Ianadmin

Brigl & Bergmeister, Niklasdorf & Vevče | Well equipped for the future

With the start up of the new film press at the Niklasdorf mill in Austria in November 2015, BRIGL & BERGMEISTER has completed the 3-phase investment programme, “Innovation One” launched in 2013. In 2013, the company already invested in a film press for the Vevče mill in Slovenia, thus ensuring both mills' future competitiveness.

Advantages of the film press

The newly installed film press replaces the conventional size press and offers numerous benefits. For example, the paper machine's speed is increased even further, while quality is improved and the product range is extended. The traditional range of one-side coated papers can now be produced with an even more selective and consistent surface quality. The new components of the plant are designed to allow for further increases in production capacity in the future.

Extension of the product portfolio

Spring 2014 saw investments in the headbox, which form the basis for a new future-oriented and innovative product portfolio. They allow Brigl & Bergmeister to offer a complete range of siliconizing base papers (called CCK – Clay Coated Kraft) under the brand name “NiklaSilico” within the sector of “Graphic Arts Applications”. With the new headbox, the maximum achievable grammage has been significantly increased to 137 g/m².

Customised embossing patterns

This year, investments in a third embossing calender were also made, in order to provide additional capacity for embossed speciality papers. Thus, B&B can also offer customised embossing patterns to the food & beverage industry.

Further reduction of the environmental impact

These investments also reflect B&B's motto “Think & Act Green”. Both the Niklasdorf and the Vevče mills already show industry-leading measures in terms of environmental protection. Thanks to the investments made, further energy savings will be achieved in the future by reducing the required steam and electricity consumption. Other resource-saving aspects, such as savings in particular production materials and increased machine efficiency, also contribute to accomplishing this aim.

The investments at both sites in recent years have increased the annual capacity of the B&B Group to 190,000 tonnes. B&B’s focus will remain on high-grade speciality papers for labels and flexible packaging for the consumer packaged goods industry.

B&B is the leading manufacturer of label papers and flexible packaging papers. Annually, some 100 billion labels are printed on B&B papers, and our papers bear the face of innumerable famous brands.

The Brigl & Bergmeister plant is located at the heart of Europe, in Niklasdorf in Styria | Austria.

ENAGES, the thermal recycling plant of B&B, supplies the factory with 100% CO2-neutral energy in the form of steam and electricity.

The Papirnica Vevče factory is situated in Slovenia, in the greater area of Ljubljana. A cooperation that had originally started as a joint venture has developed into a fully-fledged partnership. Since 2004, Papirnica Vevče has been a 100% subsidiary of Brigl & Bergmeister.

Brigl & Bergmeister, ENAGES as well as Papirnica Vevče are part of the Vienna-based Roxcel group of companies.

The Future of Fluff Pulp to 2020

![]() Fluff pulp demand in 2015 is 5.4 million air dried tonnes, up from 4.7 million air dried tonnes in 2010, for an annual growth in consumption of 3.1% per year. The Future of Fluff Pulp to 2020 predicts that demand for fluff pulp in 2020 is 6.5 million air dried tonnes; projected annual growth for 2015-20 is 3.6%. Diapers/nappies are the largest end use market with about 33.7% of the market in 2015, while nonwovens are the fastest growing end use at 5.3% annual growth for 2015-20.

Fluff pulp demand in 2015 is 5.4 million air dried tonnes, up from 4.7 million air dried tonnes in 2010, for an annual growth in consumption of 3.1% per year. The Future of Fluff Pulp to 2020 predicts that demand for fluff pulp in 2020 is 6.5 million air dried tonnes; projected annual growth for 2015-20 is 3.6%. Diapers/nappies are the largest end use market with about 33.7% of the market in 2015, while nonwovens are the fastest growing end use at 5.3% annual growth for 2015-20.

Order before 31 December and SAVE 10%

(£3,780 / $5,850 / €4,815)

The Future of Fluff Pulp to 2020 is based on both primary and secondary research. Primary research included interviews with key participants in marketing, sales, production and product development for the entire fluff pulp supply chain: raw materials, fluff pulp producers, and fluff pulp end-users. Key participants interviewed included personnel from fluff pulp producers, diaper/nappy producers, feminine hygiene producers, adult incontinence producers and fluff pulp using nonwoven producers and general industry experts. These general industry experts include personnel from major process equipment suppliers, and other industry consultants. Secondary research included information acquired from technical literature, reports, papers, conference proceedings, company information, and other trade, business or government.

The Future of Fluff Pulp to 2020 is available for £3,780 / $5,850 / €4,815 until Thursday, December 31.

| What will you discover? | ||||||

|

Europe/Asia:

Steve Hill

This email address is being protected from spambots. You need JavaScript enabled to view it.

44(0) 1372 802025

North/South America:

Josh Rabb

This email address is being protected from spambots. You need JavaScript enabled to view it.

1 330 762 7441 ext. 1206

Verso Stevens Point Mill Earns 2015 Green Masters Award for Sustainability Initiatives and Performance

Verso Corporation (OTCQB: VRSZ), a leading supplier of printing papers, specialty papers and pulp, have just announced that its mill in Stevens Point, Wisconsin, has earned a 2015 Green Masters Award for the second year in a row. Verso is among an exclusive group of leading companies in Wisconsin that was recognized by the Wisconsin Sustainable Business Council for significant and ongoing sustainability practices.

Verso Corporation (OTCQB: VRSZ), a leading supplier of printing papers, specialty papers and pulp, have just announced that its mill in Stevens Point, Wisconsin, has earned a 2015 Green Masters Award for the second year in a row. Verso is among an exclusive group of leading companies in Wisconsin that was recognized by the Wisconsin Sustainable Business Council for significant and ongoing sustainability practices.

"Sustainability is one of Verso's founding principles and is integral to the decisions we make across our business every day," said Becky Burris, Verso Vice President of Environmental, Health, Safety and Sustainability. "As we seek to reduce our environmental footprint, we challenge ourselves and our suppliers to find new and better ways to use resources more efficiently and further reduce air emissions, water discharges and waste. We are very proud to be recognized by the Green Masters Program for our sustainability initiatives at the Stevens Point Mill."

The Stevens Point Mill was judged in a competitive process on a comprehensive range of key sustainability areas, including energy, water, waste management, emissions and transportation, as well as educational and community outreach. The Green Masters Award designation is the highest tier attainable in this competitive process and is only made available to Green Masters Program participants scoring in the top 20 percent of all program participants, based on points awarded for sustainability practices in these key sustainability areas.

The Stevens Point Mill produces specialty papers for food, beverage and consumer goods applications. The mill works within stringent operational standards, constantly striving to improve internal processes, and has invested in continuous improvement methodology that has led to a number of successful sustainability projects. "Our overarching sustainability goal is continuous performance improvement in everything we do," said Stevens Point Mill Manager Craig Helgeson. "The Stevens Point Mill continues to make noteworthy progress in sustainably manufacturing and delivering high quality specialty papers. It is rewarding to be recognized alongside other companies in Wisconsin who are sustainability leaders."

Notable accomplishments for the Stevens Point Mill in 2015:

- Carbon Emissions Reduction: Two-year reduction of 8.8 percent in carbon emissions produced per ton of paper manufactured

- Water Usage Reduction: Two-year reduction of nearly 19 percent of total water usage per ton of paper manufactured

- Total Energy Usage Reduction: Nearly 4 percent reduction in energy usage over prior year per ton of paper manufactured

- Transportation Sustainability: Over 86 percent of shipments utilize the U.S. Environmental Protection Agency's SmartWay™ transportation partners

The 2015 Green Masters Award was presented to Verso today at the 8th Annual Wisconsin Sustainable Business Council Conference at the University of Wisconsin-Oshkosh in Oshkosh, Wisconsin.

About the Green Masters Program

The Green Masters Program is an objective, points-based recognition program that enables Wisconsin institutions of all sizes and from any sector to join a group of like-minded companies that are "on the road to sustainability." Developed by the Wisconsin Sustainable Business Council, in conjunction with the University of Wisconsin, the Green Masters Program helps to recognize Wisconsin's sustainability leaders and encourage continuous improvement. Nearly 200 Wisconsin Businesses are participating in the program, and only the top 20 percent achieve the highest "Green Master" designation.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.

Mondi ranks first in mill performance in the EMGE cut-size survey 2015

Mondi’s Color Copy, IQ, and MAESTRO® all ranked in top 10 for brand awareness in Europe

International packaging and paper company Mondi ranks again first in mill performance with their Uncoated Fine Paper mills in the new EMGE cut-size industry survey for 2015, even improving on its top rating in 2013. In terms of brand awareness, Color Copy, IQ, MAESTRO® and Mondi are all ranked within the top 10 in Europe. Snegurochka is the best known brand in Russia, mentioned by 75% of all Russian participants, while in Austria and Switzerland IQ, Mondi and Color Copy took the first three spots, with 40% of participants mentioning these brands.

International packaging and paper company Mondi ranks again first in mill performance with their Uncoated Fine Paper mills in the new EMGE cut-size industry survey for 2015, even improving on its top rating in 2013. In terms of brand awareness, Color Copy, IQ, MAESTRO® and Mondi are all ranked within the top 10 in Europe. Snegurochka is the best known brand in Russia, mentioned by 75% of all Russian participants, while in Austria and Switzerland IQ, Mondi and Color Copy took the first three spots, with 40% of participants mentioning these brands.

“We are really pleased with the results of the EMGE survey, particularly our mill performance being ranked first in Europe yet again, for the seventh time in a row,” said Johannes Klumpp, Marketing & Sales Director Mondi Uncoated Fine Paper. Being ranked first in Europe in the performance ratings for reliability of delivery – the most important factor according to the survey – product range and innovative marketing approach, is a testament to our firm focus on customer needs and our continued drive to innovate and do things better,” he explained. In Russia Mondi Uncoated Fine Paper’s outstanding customer service level was rated highest, and achieved top marks for a total of seven out of thirteen criteria including its product range and innovative marketing approach.

The EMGE cut-size brand and supplier benchmarking survey covers the image of white cut-size paper mills and mill brands in Western and Eastern Europe in 2015. This report presents the results of an interview survey among the trade (paper merchants, Original Equipment Manufacturers/OEMs, and Office Stationary Distributors/OSDs). The research focuses on mills and mill brands covering customer awareness, factors of importance and product/mill performance.

“We aim to continue to excel at what is important to our customers: reliable delivery of the right products at the right time and excellent customer service, every day” concluded Mr. Klumpp.

We are Mondi. IN TOUCH EVERY DAY.

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are in central Europe, Russia, North America and South Africa. We offer over 100 packaging and paper products, customised into more than 100,000 different solutions for customers and end consumers. In 2014 Mondi had revenues of €6.4 billion and a return on capital employed of 17.2%.

The Mondi Group is fully integrated across the packaging and paper value chain – from managing forests and producing pulp, paper and compound plastics to developing effective and innovative industrial and consumer packaging solutions. Our innovative technologies and products can be found in a variety of applications including hygiene components, stand-up pouches, super-strong cement bags, clever retail boxes and office paper. Our key customers are in industries such as automotive; building and construction; chemicals; food and beverage; home and personal care; medical and pharmaceutical; packaging and paper converting; pet care; and office and professional printing.

Mondi has a dual-listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc under the ticker code MNDI.

For us, sustainable development makes good business sense. We don’t just talk about sustainability; we make it part of the way we work every day. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is a business unit of Mondi’s Europe & International Division. In 4 paper mills in Austria, Slovakia, and Russia Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

Valmet's headbox technology awarded first prize at ATIP Innovation Contest

Valmet won this year's prestigious 'Palme d'Or' Innovation Award with its OptiFlo headbox with Aqua layering technology. The award was given by the French Paper Industry Technical Association (ATIP). The innovation contest was arranged in connection with the ATIP Conference and Exhibition in Grenoble, France on November 24-26, 2015.

The ATIP Innovation Award rewards innovative equipment and solutions for pulp and paper industry. The award is highly regarded among the European pulp and paper industry and it is divided into three categories: Gold - Palme d'Or, Silver - Palme d'Argent and Bronze - Palme de Bronze. The ATIP Innovation Award winners are selected by a committee consisting of Paper Mill Managers, R&D Directors, Technology Directors and Production Managers from the French paper industry. The ATIP Innovation Award was established already in 1995.

Award ceremony from left Rémi Poirson, Mill Manager of Smurfit Kappa Saillat-sur-Vienne, Jean-Nicolas Bailly, Mill Improvement Manager from Valmet, Marc Bortolotti, Senior Sales Manager from Valmet, Hugues Leydier, President of ATIP and Daniel Gomez, Director of ATIP

Raw material savings with Aqua layering technology

Valmet's OptiFlo headbox with new innovative Aqua layering technology makes it possible to produce a two-layer sheet with very good layer coverage using only one headbox and one forming unit. A thin layer of water is used as a headbox wedge to separate different stocks fed into the headbox. Previously this separation has been done with mechanical elements like vanes and solid wedges.

Valmet's OptiFlo headbox with new innovative Aqua layering technology makes it possible to produce a two-layer sheet with very good layer coverage using only one headbox and one forming unit. A thin layer of water is used as a headbox wedge to separate different stocks fed into the headbox. Previously this separation has been done with mechanical elements like vanes and solid wedges.

The layer separation with water delivers excellent layer coverage without mixing of the layers. It enables lower grammages on top ply of the paper and significant raw material savings. Besides delivering excellent layer purity, the separating water layer can also act as a carrier for different additives enabling a totally new dosage point for chemicals. This delivers the same end product strength with less raw materials or with raw materials of poorer quality. Cost efficiency of papermaking can be further improved by for example feeding reject stock through the water layer together with additives. This reject stock would normally be used as landfill.

Innovation is a result of seamless team work.

Valmet's technology development aims at ensuring advanced and competitive technologies and services, enhancing raw material and energy efficiency and promoting renewable materials.

"We would not have been able to present this innovation without the hard work and contribution of several teams in Valmet. We have a long history of bringing new innovations to the market and we focus on solutions that improve energy and raw material efficiency. The pilot facilities that Valmet has play a crucial role in both testing and demonstrating the value of new technology for our customers in realistic process conditions," says Sami Anttilainen, Vice President, Technology at Valmet.

For further information, please contact:

Sami Anttilainen, Vice President, Technology, Paper Mills Business Unit, Valmet, tel. +358 10 672 6501

Philippe Bentz, Vice President, Sales, SEMEA, Phone +33389753312

Information about Aqua layering at valmet.com:

http://www.valmet.com/aqua-layering

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

UBM Asia co-locates two leading industry events on pulp, paper and renewable energy in Bangkok

UBM Asia, organiser of Asian Paper – the region’s premier event for the pulp, paper, packaging, corrugated and print industry, and ASEAN Sustainable Energy Week, a dedicated event in Southeast Asia for renewable energy sources and technology, has announced to co-locate both events for their next edition, which will be held in June 2016 at the Bangkok International Trade and Exhibition Centre (BITEC). The two events will provide pulp, paper, packaging, corrugated and print industry professionals access to renewable energy sources and technology, including wind and solar power, thermal and waste energy, hydro-powered programs, as well as bio-mass and other forms of green technology.

The success of ASEAN Sustainable Energy Week reflects the growing opportunities for the renewable energy market in the ASEAN region, with Thailand currently promoting alternative energy as a national agenda issue with a goal to increase the share of renewable energy to 25% of the country’s energy demand by the year 2021.

“We are delighted to be able to work in close co-operation with ASEAN Sustainable Energy Week in creating a must-attend event for important industry decision makers, C-level executives, such as Buyers & Sourcing Personnel, CEOs & Decisions Makers, Industry Associations, Key Government Officials, Mill Owners, Managers & Supervisors, Paper Merchants, Paper Technologists, Paper Traders, Distributors, Wholesalers, Designers, Printer & Publishers, and R & D Professionals etc.,” said Jennifer Lee, Event Manager, Asian Paper.

Expected to attract over 30,000 trade visitors, Asian Paper Bangkok, now in its 14th edition, and ASEAN Sustainable Energy Week in its 16th edition, will provide an invaluable opportunity to experience and view innovations in all of these sectors, while providing key networking possibilities. Apart from the trade show, both events will also feature a stellar conference with hot topics addressing the trends, forecasts and innovations, as well as technical tracks, in the case of Asian Paper, which will focus on the latest developments in the pulp, paper, packaging, corrugated and print production and maintenance with innovative veteran speakers.

Asian Paper Bangkok will be held from 1-3 June, 2016 and ASEAN Sustainable Energy Week will be held from 1-4 June, 2016 at the Bangkok International Trade and Exhibition Centre (BITEC).

About UBM Exhibition Singapore Pte Ltd (www.ubmasia.com.sg)

A member of the UBM Asia Group of Companies, we organise events and conferences in a variety of industries, including aquatic and pet, cruise tourism, information technology, jewellery, paper and nonwovens, etc. The company stages leading events in its targeted industries across the world, attracting quality exhibitors, trade visitors, conference attendees and speakers from all over the world. These events are important business platforms where our customers can meet and network with their new and existing business partners face-to-face.

About UBM Asia (www.ubmasia.com)

Owned by UBM plc listed on the London Stock Exchange, UBM Asia is Asia's leading exhibition organiser and the biggest commercial organiser in mainland China, India and Malaysia. Established with its headquarters in Hong Kong and subsidiary companies across Asia and in the US, UBM Asia has a strong global network of 30 offices and 1,300 staff in 24 major cities. We operate in 20 market sectors with 230 exhibitions and conferences, 23 trade publications, 20 online products for over 1,000,000 quality exhibitors, visitors, conference delegates, advertisers and subscribers from all over the world.

About UBM plc (www.ubm.com)

UBM plc is a leading global company. We inform markets and bring the world's buyers and sellers together at events, online and in print, and provide them with the information they need to do business successfully. We focus on serving professional commercial communities, from doctors to game developers, from journalists to jewellery traders, and from farmers to pharmacists around the world. Our 6,600 staff members in 31 countries are organized into specialist teams that serve these communities, helping them to do business and to work effectively and efficiently in their respective markets.

The Paper Packaging Industry’s view on the Circular Economy Legislative Package

The Paper Packaging Coordination Group comprises the major European paper and board packaging associations¹ which represent the interests of a wide range of packaging products used in transport, retail and consumer packaging. Paper and board packaging is based on a renewable resource (the forest) and is recyclable. We support the concept of a Circular Economy in which raw materials are sourced from renewable, responsibly managed resources and where possible, recycled after use.

The Paper Packaging Coordination Group comprises the major European paper and board packaging associations¹ which represent the interests of a wide range of packaging products used in transport, retail and consumer packaging. Paper and board packaging is based on a renewable resource (the forest) and is recyclable. We support the concept of a Circular Economy in which raw materials are sourced from renewable, responsibly managed resources and where possible, recycled after use.

The members of our associations are directly affected by proposals in the Circular Economy legislative package published today, which amend the waste and packaging waste legislation. We will submit our detailed responses to specific proposals when we have had time to study them, but meanwhile we wish to present our joint approach on the major topics which affect us:

- 1.Recycling targets for paper and board

- ·Targets should be ambitious and reflect technical and economic realities

- ·For materials, a clear focus on recycling should be ensured

- ·Packaging recycling targets should be proportionate between different consumer packaging materials, fairly taking into account each material’s situation, achievements and potential for improvement. High achievement of one packaging material should not compensate for another material’s lower achievement.

- 2.Need to revise the calculation method before setting new targets

- ·The method for the calculation of recycling rates should be harmonised, providing clarity and simplification for ease of application

- ·The “input” method should be the basis of the calculation

- ·EU requirements for recycling should apply equally to exports of paper for recycling and should be enforced

- 3.Design of packaging

- ·Additional mandatory design requirements at national level for packaging will undermine the objectives of the Packaging and Packaging Waste Directive (PPWD)

- Composition of municipal waste

- Retailers should have the freedom to choose the method of collection of their secondary and tertiary packaging waste

- 5.Minimum requirements for Extended Producer Responsibility

- ·The scope of EPR and roles and responsibilities of each actor involved in packaging waste management should be clearly defined

- 6.Landfill and incineration of waste

- ·Recyclables should not be sent to landfill

- ·Separate collection of materials should be strengthened

- ·Incineration of recyclables should be restricted

- 7.Ecodesign and product design

- ·The essential requirements in the PPWD and related CEN standards are sufficient to provide guidance for ecodesign of packaging

- ·Packaging should serve the functionality and the safety of the product first

- ·Packaging should not be seen in isolation from the product

- ·Ecodesign concepts as part of a product’s design, should encompass the whole life cycle of the product with its packaging

- 8.Renewability of material resources

- ·Renewability of material resources is a natural driver for circularity and should be an essential element of a Circular Economy

We particularly welcome the consideration of the role of the bioeconomy in Circular Economy thinking, as we have strongly advocated that sustainable, natural, renewable resources play an essential role in completing the loop of a Circular Economy.

For further information please read the Paper Packaging Coordination Group’s position paper on the Circular Economy package http://www.cepi.org/positionpaper/PPCGcirculareconomy

Xerium Technologies to Meet With Investors at Paper, Packaging and Builders Conference

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has announced that Harold Bevis, President and CEO and Cliff Pietrafitta, Chief Financial Officer will meet with the investment community at the Bank of America Paper, Packaging and Builders Conference December 9-10, 2015 at The Four Seasons Hotel, 200 Boylston Street in Boston, MA.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has announced that Harold Bevis, President and CEO and Cliff Pietrafitta, Chief Financial Officer will meet with the investment community at the Bank of America Paper, Packaging and Builders Conference December 9-10, 2015 at The Four Seasons Hotel, 200 Boylston Street in Boston, MA.

Investors and interested parties are invited to review the company’s latest investor presentation by visiting the Xerium website at www.xerium.com under the Investor Relations section.

About Xerium (NYSE:XRM)

Xerium Technologies, Inc. is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to the production of paper, paperboard, tissue, pulp, building products, nonwoven fabrics, and variety of industrial applications. Xerium products are specifically designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Source: Xerium Technologies, Inc.

Xerium Technologies, Inc.

Cliff Pietrafitta, Chief Financial Officer

919-526-1444

This email address is being protected from spambots. You need JavaScript enabled to view it.

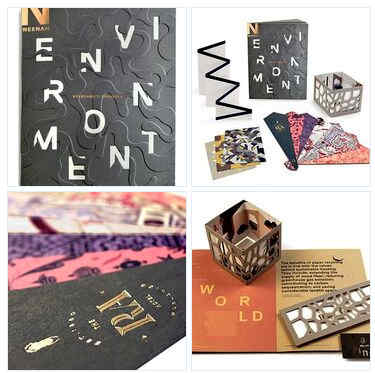

New Neenah ENVIRONMENT Promotion Spotlights Direct Mail

New Neenah ENVIRONMENT Promotion Spotlights Direct Mail

The new “Everybody’s Business” promotion from Neenah focuses on getting a brand’s message, and sustainable values, delivered.

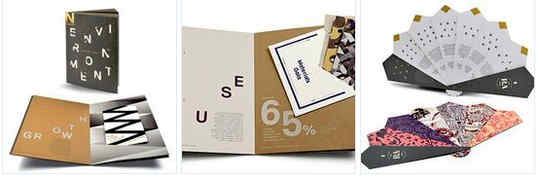

Neenah’s new Everybody’s Business promotion combines the power of direct mail, touch and sustainable messaging to create an interactive and educational promotion. The perfect bound book, and its creatively designed direct mail inserts, are all produced on a variety of Neenah ENVIRONMENT® Papers.

“The USPS recently reported that 93% of online responses are driven by direct mail — it’s clear that this remains an extremely effective marketing medium,” said Kathy Kemps, Senior Brand Manager, Neenah. “And we have research telling us that touch and texture lead to high levels of brand connection and recall. Then we see that 65% of paper consumed in the US last year was recovered for recycling. What this means is that you can create a beautiful, memorable message that drive results while staying true to the environment.”

Neenah’s Everybody’s Business promotion houses four uniquely designed direct mail inserts, including:

· A gala invite that uses three single panels, each with different die cut patterns to deliver its event message, agenda, and rsvp.

· A grometted, six-bladed, multi-patterned fan brochure that conveys the essence of new hotel Ra, named for the Sun God.

· A three-piece, die cut “build-it-yourself” pop up that showcases a new sustainable housing complex complete with a retail gift card.

· An ascending six-panel accordion fold informational brochure for a financial summit.

“Everybody’s Business is designed to inspire unique ideas, and highlight the ease of delivering a brand’s sustainability message without sacrificing quality,” said Kemps.

The 8 x 10.5 book and its inserts are all produced with a variety of printing processes on a combination of colors and textures from the Neenah ENVIRONMENT Papers’ collection, including six colors that were introduced into the line last year —Weathered, Stone, Husk, Grocer Kraft, Concrete and Wrought Iron — as well as Neenah’s proprietary RAW® finish.

Neenah ENVIRONMENT Papers feature exquisite whites and midtone colors. These natural and earthy tones help communicate a brand’s message and values. ENVIRONMENT Papers are truly is the most premium of sustainable and the most sustainable of premium.

To get the new Neenah Environment Everyone’s Business promotion, contact your local merchant or Neenah sales rep.

About Neenah

For more than 100 years, Neenah Paper (NYSE: NP) has been an innovative leader in the creation and manufacturing of papers for premium writing, text, cover, digital, packaging and specialty needs. The Neenah signature portfolio includes market leading brands such as CLASSIC®, ENVIRONMENT®, and ROYAL SUNDANCE® Papers. The company also offers envelopes in thousands of unique colors, finishes and styles.

Neenah is committed to developing relevant mobile and online technologies including Neenah Cabinet™ for iPad, iPhone and Android. With multiple manufacturing facilities in Wisconsin, prime importance is also placed on recycled and alternative fiber products through the Neenah Green initiative. For more information on Neenah call (800) 558-5061. Follow Neenah on Twitter: @neenahpaper; subscribe to the Neenah Facebook page; or visit Against the Grain, Neenah’s blog for designers, printers and paper-lovers.

Contact

Neenah, Jamie Saunders, 678-518-3222, This email address is being protected from spambots. You need JavaScript enabled to view it.

@neenahpaper

BRITISH MANUFACTURERS STAGE WORLD-FIRST DRIVE ACROSS PAPER BRIDGE

A Range Rover has traversed a specially constructed bridge made from James Cropper PLC paper in a jaw-dropping celebration of the luxury SUV’s 45th birthday.

The unique freestanding bridge was commissioned in collaboration with British artist Steve Messam and specialist British paper manufacturer James Cropper PLC, to showcase Land Rover’s flagship model, at the 13th China International Automobile Exhibition held in Guangzhou from 20 to 29 November 2015.

The five-metre bridge, constructed solely from paper and completely free from glue or bolts, was built using Natural Crystal 330gsm high-quality white paper. The paper was produced by bespoke paper manufacturer James Cropper PLC, which also celebrates its own landmark 170-year anniversary this year.

The hand-built bridge took three days to construct, using 54,390 sheets of paper in order to support the 2,374 kilogram vehicle. The feat of engineering and artistry was erected in China, the birthplace of paper, in the ancient water city of Suzhou – famous for its bridges and nicknamed the ‘Venice of the East’.

Artist and paper bridge designer, Steve Messam, said: “Paper structures capable of supporting people have been built before but nothing on this scale has ever been attempted. It’s pushing engineering boundaries, just like the Range Rover, and the ease and composure with which the vehicle negotiated the arch was genuinely breathtaking.”

The project follows the success of Steve Messam and James Cropper PLC’s collaboration on a pedestrian bridge installation over a stream in the heart of Britain’s stunning Lake District countryside – home to James Cropper PLC – in May this year.

Chris Brown, commercial director at James Cropper, added: “It’s an honour to collaborate with fellow British manufacturers and designers to be a part of this world-first, which puts our paper’s durability to the ultimate test. The combined expertise of Land Rover, Steve Messam and James Cropper represents the highest standard of British engineering, manufacturing and design.”

The James Cropper Group has well-established links with the automotive and engineering sector via its Technical Fibre Products (TFP) division, which manufactures non-woven materials from carbon, glass and polymer fibres, used in the production of lightweight composites for car manufacturing.

The challenging drive was negotiated by Land Rover Experience chief instructor, Chris Zhou, using a variety of all-terrain technologies to preserve the delicate fabric of the unique structure.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high-quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

As well as paper products, James Cropper PLC also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors. For further information visit: www.jamescropper.com and www.tfpglobal.com