfill, bringing with it both environmental and financial benefits for Smurfit Kappa.”

Countrystyle’s Managing Director, Chris Howard, said, “This contract cements our relationship with Smurfit Kappa and justifies our significant investment in aiding the recovered paper sector in the recycling and reuse of by-products from its processes.

“This win further demonstrates Countrystyle’s continued ability to provide innovative, professional and cost-effective solutions across the spectrum of collection and treatment services.”

Countrystyle continues to expand its operations, both in and outside of Kent, providing integrated and innovative recycling and resource management solutions for local authorities, businesses and the general public alike.

Countrystyle Recycling

Countrystyle Recycling is a leading, privately owned waste management and recycling company capable of handling, processing, disposing and recycling almost all forms of waste. Its flagship facility, at Ridham in

Sittingbourne, Kent, provides specialist services for the recycling of plasterboard and wood. Other services include in-vessel composting, two waste transfer stations and an extensive commercial waste recyclable collection service providing local authorities and businesses with closed loop waste and resource management recycling services. For more information please see www.countrystylerecycling.co.uk

Smurfit Kappa

Smurfit Kappa is one of the leading providers of paper-based packaging solutions in the world, with around 43,000 employees in approximately 350 production sites across 33 countries and with revenue of €8.1 billion in 2014. Smurfit Kappa’s Townsend Hook site will produce approximately 250,000 tonnes per year of quality recycled containerboard material from its new machine. For more information please see www.smurfitkappa.com