Ianadmin

Fibria projects Capex of R$ 2.05 billion in 2016 at the 5th Fibria Day held in New York

World’s largest eucalyptus pulp producer participates in the closing bell ceremony of the New York Stock Exchange (NYSE)

Fibria, a Brazilian forestry company and the world’s leading eucalyptus pulp producer, has announced an estimated Capex in 2016 of R$ 2.05 billion (US$ 516 million). This amount, which does not include investments earmarked for expansion of the Três Lagoas unit in Mato Grosso do Sul State, was announced this Wednesday at the 5th Fibria Day, the annual meeting between key executives from the company and market analysts and investors, held at the New York Stock Exchange (NYSE).

Fibria, a Brazilian forestry company and the world’s leading eucalyptus pulp producer, has announced an estimated Capex in 2016 of R$ 2.05 billion (US$ 516 million). This amount, which does not include investments earmarked for expansion of the Três Lagoas unit in Mato Grosso do Sul State, was announced this Wednesday at the 5th Fibria Day, the annual meeting between key executives from the company and market analysts and investors, held at the New York Stock Exchange (NYSE).

Due to the exchange rate (dollar/real) and the cost rationalization efforts, the company’s Capex in 2015 will be US$ 584 million.

In New York, Fibria executives will also participate in the closing bell ceremony along with NYSE representatives. Fibria is represented by CEO Marcelo Castelli, together with the Chief Financial and Investor Relations Officer Guilherme Cavalcanti, the Commercial & International Logistics Officer Henri Philippe Van Keer, the Innovation & Technology Officer Fernando Bertolucci, the Corporate Strategy & New Businesses Development Officer Vinícius Nonino, and other members of the management.

“We did our homework very well and are now reaping the rewards. Since our previous meeting with analysts and investors last year in New York, we have reduced our leverage from 2.52 times to 1.58 times, we have been assigned investment grade by Moody’s and Standard & Poor's, we have announced the expansion of the Três Lagoas unit at an investment of R$ 8.7 billion (US$ 2.2 billion), and increased Fibria’s net revenue by 60%”, said CEO Marcelo Castelli.

Mr. Castelli also highlighted the approval given by the extraordinary shareholders meeting held on November 30 to the distribution of dividends amounting to R$ 2 billion. The factors behind the Company’s decision to submit this proposal include low leverage, strong cash generation, low average cost of debt and the fact that funding for the Horizonte 2 Project has already been settled.

Horizonte 2 Project – expansion of the Três Lagoas unit (MS)

One of the highlights of Fibria’s presentation was the Horizonte 2 Project, one of the largest private investments in Brazil focused on exports, amounting to R$8.7 billion (approximately US$2.2 billion), which will expand the production capacity of its Três Lagoas Unit in Mato Grosso do Sul State. Of the total Capex estimated for the project, 60% will be disbursed in 2016. Around 30% of total financing for Horizonte 2, equivalent to R$2.6 billion, will come from cash generated by Fibria, which has been consistently posting operational records.

Expansion work at Três Lagoas has already started and is on schedule, with the unit expected to go operational in the final quarter of 2017. The project will generate 40,000 jobs during the expansion work. At the end of the project, 3,000 direct and indirect jobs will be created.

Investment Grade

In 2015, Fibria's rating was upgraded to investment grade by rating agencies Moody's and Standard & Poor's, joining Fitch Ratings, which had already assigned the same rating the previous year. According to the Moody’s report published in November this year, the upgrade to investment grade reflects mainly the financial discipline shown by Fibria, with its capacity to consistently lower its leverage ratios while maintaining a solid liquidity position.

Another factor highlighted by Moody's in its decision to upgrade Fibria's rating was the prospect of investments on expansion of the Três Lagoas industrial complex, while maintaining the level of debt compatible with the investment grade rating.

About Fibria

A world leader in eucalyptus pulp production, Fibria is a company that strives to meet the growing global demand for forestry products in a sustainable manner. With annual pulp production capacity of 5.3 million tons, the company has industrial units in the cities of Aracruz (Espírito Santo), Jacareí (São Paulo) and Três Lagoas (Mato Grosso do Sul), and in Eunápolis (Bahia), where it operates the Veracel plant through a joint operation with Stora Enso. In May 2015, Fibria announced the expansion of its Três Lagoas unit in Mato Grosso do Sul, which will receive a new line with the capacity to produce 1.75 million tons of pulp per year. The new line, which will receive investment of US$2.5 billion, is slated to start operations in the fourth quarter of 2017. Fibria has 968,000 hectares of forests, with 561,000 hectares of planted forests and 342,000 hectares of environmental preservation and conservation areas. The pulp manufactured by Fibria is exported to more than 40 countries.

For more information, please visit www.fibria.com

Mohawk named exclusive North American distributor for The Curious Collection & Conqueror

Mohawk, North America’s largest privately-owned manufacturer of fine papers, envelopes and specialty substrates for commercial and digital printing, has been named the exclusive North American distributor for The Curious Collection & Conqueror lines of fine papers.

Mohawk will oversee all North American distribution, marketing and sales for these product lines beginning January 1, 2016, and will begin accepting orders for The Curious Collection & Conqueror on December 28, 2015.

Mohawk has been named the exclusive North American distributor for The Curious Collection & Conqueror lines of fine papers, overseeing all North American distribution, marketing and sales for the product lines beginning January 1, 2016.

“We are very pleased to be named as exclusive distributor for The Curious Collection & Conqueror in North America as a result of our strategic partnership with Arjowiggins Creative Papers. We know that materials matter, and we believe these grades uniquely complement our legacy collection of Mohawk fine papers. We look forward to the opportunity to grow sales significantly through our extensive network of merchant partners and through our strong relationships in the print, design and packaging communities,” said Bart Robinson, Senior Vice President, Marketing, Mohawk.

The strategic alliance began earlier this year when Arjowiggins Creative Papers granted Mohawk exclusive rights to manufacture, license, market and distribute Arjowiggins Creative Papers’ luxury packaging products, Delos and Butterfly, while Arjowiggins Creative Papers was granted exclusive rights to manufacture, market and distribute Mohawk Superfine with iTone® through select merchants worldwide. The decision to allow Mohawk exclusive rights to market and distribute The Curious Collection & Conqueror is an extension of this alliance.

The Curious Collection is comprised of the following seven beautiful and tactile grades of extraordinary papers for special projects that call for very saturated color and/or unusual textures.

Curious Translucents:Naturally translucent papers for use with designs where layering or show through is desired.

Curious Particles:A 100% recycled flecked paper with inclusions for added interest.

Curious Metallics:A rich, glittering alloy adds a shimmery, visual appearance and tactile texture in 24 fashion-forward and complementary colors.

Curious Cosmic:Shimmery reflective colors with an extraordinary soft matte metal effect and a remarkable, patented tactile feel.

Curious Matter:An innovative paper featuring potato starch to create an intriguing tactile experience.

Curious Touch:A deep soft matte texture as remarkable as it appears.

Curious Skin:Distinctive surface and saturated, bold colors invite recipients to touch and feel.

Mohawk will launch a new swatchbook featuring the entire line of papers (150 skus) within The Curious Collection in early 2016. The Curious Collection is manufactured with FSC Certified pulps, using renewable energy credits (RECS) from Green-e® certified energy sources.

Since 1888, Conqueror has been known in Europe as the gold standard for brand identity and projects ranging from corporate stationery to exclusive invitations.

Arjowiggins and Mohawk are like-minded fine paper manufacturers with legendary brands that have driven the premium paper segment globally for over a century. The companies share core values of heritage, innovation, operational excellence, craftsmanship, safety-focused manufacturing, environmental commitment and social responsibility.

For more information about The Curious Collection and Conqueror lines, please visit www.mohawkconnects.com.

ABOUT MOHAWK

Mohawk is North America’s largest privately-owned manufacturer of fine papers and envelopes which are preferred for commercial and digital printing, photo specialties and high-end direct mail. Mohawk fine papers and envelopes include the signature brands Mohawk Superfine® and Strathmore®, as well as proprietary treatments Inxwell® and i-Tone®. With a culture of innovation, Mohawk’s business model now extends beyond paper manufacturing into new areas of growth, including digital substrates, which connect designers and printers to new markets.

As a leader in environmentally and socially responsible business practices, Mohawk was the first U.S. manufacturer of commercial printing papers to match 100% of its electricity with wind power renewable energy credits and the first U.S. premium paper mill to shift toward carbon neutral production. Mohawk’s portfolio of recycled papers is certified by Green Seal and the Forest Stewardship Council (FSC).

Mohawk is a fourth-generation, family-owned and operated business based in Cohoes, New York, with global sales and operations located throughout North America, Europe and Asia. For more information, please visit www.mohawkconnects.com.

Valmet-delivered TwinRoll press installed at Södra Cell's Mönsterås pulp mill in Sweden

A Valmet-delivered TwinRoll Evolution press was successfully installed at Södra Cell's Mönsterås pulp mill in Sweden during the yearly shutdown in the end of September. This is the 85th TwinRoll Evolution press Valmet has delivered since the model was launched in 2009.

"The new wash press will play an important role in our process to secure a grade of pulp that meets customer requirements and to achieve improved availability," says Olof Hellström, one of Södra's project managers.

Fast commissioning

Lars Harrysson, project leader at Södra, said that the installation and commissioning were highly successful, and that the schedule was maintained throughout the project. "Everything has worked out, and everyone has done their utmost to get the new press installed and running," says Harrysson.

"The shutdown in Mönsterås was well planned which created the best possible conditions and enabled the efficient installation. Slightly more than one day after the start-up the press was up and running in nominal production of soft wood pulp, with a dryness that was well above the promised. The training was an important piece in the success. Committed and interested operators enabled a quick knowledge transfer," says Mikael Johansson, Project Manager at Valmet.

Information about the customer Södra Cell and the Mönsterås mill

Södra is an economic association with a membership base of about 51,000 forest owners in southern Sweden. Södra has built up a considerable production of paper pulp, wood products and biofuels. Södra employs about 3,500 people and has three business areas Södra Skog, Södra Cell and Södra Wood. Södra Cell is one of the largest players in the world in the area of softwood pulp and operates three pulp mills in Sweden: Mörrum, Mönsterås and Värö.

Södra Cell Mönsterås is Södra's biggest pulp mill with a capacity of 750,000 tonnes per year of pulp. In addition to electricity, the mill delivers district heating to the municipality of Mönsterås and to Södra's sawmill in the area. Furthermore, the mill supplies tall oil for biodiesel. Södra is in a period of substantial investments and plans to invest more than 30 million euros in the pulp mill in Mönsterås during 2015 and 2016. This will lead to more efficient energy usage and increase productivity at the mill.

For further information, please contact:

Mikael Johansson, Project Manager, Pulp and Energy Business Line, Valmet tel. +46 70 653 3807

John Schauer Joins Xerium as Top Leader for Nonwovens Market

Xerium Technologies, Inc. (NYSE:XRM) — Xerium has just announced the hiring of Mr. John Schauer to the position of Product Manager – Nonwovens Market. Mr. Schauer comes to Xerium with 30 years of management and technical leadership experience and most recently held the role of North America Nonwoven Manager for a one of Xerium’s chief competitors in this market.

Xerium Technologies, Inc. (NYSE:XRM) — Xerium has just announced the hiring of Mr. John Schauer to the position of Product Manager – Nonwovens Market. Mr. Schauer comes to Xerium with 30 years of management and technical leadership experience and most recently held the role of North America Nonwoven Manager for a one of Xerium’s chief competitors in this market.

Mr. Schauer will be responsible for leading Xerium’s North America Nonwovens business plan as well as coordinating Xerium’s global efforts. John will also support our active engagement with The Nonwovens Institute at North Carolina State University.

David Pretty, Xerium President of North America and Europe, said, “The nonwoven market is an important part of Xerium’s strategic plan. Xerium is a leading global supplier of technically advanced belts, fabrics, aprons, and roll cover technology in this market. Our newest Huycon belts have proven successful on some of the world’s most demanding nonwoven lines. As a result, our Gloggnitz, Austria facility was recently expanded to keep pace with the increased demand in the Americas, Europe, and Asia. John Schauer’s seasoned leadership is a significant step forward for Xerium to further advance in this growing market.”

John Schauer said, “I am excited to join Xerium and am thankful to be leading the value creation platform for North America. I look forward to creating value for Xerium and its customers. Xerium is well positioned to achieve its strategic objectives.”

About Xerium

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Source: Xerium Technologies, Inc.

Xerium Technologies, Inc.

Cliff Pietrafitta, 919-526-1400

Chief Financial Officer

This email address is being protected from spambots. You need JavaScript enabled to view it.

LignoCity – a new centre for new green technologies

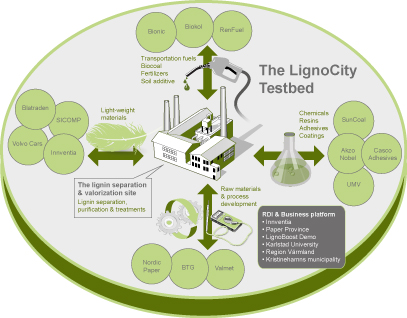

Innventia, Nordic Paper and Paper Province have started a collaboration to develop the future forest-based bioeconomy. The first step is to establish an open test bed called LignoCity. Here, companies can develop and scale up technology that refines lignin to new climate-friendly fuels, chemicals and materials.

LignoCity – a new centre for new green technologies

As the world heads towards a bio-based economy, lignin – a by-product of pulp production – is increasingly seen as a raw material with great potential. Lignin could be a green alternative for producing fuels and energy as well as chemicals and lightweight materials. Great efforts are being made to develop processes and to refine different lignin qualities for different applications.

Thanks to a broad newly established collaboration initiated by Innventia, Nordic Paper and Paper Province, several of these initiatives can now be realised. With financial support mainly from VINNOVA, Innventia’s demonstration plant in Bäckhammar will be further developed and made into an open test bed for companies who want to evaluate and validate new refining concepts in the lignin area. The plant is currently the only one in the world that can produce tailor-made lignin qualities in sufficient quantities for upscaling. The purpose of LignoCity is to create a centre where ideas are brought together and opportunities for commercial development are identified and supported. Lignin from kraft pulp production and other sources, for example from ethanol and sugar production, can be processed at the plant. The project involves 18 industrial and public players, including Karlstad University, the municipality of Kristinehamn and Casco Adhesives AB.

“With LignoCity, we are bringing together business models, technological development and infrastructure for research, development and innovation. In the long term, we also hope to be able to extract other components from the black liquor and tackle other process streams,” says Per Tomani, manager for the LignoCity project and the Lignin & Carbon Fibres focus area manager at Innventia.

“It is extremely valuable for the region’s businesses to have access to this type of open test facility, so that we can continue the development of a forest-based bioeconomy,” says Maria Hollander, CEO of Paper Province.

Kristinehamn is aiming high when it comes to innovations concerning new green fuels. Our goal is to profile ourselves as a municipality with a viable and creative business, where we carry on our technical traditions by creating future innovation. Efforts like LignoCity can help creating jobs and we are proud that the municipality contributes to this, says Carina Welin, Information manager.

Innventia established the demonstration plant in 2006 in order to demonstrate the LignoBoost process. This technology, which today is owned by Valmet and installed at pulp mills in the United States and Finland, was developed in collaboration between Innventia and Chalmers. Thanks to LignoBoost, it is possible to obtain a lignin that is so clean it can be used as a raw material for carbon fibre. Innventia runs a number of research projects in this area, and has built up an infrastructure for testing and demonstration in collaboration with the research institute Swerea SICOMP.

In addition to Innventia, Nordic Paper and Paper Province, the following organisations are involved in LignoCity: Akzo Nobel Bygglim AB, Region Värmland, Biokol Sverige AB, LignoBoost Demo AB, Blatraden AB, BTG Instruments AB, Bionic Group of Companies, Ren Fuel K2B AB, SunCoal Industries GmbH, Swerea, UMV Coating Systems AB, Valmet Power AB and Volvo Cars. More companies are welcome to join the venture.

Valmet to supply key technology to SCA's Östrand pulp mill expansion project in Sweden

Valmet has received a major order to deliver cooking, fiber line and evaporation plant to SCA's Östrand pulp mill located in Timrå, Sweden. This delivery is part of SCA's investment to upgrade the production of bleached softwood kraft pulp at the Östrand mill from today's capacity of 430,000 tons to 900,000 tons per year. The last start-up of the renewed pulp mill is scheduled for May 2018.

Valmet has received a major order to deliver cooking, fiber line and evaporation plant to SCA's Östrand pulp mill located in Timrå, Sweden. This delivery is part of SCA's investment to upgrade the production of bleached softwood kraft pulp at the Östrand mill from today's capacity of 430,000 tons to 900,000 tons per year. The last start-up of the renewed pulp mill is scheduled for May 2018.

The order is included in Valmet's fourth quarter 2015 orders received. The value of the order is not disclosed.

In SCA's press release on December 2, 2015 SCA's project director Ingela Ekebro explained about the goals of the project: "The new pulp mill will have world class technology. We are going to produce pulp with top quality, while our environmental performance is the best achievable and we are going to do it with a cost efficiency that allows us to successfully compete with other pulp suppliers worldwide."

"This major agreement with SCA is a strong continuation of Valmet's and SCA's long term cooperation and an important achievement for our pulp technology business. The project has a significant employment impact to Valmet in Sweden, since a significant part of the equipment to be delivered in this project, will be engineered and produced in our Swedish units," says Bertel Karlstedt, President, Pulp and Energy Business Line, Valmet.

The estimated employment impact of the order is about 150 man years mainly in Sweden. A large part of the order will be delivered from Valmet's Swedish units: the cooking plant from Karlstad, fiber line from Sundsvall, and evaporation plant from Gothenburg.

Valmet has earlier delivered both pulp and tissue technology to SCA and has also extensive services contracts with SCA. The most recent delivery was the new Compact Cooking G2 for the SCA Obbola kraftliner mill.

Details about Valmet's delivery

Valmet's delivery includes a Compact Cooking G2 together with a TwinRoll press based fiber line for both ECF and TCF pulp production at a capacity of 2,850 air dry tons per day (adt/d). The evaporation plant consist of 7 effects with a TUBEL superconcentrator for high dry solids and has a capacity of 1,150 tons of evaporated water per hour. The total package is optimized for superior water and energy efficiency.

Information about the customer SCA

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. The company's sales are conducted in about 100 countries under many strong brands, including the leading global brands. As Europe's largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm

For further information, please contact:

Stefan Mattsson, Vice President, Fiber Processing Business Unit, Valmet, tel. +46 70 653 38 18

Bertel Karlstedt, President, Pulp and Energy, Valmet, tel. +358 10 676 3026

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

SCA: Early Termination of U.S. Hart-Scott-Rodino Waiting Period

SCA (NASDAQ OMX Stockholm: SCA), a leading global hygiene and forest products company, and Wausau Paper Corp. (“Wausau Paper”) (NYSE: WPP), a North American Away-from-Home tissue company, has announced early termination of the waiting period required under the U.S. Hart-Scott-Rodino Antitrust Improvements Act of 1976, as amended, in connection with SCA’s agreement to acquire Wausau Paper for USD 10.25 per share or total consideration of USD 513 million (approximately SEK 4.2 billion) in cash.

SCA (NASDAQ OMX Stockholm: SCA), a leading global hygiene and forest products company, and Wausau Paper Corp. (“Wausau Paper”) (NYSE: WPP), a North American Away-from-Home tissue company, has announced early termination of the waiting period required under the U.S. Hart-Scott-Rodino Antitrust Improvements Act of 1976, as amended, in connection with SCA’s agreement to acquire Wausau Paper for USD 10.25 per share or total consideration of USD 513 million (approximately SEK 4.2 billion) in cash.

As previously announced on October 13, 2015, the acquisition is a strategic fit for SCA and strengthens the company’s presence in North America. The Wausau Paper portfolio complements SCA’s offerings in North America and gives the company access to premium tissue production in the region. The combined operations will provide SCA and Wausau customers with access to a comprehensive portfolio of food service offerings and premium tissue and washroom products.

The transaction is expected to close during Q1 2016, subject to approval by the Wausau Paper shareholders and other customary closing conditions.

About SCA

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. More information at www.sca.com.

About Wausau Paper

Wausau Paper produces a complete line of Away-from-Home towel and tissue products that are marketed along with soap and dispensing system products under a number of brands including Artisan™, DublNature®, DublSoft®, EcoSoft®, and related custom brands. Wausau Paper is listed on the NYSE under the symbol WPP. To learn more about Wausau Paper, visit www.wausaupaper.com

Proposed Acquisition Risks and Uncertainties

- SCA’s business and the business of Wausau Paper may not be integrated successfully or such integration may be more difficult, time-consuming or costly than expected;

- Expected combination benefits from the proposed acquisition may not be fully-realized or realized within the expected time frame;

- Wausau Paper’s shareholders may not approve the acquisition;

- The regulatory approvals and any other required approvals in connection with the acquisition may not be obtained on the proposed terms or on the anticipated schedule;

- evenues following the acquisition may be lower than expected; and

- Operating costs, customer loss and business disruption, including difficulties in maintaining relationships with employees, customers, clients or suppliers, may be greater than expected following the acquisition.

New factors that could cause actual results to differ materially from those described in forward-looking statements emerge from time to time, and it is not possible to predict all such factors, or the extent to which any such factor or combination of factors may cause actual results to differ from those contained in any forward-looking statement. We assume no obligation to update publicly any such forward-looking statements, whether as a result of new information, future events, or otherwise.

Additional Information:

This communication may be deemed solicitation material in respect of the proposed acquisition of Wausau Paper by SCA. In connection with the proposed acquisition, Wausau Paper plans to file with the SEC and furnish to its shareholder a proxy statement and other relevant documents. Wausau Paper’s shareholders are urged to read the proxy statement when it becomes available and any other documents to be filed with the SEC in connection with the proposed acquisition or incorporated by reference in the proxy statement because they will contain important information about the proposed acquisition. Such proxy statement, when it becomes available, can be obtained for viewing, printing, and downloading from Wausau Paper’s website at www.wausaupaper.com. Other SEC filings containing information about each party to the proposed merger transaction can be obtained for viewing, printing, and downloading (without charge) at the SEC’s internet site (http://www.sec.gov). Wausau Paper will furnish to any of its shareholders (without charge) a copy of the proxy statement and the filings with the SEC that will be incorporated by reference therein, when the documents become available, upon written or oral request to the Secretary, Wausau Paper Corp., 100 Paper Place, Mosinee, WI 54455.

The directors and executive officers of each party may be deemed to be participants in the solicitation of proxies from Wausau Paper’s shareholders in respect of the proposed acquisition. Information regarding the directors and executive officers of Wausau Paper is currently available in its proxy statement for its 2015 annual meeting of shareholders filed with the SEC by Wausau Paper on April 10, 2015. Information regarding the directors and executive officers of SCA is currently available on its website at www.sca.com/en/About_SCA/Corporate_Governance/. Other information regarding the participants in such proxy solicitation and a description of their direct and indirect interests, by security holdings or otherwise, will be contained in the proxy statement and other relevant materials that will be filed by Wausau Paper with the SEC when they become available.

Any information concerning Wausau Paper contained in this document has been taken from, or is based upon, publicly available information. Although we do not have any information that would indicate that the information contained in this document that has been taken from such documents is inaccurate or incomplete, we do not take any responsibility for the accuracy or completeness of such information.

Twin Rivers Paper Company Invests in Core Business

Twin Rivers Paper Company recently completed a series of upgrades to its No. 7 Paper Machine, enhancing the overall quality, efficiency and capabilities of a machine instrumental to manufacturing products supporting the specialty packaging, publishing, and label markets.

Twin Rivers Paper Company recently completed a series of upgrades to its No. 7 Paper Machine, enhancing the overall quality, efficiency and capabilities of a machine instrumental to manufacturing products supporting the specialty packaging, publishing, and label markets.

“PM7 is a workhorse for Twin Rivers, serving deadline driven and technically challenging markets. It produces many of our hallmark grades and the work completed brings both enhanced capacity for strategic grades and critical redundancy of supply.”

“PM7 is a critical machine that supports our leadership positions in all segments of our business. The upgrade is evidence of the ongoing commitment to invest capital that aligns with our strategic direction and to ensure the long term viability of the operation. Since our new ownership took the helm over $25MM has been invested throughout the Twin Rivers system,” commented Dave Deger, Vice President of Strategy and Marketing. “We recognize this is a particularly challenging time for the industry so it is great to be a part of a team that values continuous improvement of the operations.”

Key enhancements include an upgraded size press, improved coating flexibility, installation of a dandy roll, and slitter/rewinder modifications. The end result is a more capable asset that is well positioned to produce a diverse range of products including grease resistant packaging papers; lightweight opaque papers used for pharmaceutical, financial and religious publishing; and base papers used in a variety of label applications.

Deger added, “PM7 is a workhorse for Twin Rivers, serving deadline driven and technically challenging markets. It produces many of our hallmark grades and the work completed brings both enhanced capacity for strategic grades and critical redundancy of supply.”

Aside from the No. 7 Paper Machine, Twin Rivers operates four additional paper machines that manufacture a range of coated and uncoated papers with options in fiber content, functional characteristics, aesthetics and sustainability. The company is known for rapid innovation and its commitment to co-development.

Twin Rivers Paper Company is an integrated specialty paper company that manufactures packaging, label and publishing products for targeted markets and applications. The company has operations in Maine and New Brunswick. For more information, visit the website at www.twinriverspaper.com.

Contacts

Twin Rivers Paper Company

Dave Deger, 207-523-2355

Vice President, Strategy and Marketing

This email address is being protected from spambots. You need JavaScript enabled to view it.

Voith Paper Upgrades North American Roll Cover Plants with Investments in New Equipment and Technology

![]() Voith Paper, a long-time leader in roll covers and mechanical roll service for paper machines, has recently made significant investments in its North American roll cover facilities to support the manufacture of new products and ensure roll cover consistency and timely delivery.

Voith Paper, a long-time leader in roll covers and mechanical roll service for paper machines, has recently made significant investments in its North American roll cover facilities to support the manufacture of new products and ensure roll cover consistency and timely delivery.

Voith Paper has recently made significant investments in its North American roll cover facilities.

"We're continuously seeking to elevate the quality of our products and their performance on our customers' machines," said John Fox, President of Voith Paper North America. "To this end, we've introduced new technologies, upgraded equipment and made process improvement in all five of our North American roll cover plants."

Voith Paper's specific plant investments include:

- WebNet bonding technology incorporated into the polyurethane manufacturing process

- Technology installation and upgrades for polyurethane casting in cover manufacturing plants

- Installation of advanced work cells in all mechanical roll service plants

"By keeping our facilities on the leading edge in terms of technology and efficiency, we are able to improve value add and delivery time for our customers," Fox said.

Voith's Neenah roll covers plant continues to be the one-stop roll service center for the Midwest, providing rubber, poly, resin calender, resin press, ceramic/thermal spray cover manufacturing, as well as mechanical roll service. This facility offers a freight advantage to regional customers thanks to its breadth and depth of offerings.

In addition to Neenah, Voith Paper has roll cover plants in Springfield, Ore., West Monroe, La., Austell, Ga., and Hawkesbury, Ontario.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Contacts

Voith Paper

Terri Robinson, 001-252-265-4405

Kadant Awarded Turnkey Fiber Processing Line for New Tissue Machine

![]() Kadant Inc. has just announced it received an order totaling approximately $3 million from a tissue producer in Latin America for a fiber processing line to produce pulp from virgin fiber and recycled “mill broke” fiber. The turnkey project features Kadant’s new compact fiber processing system concept designed specifically for virgin fiber pulping applications.

Kadant Inc. has just announced it received an order totaling approximately $3 million from a tissue producer in Latin America for a fiber processing line to produce pulp from virgin fiber and recycled “mill broke” fiber. The turnkey project features Kadant’s new compact fiber processing system concept designed specifically for virgin fiber pulping applications.

“This turnkey order includes some of our latest design concepts in fiber processing equipment that more efficiently and effectively produce pulp from both virgin and recycled sources allowing the producer to compete more cost-effectively.”

“As a well-regarded supplier of recycled fiber processing equipment, we are pleased to be recognized for our advances in virgin fiber processing equipment with this order from a major tissue producer in Latin America,” said Jonathan W. Painter, president and chief executive officer of Kadant. “This turnkey order includes some of our latest design concepts in fiber processing equipment that more efficiently and effectively produce pulp from both virgin and recycled sources allowing the producer to compete more cost-effectively.”

About Kadant

Kadant Inc. is a global supplier of high-value, critical components and engineered systems used in process industries worldwide. The Company’s products, technologies, and services play an integral role in enhancing process efficiency, optimizing energy utilization, and maximizing productivity in resource-intensive industries. Kadant is based in Westford, Massachusetts, with revenues of $402 million in fiscal 2014 and 1,800 employees in 18 countries worldwide. For more information, visit www.kadant.com.